Method for producing burst-resistant non-layering paper from amphoteric starch

An amphoteric starch and burst-resistant technology, which is applied in the field of papermaking, can solve problems such as delamination cracking, insufficient bonding force of paper layers, and affecting the use of composite paper, and achieve the effects of improving quality, increasing bonding strength, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

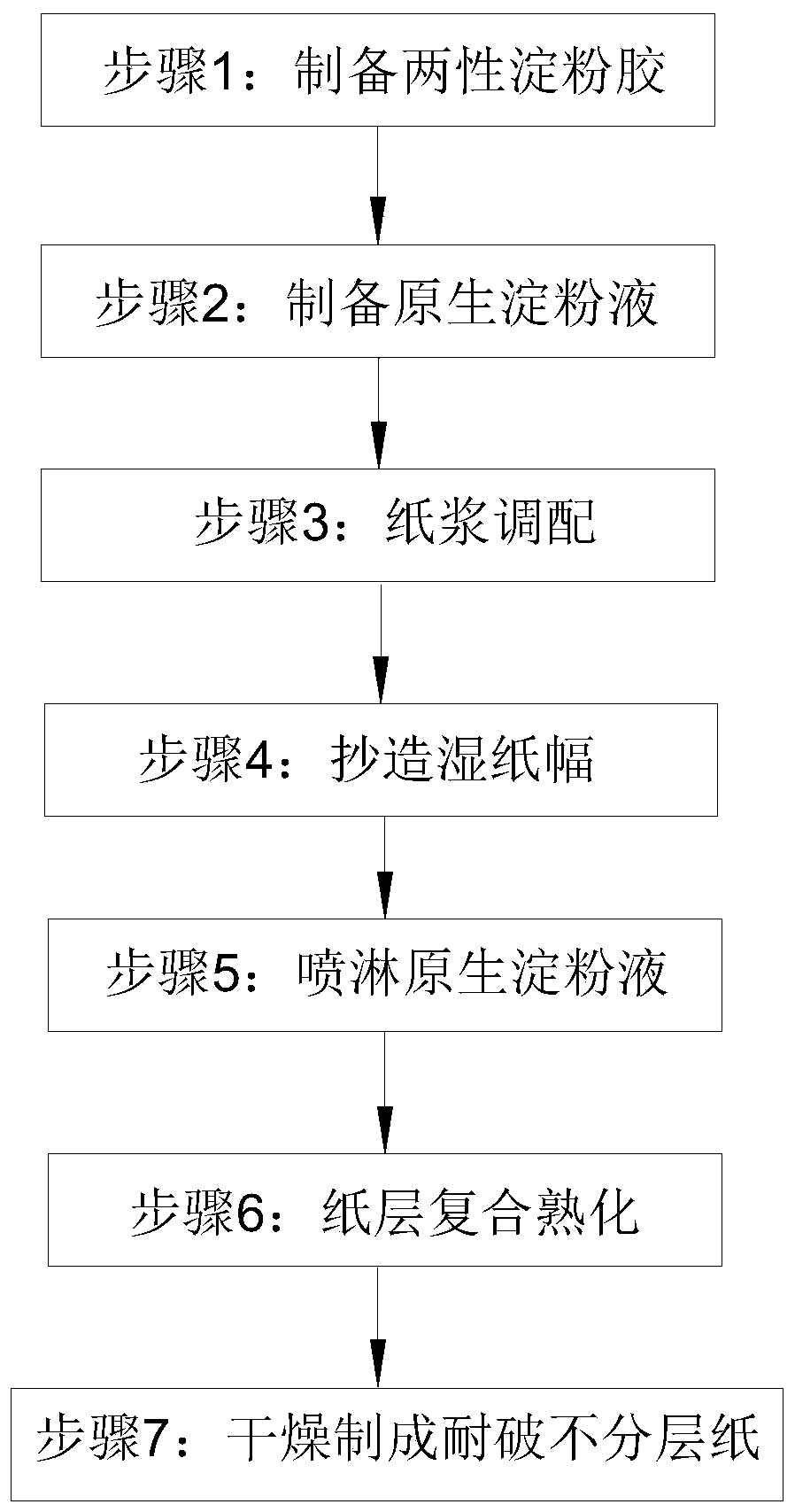

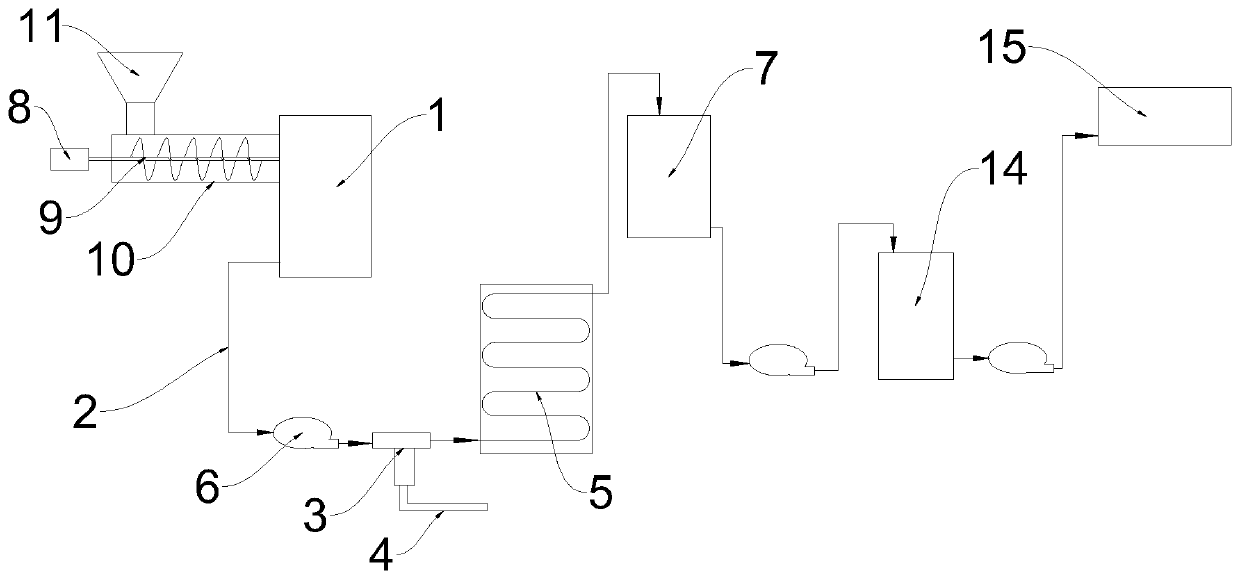

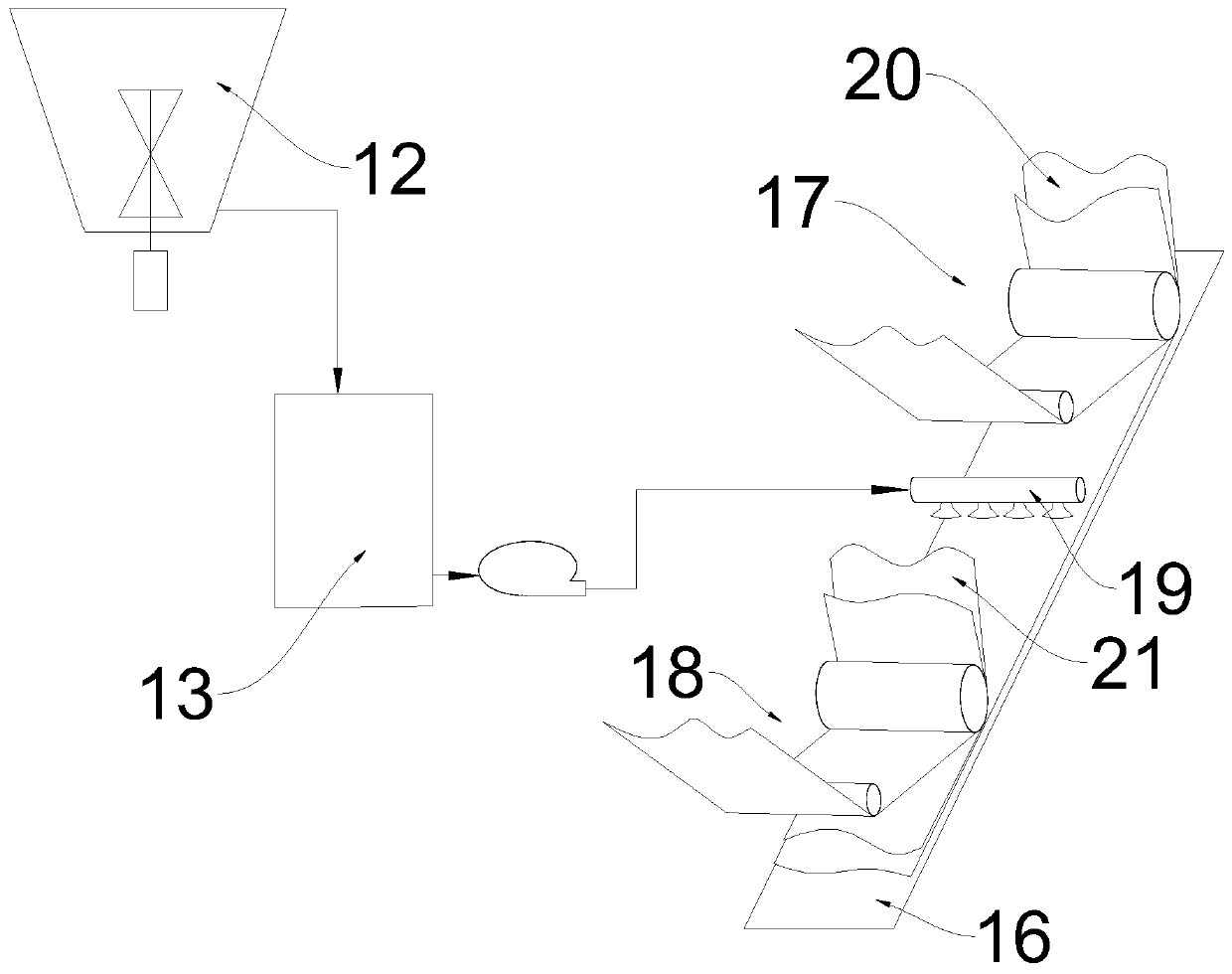

[0037] A method for producing burst-resistant and non-delaminated paper using amphoteric starch, comprising the following steps:

[0038] (1) Preparation of amphoteric starch glue: see figure 1 with figure 2 , first choose amphoteric starch, due to the packaging and storage problems of amphoteric starch, before use, the powder of amphoteric starch will gather into agglomerates, which will affect the mixing process. , in order to facilitate sufficient mixing and stirring, so it is necessary to powder the amphoteric starch through a powder-opening device and then pass it into the first dissolving tank 1, and then pass it into the first dissolving tank 1 while the amphoteric starch is passing into the first dissolving tank 1 Continuously pour in clean water and stir continuously to fully mix and dissolve the amphoteric starch and clear water to obtain amphoteric starch liquid, then heat the gelatinized amphoteric starch liquid to obtain amphoteric starch concentrated glue, and ...

Embodiment 2

[0049] A method for producing burst-resistant and non-delaminated paper using amphoteric starch, comprising the following steps:

[0050] (2) Preparation of amphoteric starch glue: see figure 1 with figure 2 , first choose amphoteric starch, due to the packaging and storage problems of amphoteric starch, before use, the powder of amphoteric starch will gather into agglomerates, which will affect the mixing process. , in order to facilitate sufficient mixing and stirring, so it is necessary to powder the amphoteric starch through a powder-opening device and then pass it into the first dissolving tank 1, and then pass it into the first dissolving tank 1 while the amphoteric starch is passing into the first dissolving tank 1 Continuously pour in clean water and stir continuously to fully mix and dissolve the amphoteric starch and clear water to obtain amphoteric starch liquid, then heat the gelatinized amphoteric starch liquid to obtain amphoteric starch concentrated glue, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com