Parallel power supplying method of electrolytic aluminum different-power-supply-point direct-current sides

A power supply method, electrolytic aluminum technology, applied in the direction of emergency power supply arrangements, electrical components, circuit devices, etc., can solve the problems of poor self-stress adjustment ability, power supply system dependence on large power grids, etc., to reduce overshoot and reduce cross-network the risk, the effect of avoiding the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

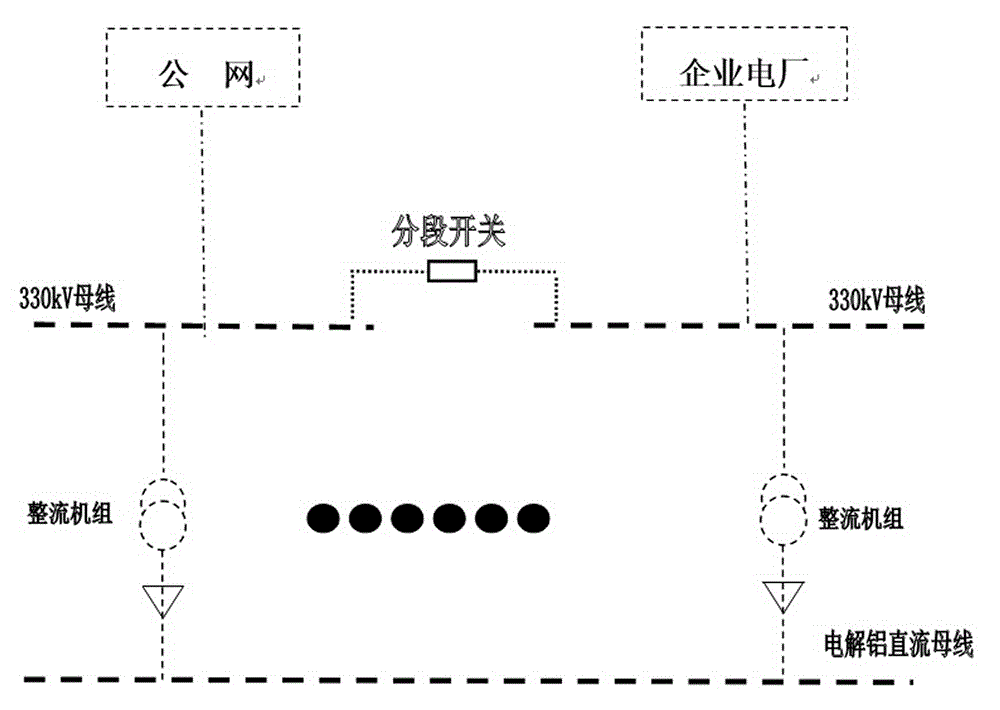

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] A parallel power supply method for DC sides of different power supply points of electrolytic aluminum, which is used for conversion between public power grids and autonomous power grids. The public power grid is connected to the independent power grid with an AC power supply bus, and a segmental transfer switch is installed on the AC power supply bus, and a rectifier unit is installed between the AC power supply bus and the electrolytic aluminum DC bus. There is a switching station between the autonomous power grid and the AC power supply busbar. A substation is provided at the connection end between the switch station and the AC power supply busbar.

[0016] When the power grid is working normally, the sub-section transfer switch is in the off state, and the electrolytic aluminum operation mainly relies on the power supply of the independent power grid. When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com