Low-tar double-bed gasifying method and device

A gasification device and low-tar technology, applied in fixed-bed gasification, gasification process, chemical modification of combustible gas, etc., can solve the problems of low tar content, high tar content, insufficient clean energy utilization rate, etc., and achieve gas The effect of high chemical strength, reducing tar content, and avoiding catalyst sintering failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

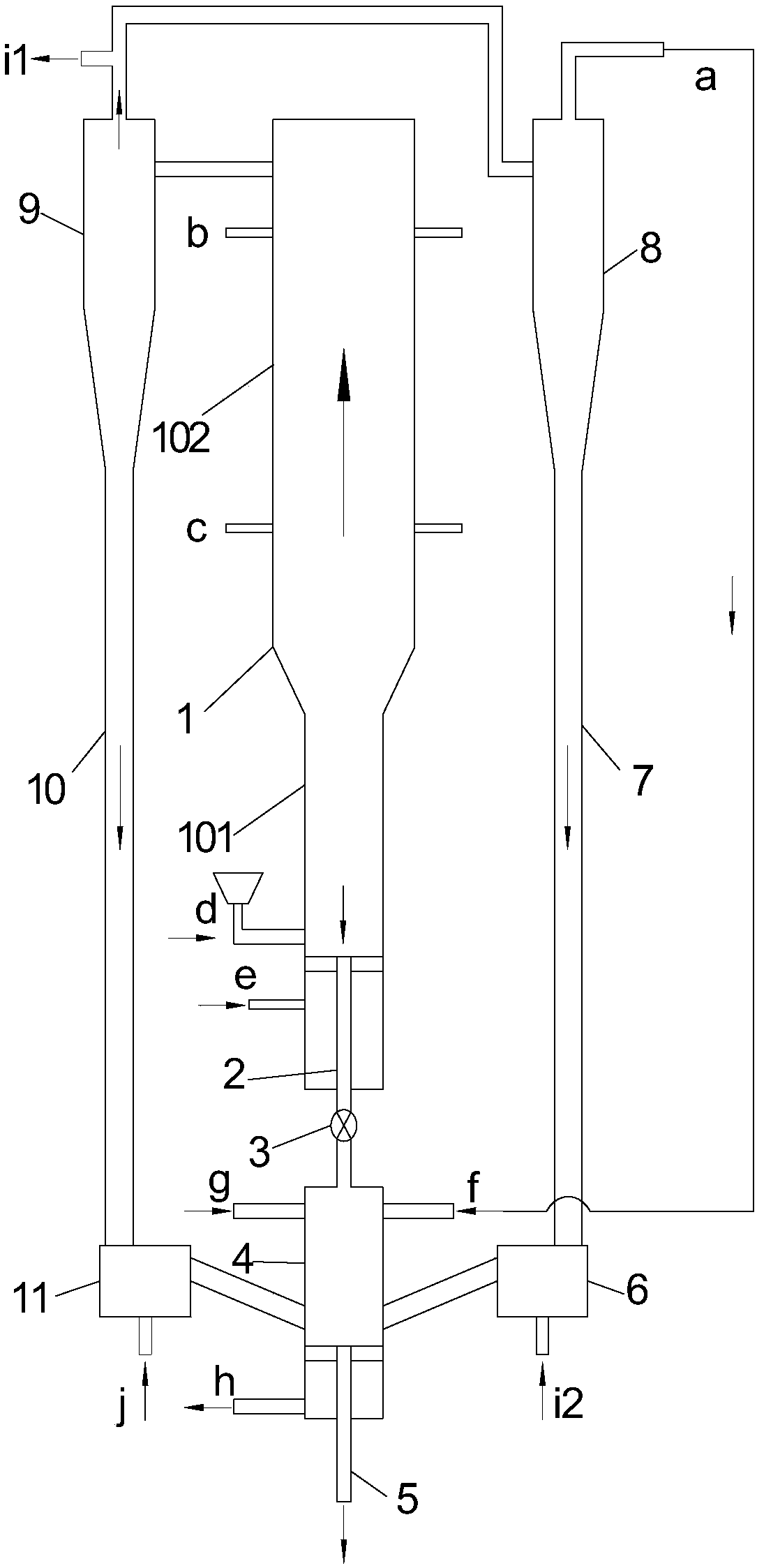

[0035] Biomass particles enter the fluidized bed gasifier 1 and undergo a series of chemical reactions with the gasification agent. The gasification temperature is about 600°C. The initial gasification product enters the dilute phase zone 102 and first reacts with the catalyst injected into the bed Catalytic reaction, tar catalytic cracking, concentration reduction, catalytic cracking reaction temperature of about 750 ° C, and then oxidative combustion reaction with the oxidant passed through the upper part, forming a high temperature zone, about 1050 ° C. At this time, the gasified slag enters the fixed bed 4 through the slag discharge pipe 2, and the gasification gas carrying fly ash particles passes through the primary cyclone separator 9 and the secondary cyclone separator 8 to realize gas-solid separation. The carbon residue particles enter the fixed bed 4 through the first-stage feeder 11 and the second-stage feeder 6, and form a catalytic bed together with the slag. The...

Embodiment 2

[0037] Biomass particles enter the fluidized bed gasification furnace 1 and undergo a series of chemical reactions with the gasification agent. The gasification temperature is about 750°C. Catalytic reaction, tar catalytic cracking, concentration reduction, catalytic cracking reaction temperature is about 700 ° C, and then oxidative combustion reaction with the oxidant passed through the upper part, forming a high temperature zone, about 950 ° C. At this time, the gasified slag enters the fixed bed 4 through the slag discharge pipe 2, and the gasification gas carrying fly ash particles passes through the primary cyclone separator 9 and the secondary cyclone separator 8 to realize gas-solid separation. The carbon residue particles enter the fixed bed 4 through the first-stage feeder 11 and the second-stage feeder 6, and form a catalytic bed together with the slag. The combustible gas from the cyclone separator enters the upper part of the fixed bed, reforms with the water vapor...

Embodiment 3

[0039] The biomass particles enter the fluidized bed gasifier 1 and undergo a series of chemical reactions with the gasification agent. The gasification temperature is about 700°C. Catalytic reaction, tar catalytic cracking, concentration reduction, catalytic cracking reaction temperature is about 850 ° C, and then oxidative combustion reaction occurs with the oxidant passed through the upper part, forming a high temperature zone, about 1200 ° C. At this time, the gasified slag enters the fixed bed 4 through the slag discharge pipe 2, and the gasification gas carrying fly ash particles passes through the primary cyclone separator 9 and the secondary cyclone separator 8 to realize gas-solid separation. The carbon residue particles enter the fixed bed 4 through the first-stage feeder 11 and the second-stage feeder 6, and form a catalytic bed together with the slag. The combustible gas from the cyclone separator enters the upper part of the fixed bed, reforms with the water vapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com