Impingement flow partially premixed low nitrogen gas burner

A gas burner and impinging flow technology, applied in the direction of gas fuel burners, burners, combustion types, etc., can solve the problems of thermal efficiency impact, rising CO emission concentration, low thermal efficiency, etc., and achieve strong fuel adaptability and pollutant emissions. Small, wide fuel adaptability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The impinging flow partially premixed low-nitrogen gas burner provided by the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

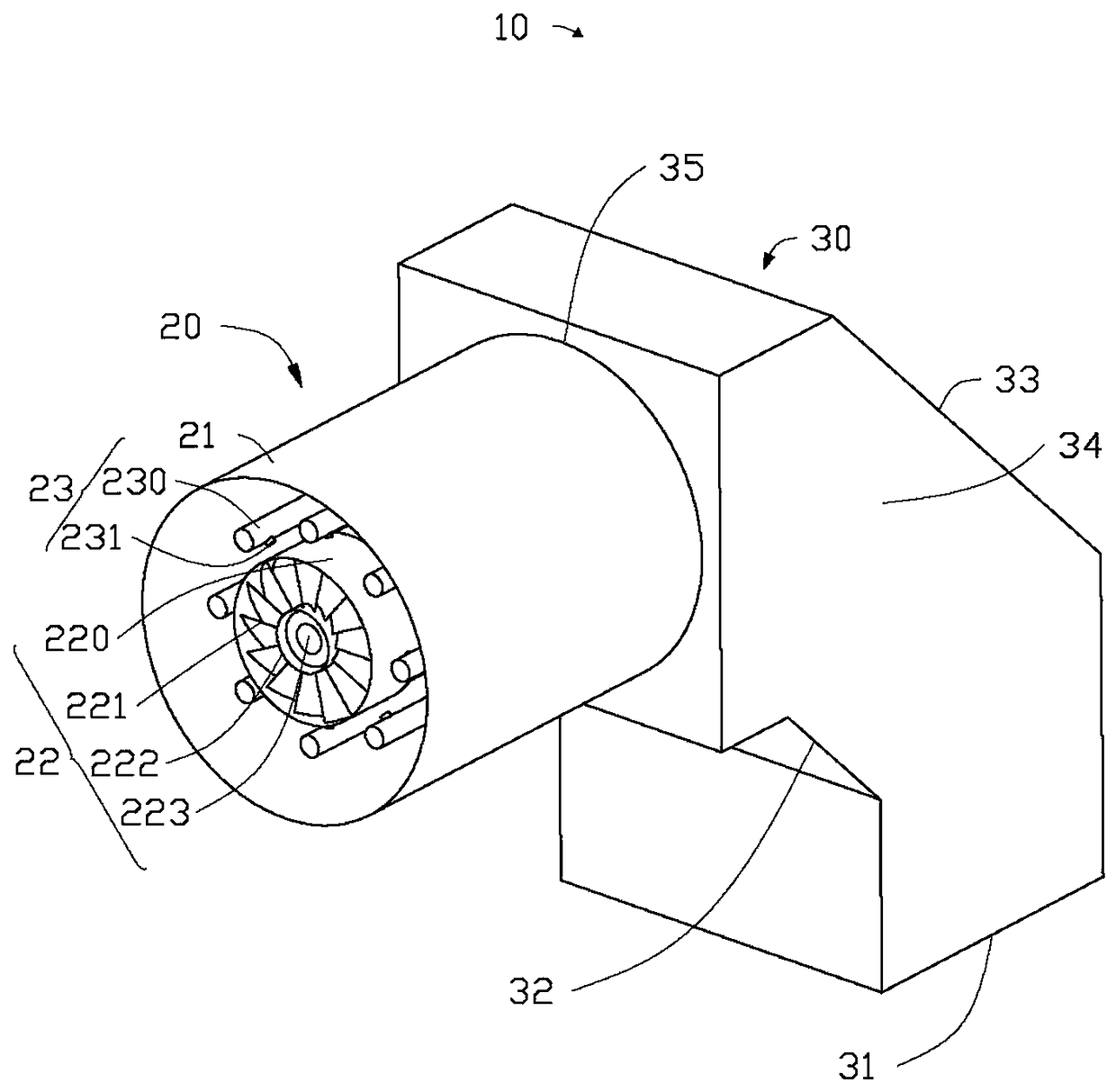

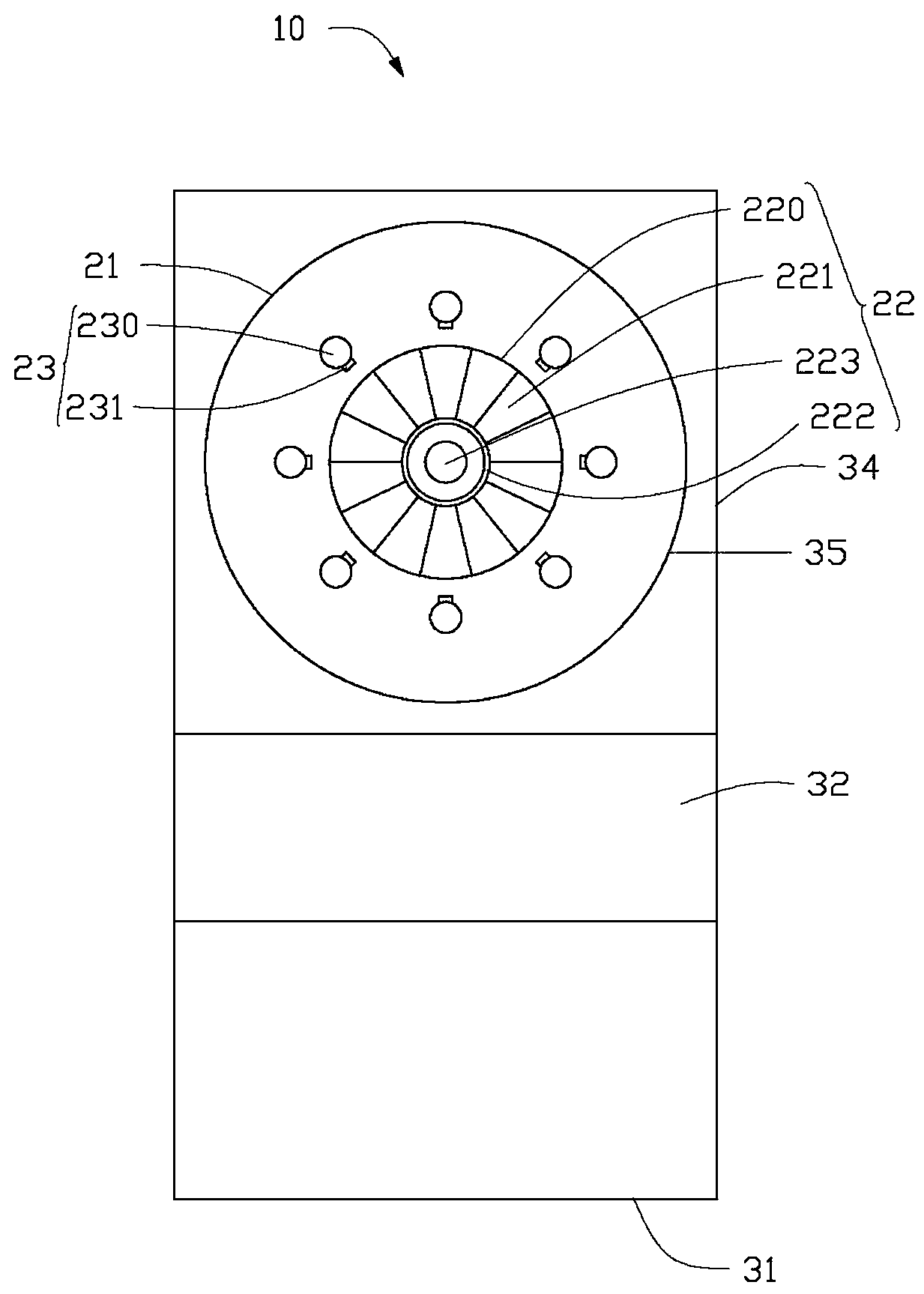

[0023] see figure 1 , the embodiment of the present invention provides an impingement flow partly premixed low nitrogen gas burner 10, the impingement flow part premixed low nitrogen gas burner 10 includes a combustion head 20 and a front flow channel 30, the combustion head 20 and the front flow channel The lanes 30 are connected together and communicate.

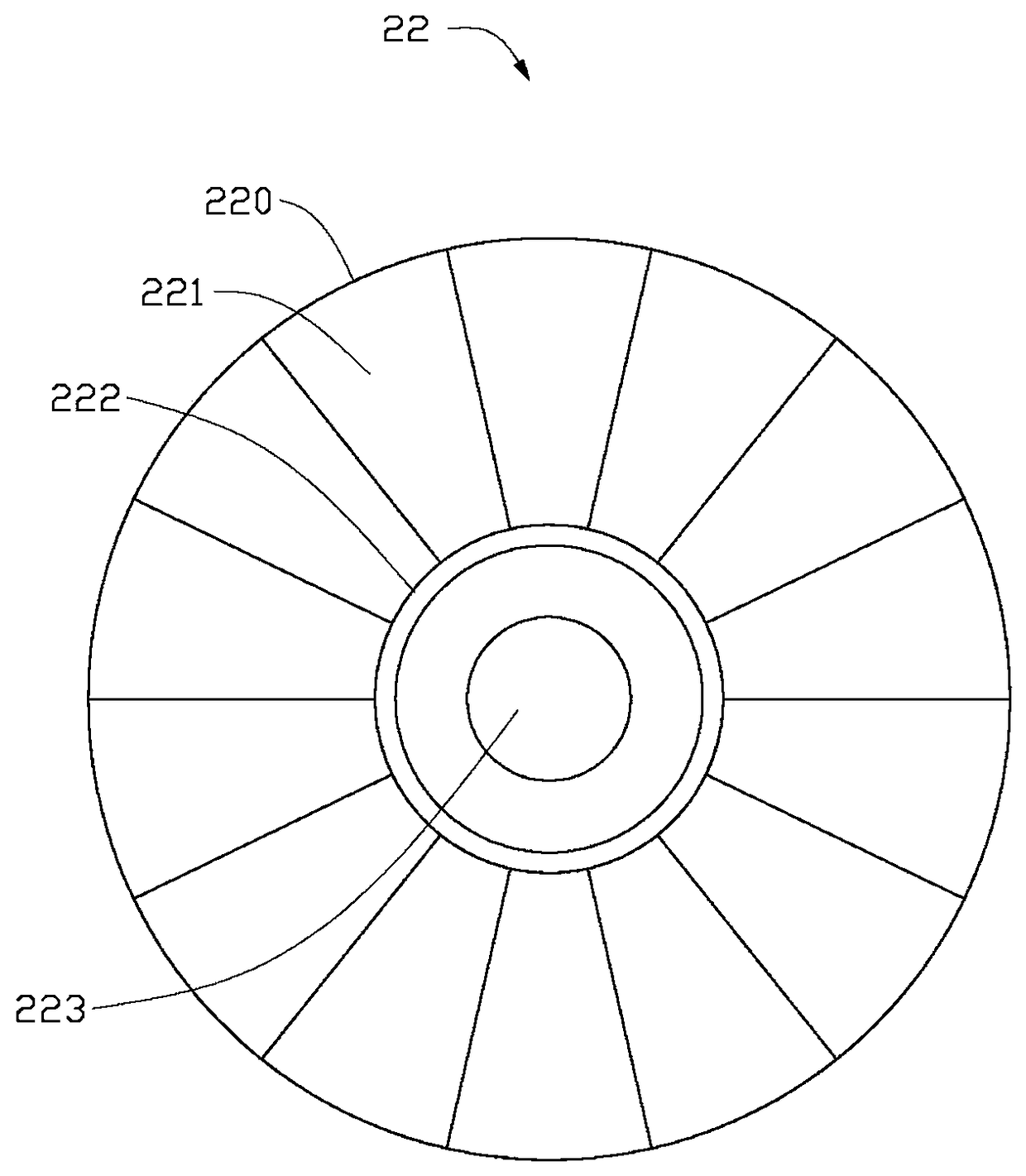

[0024] The combustion head 20 includes a cylindrical air flow passage 21, a swirler 22 arranged inside the cylindrical air flow passage 21, a fuel injector arranged outside the swirler 22 and inside the cylindrical air flow passage 21. Tube 23. The front flow passage 30 includes an air inlet 31, an air front deflector 32 and an air rear deflector 33 arranged behind the air inlet, an air inlet section 34 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com