Shaft drive system for power loom shafts

A drive system, heald frame technology, applied in textile, heald, dobby, etc., can solve the problems of yarn eye and shaft breakage, pawl wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

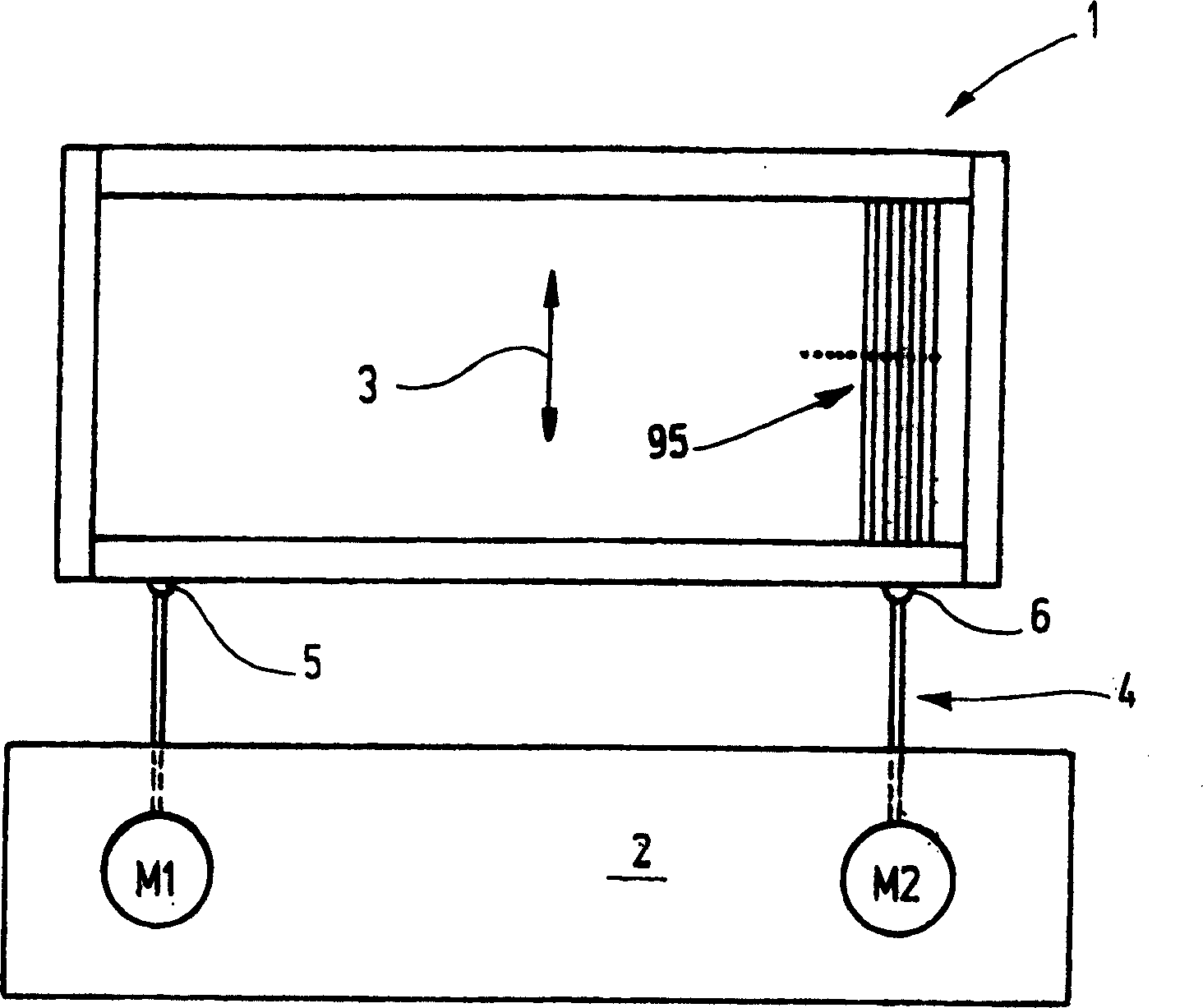

[0029] exist figure 1 A heald frame 1 with a corresponding heald frame drive system 2 is described in . The heald frame 1 is formed by a frame provided with thread guide eyes 95 , which is moved upwards and downwards during operation, as indicated by an arrow 3 . A tie rod 4 is used for the drive, which is connected to the heald frame 1 at two or more points 5 , 6 and forms the output of the heald frame drive system 2 . The heald frame drive system 2 has one or more drive sources, for example in the form of motors M1, M2. These are, for example, electric servomotors, which are connected to the tie rod 4 via a screw drive, a belt drive or another drive which converts the rotation of the motor into a linear movement. As another option, a linear motor, a linear stepping motor, etc. can be applied. In some cases a single motor is sufficient, in other cases two or more motors are necessary.

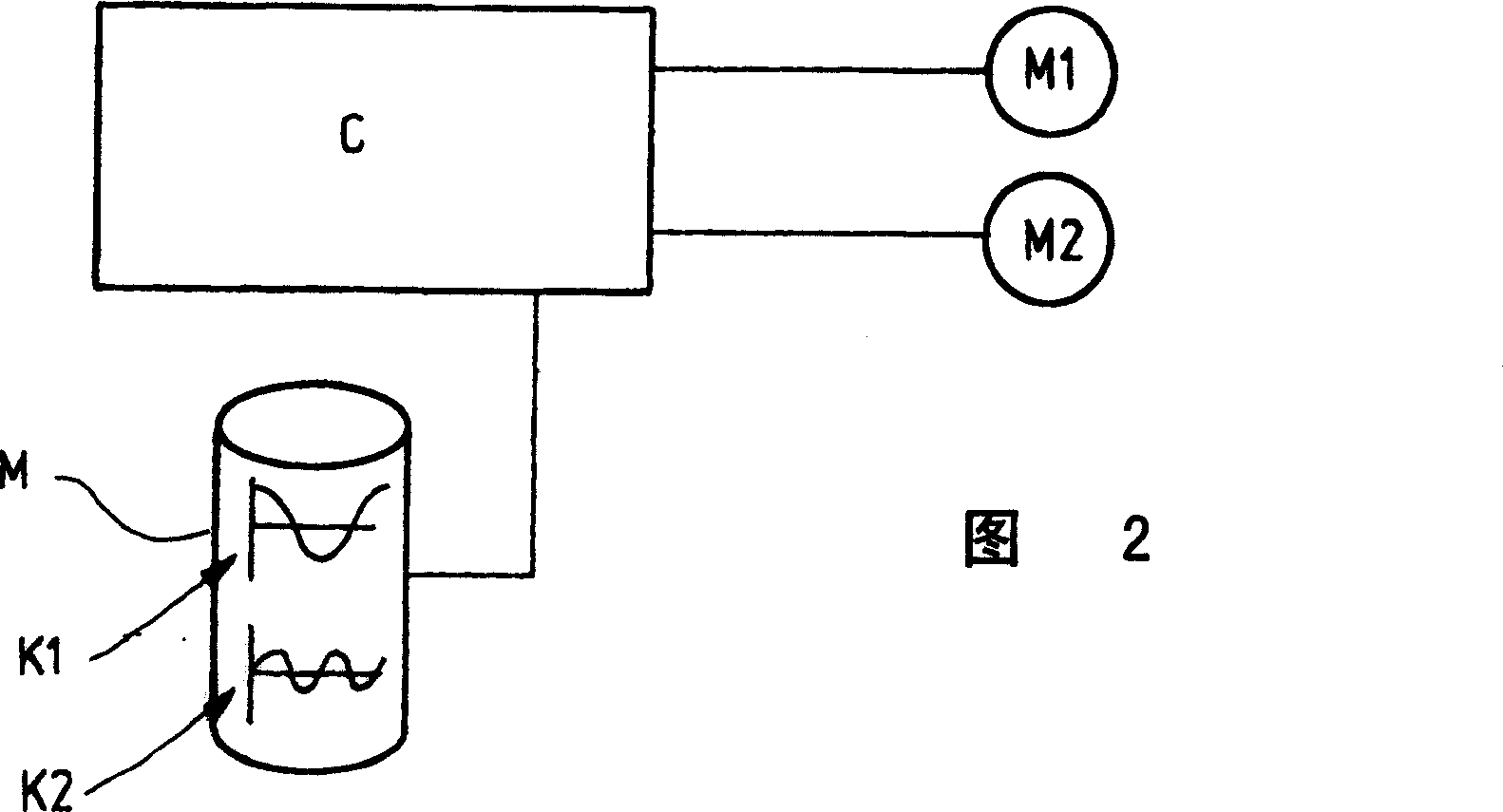

[0030] The motors M1, M2 are controlled by a control unit C, which is connected to a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com