Patents

Literature

60results about How to "Affect normal production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of composite alga fertilizer

InactiveCN108424252AAffect normal productionWithout degrading propertiesBio-organic fraction processingOrganic fertiliser preparationPlant hormoneFreeze-drying

The invention discloses a preparation method of a composite alga fertilizer. The preparation method comprises following steps: step one, preprocessing alga to obtain alga particles; step two, dissolving alga particles by distilled water to obtain an alga colloidal solution; step three, carrying out enzymatic hydrolysis; step four, subjecting the mixed solution to centrifugation, collecting the supernate, placing supernate in a vacuum freeze-drying machine, and dehydrating the supernate to obtain alga powder; step five, preparing a strain fermenting liquid; and step six, slowly adding the strain fermenting liquid into the alga powder to form a fermentation heap, carrying out fermentation for 14-20 hours, pushing over the fermentation heap, building a new fermentation heap, repeating for 5-6times, and then paving the fermentation heap to obtain the composite alga fertilizer. The preparation method has the advantages that alga is processed by an enzymatic hydrolysis method, the effectivecomponents of alga such as nutrients, plant hormones, and the like can be maximally maintained; moreover, the alga colloidal solution is enzymatically hydrolyzed under an acidic condition, the effectof the enzymatic hydrolysis is better, the enzymatic hydrolysis quality is higher, the raw material utilization rate is increased, the production cost is reduced, and the production quality is improved.

Owner:天津市辰圣海洋生物技术有限公司

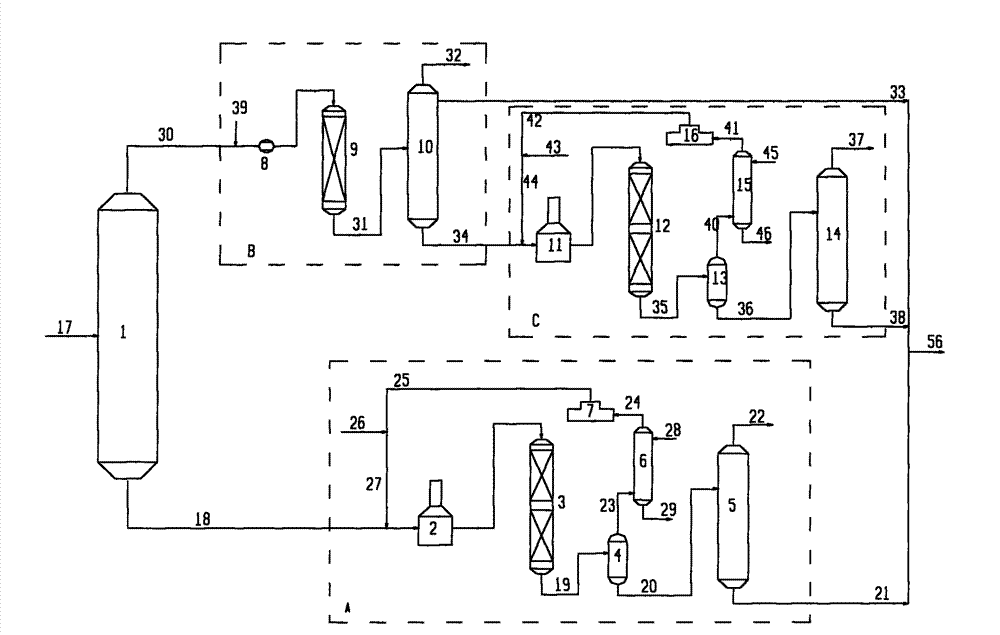

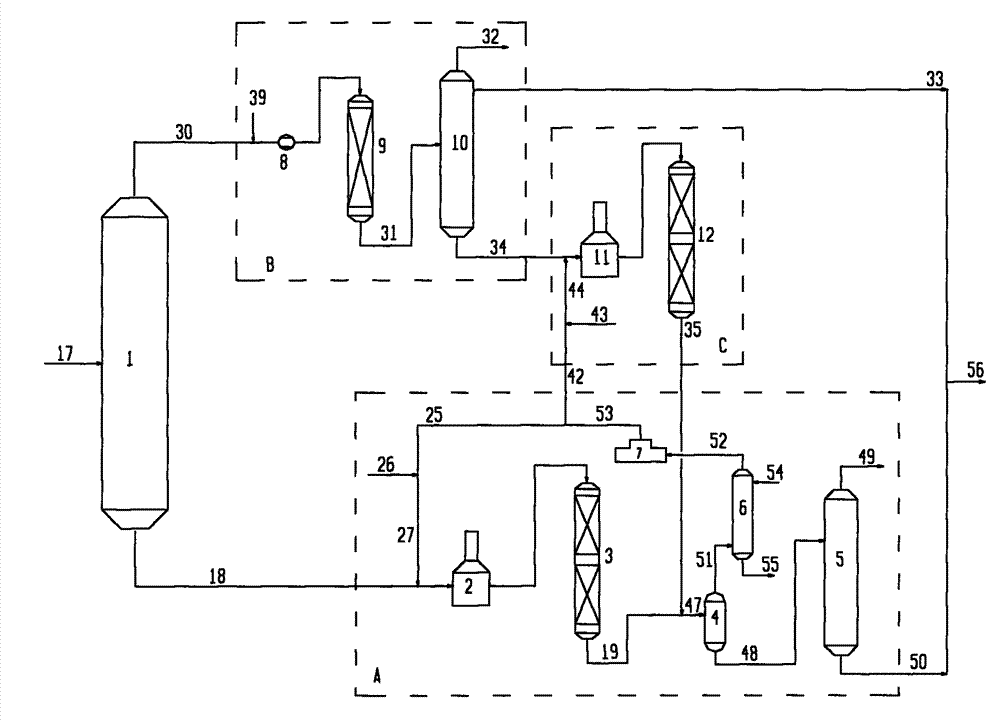

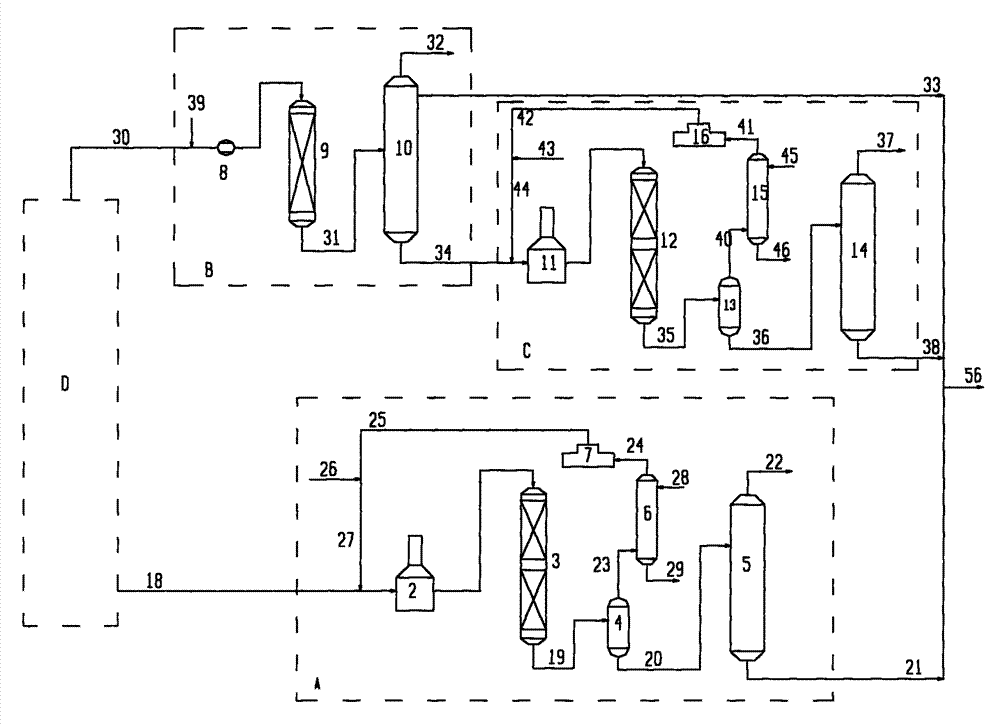

Hydrogenation method for deeply desulfurizing gasoline

ActiveCN103087771AHigh desulfurization depthReduce lossesTreatment with hydrotreatment processesHydrogenation reactionBoiling point

The invention provides a hydrogenation method for deeply desulfurizing gasoline. The hydrogenation method comprises the steps that catalytically cracked gasoline is fractionated into light fractions and heavy fractions; the heavy fractions and hydrogen are mixed and enter into a first hydrogenation reaction zone to react to obtain low-sulfur heavy fraction oil, and the recycle hydrogen obtained through separation is recycled after desulfurization; the light fractions and hydrogen are mixed and enter into a second hydrogenation reaction zone, diene is subjected to hydrogenation saturation to obtain mono-olefin low-boiling sulfides and the mono-olefin low-boiling sulfides are converted to high-boiling sulfides; the hydrogenated light fraction oil enters a light-medium fraction fractionating tower and is divided into light fractions and medium fractions and low-sulfur light fraction oil is obtained; the medium and light fractions and hydrogen are mixed and enter into a third hydrogenation reaction zone to react to obtain low-sulfur medium fraction oil, and the recycle hydrogen obtained through separation is recycled after desulfurization; and the heavy fraction oil, the light fraction oil and the medium fraction oil are mixed to obtain the low-sulfur gasoline product. Aiming to produce the gasoline with sulfur content not more than 10mu g / g, the method provided by the invention has the characteristics of high desulfurization depth, long device running period and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

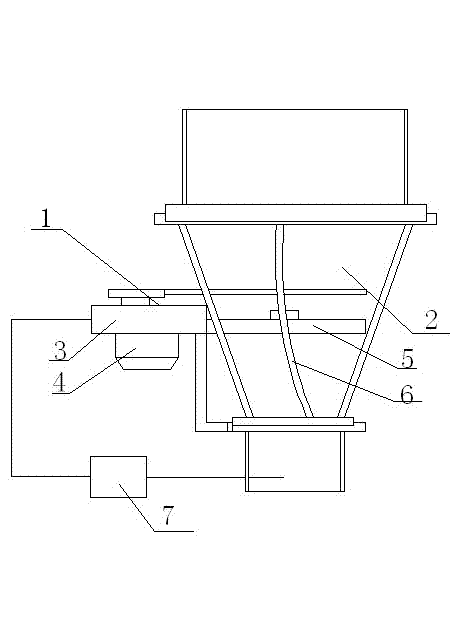

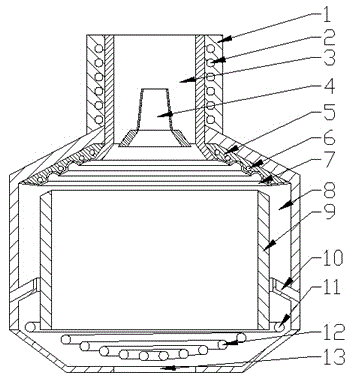

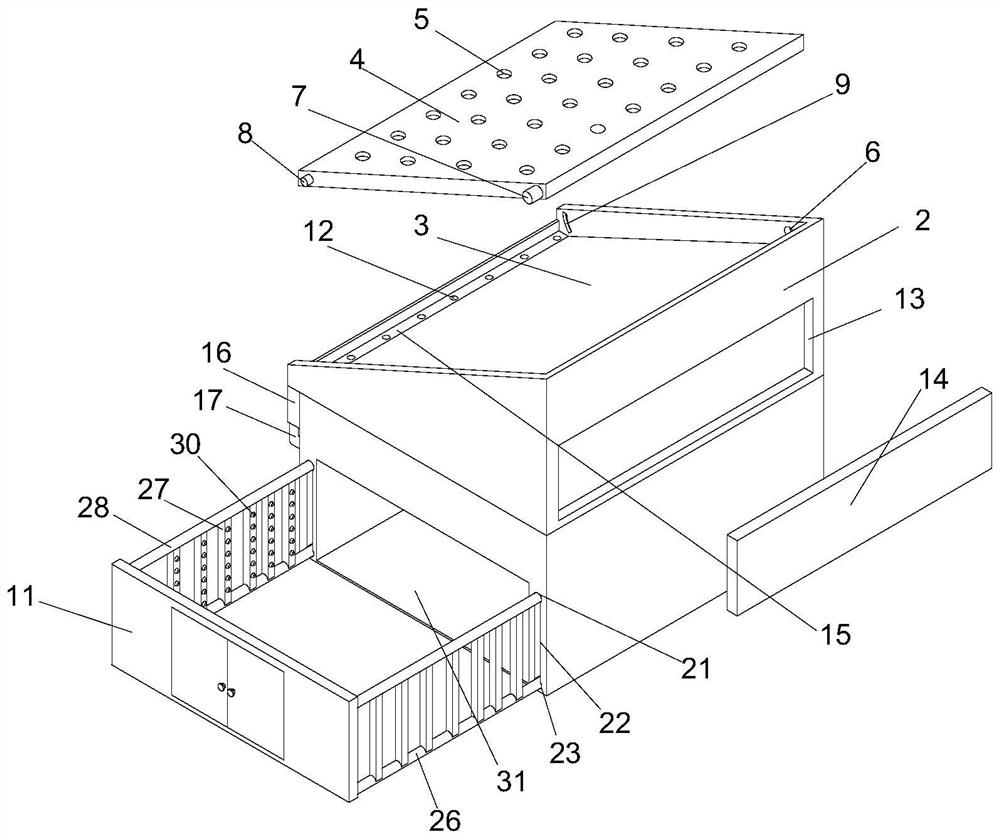

Storage bin automatic detection blockage clearing device

The invention relates to a storage bin automatic detection blockage clearing device. The storage bin automatic detection blockage clearing device consists of a storage bin blockage clearing device and an automatic control system which is connected with the storage bin blockage clearing device, wherein the storage bin blockage clearing device is arranged on a lower storage bin section. The storage bin automatic detection blockage clearing device can solve the problems of bulk material bridging and arched blockage of the lower part of a bin body of a conical storage bin or a hyperbolic storage bin, the blockage clearing area is large, coagulated arched blockage, bridging blockage, freezing, funnel flow and groove-like flow are absolutely cleared, and automatic detection blockage clearing can be realized.

Owner:山东天元节能环保工程有限公司

Method for preparing seaweed fertilizer by taking Enteromorpha as raw material

InactiveCN108409372AAffect normal productionWithout degrading propertiesBio-organic fraction processingOrganic fertiliser preparationEnzymatic hydrolysisColloid

The invention discloses a method for preparing a seaweed fertilizer by taking Enteromorpha as raw material. The method comprises the following steps: S1, cleaning the Enteromorpha, and performing airdrying and smashing to obtain seaweed particles; S2, dissolving the seaweed particles into a seaweed colloid solution; S3, performing enzymatic hydrolysis on the seaweed colloid solution to obtain a mixed solution; S4, centrifuging the mixed solution, collecting supernatant, adding chitosan into the supernatant, mixing and putting the mixture into a vacuum freeze dryer for dehydration to obtain seaweed powder; S5, preparing strain fermentation broth; S6, slowly adding the strain fermentation broth into the seaweed powder with continuous stirring, and stacking into a fermentation heap; S7, overturning the fermentation heap, re-stacking into a new fermentation heap, and spreading the fermentation heap to form the seaweed fertilizer. The Enteromorpha is treated through an enzymatic hydrolysismethod, so that effective components such as nutrient elements and phytohormones in the Enteromorpha can be kept to the maximum extent, little damage is caused to the effective components in the Enteromorpha, and the effect of the fertilizer at a later stage is not influenced.

Owner:天津市辰圣海洋生物技术有限公司

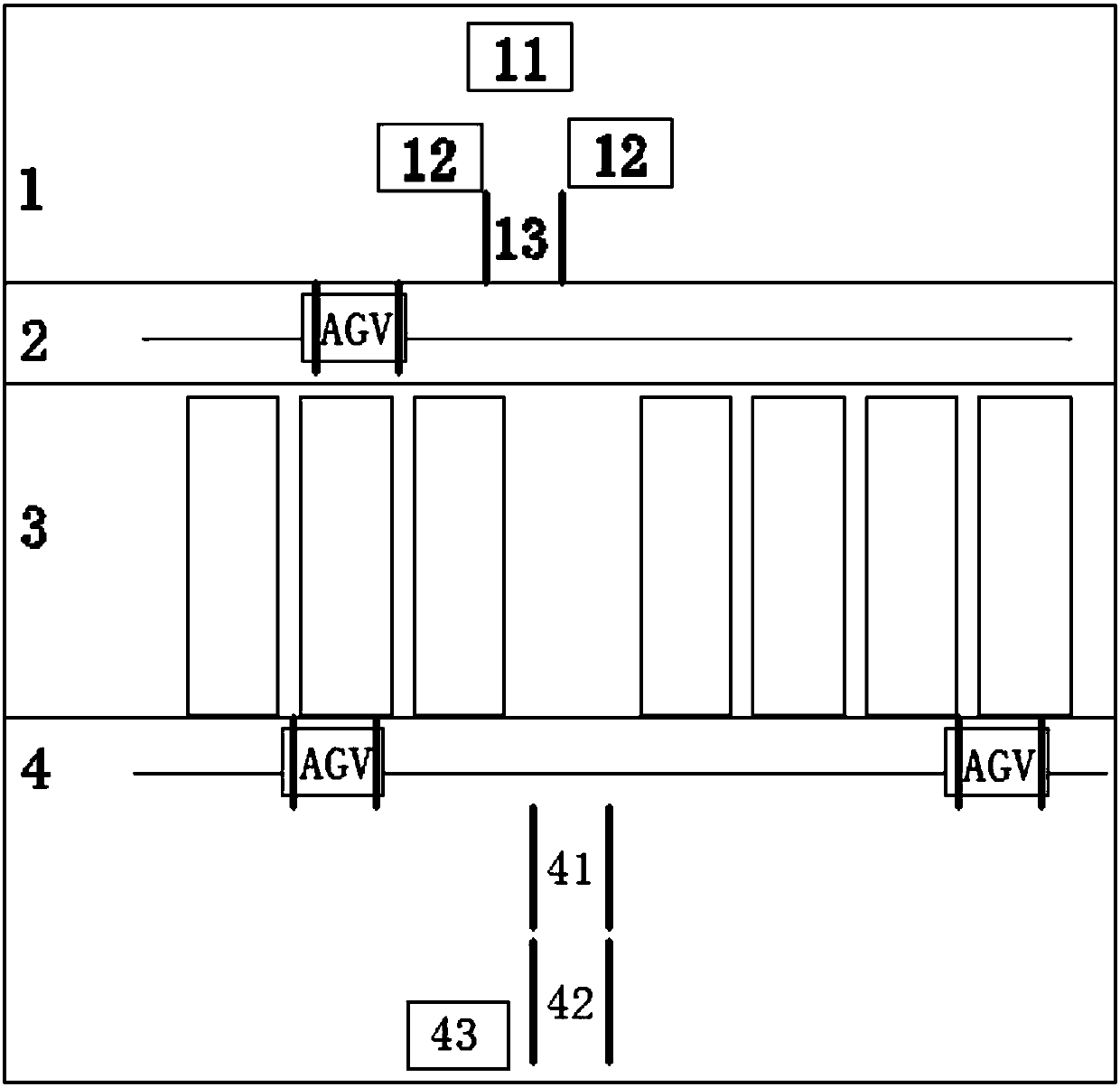

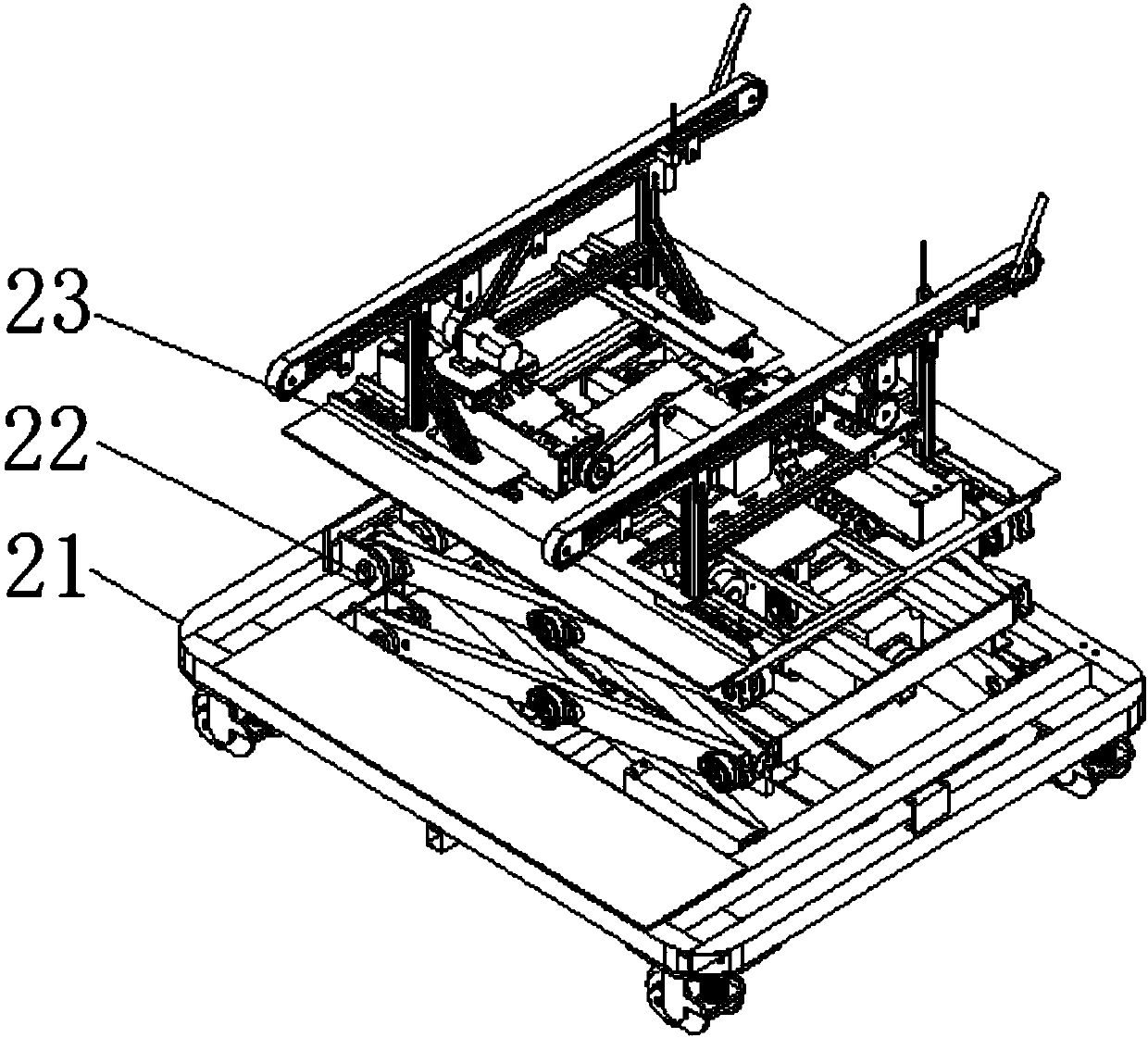

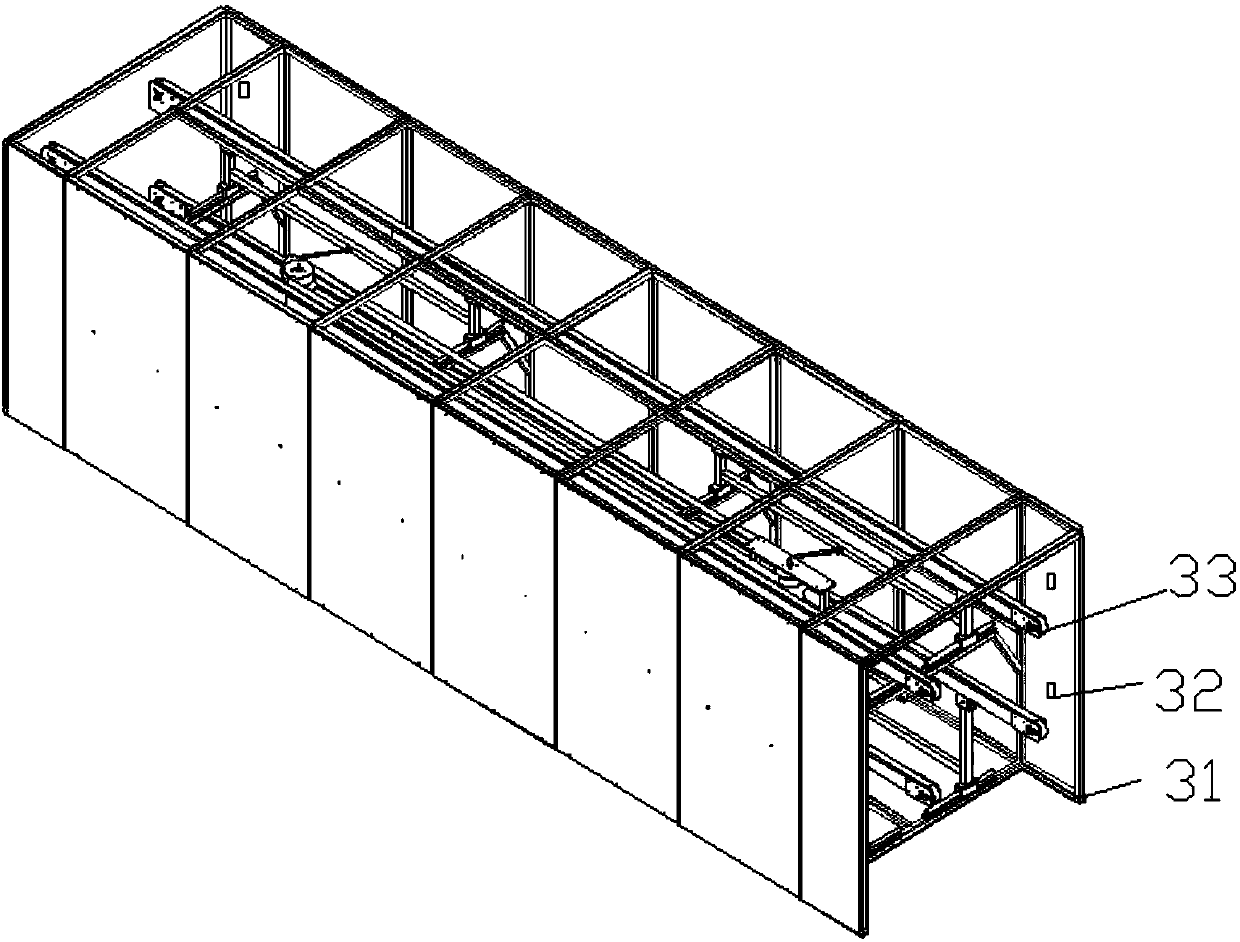

Vehicle bumper repairing, maintaining, carrying and storing system

ActiveCN107685792AIncrease the switching frequencyReduce labor intensityVehiclesProduction lineControl system

The invention discloses a vehicle bumper repairing, maintaining, carrying and storing system which is characterized by comprising a repairing and maintaining region, a conveying region, a storage location region, a guiding and fetching region and a control system. An inlet side of the repairing and maintaining region is connected with an injection molding machine at a previous station, and an outlet side of the repairing and maintaining region is connected with an inlet side of the conveying region; an inlet side of the storage location region is connected with an outlet side of the conveyingregion, and an outlet side of the storage location region is connected with an inlet side of the guiding and fetching region; an outlet side of the guiding and fetching region is connected with an inlet side of a coating production line at a next station. Each of the conveying region and the guiding and fetching region comprises at least one lift type AGV (automatic guide vehicle). The storage location region comprises a plurality of storage locations, and the storage locations are parallelly arrayed. The vehicle bumper repairing, maintaining, carrying and storing system has the advantages that flexible manufacturing production takt and requirements can be met by the multiple lift type AGV and the storage locations, the bumper type switching frequencies can be increased, labor environmentscan be improved, the labor intensity of workers can be relieved, the error rates of the workers can be lowered, labor loss in carrying procedures can be prevented, and bumpers can be efficiently intelligently managed.

Owner:HEBEI UNIV OF TECH

Method for improving yield of low-permeability heavy oil well

ActiveCN106050209AHigh porosityImprove permeabilityFluid removalDrilling compositionOperabilityField tests

The invention belongs to the technical field of tertiary oil recovery, and particularly relates to a method for improving the yield of a low-permeability heavy oil well. Specifically, the method comprises the following steps of screening of the oil well, fracture of the oil well, single-well throughput treatment of the oil well, and treatment of a shaft of the oil well. The method has the characteristics of being simple in process and high in operability, and is beneficial for field application and popularization. The method is high in pertinence, a series of technical measures can be selected in a targeted mode according to the characteristics of the low-permeability heavy oil well, accordingly, the yield of the oil well can be greatly improved, the period of validity of the oil well can be greatly prolonged, the oil increase amount of the single well is higher than 1000 tons, the period of validity is longer than 3 years, and the input-output ratio is 1:5. Thus, the method can be widely applied to field tests for yield improvement of the low-permeability heavy oil well.

Owner:YANTAI ZHIBEN INTPROP OPERATIONS MANAGEMENT CO LTD

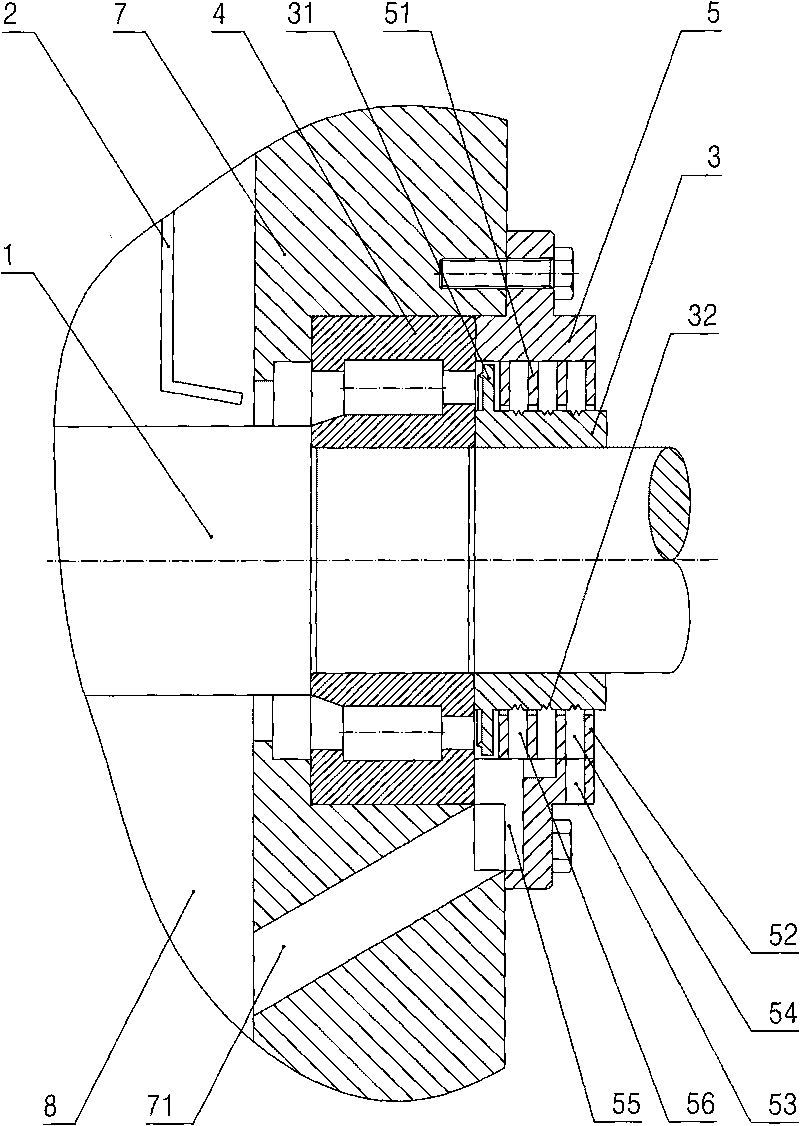

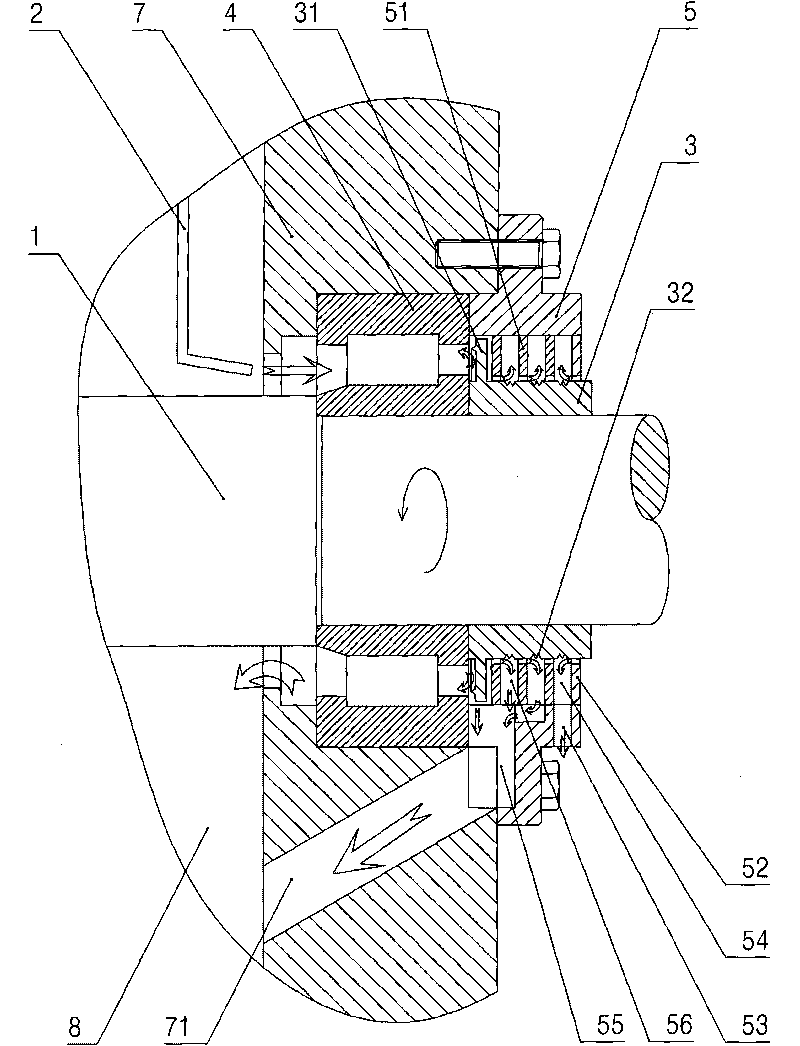

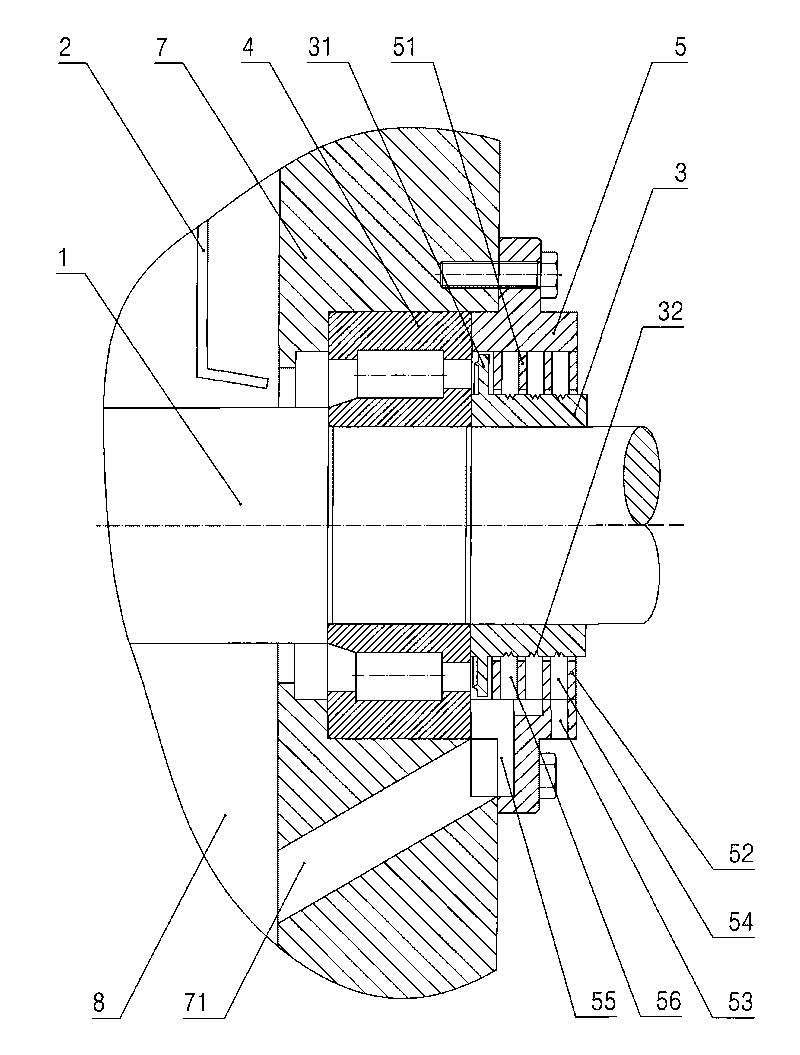

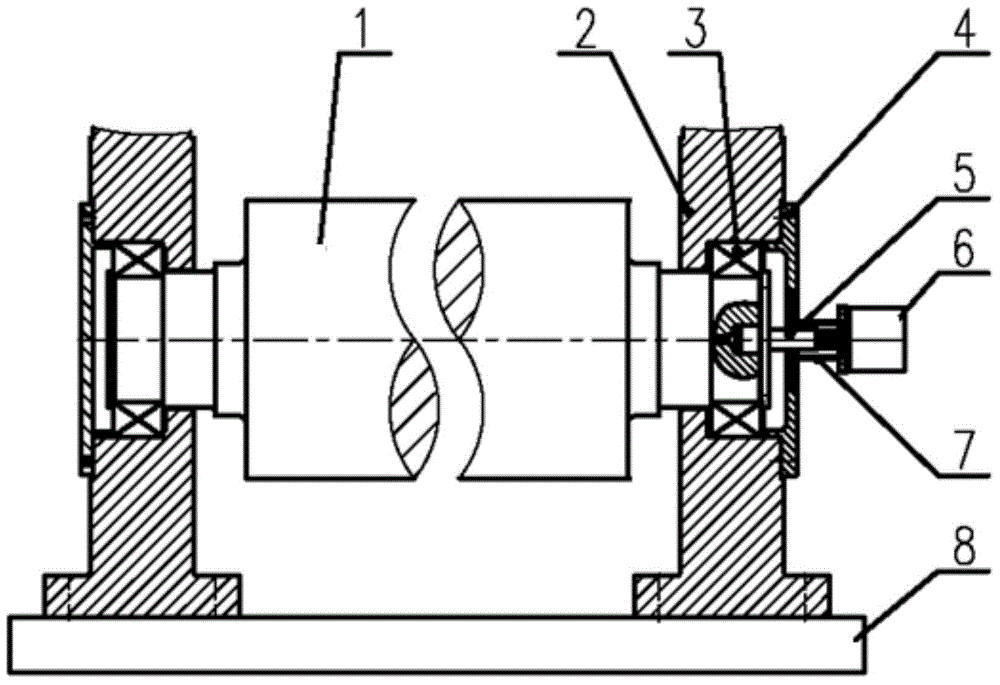

Sealing device for drive mechanism of horizontal centrifuge

The invention discloses a sealing device for a drive mechanism of a horizontal centrifuge, which can prevent foreign liquid from entering an oil tank and recover a small amount of lubricating oil, and comprises a bearing seat arranged on a rack, a bearing arranged in the bearing seat and a gland arranged at the outer side of the bearing, wherein the bearing seat is internally provided with an oil returning slot; a main shaft is arranged in the bearing in a penetrating way and penetrates through the gland; a sealing case is arranged between the gland and the main shaft; a main baffle ring is arranged at the inner side of the sealing case; a leakage-proof ring and at least two subsidiary baffle rings are arranged on the inner wall of the gland; the leakage-proof ring is arranged at the outermost part; gaps are respectively arranged between the main baffle ring and the gland, the leakage-proof ring and the sealing case, and the subsidiary baffle rings and the sealing case; a liquid stopping trough is formed between the leakage-proof ring and the adjacent subsidiary baffle ring thereof; the liquid stopping trough is communicated with the liquid returning slot arranged at the outer side of the gland; an oil stopping groove is formed between two adjacent subsidiary baffle rings; and the oil stopping groove is communicated with the oil returning slot by an oil returning channel arranged at the inner side of the gland. The sealing device is mainly used in a high-speed horizontal centrifuge.

Owner:JIANGSU PEONY CENTRIFUGE MFG

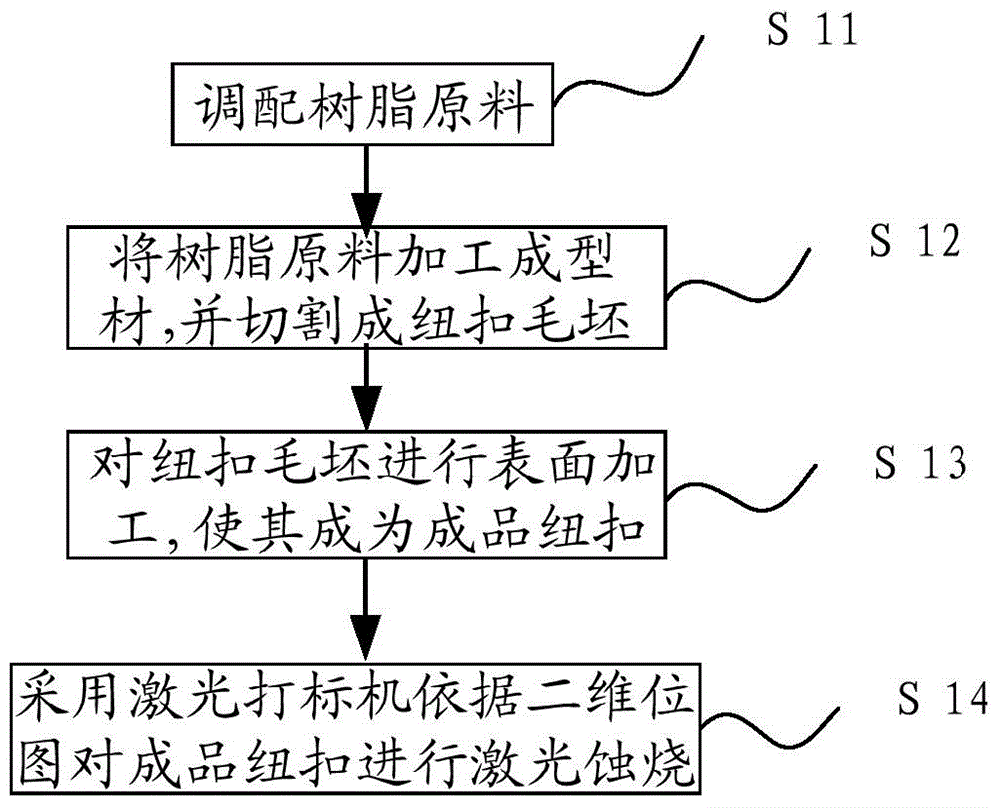

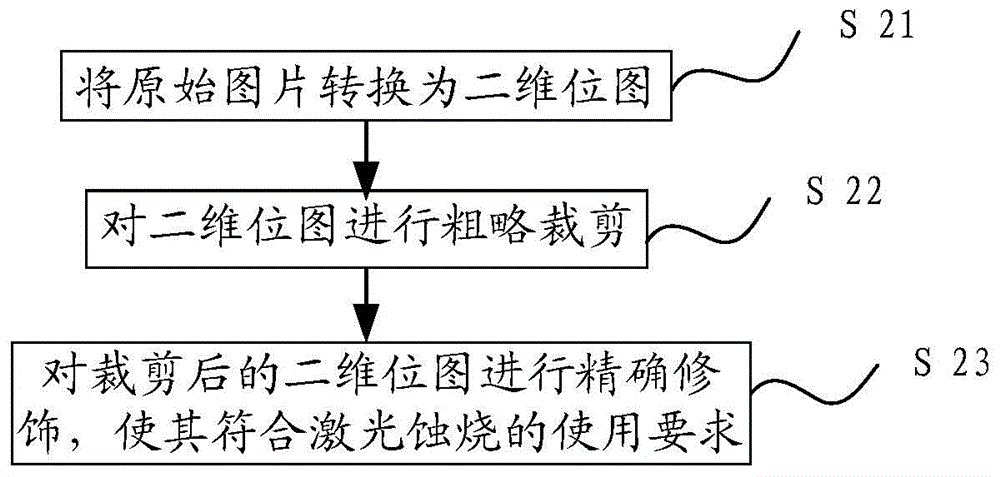

Mold button pattern production process

The present application discloses a mold pattern button production process comprising the following steps: a resin material is prepared; the resin material is processed into a sectional material, and the sectional material is cut into a button workblank; the outline of the button workblank is processed, and the button workblank is cleaned and polished to form a finished button; and a laser marking machine is used for different degrees of laser burning and erosion of different parts of the stained surface of the finished button according to pre-set two-dimensional bitmap data. According to the mold pattern button production process, by presetting of a two-dimensional bitmap, the needs of different types of mold patterns can be met, affect on button normal production due to supplies consumption can be avoided, by precise control of the laser energy value and distribution way, the consistency of the mold pattern on each individual can be precisely ensured, and in the manner of laser burning and erosion for formation of the mold patterns, the parts with the concave surface can be processed, bar-shaped profiles can also be processed, and the needs of different types of mold patterns of buttons in different materials can be met.

Owner:ZHEJIANG WEIXING IND DEV

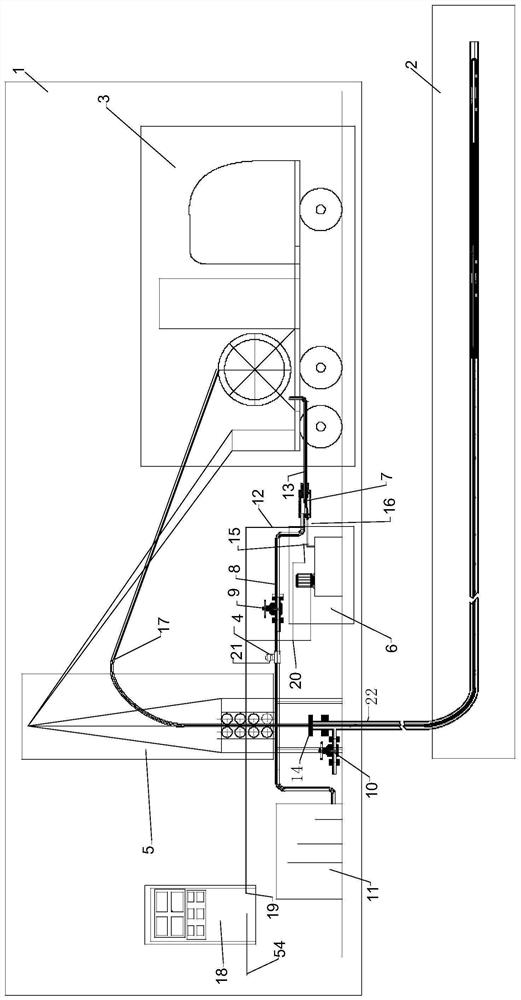

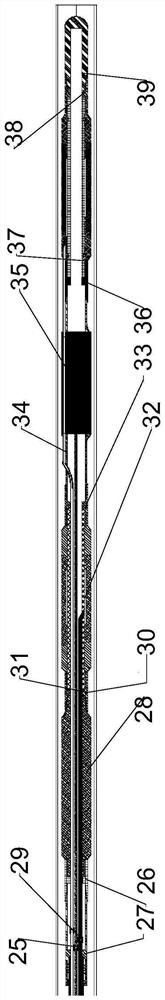

Composite coiled tubing cable horizontal well water outlet section testing system and method

PendingCN111963153AAffect normal productionMeet the test requirementsSurveyCable installations in surface ductsWater dischargeHorizontal wells

The invention discloses a composite coiled tubing cable horizontal well water outlet section testing system and method. An upper hydraulic packer assembly and a lower hydraulic packer assembly can beused for packing the position of any section in an oil well casing pipe. An oil-submerged electric plunger pump is used for pumping the liquid in the oil well casing pipe, the liquid conveyed to the ground surface by the underground oil-submerged electric plunger pump after packer setting is analyzed, and therefore whether the liquid is pure water, oil-containing water and water-containing oil, the liquid production capacity and the liquid discharging conditions of all sections can be visually observed; and an underground temperature and pressure sensor assembly is used for testing the temperature and pressure of the packed section, whether the section is the water discharging section or not can be further illustrated according to the pressure and temperature changes of produced liquid andall perforation sections, so that corresponding treatment measures are taken, and the phenomenon that water contained in the produced liquid is increased fast during oil-gas field horizontal well production till furious water logging happens, and normal production of an oil-water well is affected is avoided.

Owner:华信唐山石油装备有限公司

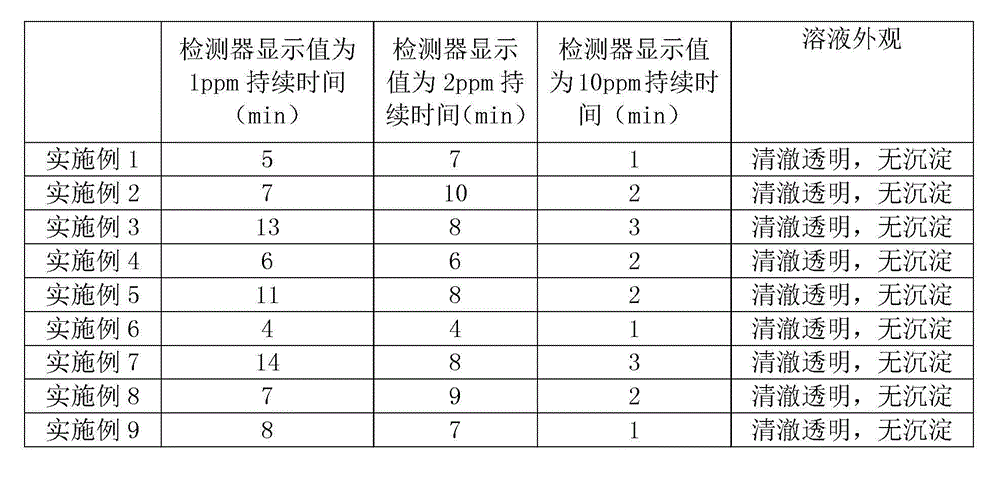

Sulfur removal agent suitable for production of oil-gas well

InactiveCN102698576BSimple recipeAffect normal productionDispersed particle separationPropanolAlcohol

The invention relates to a sulfur removal agent suitable for the production of an oil-gas well. The sulfur removal agent comprises the following components in percentage by mass: 10 to 25 percent of hexahydro-1,3,5-tris(hydroxyethyl)-s-triazine, 5 to 20 percent of alcohol amine, 5 to 20 percent of small molecular alcohol and the balance of water. The alcohol amine is one or a mixture of more thantwo of monoethanolamine, ethyleneglycol amine, diisopropanolamine, methyldiethanolamine and triethanolamine; and the small molecular alcohol is one or a mixture of more than two of methanol, ethanol and propanol. The sulfur removal agent has a simple formula, can be soluble with water, and can effectively reduce the content of hydrogen sulfide in crude oil or natural gas; simultaneously, productsgenerated by the sulfur removal agent and the hydrogen sulfide are water-soluble, and cannot block a mineshaft and influence the normal production of the oil-gas well; and the sulfur removal agent can achieve effects at the temperature of 30 to 120 DEG C and can be quickly reacted with the hydrogen sulfide.

Owner:SOUTHWEST PETROLEUM UNIV

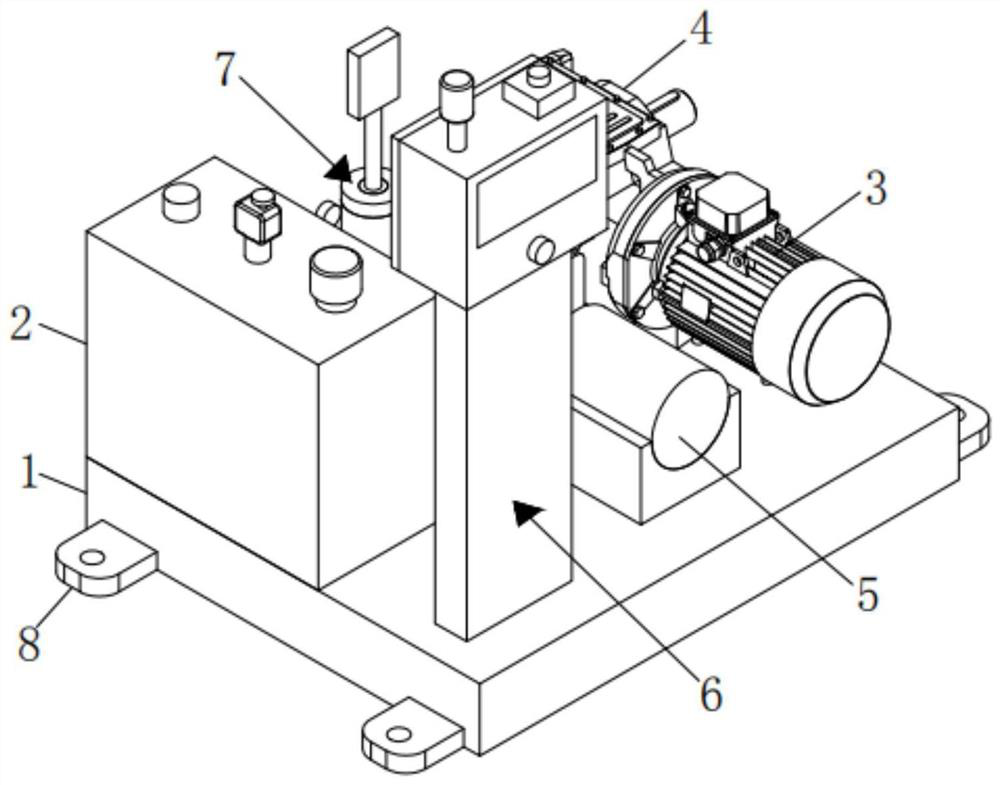

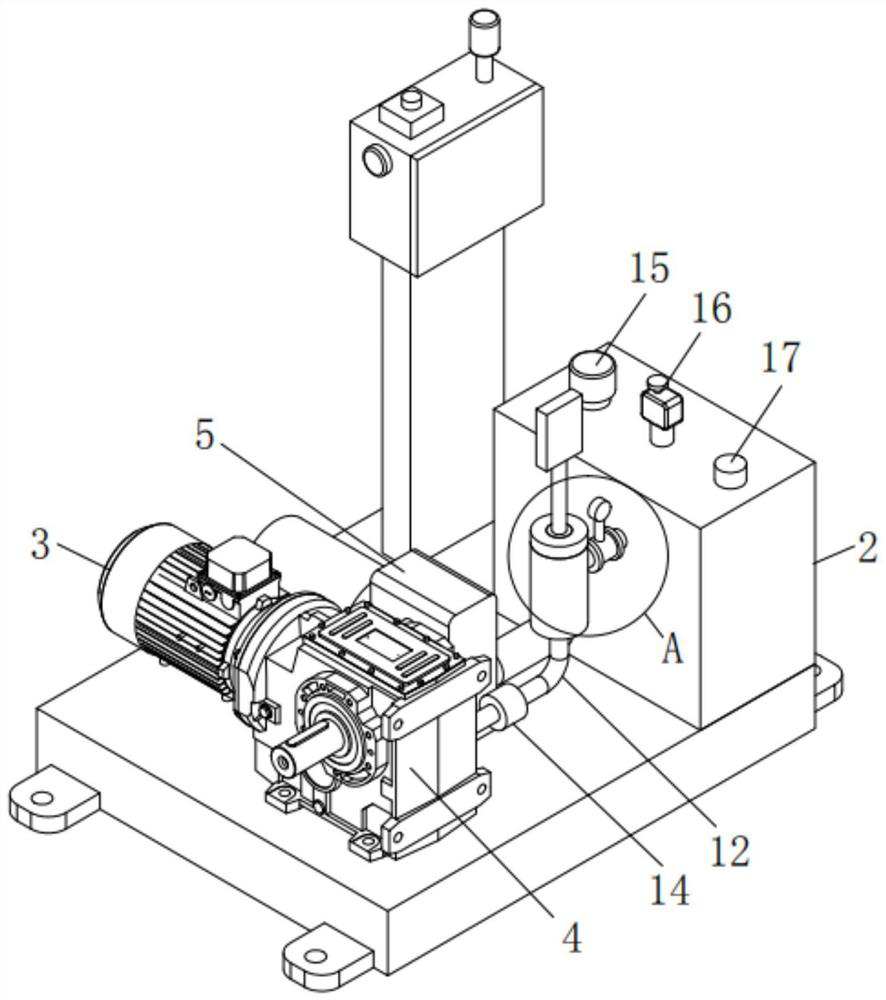

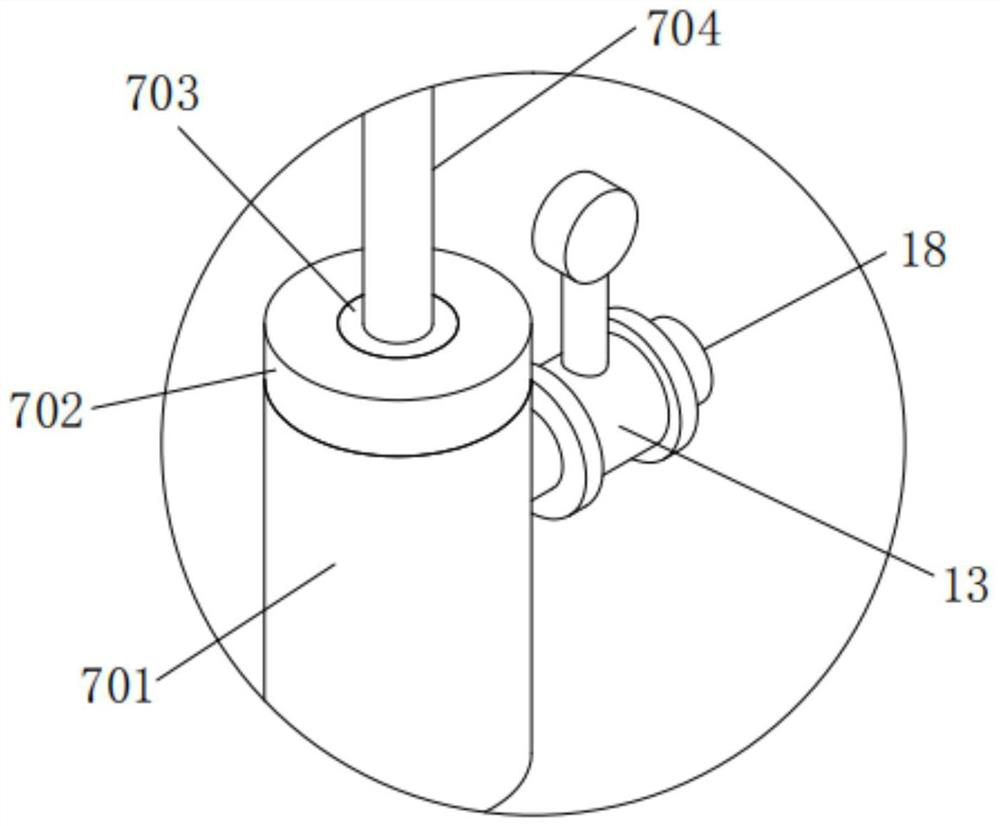

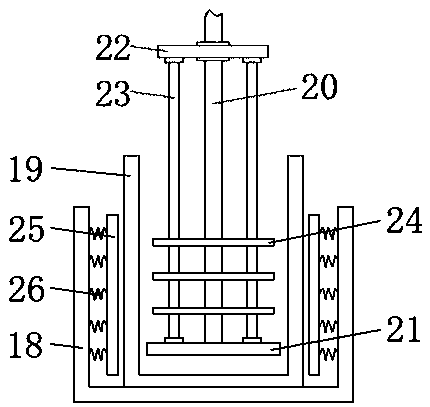

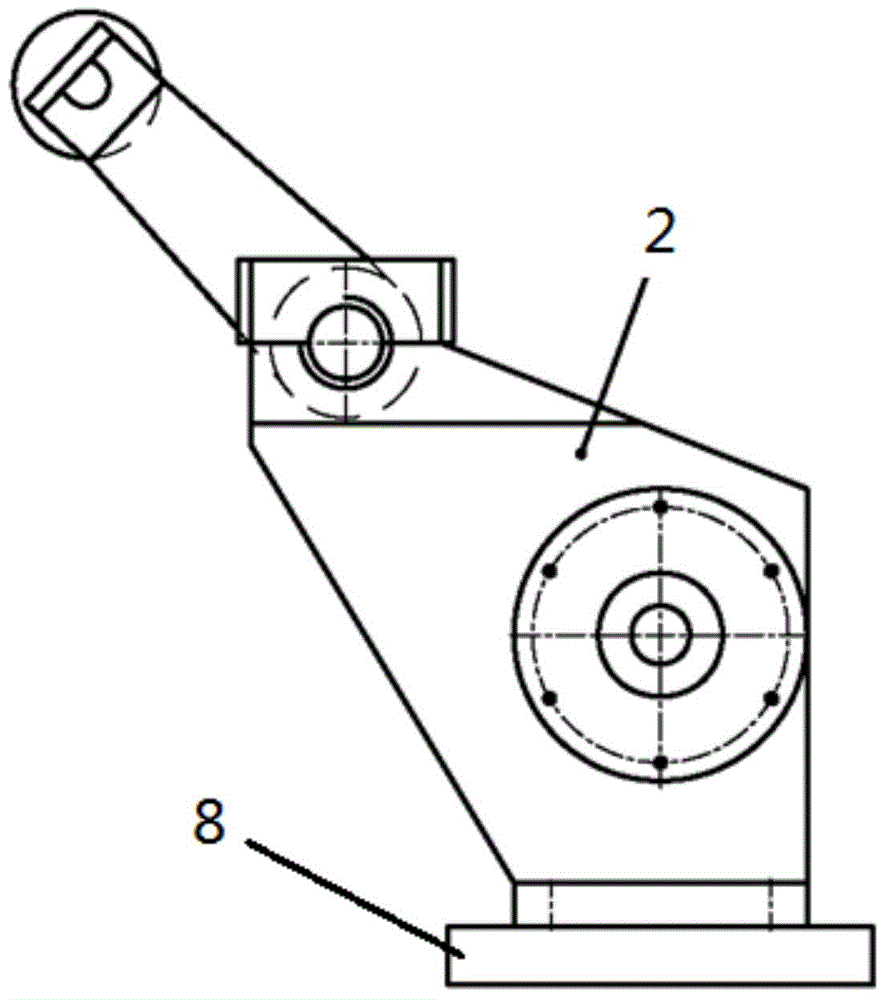

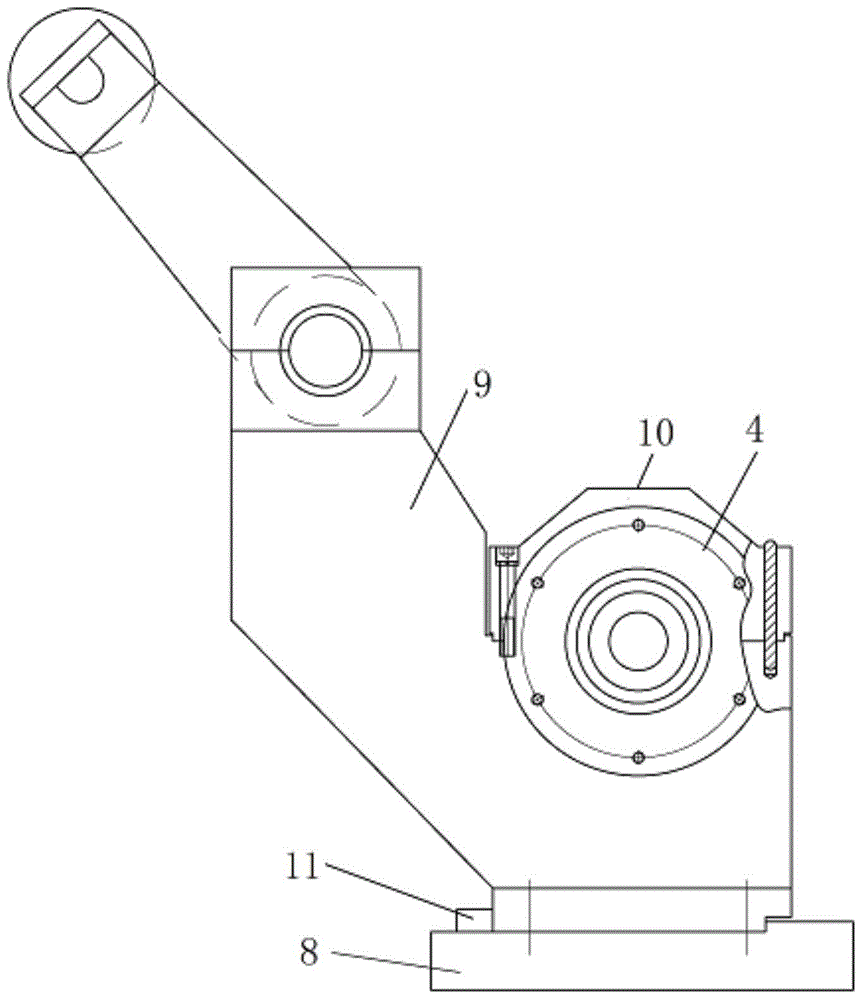

Coal face scraper conveyor speed reducer forced lubrication indicating and alarming device

InactiveCN111828601AReal-time observation of lubrication conditionsAffect normal productionGear lubrication/coolingLubrication elementsElectric machineReducer

The invention relates to the technical field of monitoring, in particular to a coal face scraper conveyor speed reducer forced lubrication indicating and alarming device. The coal face scraper conveyor speed reducer forced lubrication indicating and alarming device comprises a bottom plate, a lubricating oil tank, a lubricating pump, a motor, a speed reducer, an indicating mechanism, an alarming mechanism and a flow meter, wherein the bottom plate is horizontally arranged, the lubricating oil tank, the lubricating pump, the motor, the speed reducer and the alarm mechanism are all fixedly installed on the upper portion of the bottom plate, and a rotating shaft of the motor is fixedly connected with an input shaft of the speed reducer. The device can indicate whether an oil pipe and an oil duct convey lubricating oil normally or not in real time and give an oil shortage alarm, so that a worker can observe the lubricating condition of a high-speed shaft bearing of the speed reducer in real time, the device can be stopped in time when lubrication is poor or oil shortage occurs, and normal production of a working face is prevented from being influenced by a falling-apart locking fault of the high-speed shaft bearing of the speed reducer, so that waste of manpower and material resources and larger economic loss are avoided.

Owner:JIAOZUO COAL IND GRP CO LTD

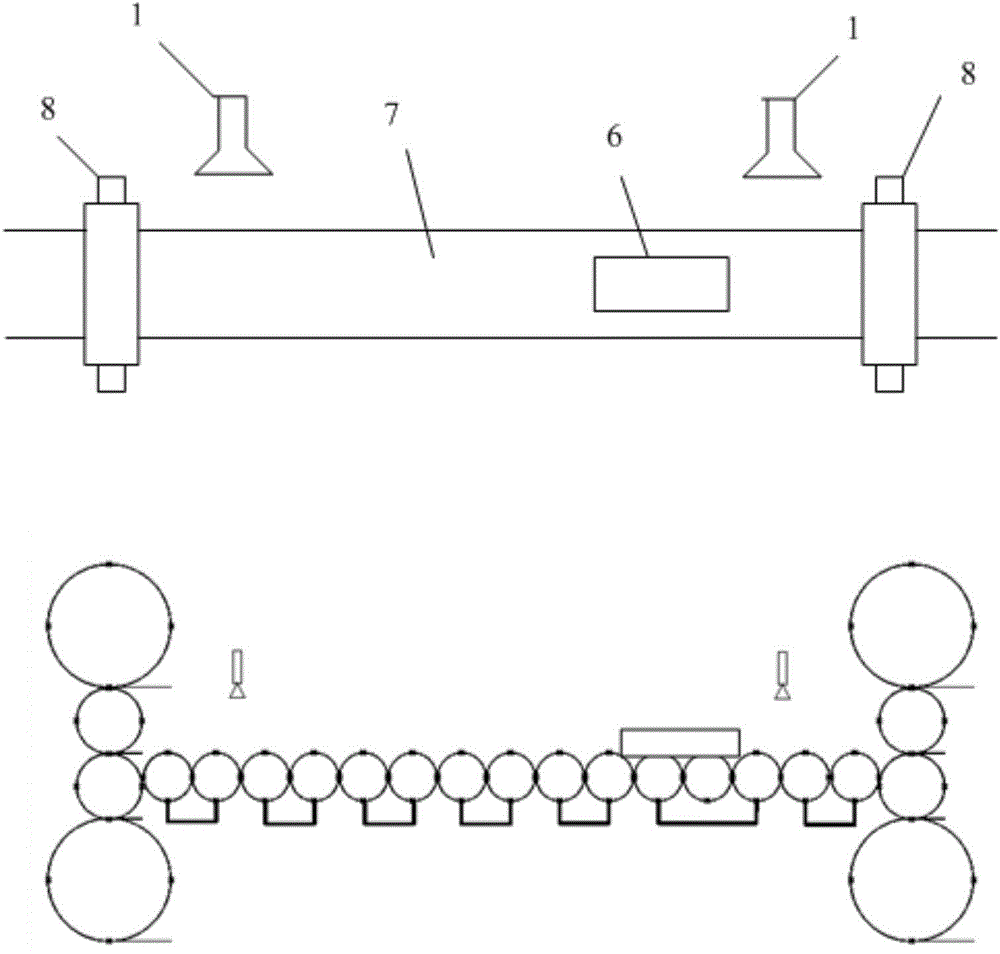

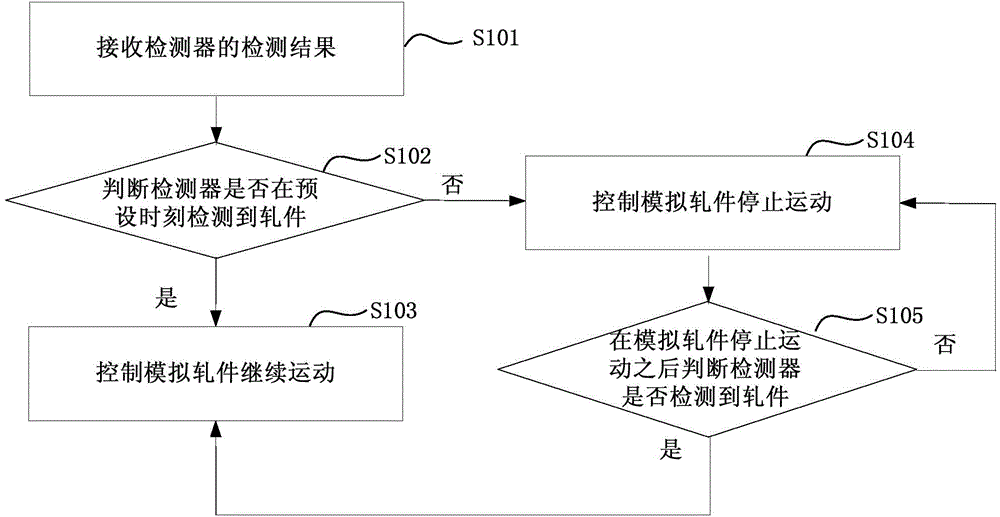

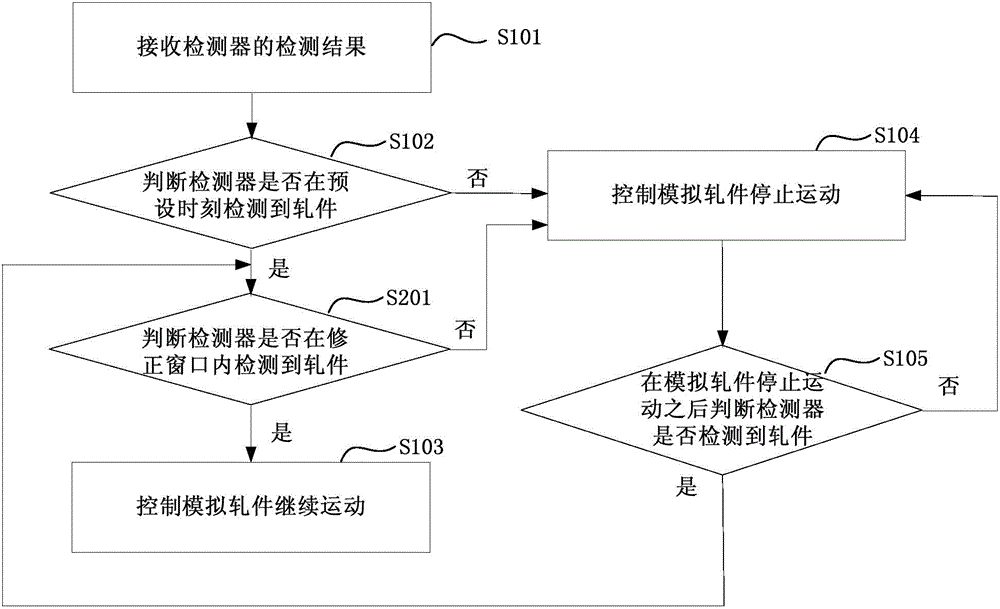

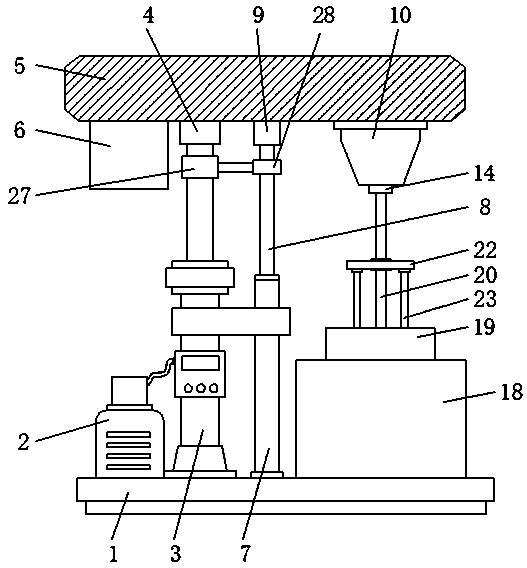

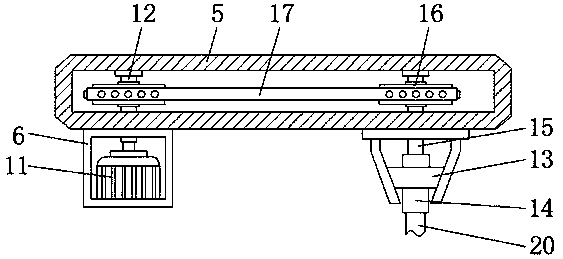

Method and device for simulating positions of rolling part

ActiveCN104353674AAffect normal productionRoll mill control devicesMeasuring devicesProduction lineAutomatic control

The embodiment of the invention discloses a method and a device for simulating positions of a rolling part. The method comprises the following steps of judging whether a detector detects the rolling part at preset time or not; when the detector does not detect the rolling part at the preset time, controlling a simulation rolling part corresponding to the rolling part in a simulation module to stop movement; when the detector detects the rolling part after the simulation rolling part stops movement, controlling the simulation rolling part to continue to move, wherein the preset time includes the time when the logic position of the simulation rolling part in the simulation module is consistent with the logic position of the simulator detector. When the logic position of the simulation rolling part exceeds the actual position of the rolling part in a production line, the movement is immediately stopped, so as to avoid the influence on the normal production of the rolling part because the simulation rolling part continues to move when the logic position of the simulation rolling part exceeds the actual position of the rolling part in the production line, and the disordering is caused when an automatic control system utilizes the logic position of the simulation rolling part in the simulation module to control the production line.

Owner:ELECTRON CO LTD

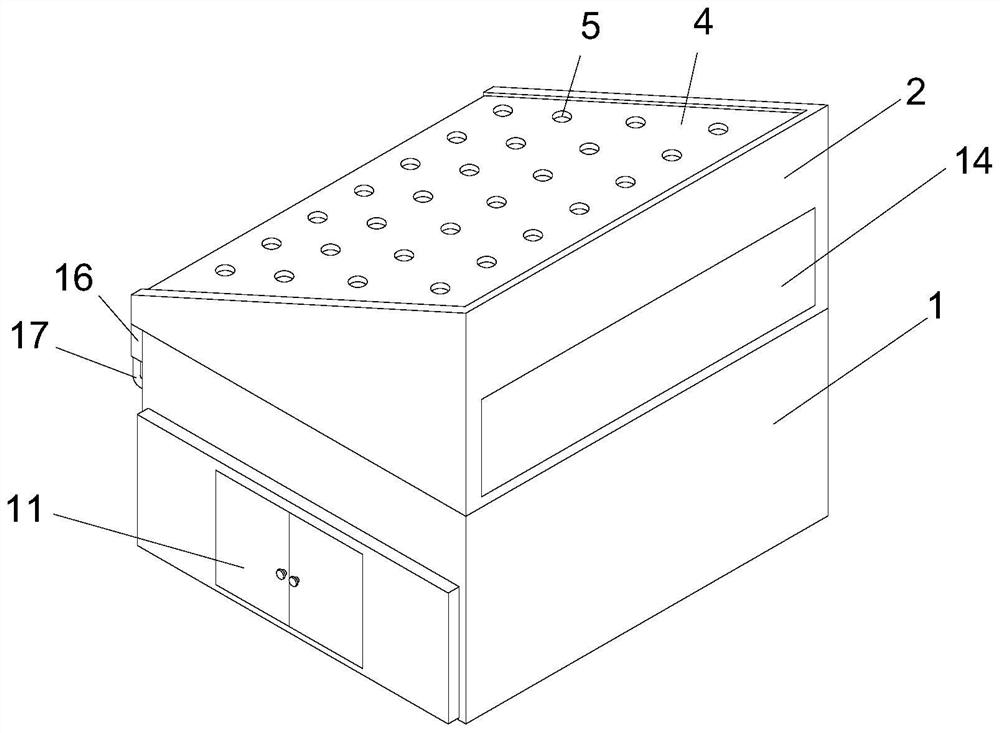

Coating preparation equipment for preparing nano exterior wall coating

InactiveCN109453686AImprove finenessQuality improvementRotary stirring mixersTransportation and packagingDrive motorFineness

The invention relates to the technical field of coating production and processing, and discloses coating preparation equipment for preparing a nano exterior wall coating. The equipment comprises a base; a hydraulic cylinder is fixedly installed at the left side of the top of the base; a hydraulic rod, positioned on the top of the base, is fixedly installed at the right side of the hydraulic cylinder; a fixed block is fixedly installed on the top of the hydraulic rod, a sleeve plate is fixedly installed on the top of the fixed block, and the bottom of the sleeve plate is fixedly provided with amotorized box positioned at the left side of the fixed block; a sleeve is fixedly installed on the top of the base. According to the coating preparation equipment for preparing the nano exterior wallcoating, a first shaft rod is driven to rotate by means of a drive motor, and a driving wheel is driven to rotate by means of the first shaft rod, so that a transmission chain drives another drivingwheel and a second shaft rod to rotate, and the high-speed rotation of a stirring shaft is realized; the stirring shaft is matched with a stirring plate for use, so that the equipment can more fully stir the raw materials of the nano coating, the fineness of the mixed coating is improved, and the quality of the coating is improved.

Owner:张雅慧

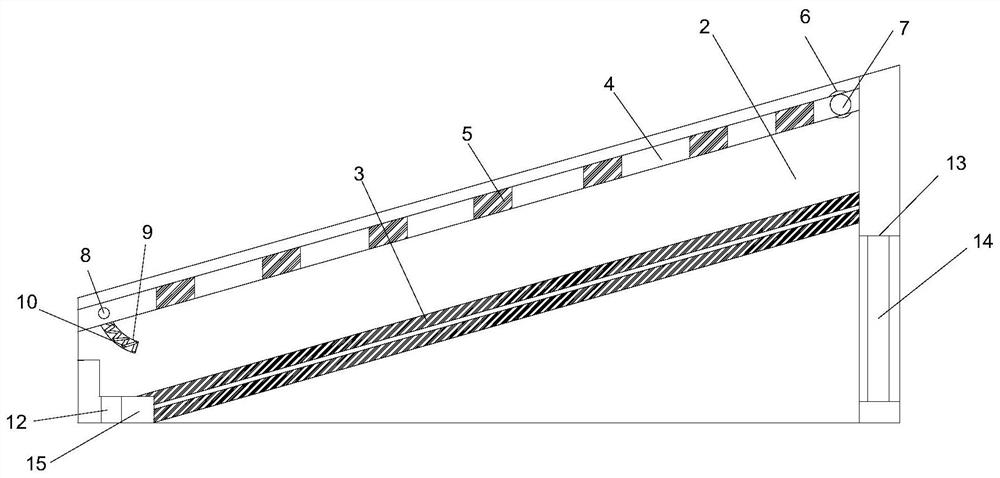

Blow molding process for children's slide components

The invention belongs to the technical field of blow molding, and particularly relates to a blow molding process for children's slide components. The blow molding process for the children's slide components comprises the following steps of S1, uniformly mixing 70 percent by mass of polyethylene, 20 percent by mass of carbon fiber reinforced polypropylene and 10 percent by mass of additive to obtain a preparation raw material of a slide component, wherein the additives comprise an anti-ultraviolet stabilizer, an anti-static agent and an anti-aging agent; S2, heating the raw material obtained inthe step S1 to a molten state, and then extruding the raw material through an extruder to obtain a parison; S3, putting the parison obtained in the step S2 into a forming device, introducing compressed air, blowing up the parison, and obtaining a formed slide component; S4, taking out the formed slide component obtained in the step S3, cutting off tailings, deflashing, then conducting polishing treatment, removing burrs on the surface of the slide component, and obtaining a finished slide component. According to the blow molding process for the children's slide components, a preparation method is simple, and the prepared slide component is high in strength, good in mechanical performance, not prone to cracking and long in service life.

Owner:WENZHOU LIYOU IND

Technology for increasing yield of low-permeability heavy oil well

ActiveCN105863598AHigh porosityImprove permeabilityFluid removalDrilling compositionOperabilityField tests

The invention belongs to the technical field of tertiary oil recovery, and particularly relates to a technology for increasing yield of a low-permeability heavy oil well. The technology specifically comprises the following steps: screening the oil well; fracturing the oil well; treating single well huff and puff of the oil well; and treating a shaft of the oil well. The technology has the features of simplicity and high operability, and facilitates field popularization and application; and the technology is high in pertinency, a series of technology measures are selected in a targeted manner according to the features of the low-permeability heavy oil well, therefore, the yield of the oil well can be greatly improved, the period of validity of the oil well can be greatly prolonged, single well oil increment is greater than 1,000 t, the period of validity is longer than 3 years, and the input-output ratio is greater than 1:5. Therefore, the technology can be widely used in a field test for increasing the yield of the low-permeability heavy oil well.

Owner:大庆三采技术有限公司

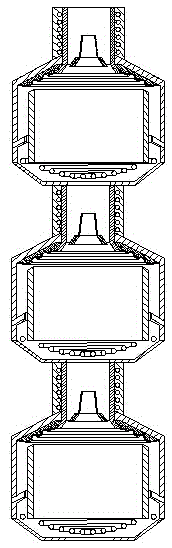

High-efficiency fractionator

InactiveCN104667557AHigh fractionation rateRelatively smallFractional distillationBiochemical engineeringFractionation

The invention relates to a high-efficiency fractionator. The high-efficiency fractionator comprises a plurality of fractionation tank bodies which are communicated with one another, wherein each fractionation tank body comprises a cylindrical shell with two sealed ends; an exhausting pipe is fixedly arranged at the top of each shell; the bottom of the shell is provided with a gas inlet; a heating assembly is arranged at the bottom of the shell; each fractionation tank body is communicated with the gas inlet in the bottom of an adjacent fractionation tank body; a fractionation assembly is arranged in each exhausting pipe and comprises a trumpet-shaped flow guide nozzle with openings in the two ends; an annular condenser is arranged at the closed end of the top of each shell; each condenser comprises a trumpet-shaped condensation surface; a cylindrical separation plate is further arranged in each shell; the axis of each separation plate and the axis of the corresponding cylindrical shell are coaxial; a plurality of liquid discharging grooves are further formed in the middle position of each separation plate; one end of each liquid discharging groove is fixed on the outer wall of the corresponding separation plate; and the other end of each liquid discharging groove penetrates through the inner wall of the corresponding shell and stretches outwards, and the side wall at one side of each liquid discharging groove is in an opening shape.

Owner:WUXI HAOYU ENERGY SAVING ENVIRONMENTAL PROTECTION EQUIP CO LTD

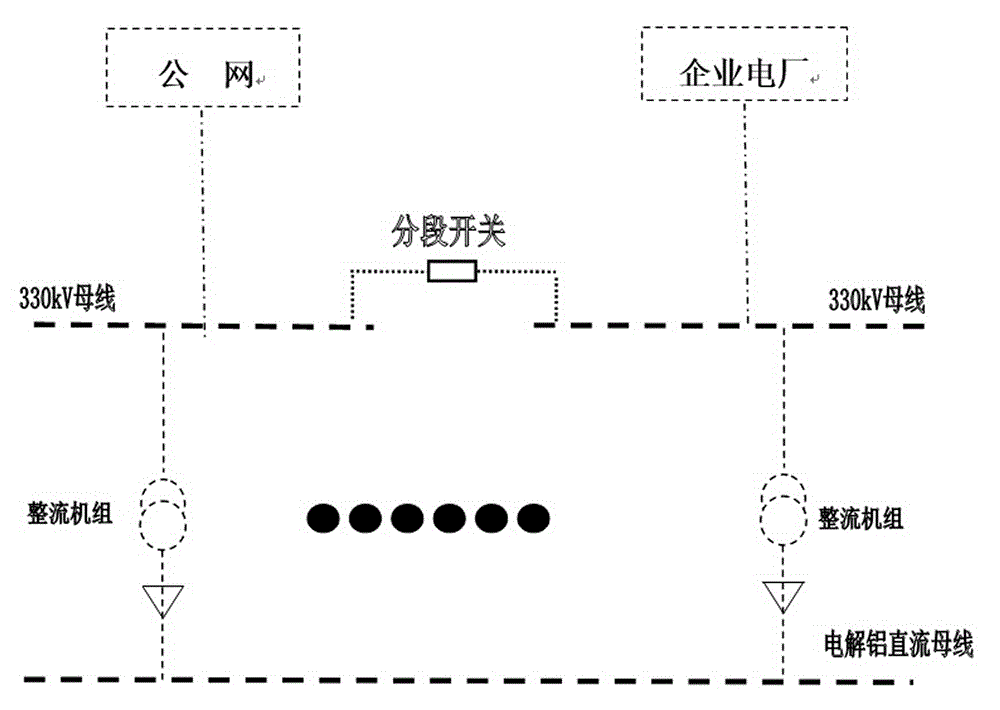

Parallel power supplying method of electrolytic aluminum different-power-supply-point direct-current sides

InactiveCN104836332AAffect safe and reliable operationReduce loadSingle network parallel feeding arrangementsEmergency power supply arrangementsElectric power systemPower grid

The invention provides a parallel power supplying method of electrolytic aluminum different-power-supply-point direct-current sides, and belongs to the technical field of electric power system operation and control. The method is used for convention between a public power grid and an autonomous power grid. The public power grid and the autonomous power grid are connected with different alternating-current power supplying buses. The different alternating-current power supplying buses are provided with sectionalized change-over switches. Rectification units are arranged between the different alternating-current power supplying buses and an electrolytic aluminum direct-current bus. Switch stations are arranged between the autonomous power grid and the alternating-current power supplying buses. Power substations are arranged on the connecting ends between the switch station and the alternating-current power supplying buses.

Owner:JIUQUAN IRON & STEEL GRP

Wild boar breeding room facilitating automatic snow removal

InactiveCN112293276AFacilitates automatic snow removalPrevent crushingAnimal housingSnow trapsSnow removalFishery

The invention relates to the technical field of wild boar breeding, and discloses a wild boar breeding room facilitating automatic snow removal. The wild boar breeding room comprises a main body and afunctional frame, the main body is of an existing structure and is not discussed, a heating system is arranged in the main body, the functional frame is fixedly connected to the main body and is a box-shaped block with a trapezoidal cross section, and the rear wall surface of the functional frame is hollow; and a connecting block is fixedly mounted at the rear end in the functional frame. According to the wild boar breeding room, by arranging two second connecting pipes and two movable blocks, when the room is used, electric telescopic rods in two second movable grooves can be started to drive the two second connecting pipes and the two movable blocks to move towards the left side of the main body and be separated from the interiors of corresponding first movable grooves and second movable grooves, and the movement range of wild boars during breeding is enlarged; and the motion amount of the wild boars in the breeding process can be ensured, meanwhile, a plurality of second connectingpipes are arranged between the second connecting pipes and the movable blocks, so that the problem that the wild boars escape from a pen formed by the two connecting pipes, the two movable blocks anda door plate is solved.

Owner:张海付

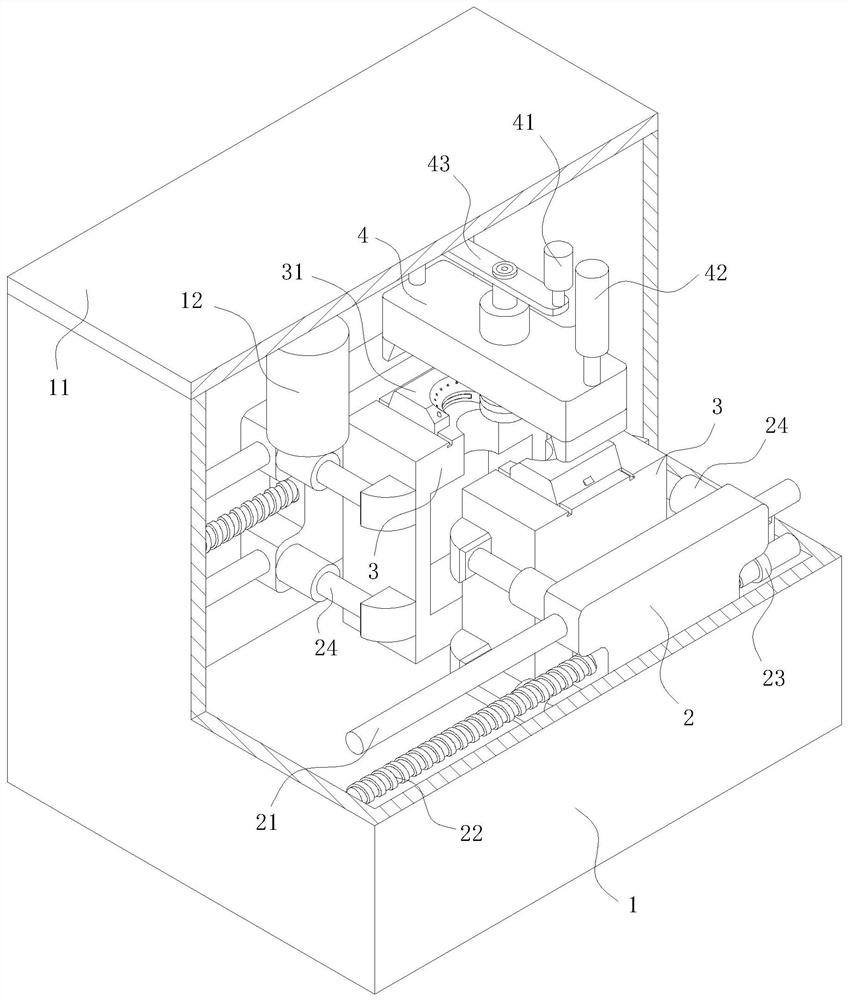

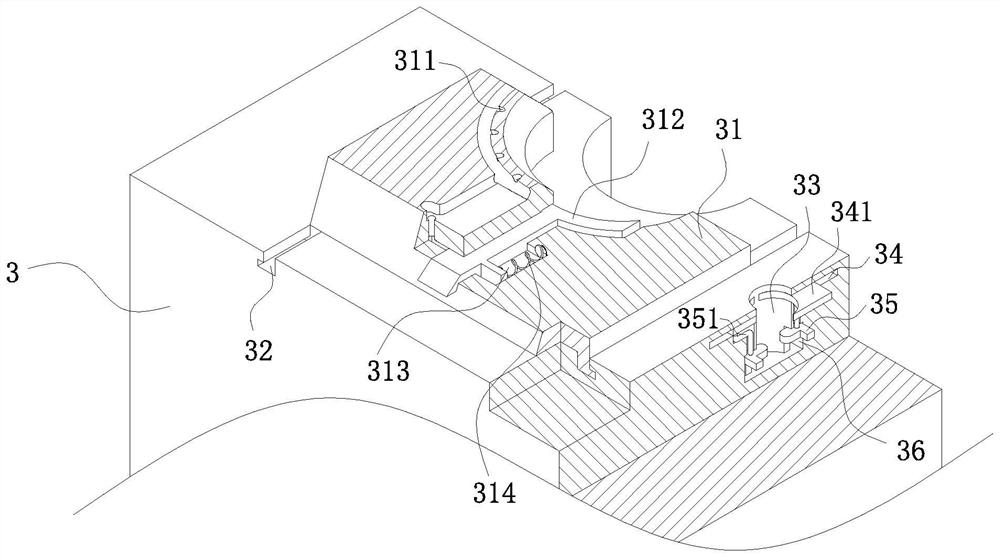

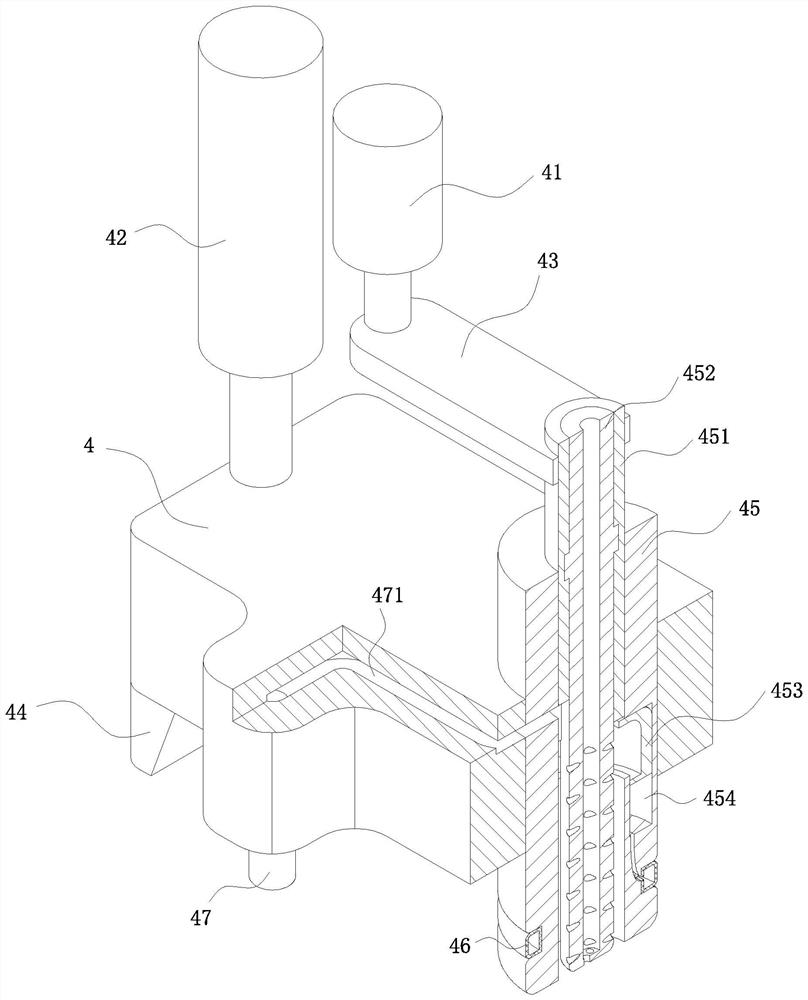

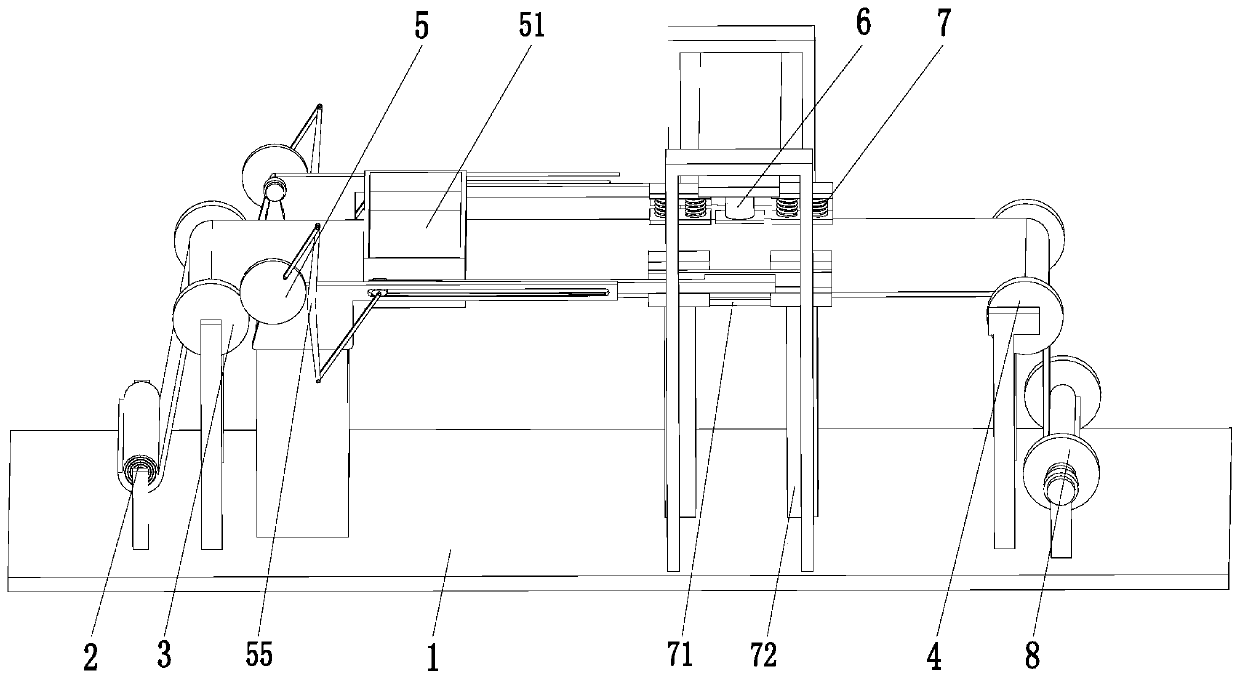

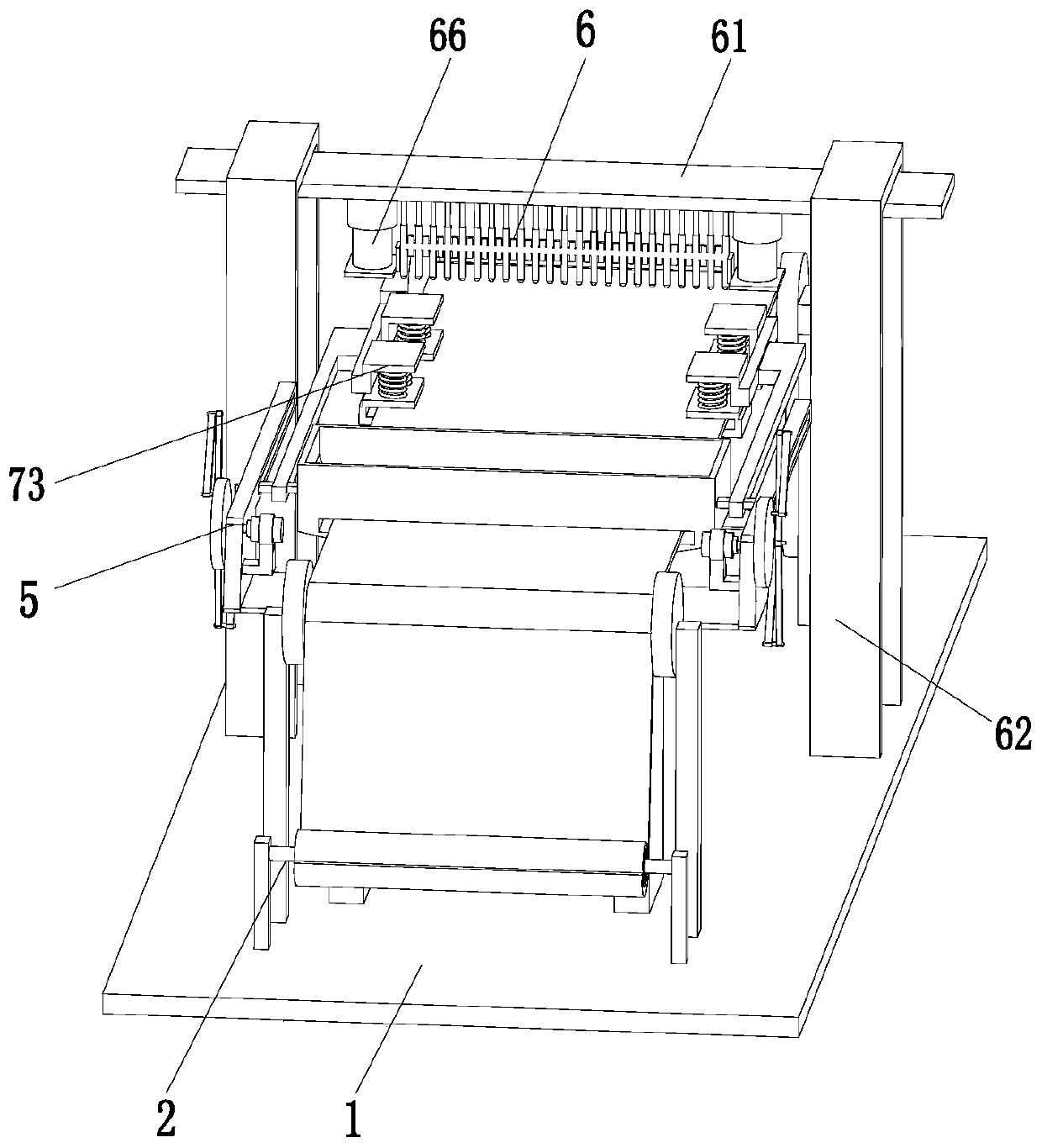

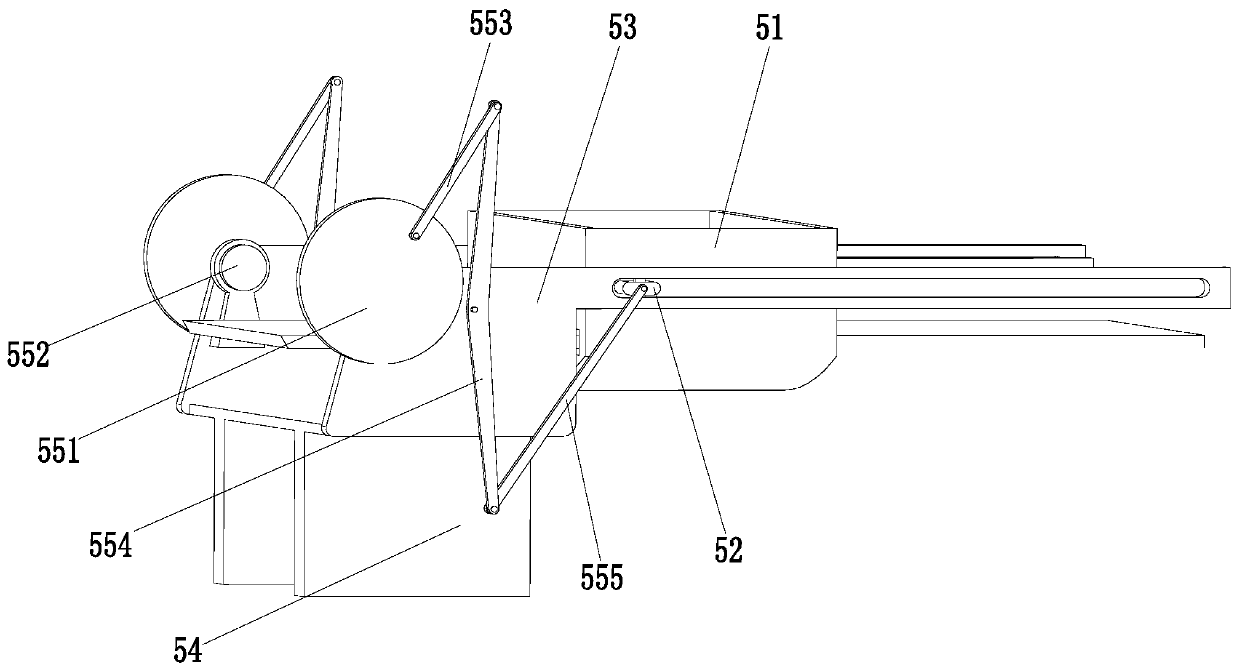

Spots breaking device of packaging rolling bag rolling machine

ActiveCN110759143ASolve the problem that it is impossible to collect and process the film scraps generated during the point-breaking process of continuous roll bagsAffect normal productionMetal working apparatusWebs handlingEngineeringMechanical engineering

The invention relates to a spots breaking device of a packaging rolling bag rolling machine. The spots breaking device comprises a bottom plate, a release roller, a guide roller, a tension roller, a collecting device, a spots breaking mechanism, a bearing device and a rolling mechanism. The guide roller is arranged on the left side above the bottom plate, the lower end of the release roller is mounted at the top end of the bottom plate, the collecting device is arranged on the right side of the guide roller, the bottom of the left end of the collecting device is mounted at the top end of the bottom plate, the spots breaking mechanism is located on the right side of the collecting device, the bearing device is arranged right below the spots breaking mechanism, the bottom of the bearing device is mounted at the top end of the bottom plate, the tension roller is located on the right side of the bearing device, the rolling mechanism is arranged on the lower right side of the tension roller, and the bottoms of the front and back ends of the rolling mechanism are mounted at the top end of the bottom plate. The spots breaking device can solve the problems that the product quality is affected as an existing spots breaking device cannot collect membrane chips generated by spots breaking and normal production of rolling bags is affected as a knife body of a spots breaking knife which islifted up is easy to pull up the rolling bag and the like.

Owner:江阴市神鹿塑胶有限公司

High-water-retention slow-release seaweed fertilizer and preparation method thereof

InactiveCN108610172AAffect normal productionWithout degrading propertiesSuperphosphatesBio-organic fraction processingSodium carboxymethylcelluloseChemistry

The invention discloses high-water-retention slow-release seaweed fertilizer and a preparation method thereof. The high-water-retention slow-release seaweed fertilizer comprises the following raw materials in parts by weight: seaweed, diatomite, carboxymethyl cellulose sodium, bentonite, chitosan, bean pulp, a dispersing agent, lauryl sodium sulfate, calcium superphosphate, methylcellulose and distilled water. The preparation method comprises the following steps: S1, performing washing, air drying and crushing on the seaweed, so as to obtain seaweed particles; S2, performing mixing and enzymolysis on the seaweed particles and other mixtures, so as to obtain a mixed solution; S3, centrifuging the mixed solution, collecting supernate, and performing fermentation; S4, preparing a membranous solution; S5, applying the membranous solution, so as to obtain a flexible glue piece; S5, laying a fermentation product into the flexible glue piece, so as to obtain the high-water-retention slow-release seaweed fertilizer. The fertilizer has the advantages that seaweed fertilizer is packaged in a membranous material, the membranous material, along with washing of rainwater or irrigation water, gradually releases the seaweed fertilizer into soil, and slow release is formed, so that a sower can reduce the applying frequency of the seaweed fertilizer during sowing.

Owner:天津市辰圣海洋生物技术有限公司

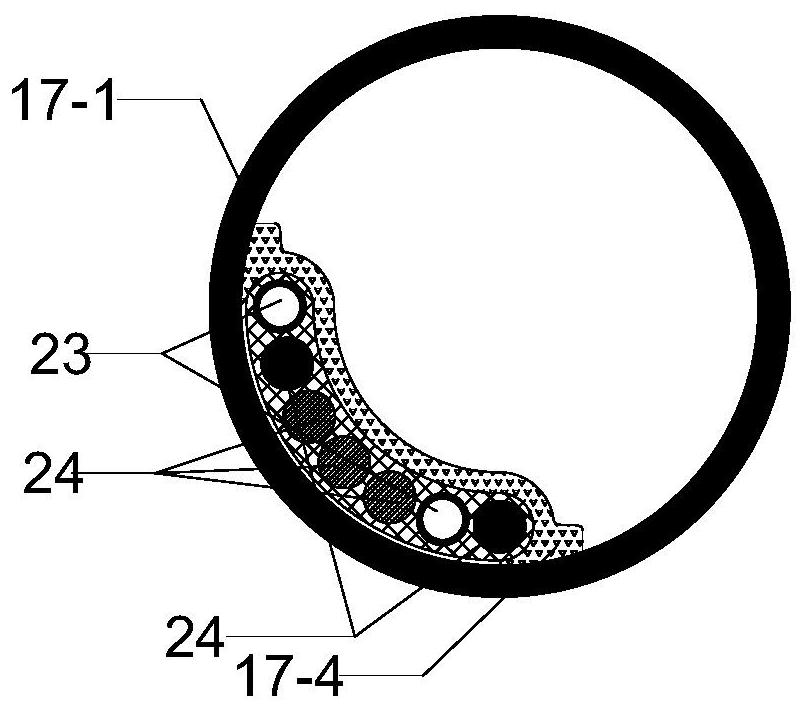

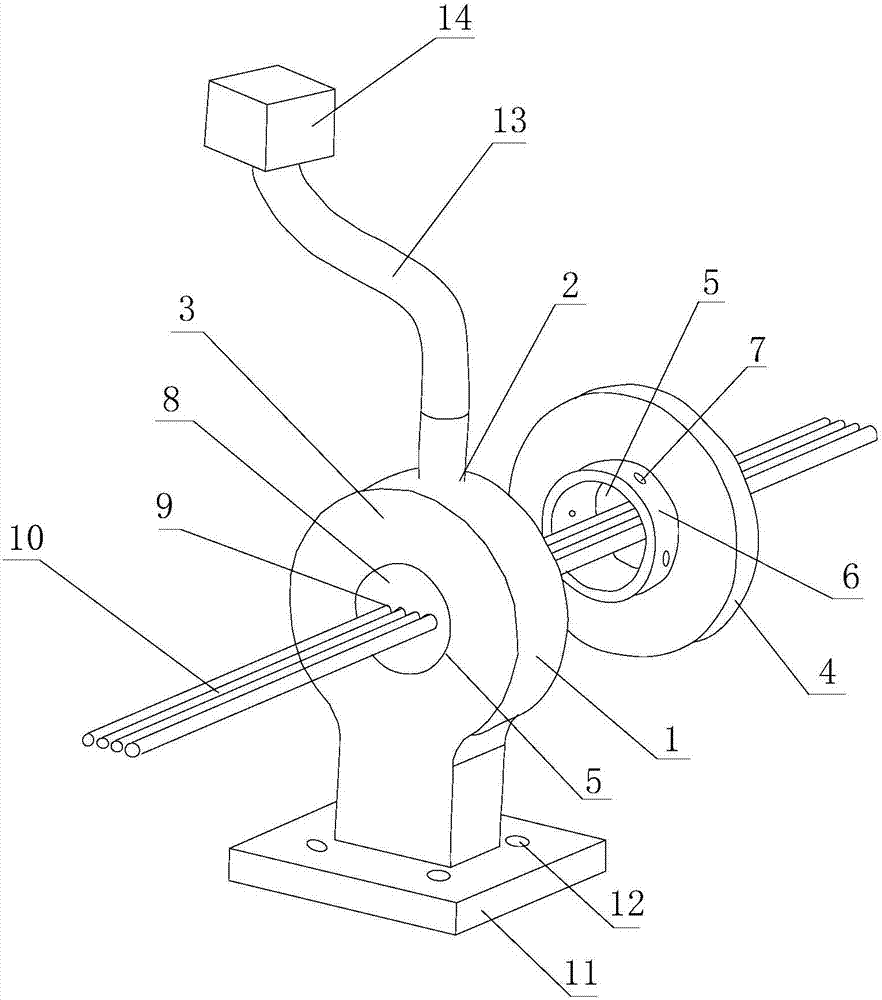

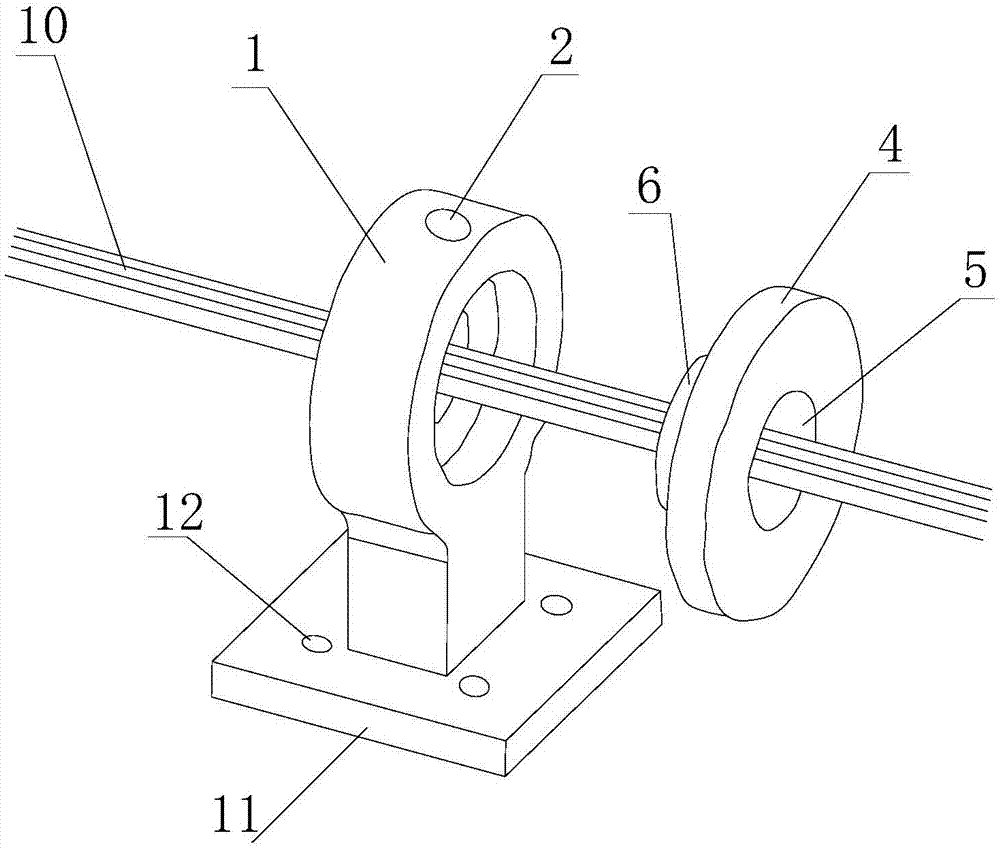

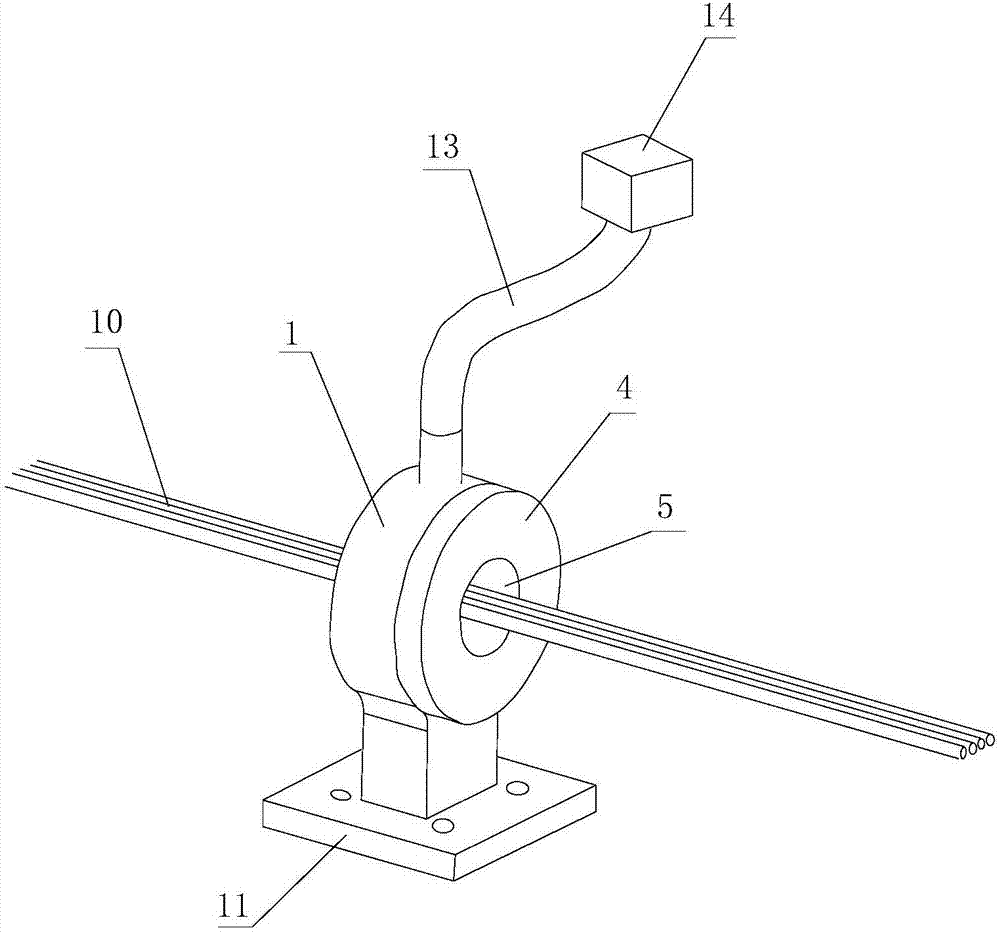

Wire collecting device integrated with air blowing function

InactiveCN107092064AAffect normal productionEasy to cleanFibre mechanical structuresEngineeringFront cover

The invention relates to the field of optical cable production, and discloses a wire collecting device integrated with an air blowing function, which comprises a ring-shaped fixing seat, a wire collecting die, a front cover and a rear cover, wherein both the center of the front cover and the center of the rear cover are provided with round holes; the side wall of the fixing seat is provided with air inlet holes; the front cover and the rear cover are arranged at two sides of the fixing seat respectively; the periphery of the round hole of the rear cover extends forwardly to form a ring-shaped bulge to abut against the front cover; a hollow ring-shaped cavity is formed between the ring-shaped bulge and the inner wall of the fixing seat; the side wall of the ring-shaped bulge is provided with multiple air holes for blowing air to the surface of the raw optical cable material walking in the cavity of the ring-shaped bulge; and the wire collecting die is arranged in the round hole of the front cover. Accumulation of dust on the surface of the raw optical cable material at the wire collecting die can be effectively avoided, and influenced normal production of the optical cable can be effectively avoided.

Owner:FENGHUO COMM SCI & TECH CO LTD

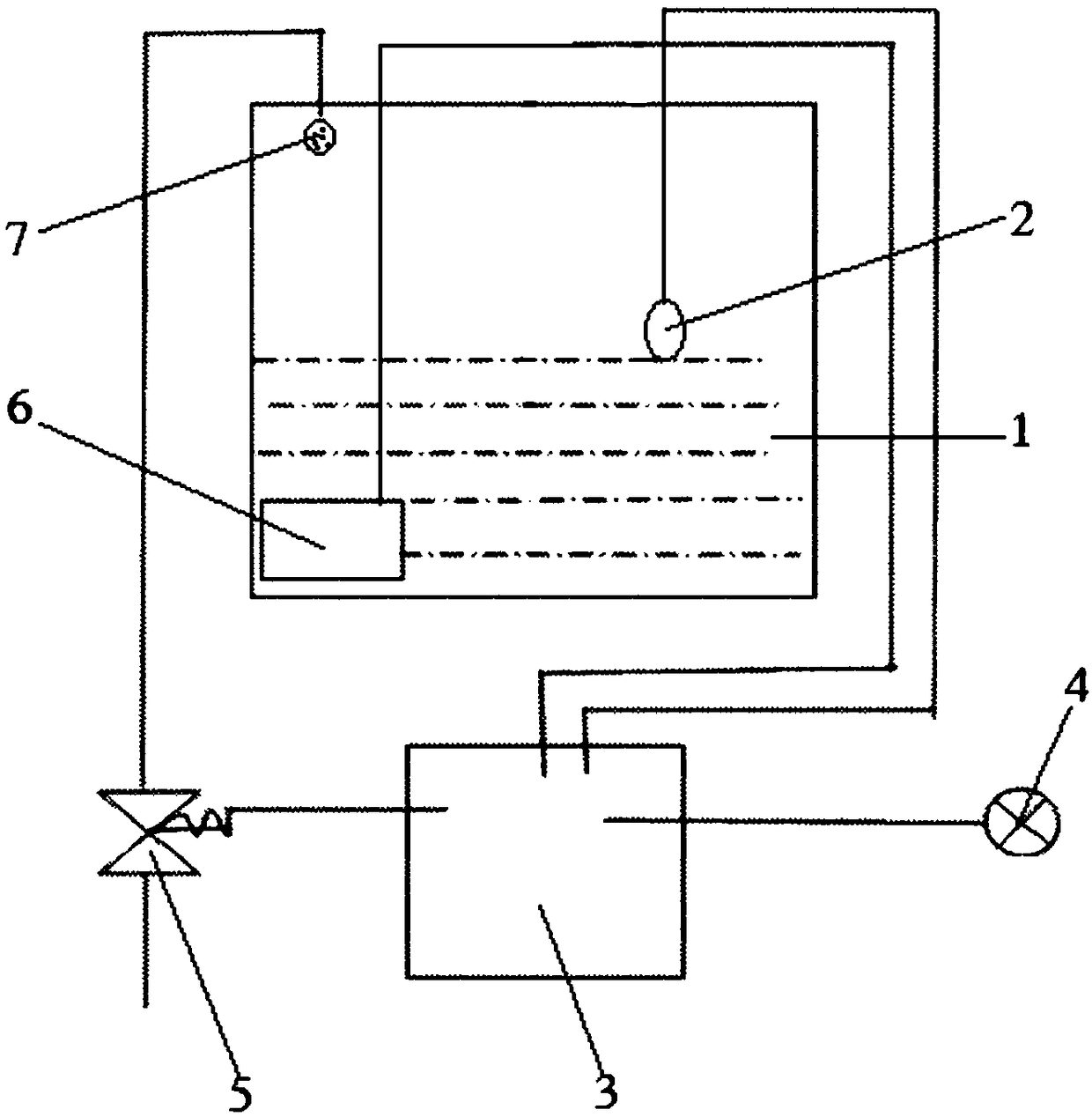

Environment-friendly liquid level alarm system for papermaking clear-water basin

PendingCN108121371AAffect normal productionMeet environmental protection requirementsLevel controlMeasurement devicesEngineeringWater quality

The invention relates to an environment-friendly liquid level alarm system for a papermaking clear-water basin. The system comprises a floating ball liquid level controller, a control box, a pump, analarm and a water quality monitoring sensor. A floating ball of the floating ball liquid level controller is arranged at the liquid surface of the basin. The water quality monitoring sensor is arranged at the bottom of the basin. The floating ball liquid level controller and the water quality monitoring sensor are connected to the control box whose output end is connected to the pump and the alarm. Compared with the prior art, according to the system, the liquid level of the clear-water basin is effectively controlled, a safety production accident due to a human error is avoided, and the lossand waste caused by the affection of the normal production of a paper machine due to a low water level and the overflow of clean water with a high water level are avoided. At the same time, due to thesetting of the water quality monitoring sensor, the pH, temperature, turbidity and dissolved oxygen of water quality can be tested, when the water quality is not up to standard, the water quality monitoring sensor sends a signal to the control box, the control box controls the alarm to emit an alarm, and the staff is timely reminded to take effective measures.

Owner:上海东冠纸业有限公司

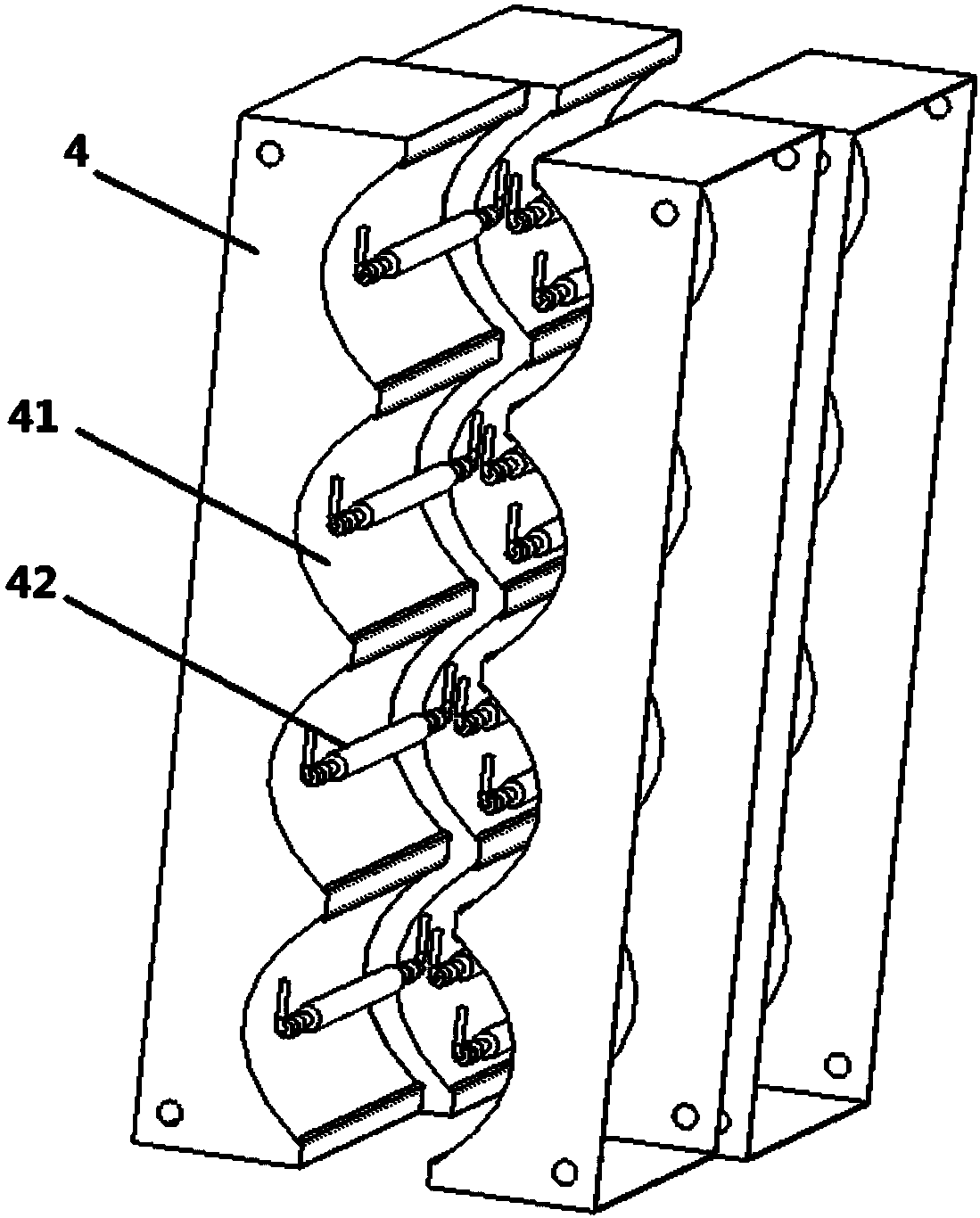

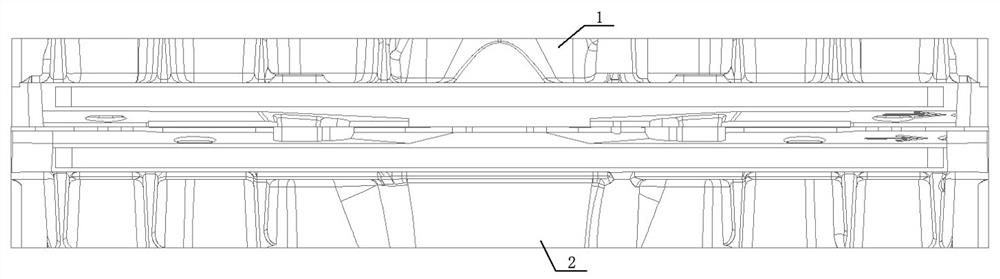

Turning roll device of reversible cold rolling mill unit

InactiveCN104438371AEasy maintenance and replacementAffect normal productionMetal rolling stand detailsGuiding/positioning/aligning arrangementsFront edgeRolling mill

The invention discloses a turning roll device of a reversible cold rolling mill unit. The turning roll device comprises two fixing bearing bases, the front edge of the lower end of each fixing bearing base is provided with a groove which is meshed and clamped with a step on a bottom plate, and the rear edge of the lower end of each fixing bearing base is provided with a positioning stopping block used for limiting. A combined piece of a turning roll and bearings at the two ends of the turning roll is mounted in an open groove in the upper portion of each fixing bearing base, and a gland bearing pedestal is buckled to the opening edge of the open groove in the upper portion of each fixing bearing pedestal. According to the turning roll device of the reversible cold rolling mill unit, the overall form of each bearing pedestal of the turning roll is changed to be of a split structure, the phenomenon that a large amount of time is consumed for dismounting, mounting and maintaining due to the fact that the device breaks down in the using process is avoided, the phenomenon that due to the difference of the technological levels of maintaining and mounting personnel, the mounting precision of equipment cannot meet the design requirement, so that the normal production of the unit is affected is also avoided, and maintaining and replacing can be achieved conveniently and quickly.

Owner:MCC SFRE HEAVY IND EQUIP

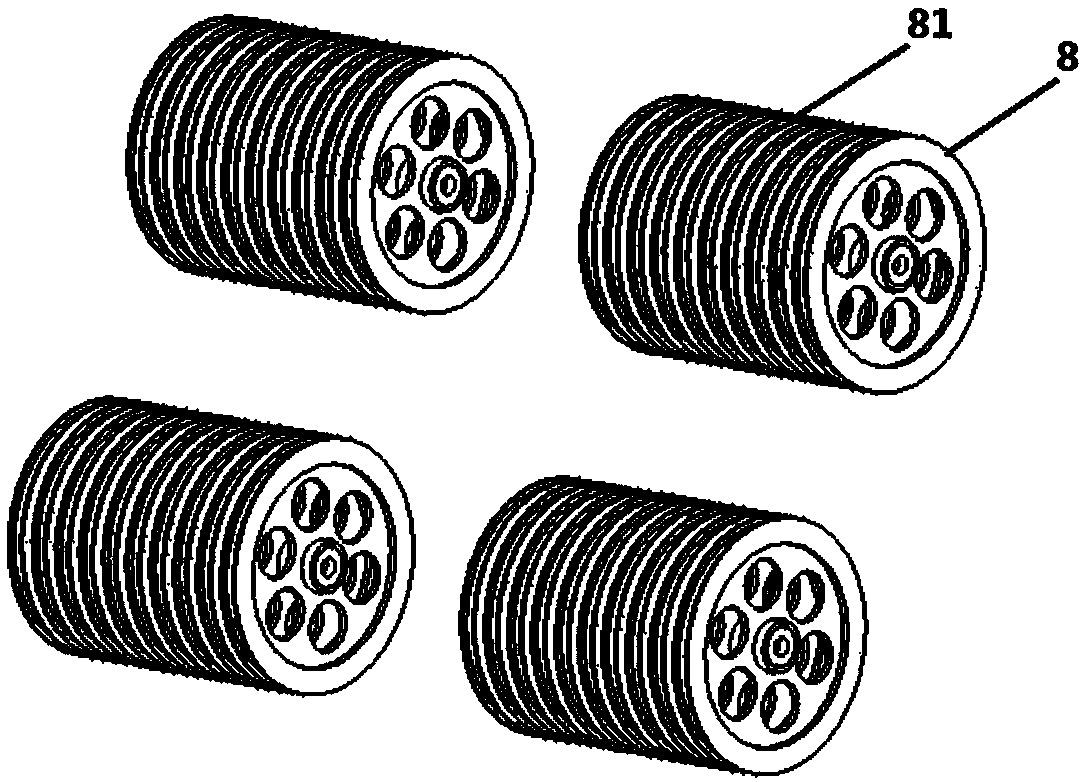

Machining and assembling method of casting and rolling roller for aluminum alloy casting and rolling

ActiveCN111804733AAvoid compromising assembly qualityAffect normal productionRollsOther manufacturing equipments/toolsEngineeringAluminium alloy

The invention provides a machining and assembling method of casting and rolling roller for aluminum alloy casting and rolling. The method comprises the following steps that firstly, an outer circle ofa roller core is machined; secondly, the average outer diameter size of the roller core is calculated; thirdly, the inner diameter target size of a roller sleeve is determined; fourthly, an inner circle of the roller sleeve is machined; fifthly, heat assembling is carried out; and sixthly, the rolling roller is machined. According to the method, the outer diameter size of the steel roller core can be measured accurately, the final machining size of the inner diameter of the roller sleeve is calculated scientifically according to the environment temperature factor, and the situation that due to the fact that the roller core and the roller sleeve are in different environment temperatures, inaccuracy of interference magnitude control is caused, and the assembling quality is influenced can beeffectively avoided. The surface roughness is selected reasonably, the assembling precision is ensured, and the machining cost is controlled reasonably. In combination with the heat assembly technology, it can be ensured that after heat assembly, during the casting and rolling production, the roller sleeve does not slide to influence normal production, the roller sleeve can be protected against damage to the greatest extent, the service life is prolonged, and maximization of benefit is achieved.

Owner:JIUQUAN IRON & STEEL GRP

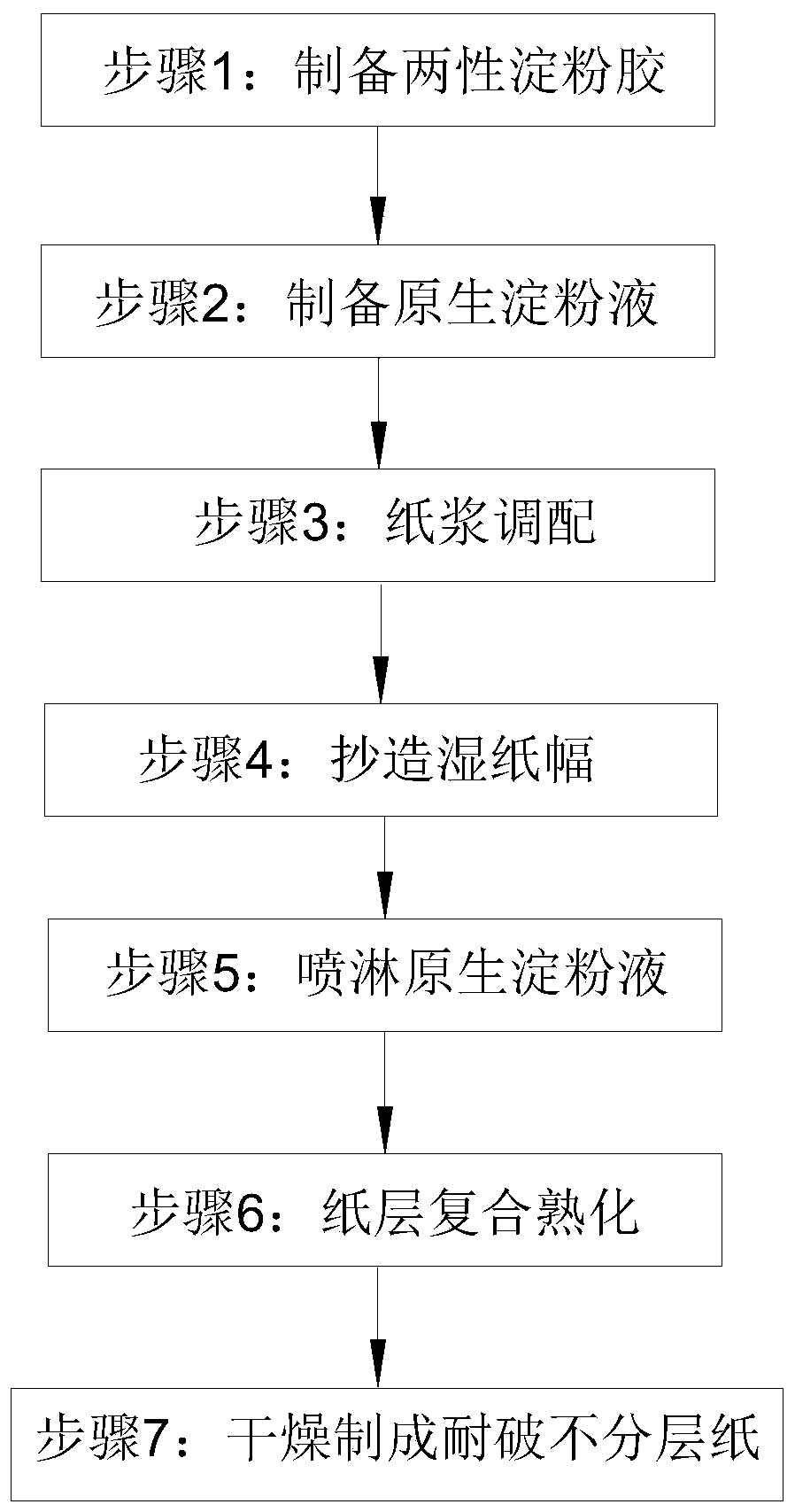

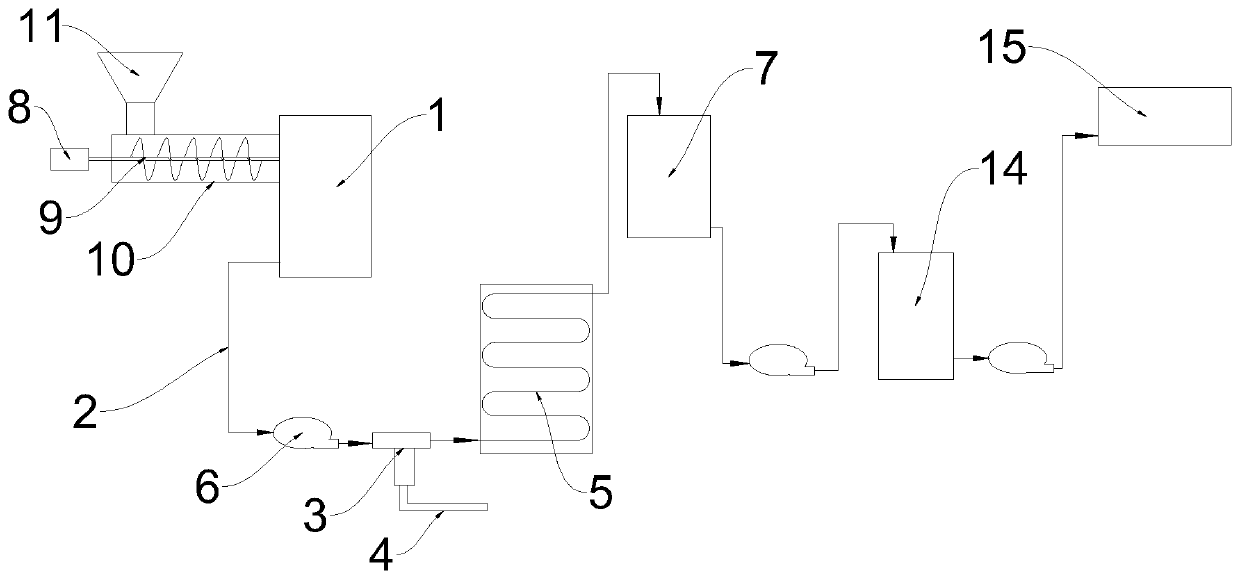

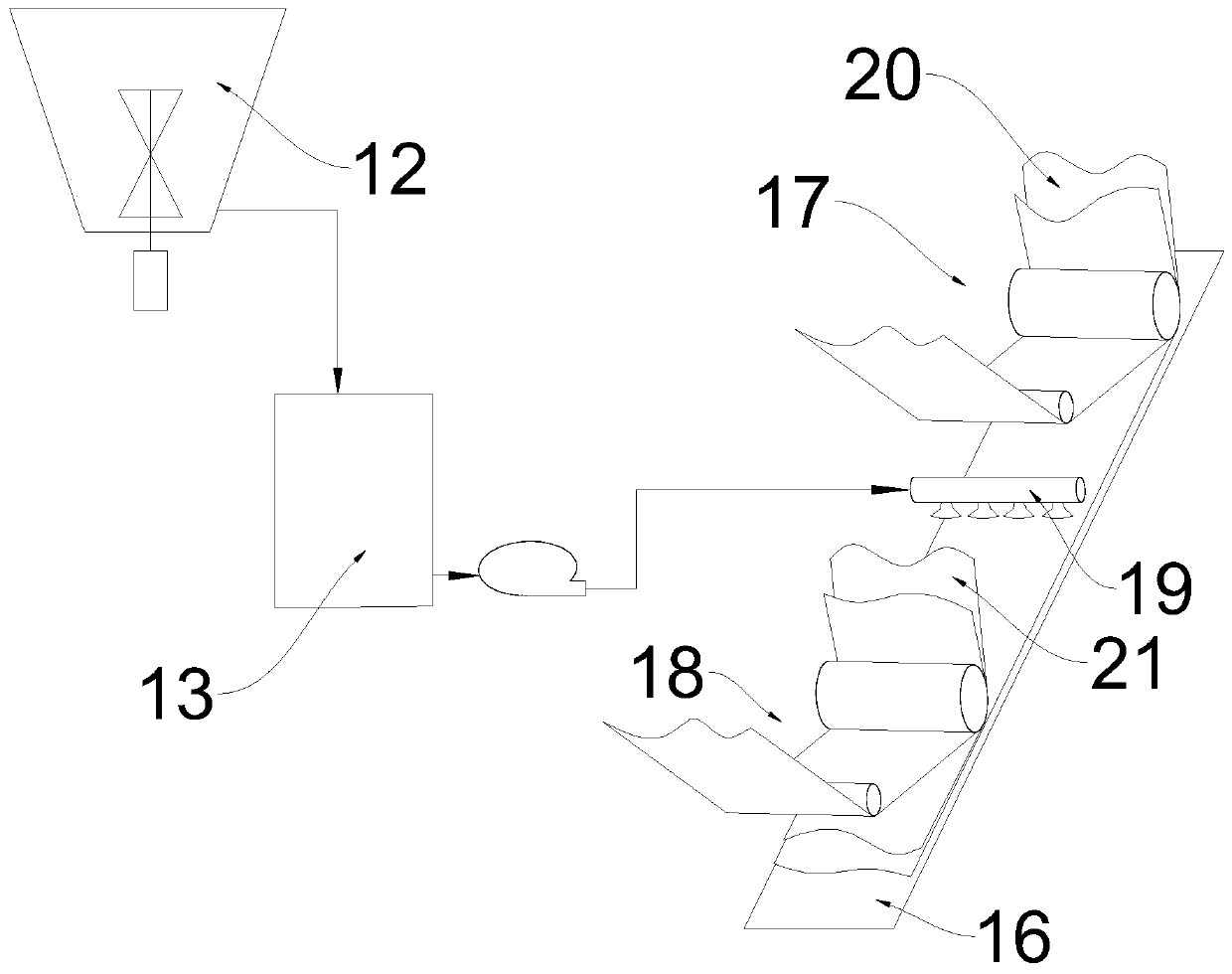

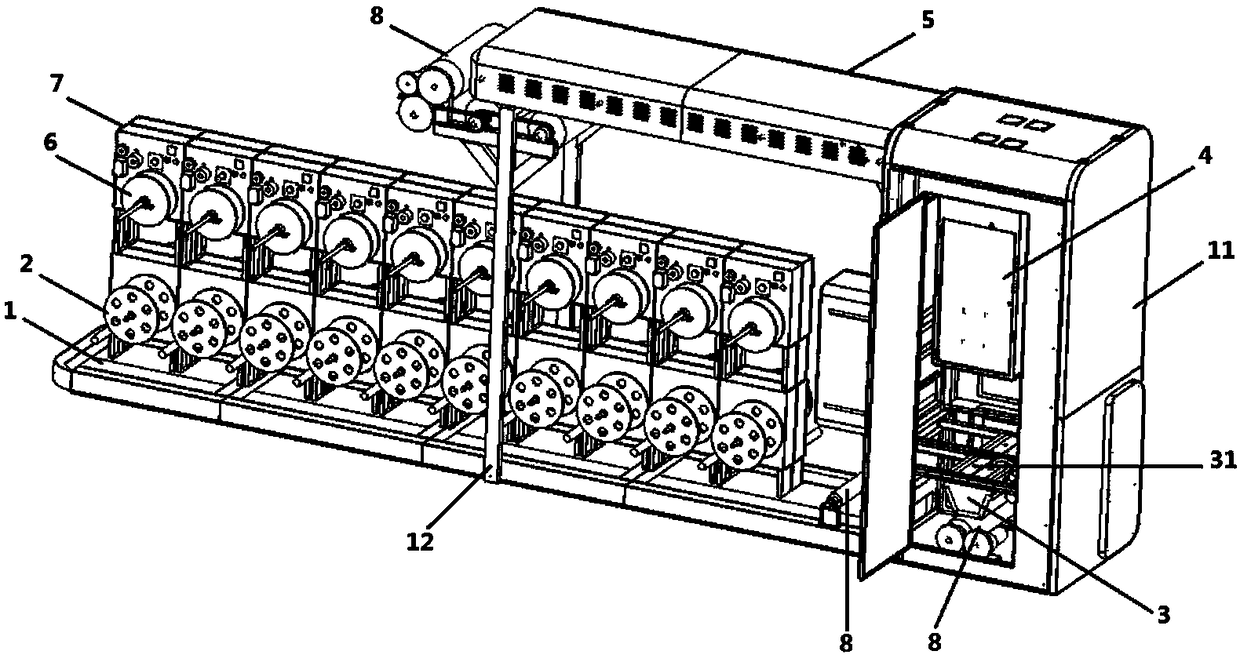

Method for producing burst-resistant non-layering paper from amphoteric starch

InactiveCN110499662AImprove adsorption capacityHigh strengthNon-fibrous pulp additionDryer sectionFiberViscose fiber

The invention relates to a method for producing burst-resistant non-layering paper from amphoteric starch. The method comprises the following steps: fully dissolving the amphoteric starch in clear water, performing heating for gelatinizing, and performing dilution to obtain an amphoteric starch glue; fully mixing and stirring native starch and clear water to prepare a native starch liquid; addingthe prepared amphoteric starch glue into a paper pulp, and performing sufficient stirring to blend the paper pulp; papermaking the blended paper pulp in a fourdrinier machine to obtain wet paper webs;spraying the native starch liquid on the wet paper webs; attaching the sprayed wet paper webs to form a composite wet paper web, and heating and curing the composite wet paper web; and drying, calendaring, coiling and slitting the composite wet paper web to obtain the burst-resistant non-layering paper. The blended amphoteric starch glue is added into the paper pulp in order to improve the strength of short fibers, the native starch liquid is uniformly sprayed between paper layers, and the cured starch glue can improve the bonding strength between the paper layers, so the purpose of producingthe burst-resistant non-layering paper is achieved.

Owner:LEE & MAN PAPER MFG

Equipment for simultaneously producing multiple glass fiber insulation pipes

InactiveCN108461235AReduce the temperatureReduce intensityInsulating bodiesGlass fiberUltraviolet lights

The invention discloses equipment for simultaneously producing multiple glass fiber insulation pipes, and belongs to the field of production equipment of the glass fiber insulation pipes. The equipment comprises a rack, wherein a pay-off device, a heating coating device, a light source curing device, a curing device after heating and a take-up device are sequentially arranged on the rack, a guideroller is further arranged on the rack and is used for guiding the glass fiber insulation pipes, the light source curing device comprises one or more groups of light reflection plates which are arranged oppositely, one or more light reflection surfaces are arranged on each light reflection plate and are sunken to form arc shapes, the positions of the light reflection surfaces on the same group oflight reflection plates are in one-to-one correspondence, and a linear ultraviolet light source is arranged in front of each arc light reflection surface and is parallel to a focus line of the light reflection surface. By the equipment, the limitation of production numbers by traditional equipment is broken through, the number of the glass fiber insulation pipes which can be theoretically and simultaneously produced is not limited according to equipment width, numbers of wiring walls and reasonable design of a take-up driving force, and the production efficiency is greatly improved.

Owner:安徽腾拓新材料科技有限公司

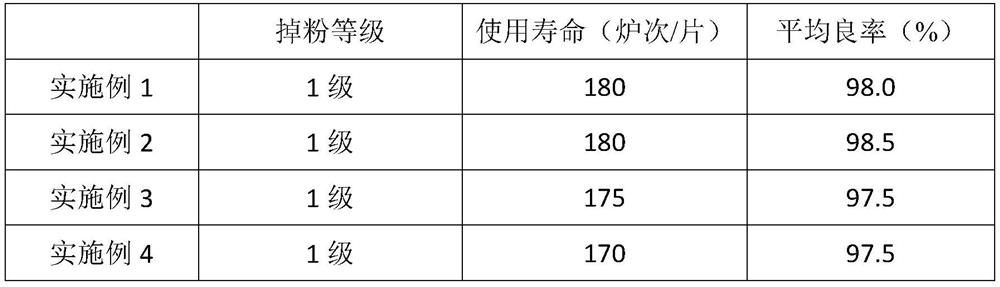

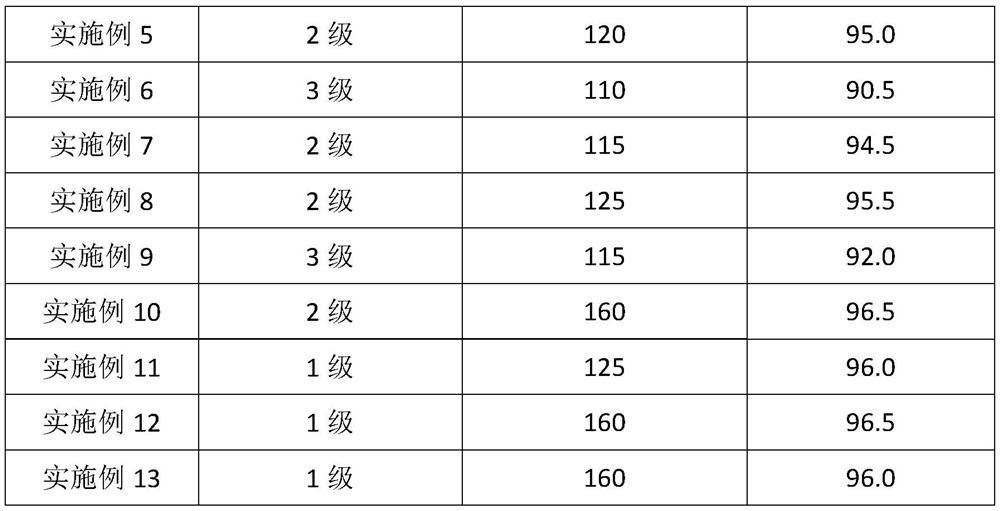

Adhesive for high-temperature photoelectric semiconductor material and preparation method thereof

ActiveCN111925752AHigh bonding strengthAvoid wastingMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAdhesive cementSemiconductor materials

The invention relates to the technical field of semiconductor material processing, in particular to an adhesive for a high-temperature photoelectric semiconductor material and a preparation method thereof. The adhesive is prepared from the following raw materials in parts by weight: 25 to 50 parts of polyvinyl acetate emulsion, 40 to 60 parts of a filler, 0 to 1.0 part of a thickening agent, 1 to3.5 parts of a functional additive, 0.1 to 0.8 part of a dispersing agent, 0.1 to 0.8 part of a defoaming agent and 3 to 12 parts of a solvent. The adhesive has higher bonding strength on a stone milldisc; after the damaged part of the coating is brushed and repaired, the phenomenon of cracking or damage does not occur again after the coating is used for multiple times, the service life is remarkably prolonged and can be improved to 180 times per piece from 100 times per piece in the prior art, and the yield in semiconductor product production is not reduced after the coating is repaired.

Owner:林俊贤

Hard alloy cutting pick

The invention discloses a hard alloy cutting pick, which is characterized by being prepared from, by weight percent, 0.5-0.65% of carbon, 0.06-0.12% of titanium, 1.2-1.6% of chrome, 4.2-5.8% of nickel, 0.26-0.32% of manganese, 0.35-0.42% of silicon, 0.01-0.022% of bismuth, 0.025-0.028% of vanadium, 0.016-0.019% of phosphorus, 3.8-3.95% of boron, 0.03-0.035% of scandium, and 0.025-0.028% of cerium;the allowance is iron and unavoidable impurities. The intensity, hardness and wear resistance of the hard alloy cutting pick are significantly improved, the service life is greatly extended, and themining cost is reduced.

Owner:湖州南浔昊骏金属制品厂

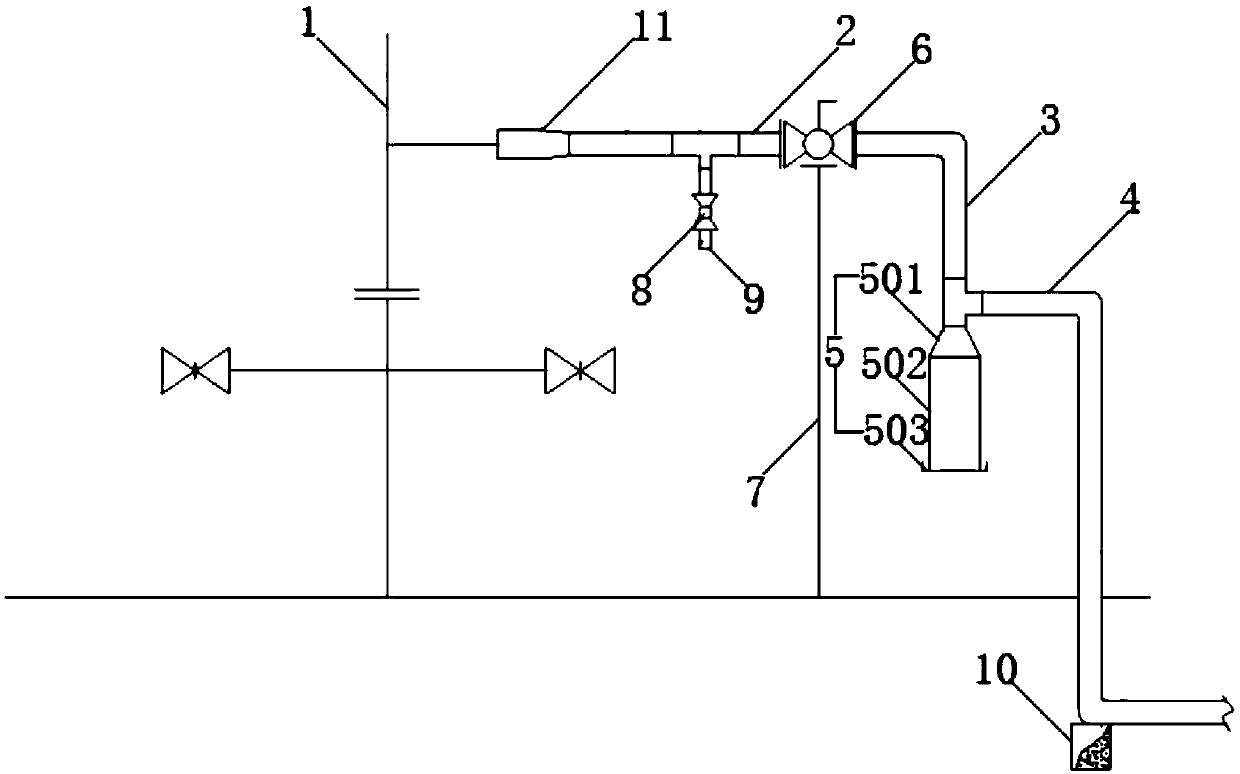

Drainage system and drainage method

The invention discloses a drainage system and a drainage method and belongs to the field of oil-gas production and development. The drainage system comprises a gas production tree, a first drainage pipeline, a second drainage pipeline and a third drainage pipeline vertically communicating to the gas production tree successively, and a sludge collecting part. The second drainage pipeline is vertical to the ground. The sludge collecting part is connected to the lower end of the second drainage pipeline for collecting solid impurities discharged by the gas production tree. The drainage system guarantees smooth operation of drainage work by arranging the gas production tree, the first drainage pipeline, the second drainage pipeline and the third drainage pipeline. By arranging the sludge collecting part and connecting the sludge collecting part to the lower end of the second drainage pipeline, the solid impurities in produced water are collected, and a condition that normal production of acoal-bed gas well is affected as drainage pipelines are blocked is avoided.

Owner:PETROCHINA CO LTD

Method for improving deformation of swage sand-coated axle sand box

PendingCN114101599AImprove thermal conductivityImprove heat resistanceMoulding machine componentsMoulding machinesMechanical engineeringComposite material

The iron mold sand-coated axle sand box comprises an upper sand box body and a lower sand box body, the middle portions in the upper sand box body and the lower sand box body are each provided with a half axle cavity which is matched with the middle portion in the upper sand box body, and corresponding sand shooting openings are evenly distributed in the axle cavities in the middle portions in the upper sand box body and the lower sand box body. Symmetrical sealing areas are formed in the edges of the axle cavities in the upper sand box and the lower sand box, symmetrical pouring systems are arranged on one sides of the axle cavities in the upper sand box and the lower sand box, and the pouring systems in the upper sand box and the lower sand box are communicated with the axle cavities; and symmetrical positioning pin sleeves are arranged on the other sides of the axle cavities in the upper sand box and the lower sand box. The sand box is simple in structure and low in cost, the phenomenon that the two ends in the length direction are deformed and upwarped in the heated state, so that normal production is affected is effectively avoided, the rejection rate caused by deformation of the sand box is reduced, and the product yield is increased.

Owner:西峡县众德汽车部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com