Hydrogen-assisted combustion coal gasification boiler

A coal gasification and subsidy technology, which is applied in the field of coal gasification boilers, can solve the problems of large and heavy processing devices, high boiler chimneys, and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

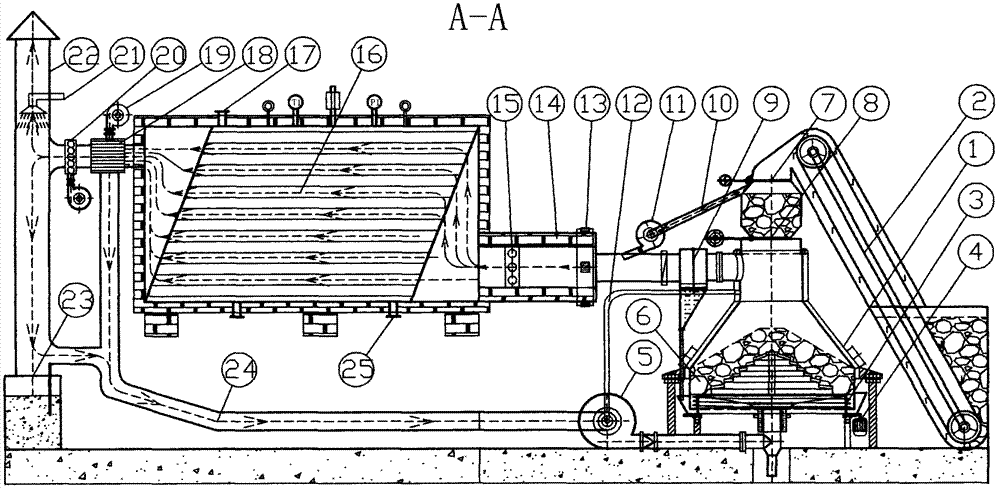

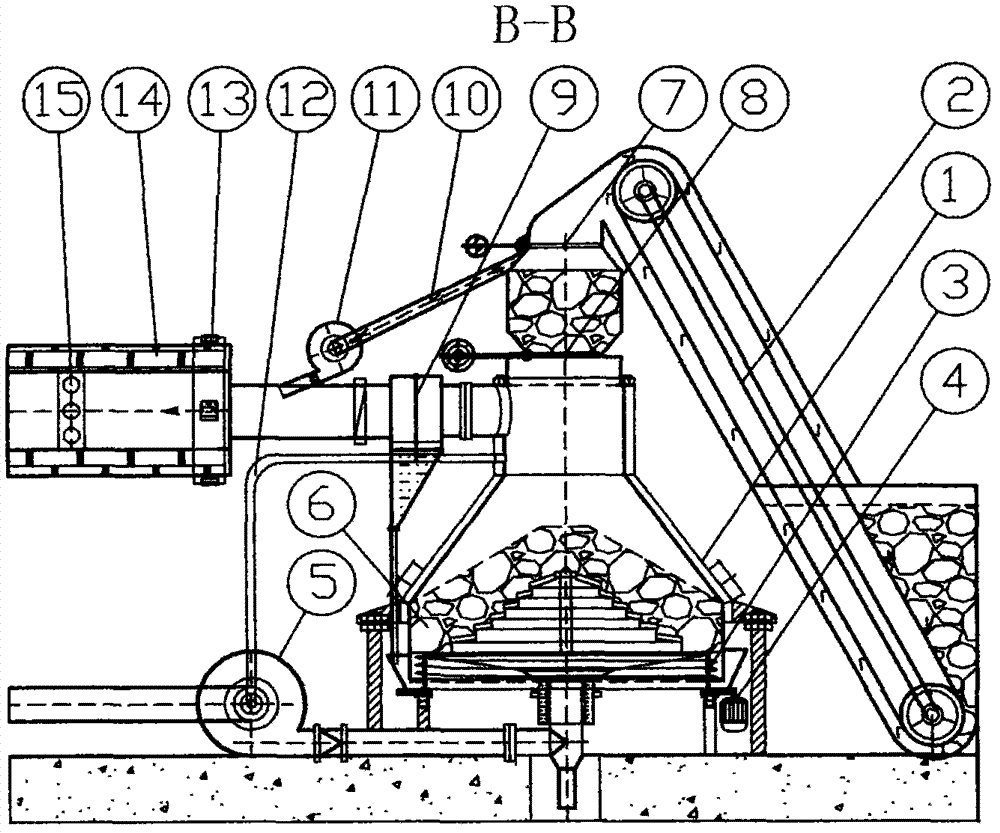

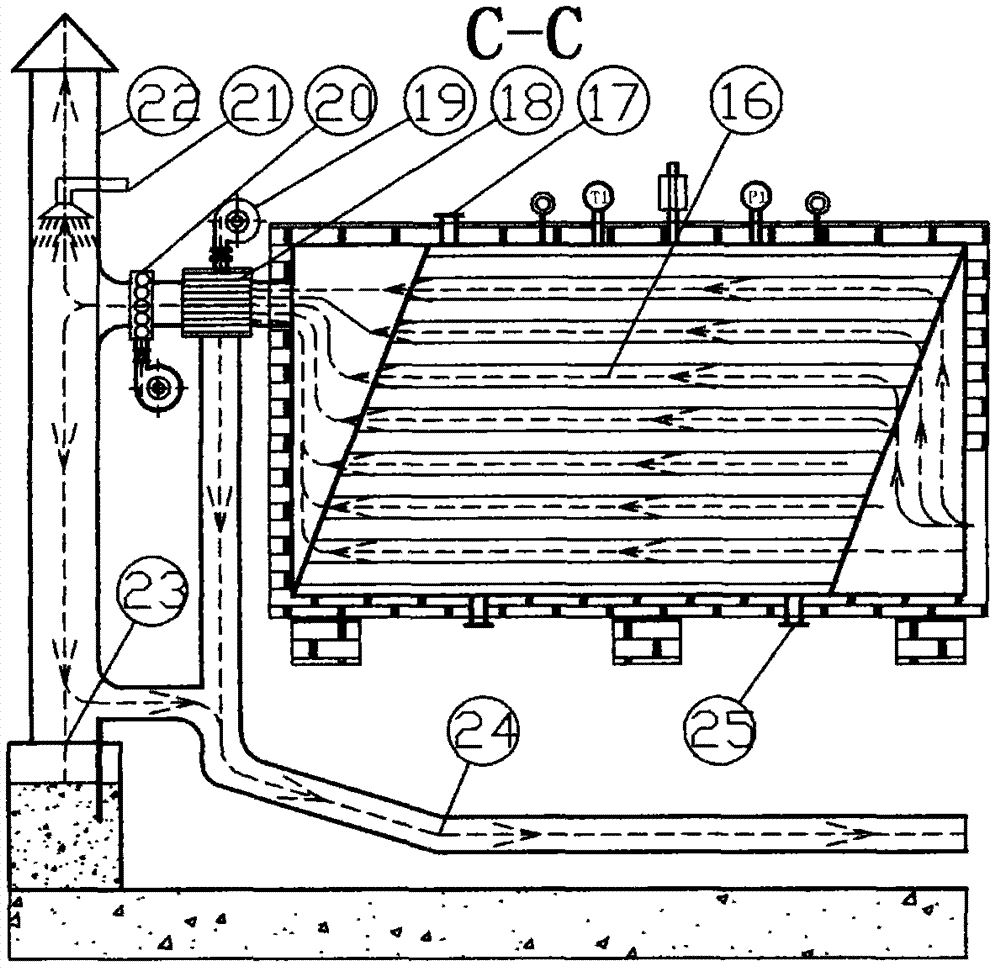

[0022] The present invention further describes the following specific examples of hydrogen-assisted combustion coal gasification boilers:

[0023]The specific scheme of the present invention is: the present invention is provided with furnace body (1) upper part to prevent coal gas from leaking primary automatic closure (7) and secondary automatic closure (8) discontinuous coal loading machine (2), through discontinuous timing rotation grate gear motor (4) Drive the spiral slag dropping plate at the bottom and side of the grate of the gas generator (3) drop slag to the slag discharge device of the water-sealed furnace ash tray, and the gas transmission pipeline is equipped with a water-sealed gas filter device (9) and a supply cylinder type The air blower (11) of the gas combustion heat-gathering device, the automatic coal-feeding sealing device and the vacuum pipe (10) on the upper part of the furnace body, the cylindrical gas combustion heat-gathering device (14) surrounded by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com