Hydrogenation method for deeply desulfurizing gasoline

A technology for deep desulfurization and gasoline, applied in the field of hydrogenation of refined hydrocarbon oil and gasoline deep desulfurization, to achieve the effect of strengthening close connection, enhancing depth and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

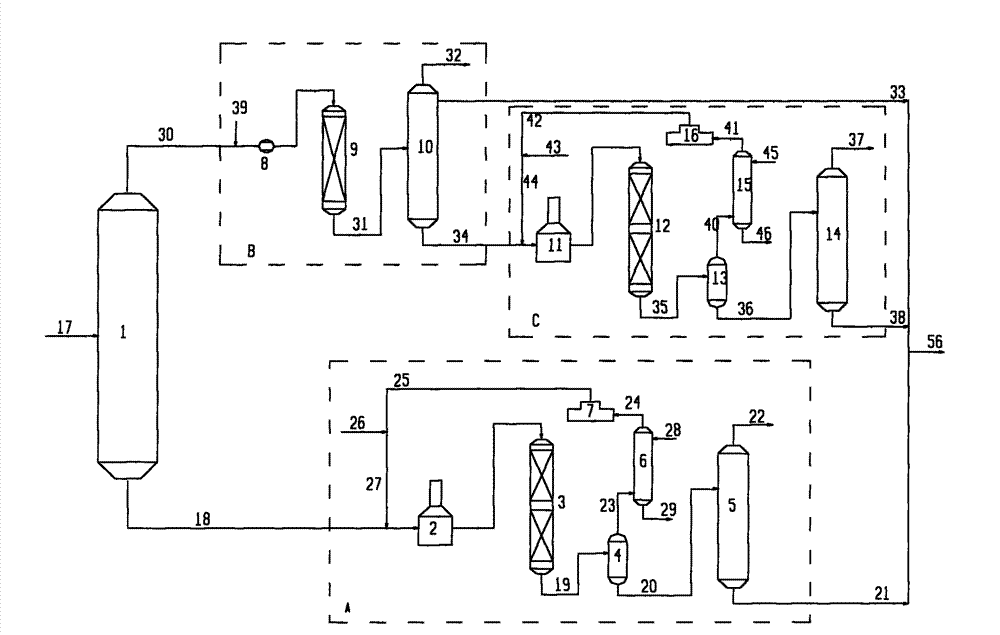

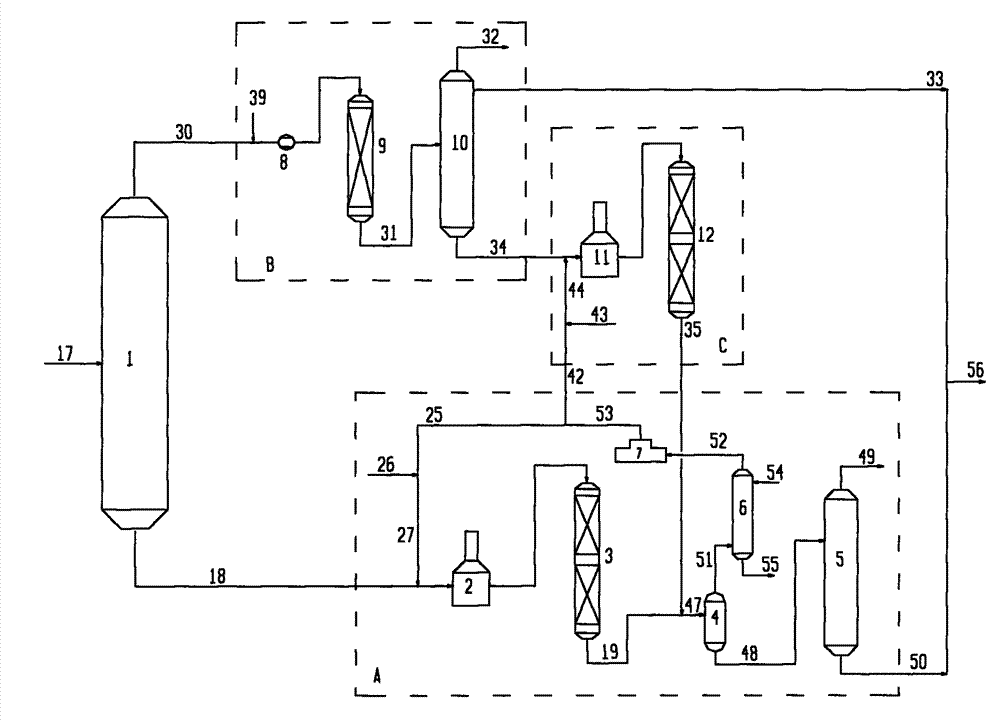

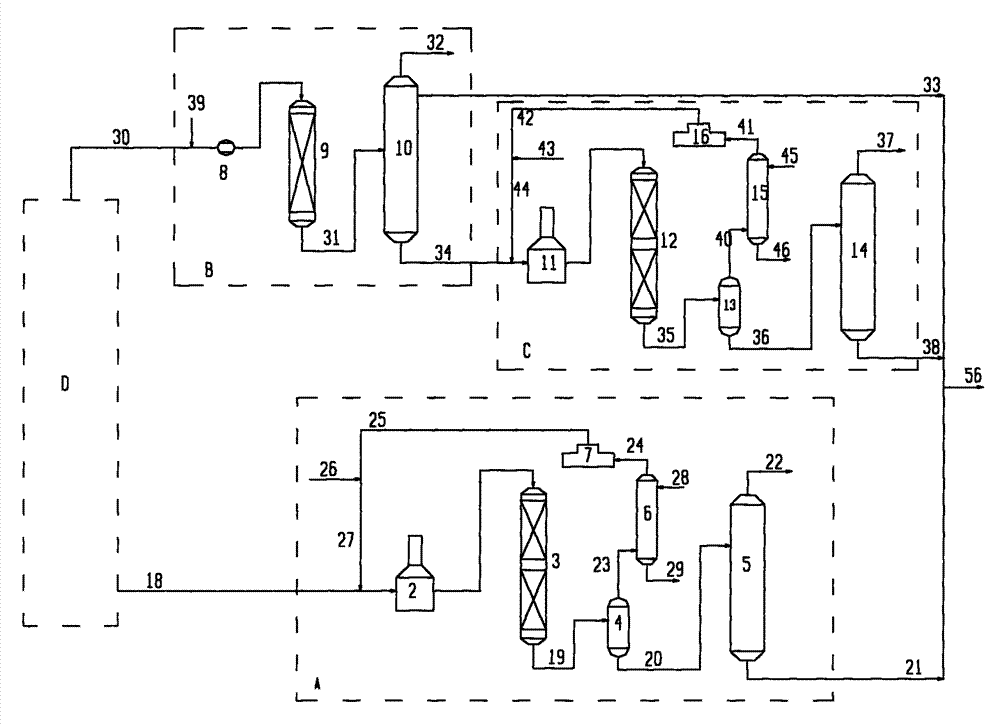

[0039] like figure 1 As shown, catalytically cracked gasoline 17 is divided into two parts through gasoline pre-fractionator 1 : light fraction 30 and heavy fraction 18 . The heavy fraction 18 is mixed with the mixed hydrogen 27, and after being heated by the heavy fraction reaction heating furnace 2, it enters the heavy fraction hydrogenation reactor 3 in the first hydrogenation reaction zone A for selective hydrodesulfurization reaction, and the heavy fraction hydrogenation reactor 3 operates Pressure 0.5~4.0MPa(g), operating temperature 230~400℃, hydrogen-oil ratio 100~500, catalyst volume space velocity 2.0~6.0h -1 . The heavy fraction reaction product 19 enters the separation system 4 for oil and gas separation, and the low fraction oil 20 enters the refined gasoline stripper 5 to remove H 2 S, the sulfur-containing tower top gas 22 is output from the top of the tower, and the refined heavy fraction 21 is output from the bottom of the tower. The circulating hydrogen 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com