Recycling method for pulling ladles into refining slag

A technology for refining slag and ladle, applied in the field of smelting, can solve problems such as affecting the yield of steel materials, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

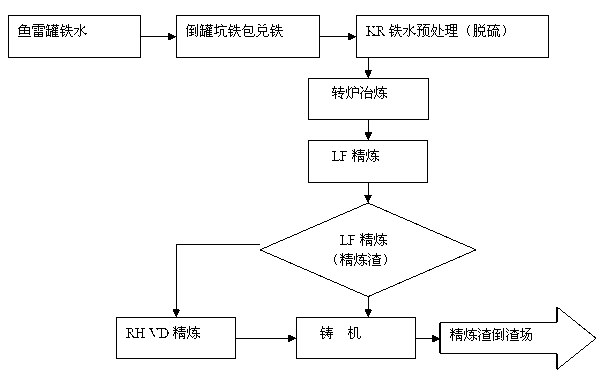

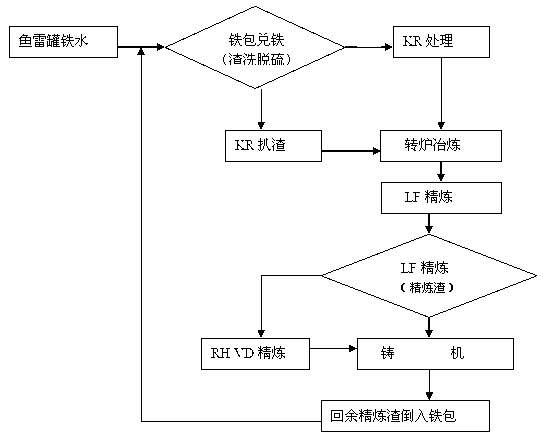

Image

Examples

Embodiment 1

[0053] In this embodiment, the steelmaking method is as follows:

[0054] Torpedo hot metal → ladle iron → KR hot metal pretreatment / KR slagging → converter smelting → LF refining → refined slag enters the caster → the surplus refined slag is poured into the iron ladle → the ladle is mixed with iron, repeat the above process.

[0055] During the process of ladle mixing with iron, the tapping speed is 20-25 tons / min. When the tapping reaches 75-80 tons, if a boiling reaction occurs, the tapping will be stopped immediately, and a small flow will be used after the liquid level is stable. For tapping, the flow rate of the small flow tapping is controlled at 15-20 tons / min;

[0056] If there is no boiling reaction, tap the iron at a rate of 18-20 tons / min to ensure that the molten iron can agitate the refining slag.

[0057] For example, after the molten iron is mixed with iron, after the KR slagging treatment, the KR slagging is divided into three levels according to the requirements of...

Embodiment 2

[0066] In this embodiment, the steelmaking method is as follows:

[0067] Torpedo hot metal → ladle iron → KR hot metal pretreatment / KR slagging → converter smelting → LF refining → refined slag enters the caster → the surplus refined slag is poured into the iron ladle → the ladle is mixed with iron, repeat the above process.

[0068] During the process of ladle ironing, the tapping speed is about 20 tons / min. When the tapping reaches about 75 tons, if boiling reaction occurs, the tapping will be stopped immediately. After the liquid level is stable, the tapping will be performed at a small flow rate. , The flow rate of the small flow rate of iron is controlled at 18 tons / min;

[0069] If there is no boiling reaction, tap the iron at a rate of about 20 tons / minute to ensure that the molten iron can stir the refining slag.

[0070] For example, after the molten iron is mixed with iron, after the KR slagging treatment, the KR slagging is divided into three levels according to the requ...

Embodiment 3

[0078] In this embodiment, the steelmaking method is as follows:

[0079] Torpedo hot metal → ladle iron → KR hot metal pretreatment / KR slagging → converter smelting → LF refining → refined slag enters the caster → the surplus refined slag is poured into the iron ladle → the ladle is mixed with iron, repeat the above process.

[0080] During the process of ladle to iron, the tapping speed is about 25 tons / min. When the tapping reaches about 78 tons, if a boiling reaction occurs, the tapping will be stopped immediately. After the liquid level is stable, the tapping at a small flow rate will be used. , The flow rate of the small flow rate of iron is controlled at 18 tons / min;

[0081] If there is no boiling reaction, tap the iron at a rate of about 20 tons / minute to ensure that the molten iron can stir the refining slag.

[0082] For example, after the molten iron is mixed with iron, after the KR slagging treatment, the KR slagging is divided into three levels according to the require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com