Method and system for treating electronic scrap smoke

A technology of electronic waste and flue gas, which is applied in the chemical industry, can solve the problems that the halogen-containing lye is difficult to meet the standard discharge, bromine cannot be extracted separately, and the solvent cannot be discharged up to the standard, so as to achieve strong promotion, maximum realization and environmental protection The effects of globalization and good market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

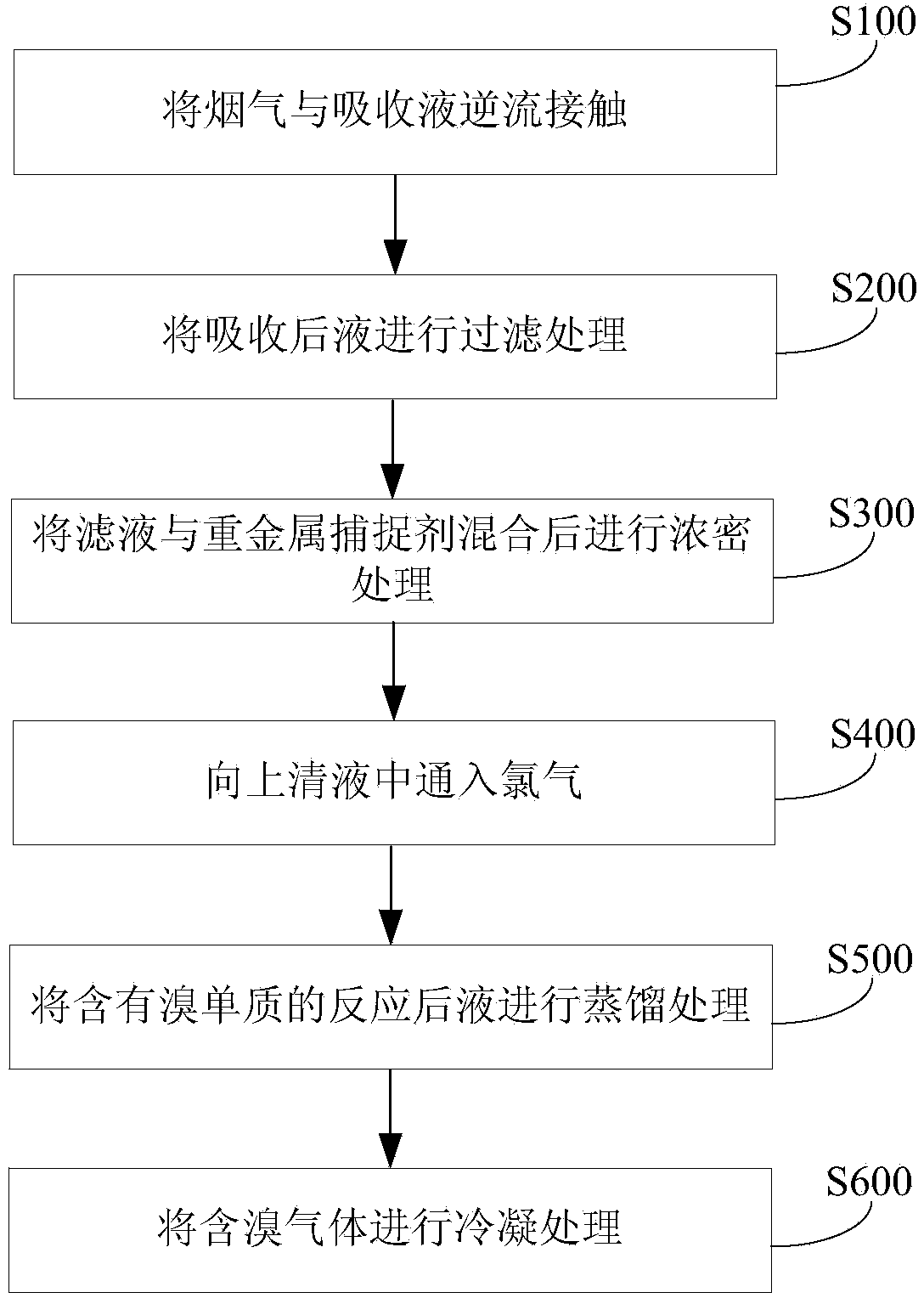

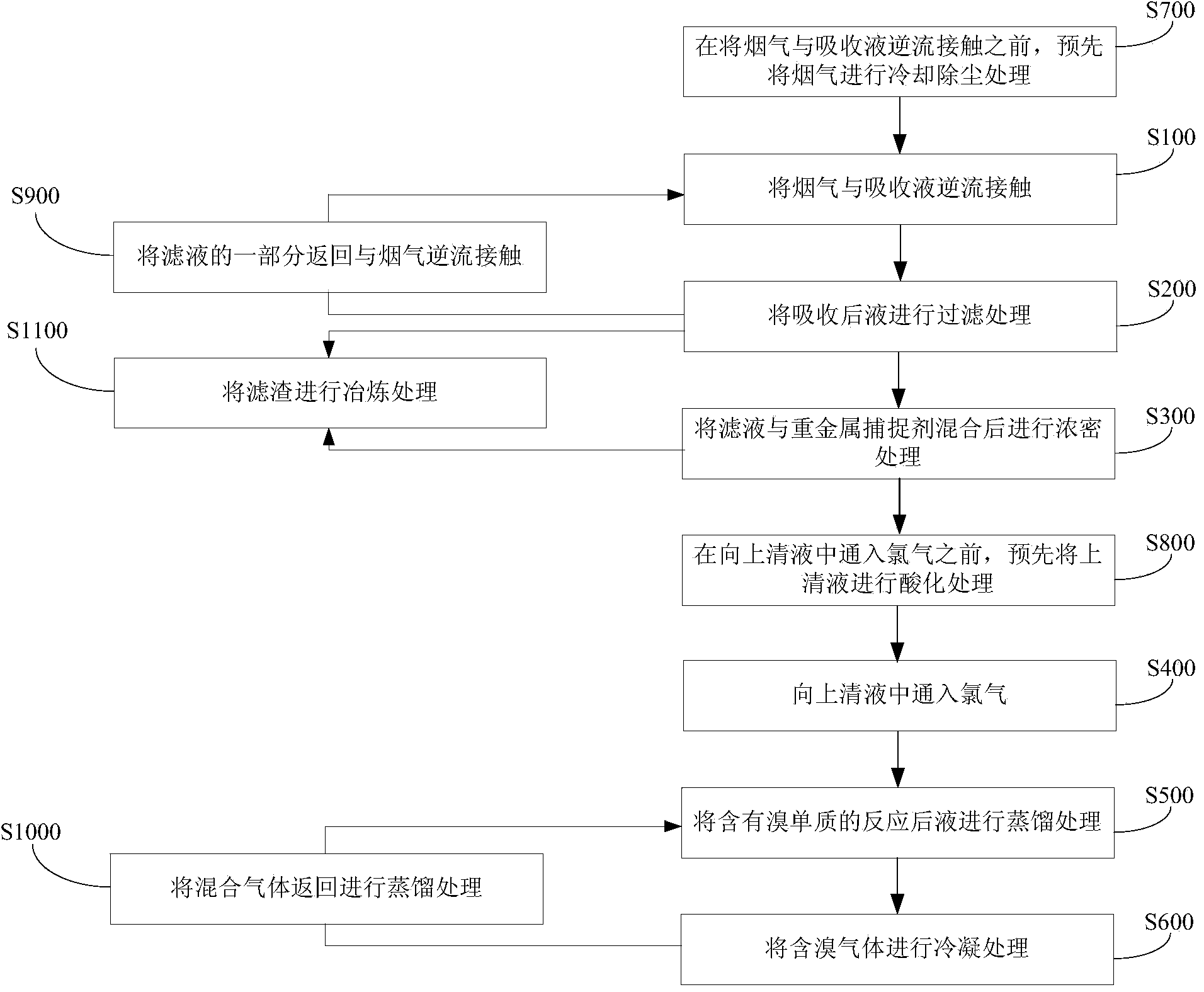

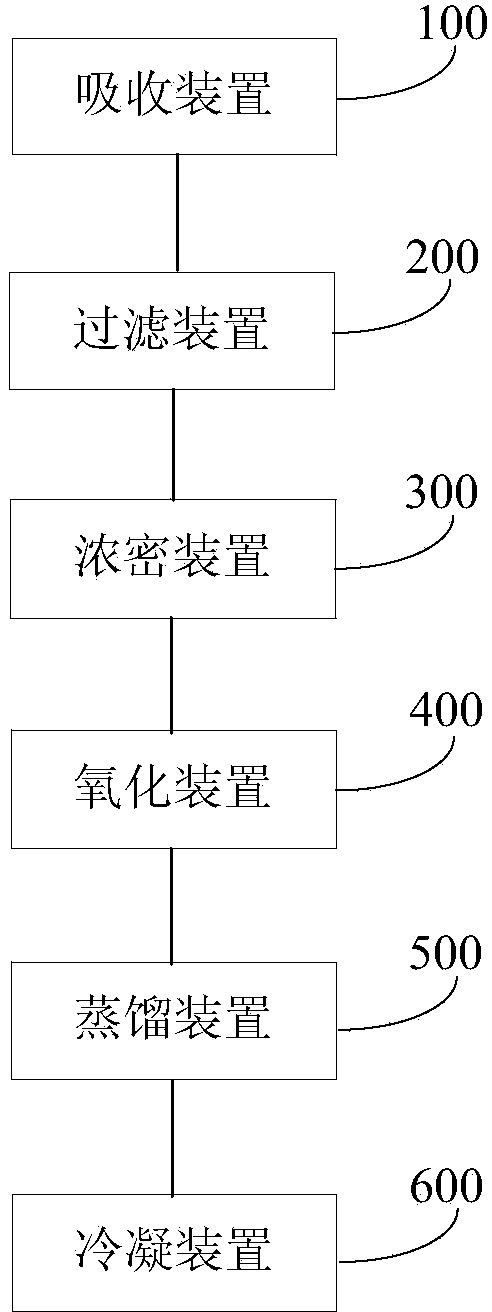

[0128] The dust-containing high-temperature flue gas of electronic waste at 1300-1600 °C generated by the smelting furnace first recovers waste heat through the waste heat boiler to reduce the temperature to about 600 °C, and then enters the flue gas quenching tower to quench the flue gas to about 200 °C, and then Enter the bag dust collector to remove the dust in the flue gas, and finally send the dust-collected flue gas from the induced draft fan to the washing tower for countercurrent contact with the absorption liquid to obtain purified flue gas and absorbed liquid, among which the purified flue gas ( SO 2 ≤170mg / Nm 3 , HCl≤58mg / Nm 3 , HBr≤73mg / Nm 3 ) is directly discharged through the chimney, and then the absorbed liquid is filtered to obtain filtrate and filter residue, which is sent to the subsequent smelting section for smelting treatment, and a part of the filtrate is returned to the scrubber to continue countercurrent contact with the flue gas, and the other part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com