Turning roll device of reversible cold rolling mill unit

A technology for turning rolls and units, which is applied to guiding/positioning/aligning devices, metal rolling stands, metal rolling mill stands, etc., can solve the problem of the large influence of human operation factors on installation and adjustment, the time-consuming and laborious re-assembly and assembly, and the problems of turning rolls. Unreasonable device structure settings, etc., to achieve the effect of convenient and quick maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

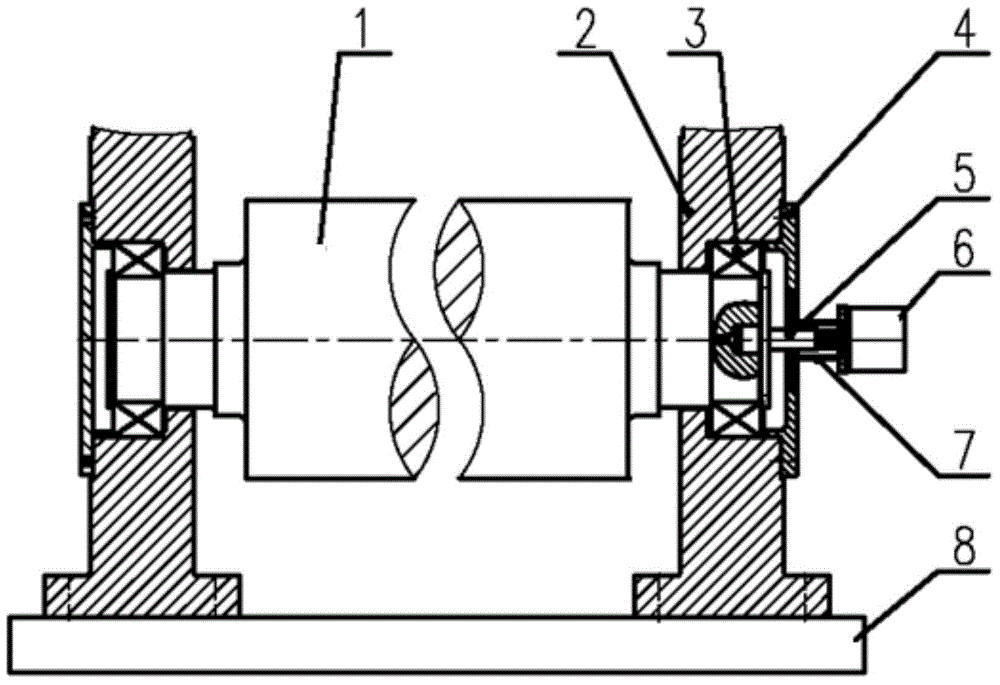

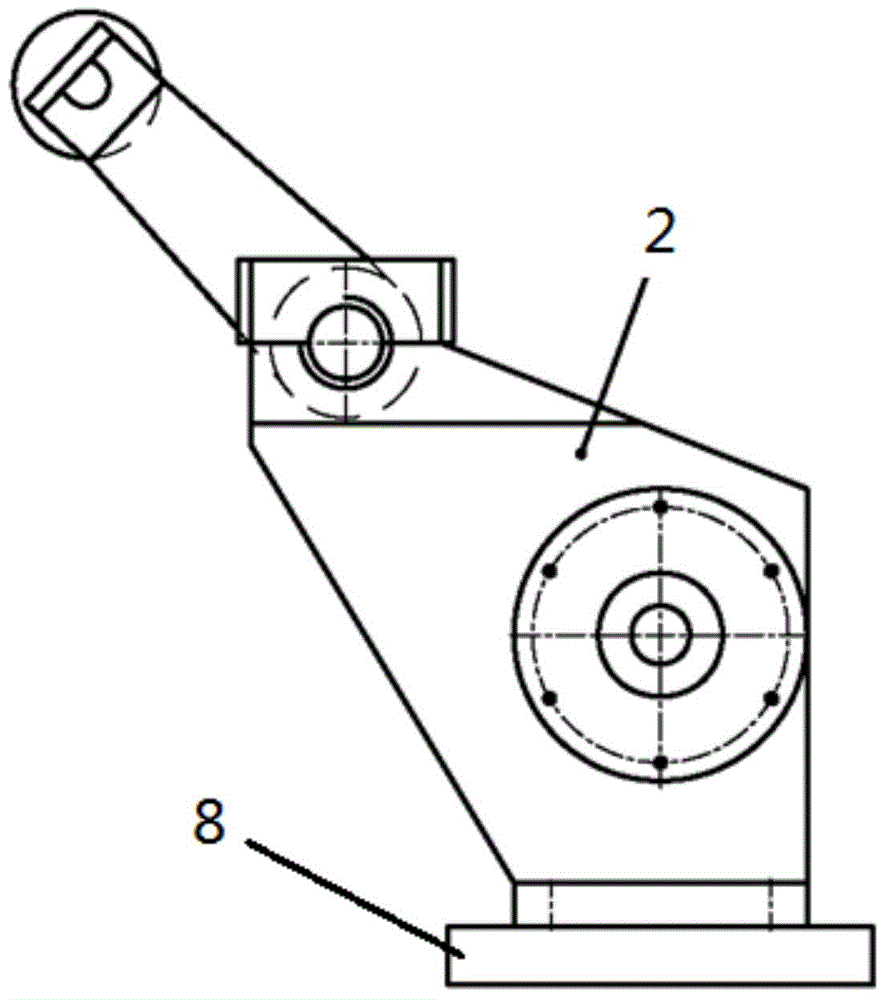

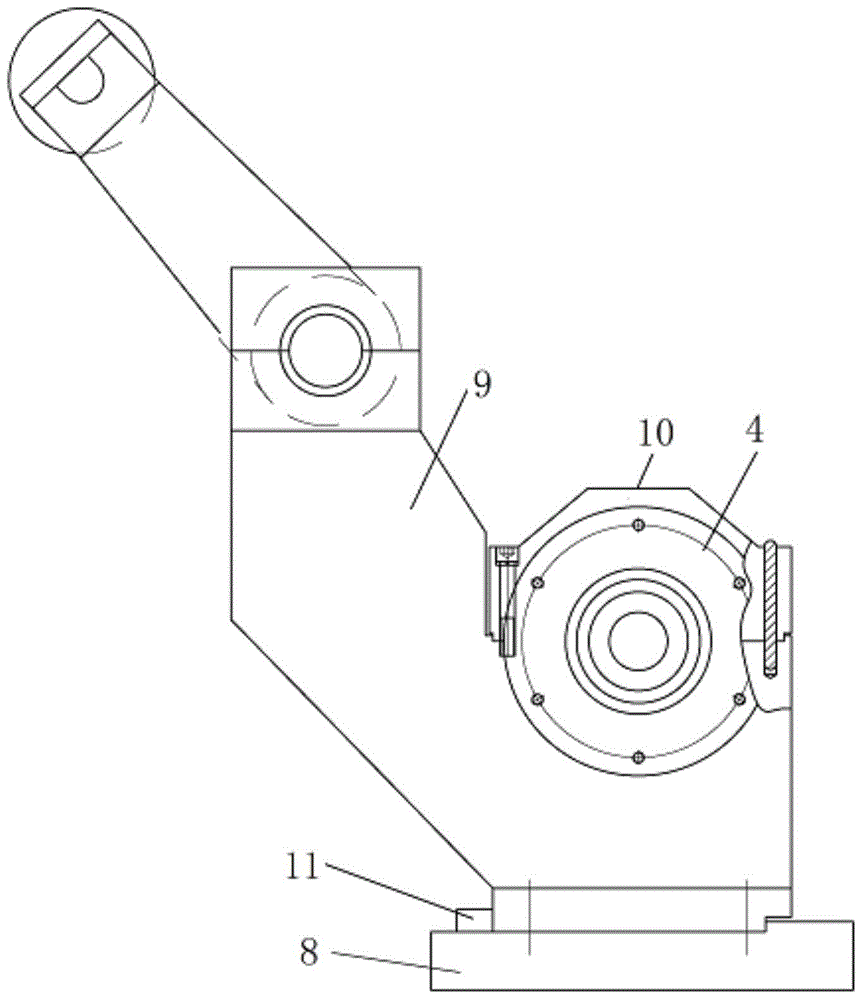

[0015] Such as figure 1 , figure 2 As shown, the structure of the existing reversible cold rolling unit steering roll device is that a bearing 3 is respectively installed on the two ends of the steering roll 1, and each bearing 3 is connected by a respective bearing seat 2, end cover 4 and connecting fasteners. It is installed on the connecting bottom plate 8, and an encoder 6 is fixedly installed on the support 7 on the outer side of the end cover 4 of the bearing 3 on one side. The rotary shaft of the encoder 6 is coaxially connected with the steering roller 1 through the small shaft 5, and rotates synchronously. Realize indirect measurement of strip speed to meet the requirements of speed and AGC thickness control. In order to ensure the level of the steering roller 1 and the parallelism with related parts during on-site installation, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com