Equipment for simultaneously producing multiple glass fiber insulation pipes

A glass fiber and insulating tube technology, applied in insulators, insulators, electrical components, etc., can solve the problems of low plant space utilization, large space occupation, space waste, etc., to improve light curing efficiency, reduce strength, and reduce energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

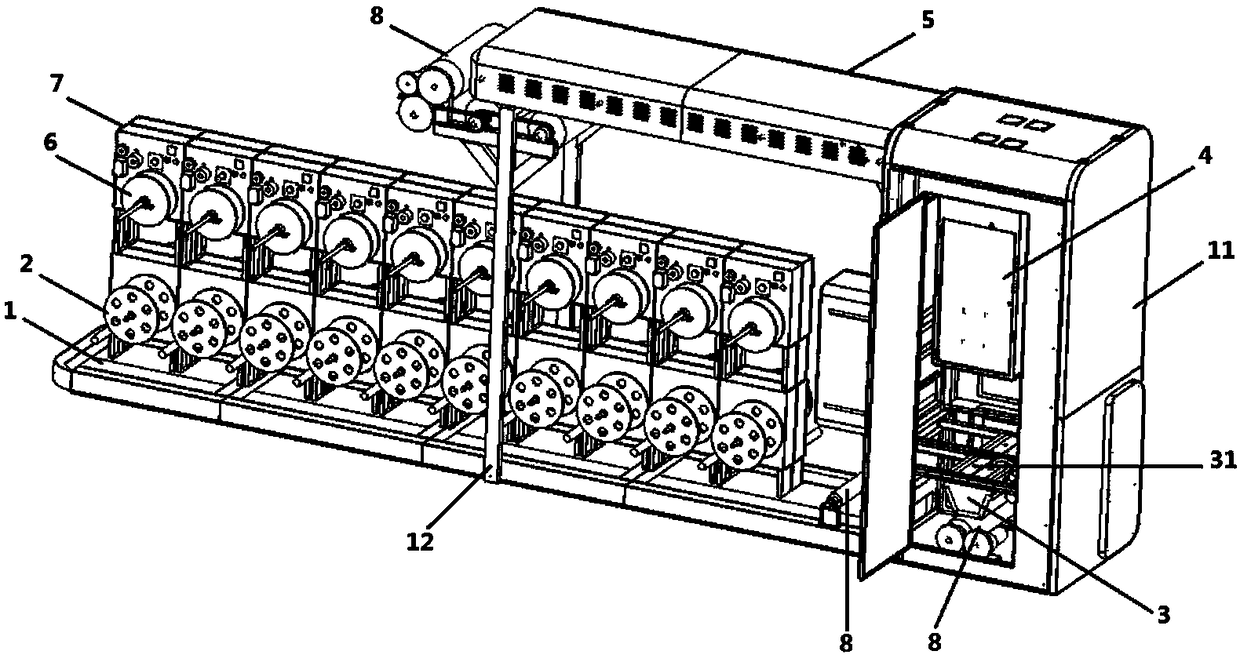

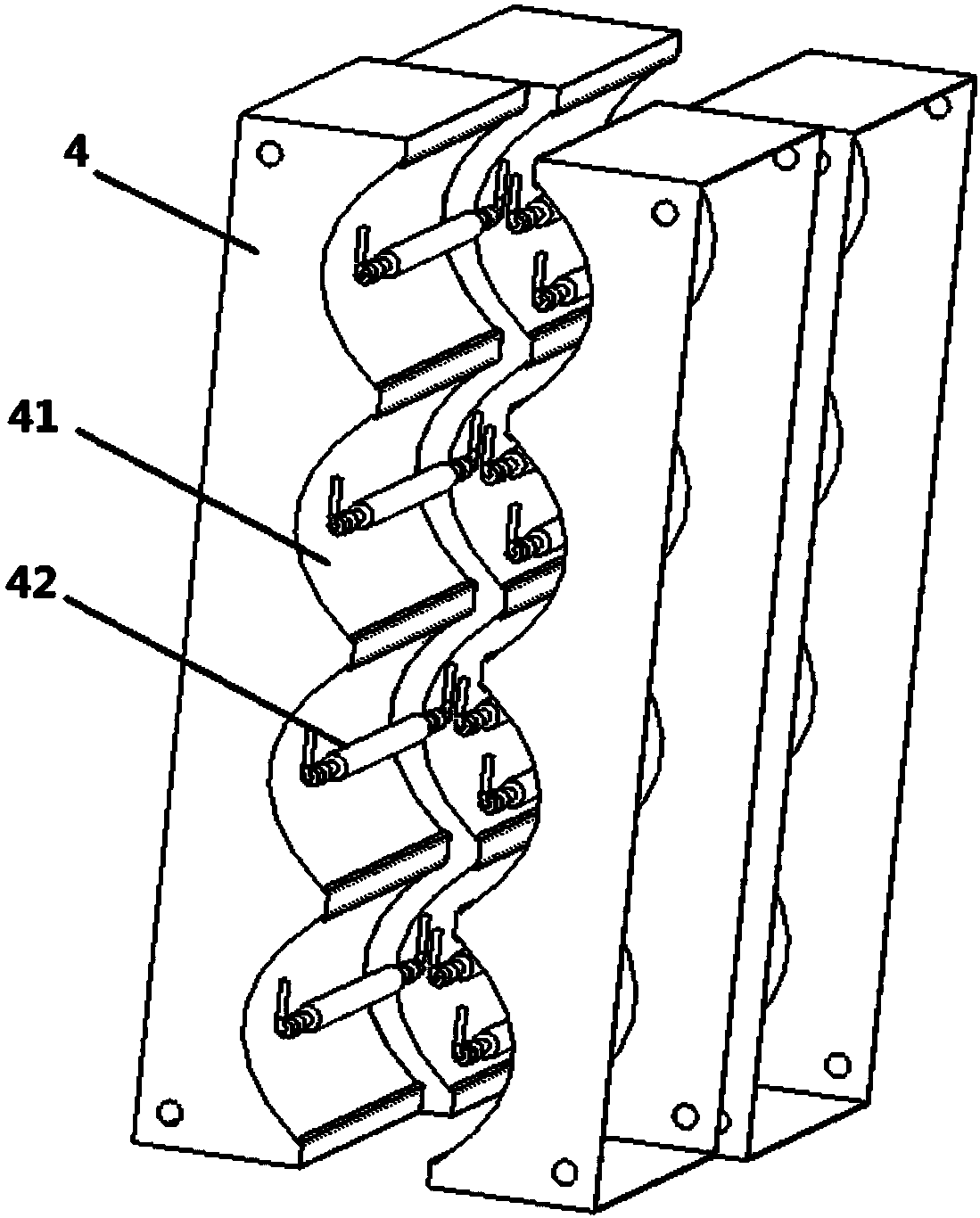

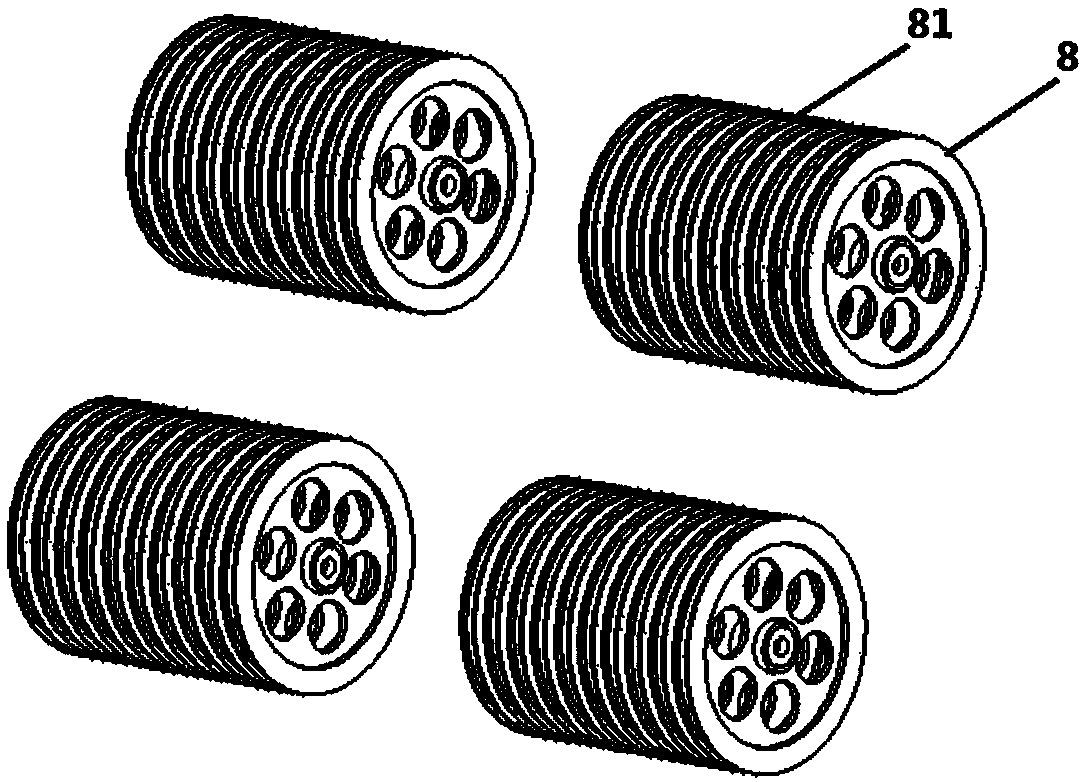

[0023] A device for simultaneously producing multiple fiberglass insulating pipes, such as figure 1 , 2 , 3, and 4, including a frame 1, the frame 1 is sequentially provided with a wire-releasing device 2, a heating coating device 3, a light source curing device 4, a post-heating curing device 5, and a wire-receiving device 6. The heating coating device 3, the light source curing device 4, and the post-heating curing device 5 are all arranged in the cabinet 11 of the frame 1, and the frame 1 is also provided with a guide roller 8 for guiding the glass fiber insulating tube. The light source curing device 4. It includes two sets of reflective plates 41 oppositely arranged. Each reflective plate 41 is provided with four concave arc-shaped reflective surfaces 42. The positions of the reflective surfaces 42 on the same group of reflective plates 41 correspond one-to-one. The arc-shaped reflective surfaces 42 The front of the front is provided with a linear ultraviolet light sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com