Coal face scraper conveyor speed reducer forced lubrication indicating and alarming device

A technology for scraper conveyors and coal mining working faces, which is applied in the direction of engine lubrication, lubricating parts, transmission parts, etc., and can solve problems affecting the normal production of working faces, bearing falling apart and locking, waste of manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

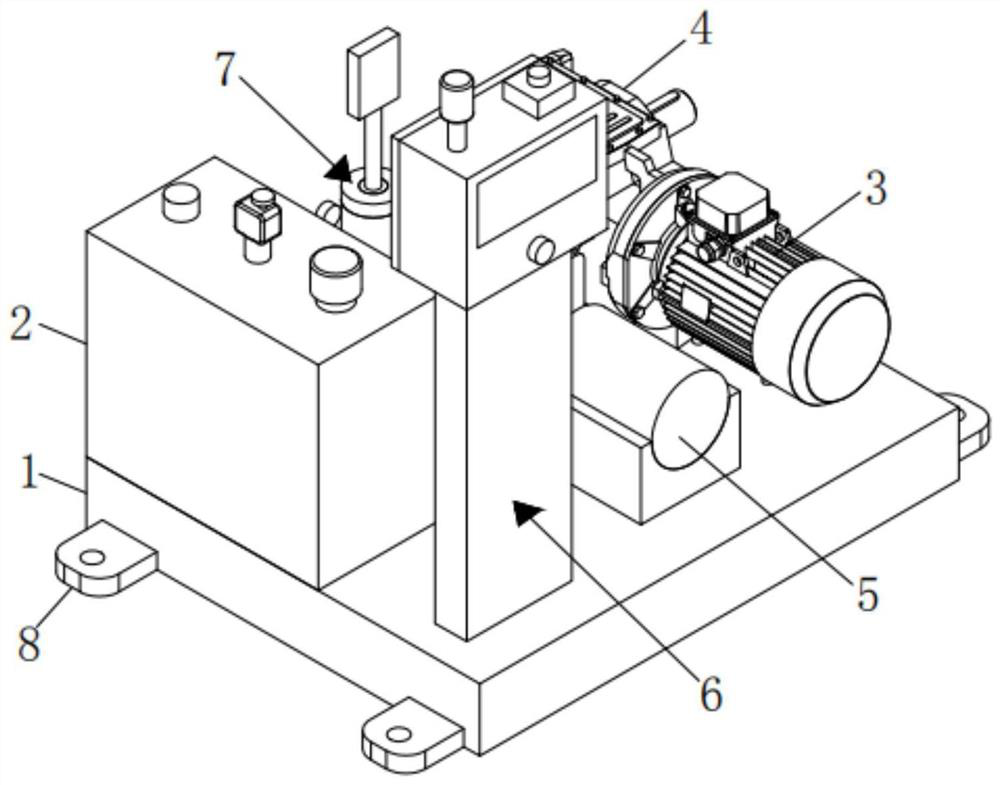

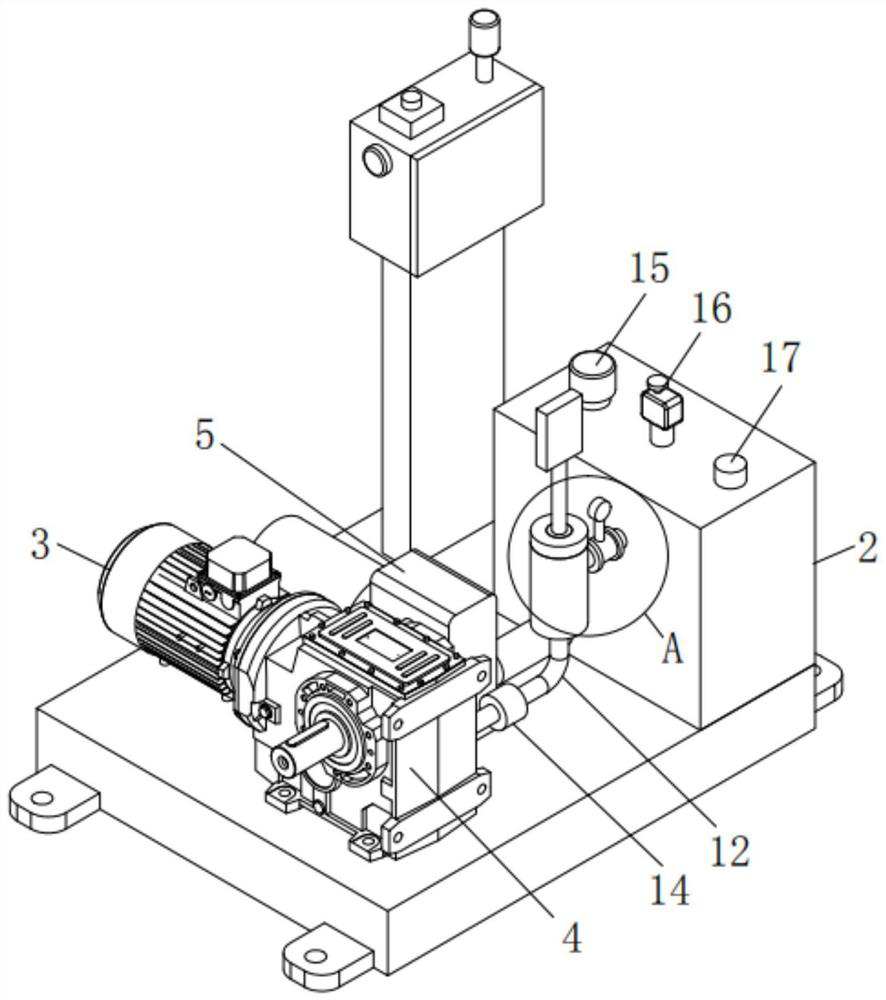

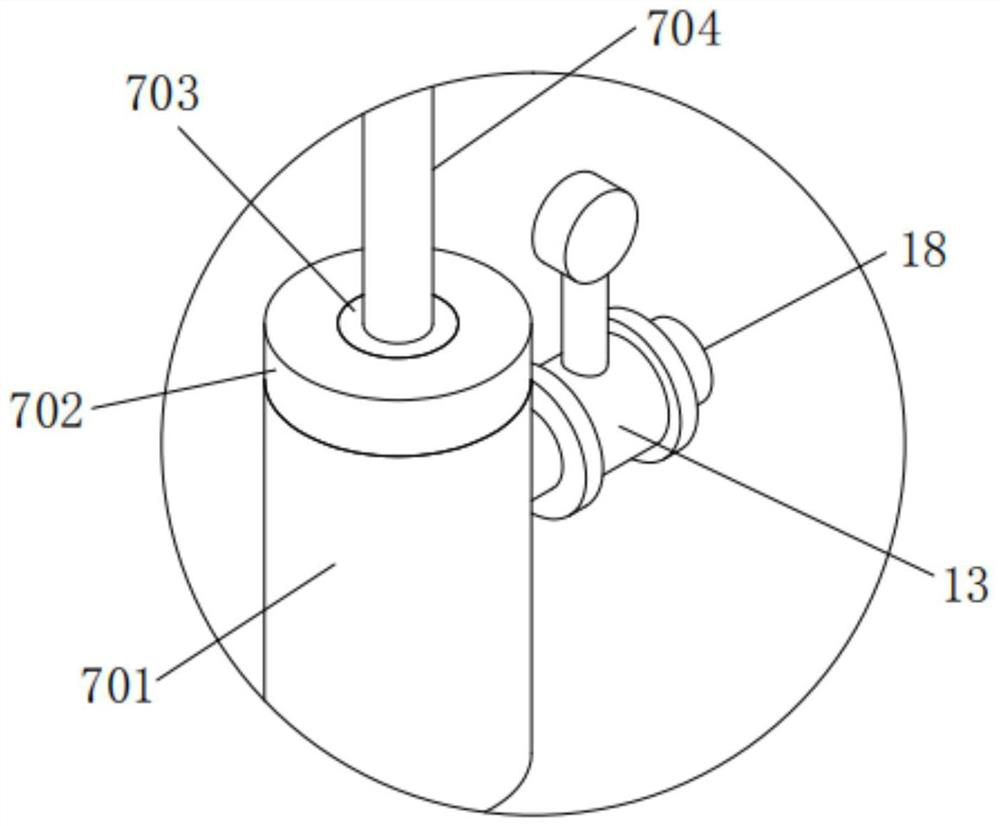

[0048] A forced lubrication indicator and alarm device for a scraper conveyor reducer on a coal mining face, such as Figure 1-10 As shown, it includes a base plate 1, a lubricating oil tank 2, a lubricating pump 5, a motor 3, a reducer 4, an indicating mechanism 7, an alarm mechanism 6, and a flow meter 13. The base plate 1 is set horizontally, and the lubricating oil tank 2, the The lubricating pump 5, the motor 3, the reducer 4 and the alarm mechanism 6 are all fixedly installed on the top of the base plate 1, and the rotating shaft of the motor 3 is fixedly connected with the input shaft of the reducer 4 , and the motor 3 is electrically connected to the alarm mechanism 6, the inside of the reducer 4 has an oil passage for lubricating its bearings, and the outside of the reducer 4 is fixedly installed with an oil passage communicating with the oil passage Oil inlet port 19 and oil return port 20, the oil outlet of the lubricating pump 5 communicates with the oil inlet port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com