Method for improving deformation of swage sand-coated axle sand box

A technology for sand-coated iron molds and sand boxes is applied in the field of improving the deformation of sand boxes of iron mold-coated axles. and good thermal fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

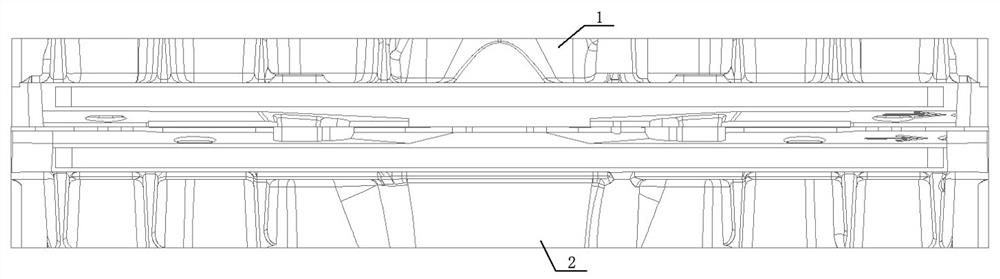

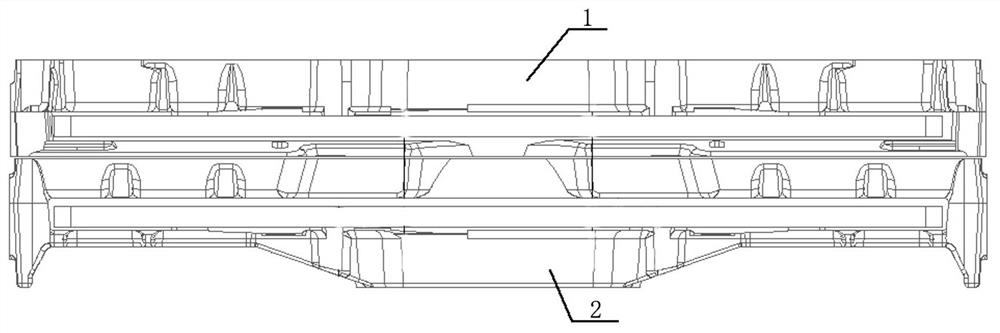

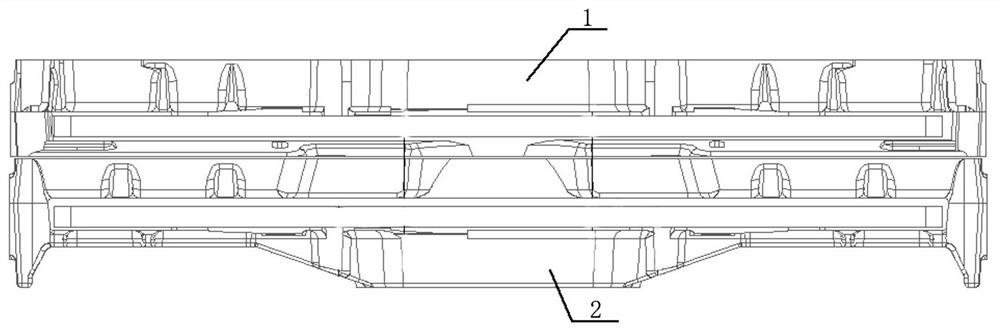

[0019] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. Such as Figure 1-6 Shown: an iron mold sand-covered axle sand box, including an upper sand box 1 and a lower sand box 2, and the middle parts of the upper sand box 1 and the lower sand box 2 are respectively equipped with a matched half car The bridge cavity 3, the axle cavity 3 in the middle of the upper sand box 1 and the lower sand box 2 are evenly distributed with corresponding sand injection ports 4, and the upper sand box 1 and the lower sand box 2 are equipped with vehicle The edge of the bridge cavity 3 is provided with a symmetrical sealing area 5, and one side of the axle cavity 3 in the upper sand box 1 and the lower sand box 2 is provided with a symmetrical pouring system 6. The pouring system 6 in the box 1 and the lower sand box 2 is connected with the axle cavity 3, and the other side of the axle cavity 3 in the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com