Adhesive for high-temperature photoelectric semiconductor material and preparation method thereof

A technology of optoelectronic semiconductors and adhesives, applied in semiconductor/solid-state device manufacturing, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem of poor control of coating thickness and uniformity, and is not suitable for repair coating Layer breakage, deposition of silicon atoms or crystals, etc., to achieve the effects of not being easily cracked or damaged, improving the uniformity and consistency of the microstructure, and improving the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

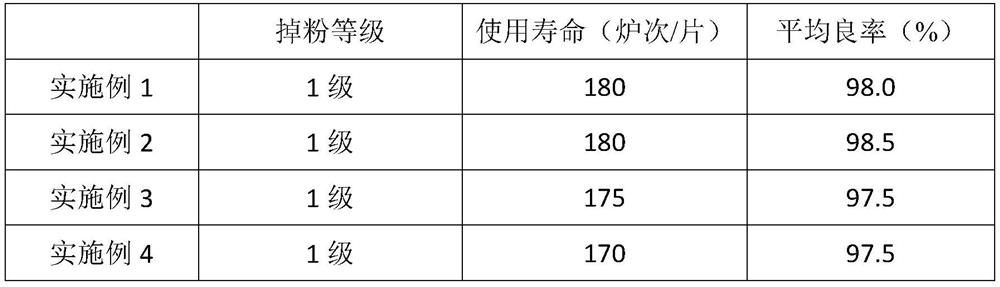

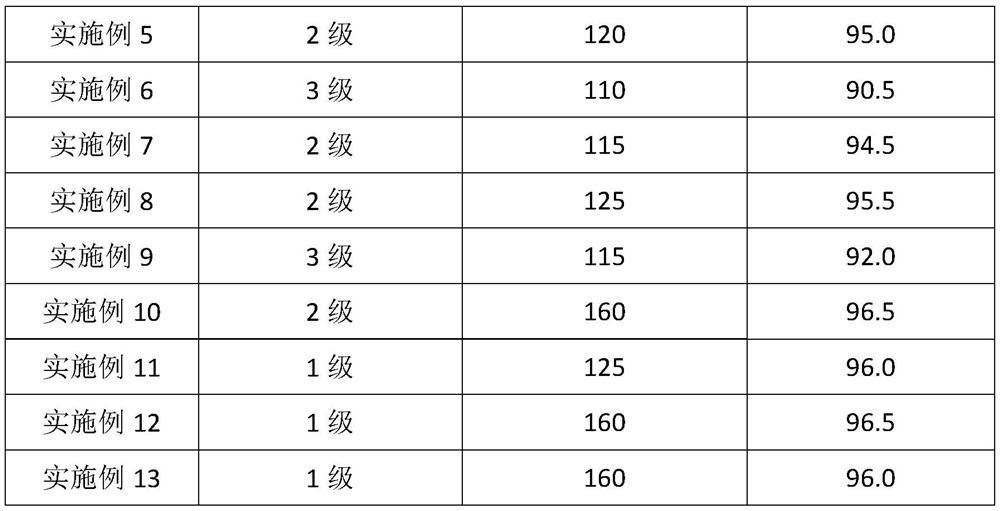

Examples

preparation example Construction

[0050] A second aspect of the present invention provides a method for preparing an adhesive for high-temperature optoelectronic semiconductor materials as described above, which includes the following steps:

[0051] (1) Take the thickener of formula quantity and add the solvent of 1 / 5 weight to stir and swell;

[0052] (2) Add filler, functional additives, polyvinyl acetate emulsion, dispersant, defoamer and remaining solvent in the stirring tank in sequence;

[0053] (3) Stir the above stirring tank, stir at 180-220 rpm for 2-5 min, then increase the stirring speed to 1200-1800 rpm, and stir for 15-30 min;

[0054] (4) Add the thickener in step (1), and stir for 10-20 minutes.

Embodiment 1

[0056] Example 1 The invention provides a kind of adhesive for high-temperature optoelectronic semiconductor material, the preparation raw material of described adhesive comprises following components: 36 parts of polyvinyl acetate emulsion, 50 parts of filler, 1.0 part of thickener, 2.0 parts of functional auxiliary agent, 0.5 part of dispersant parts, 0.4 parts of defoamer, and 10 parts of solvent.

[0057] The solvent is deionized water; the polyvinyl acetate emulsion is WX-505 of Wuhu Xingguang Synthetic Materials Co., Ltd.; the filler is a mixture of silicon powder and silicon carbide, and the weight ratio of silicon carbide and silicon powder is 1 : 4.8, the average particle diameter of described silicon powder is 30 microns, and the particle diameter of described silicon carbide is 40~50 microns, selects the green silicon carbide micropowder of Zichuan Daoxin Abrasives Factory, Zibo for use; Described thickener is hydroxyl Ethyl cellulose; the functional auxiliary agen...

Embodiment 2

[0063] Example 2 The invention provides a kind of adhesive for high-temperature optoelectronic semiconductor material, the preparation raw material of described adhesive comprises following components: 36 parts of polyvinyl acetate emulsion, 50 parts of filler, 1.0 part of thickener, 2.0 parts of functional auxiliary agent, 0.5 part of dispersant parts, 0.4 parts of defoamer, 10 parts of solvent, and 0.1 part of sodium benzoate.

[0064] The solvent is propylene glycol; the polyvinyl acetate emulsion is Shengda Chemical SD-40; the filler is a mixture of silicon carbide and silicon carbide, the weight ratio of silicon carbide and silicon powder is 1:4.8, and the silicon powder The average particle diameter of the silicon carbide is 30 microns, and the particle diameter of the silicon carbide is 40 to 50 microns, and the green silicon carbide micropowder of Zichuan Daoxin Abrasives Factory in Zibo is selected for use; the thickener is hydroxyethyl cellulose; The functional add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com