Heat-conduction oil furnace of horizontal circulating fluidized bed

A circulating fluidized bed, heat transfer oil furnace technology, applied in fluidized bed combustion equipment, fluid heaters, heat storage heaters, etc., can solve the problems of high emission of air pollutants and low combustion efficiency, and reduce initial The effect of investment, high combustion efficiency and high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention and working process will be further described below in conjunction with accompanying drawing.

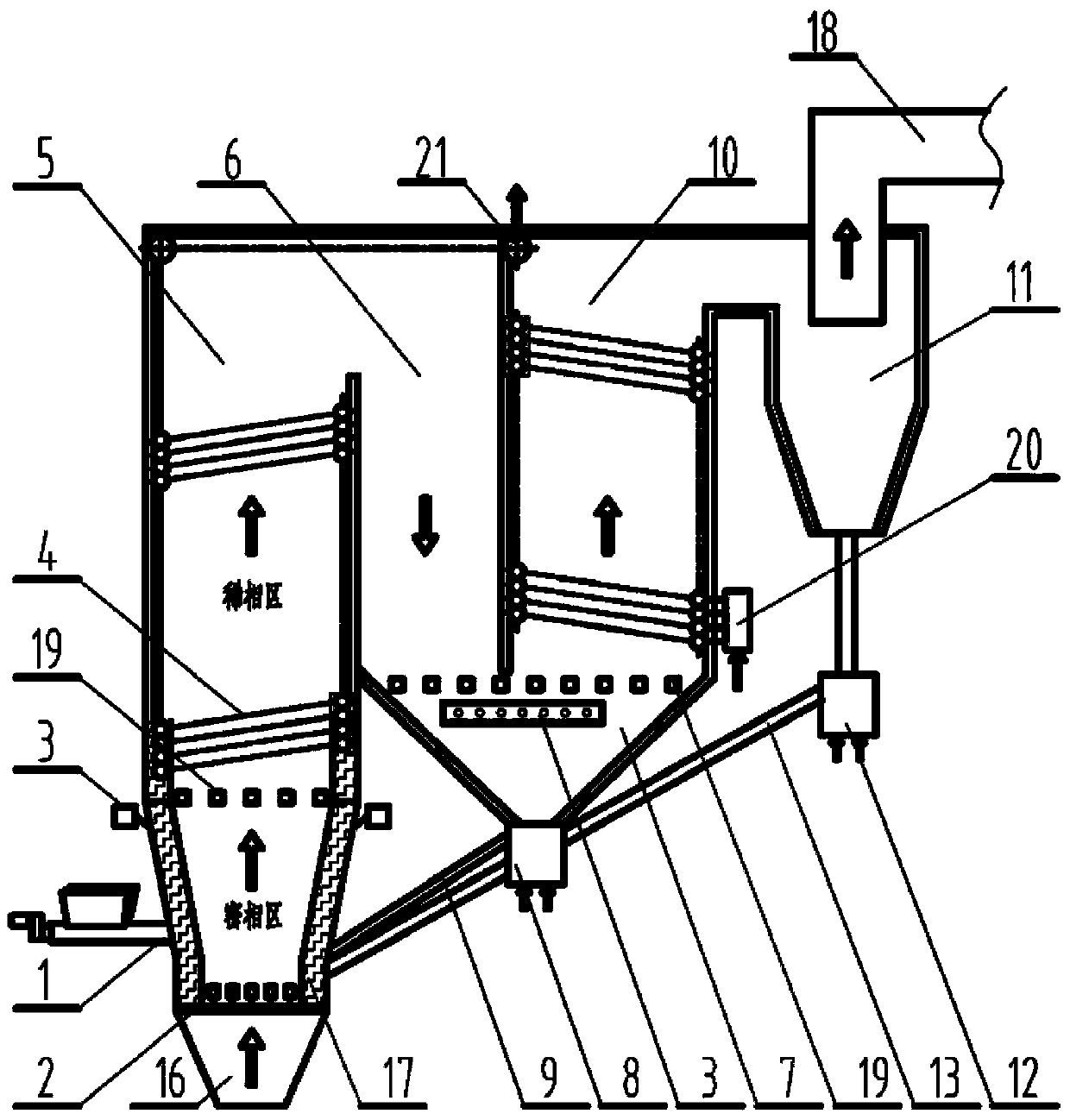

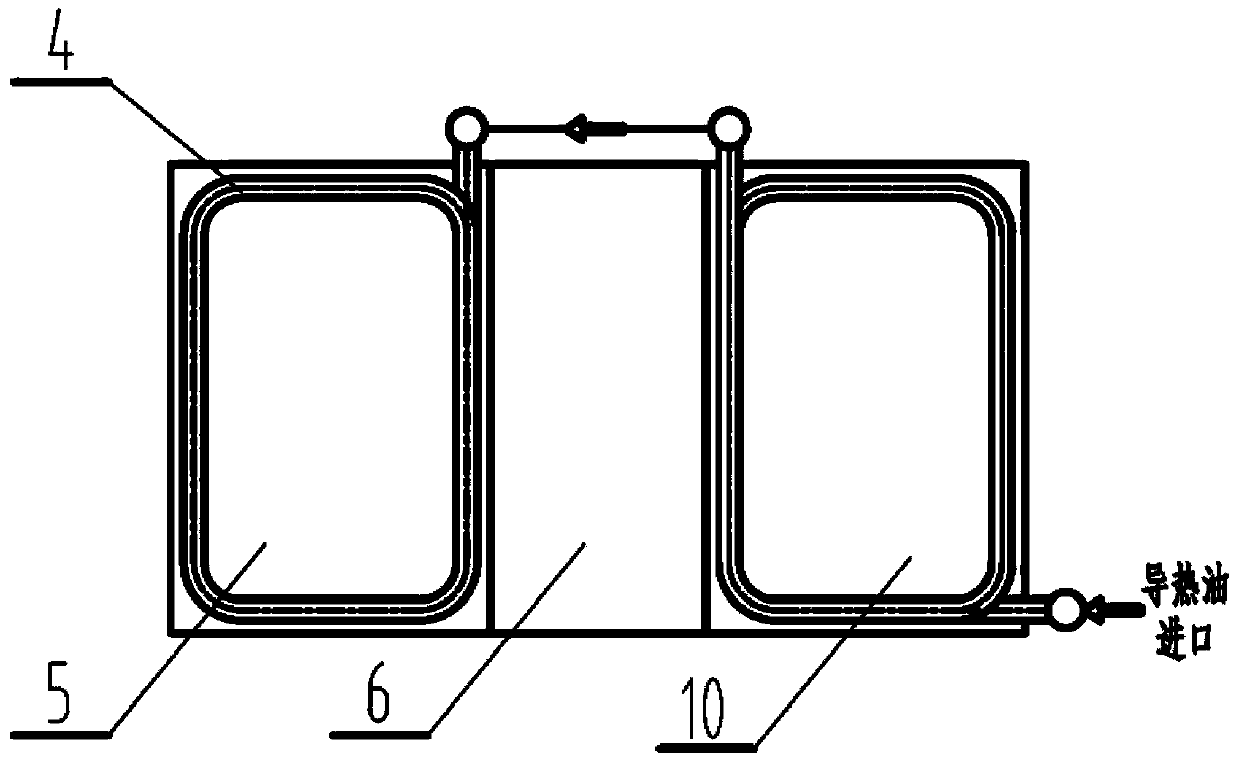

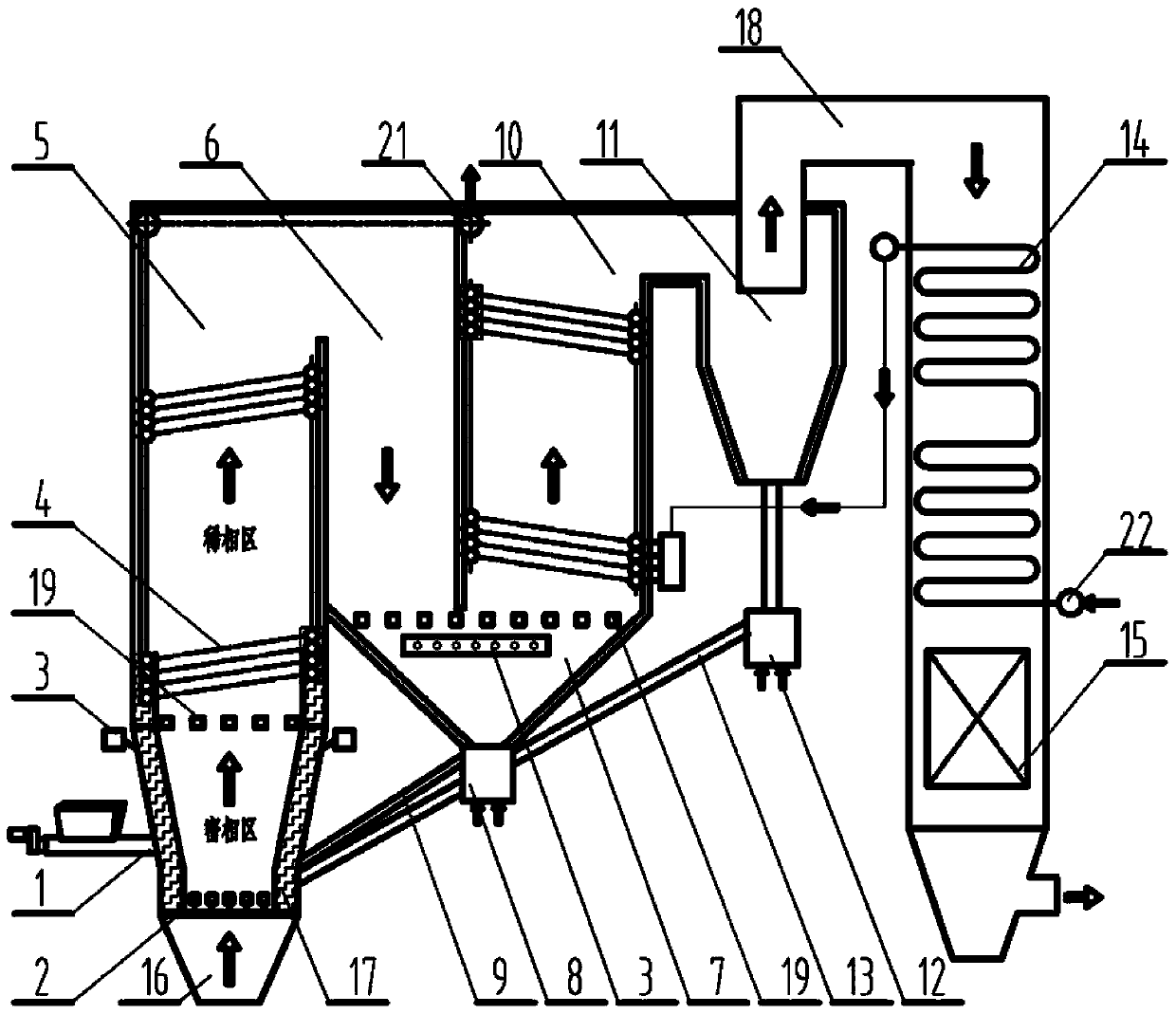

[0015] figure 1 It is a schematic diagram of a horizontal circulating fluidized bed heat-conducting oil furnace according to the present invention, which includes a feeding device 1, a main combustion chamber 5, a secondary combustion chamber 6, a burnout chamber 10, a cyclone separator 11, a separator outlet flue 18 and An induced draft fan; the air distribution plate 2 is arranged at the lower part of the main combustion chamber 5, and the primary air device 16 is arranged at the lower end of the air distribution plate 2; the wear-resistant and refractory castable layer 17 is arranged in the dense phase area of the main combustion chamber 5; 10 is arranged below the ash hopper 7, and the first-stage return device 8 is arranged below the ash hopper 7; the second-stage return device 12 is arranged under the cyclone separator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com