Circular weaving machine and method for producing a hollow profile-like fabric

A circular loom, circular technology, applied in the directions of circular looms, fabrics, looms, etc., can solve the problems of unfavorable usability of circular looms, vibrating yarn tension, unevenness, etc., and achieve the effect of uniform conveying or guiding route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

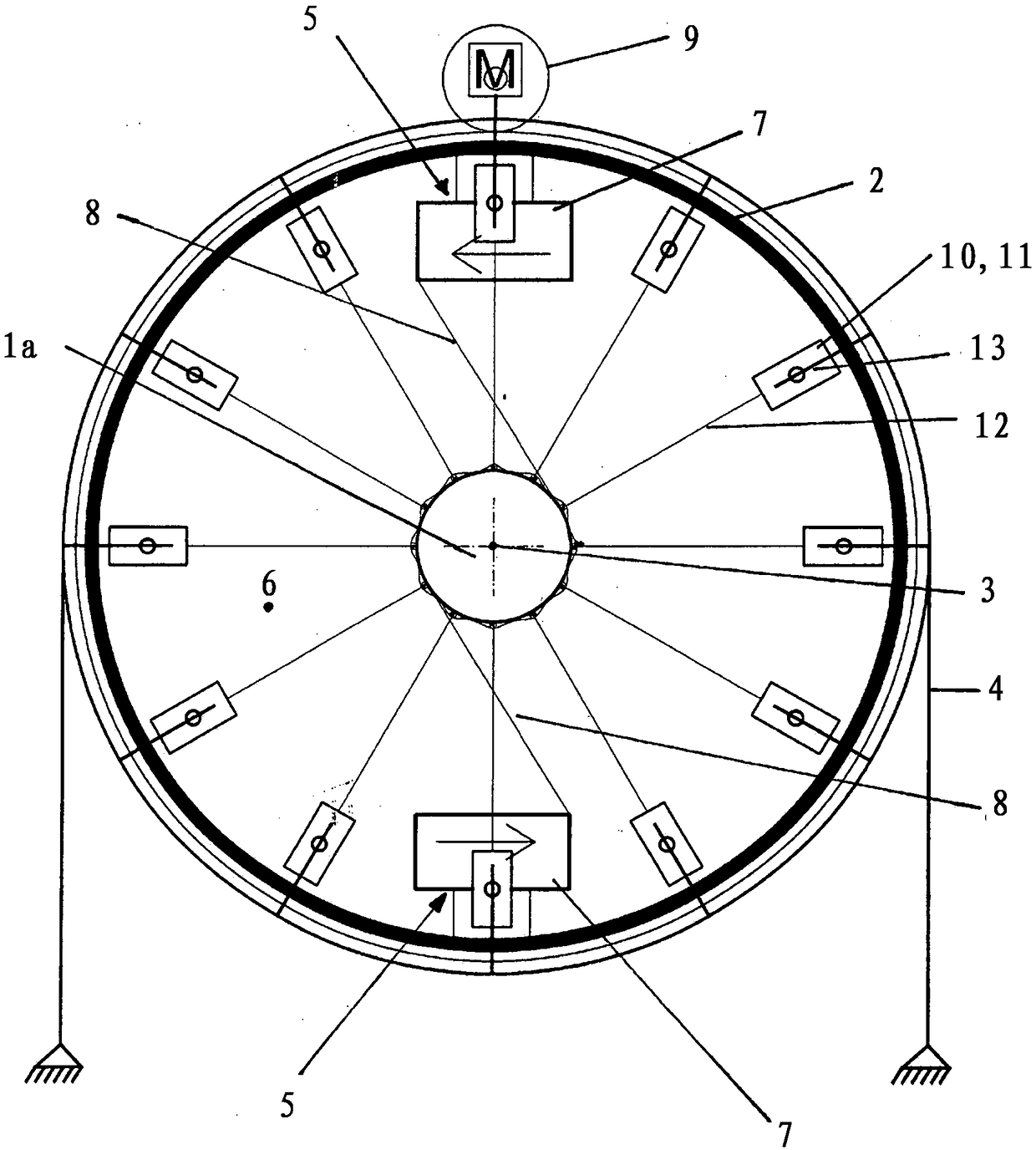

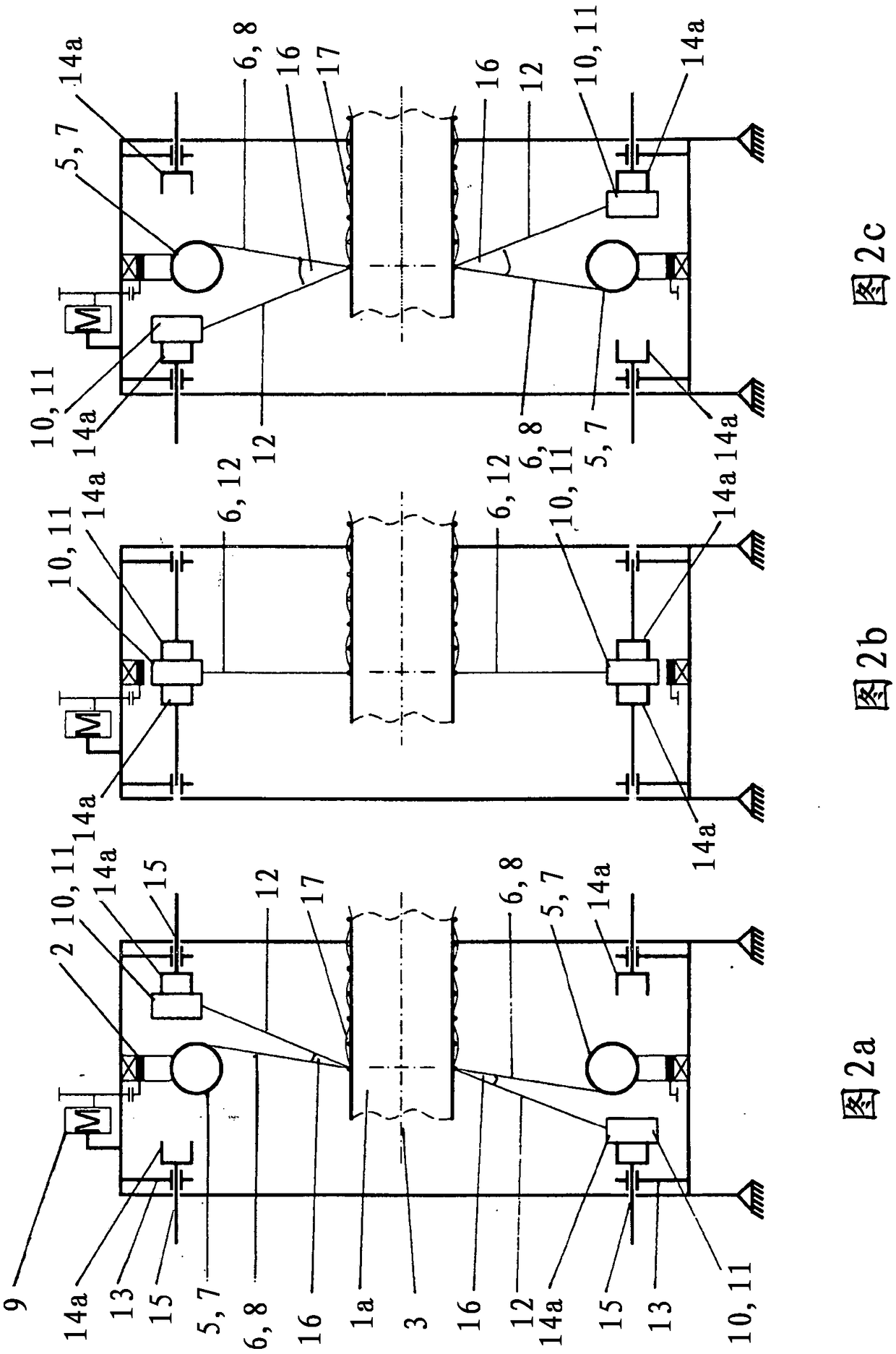

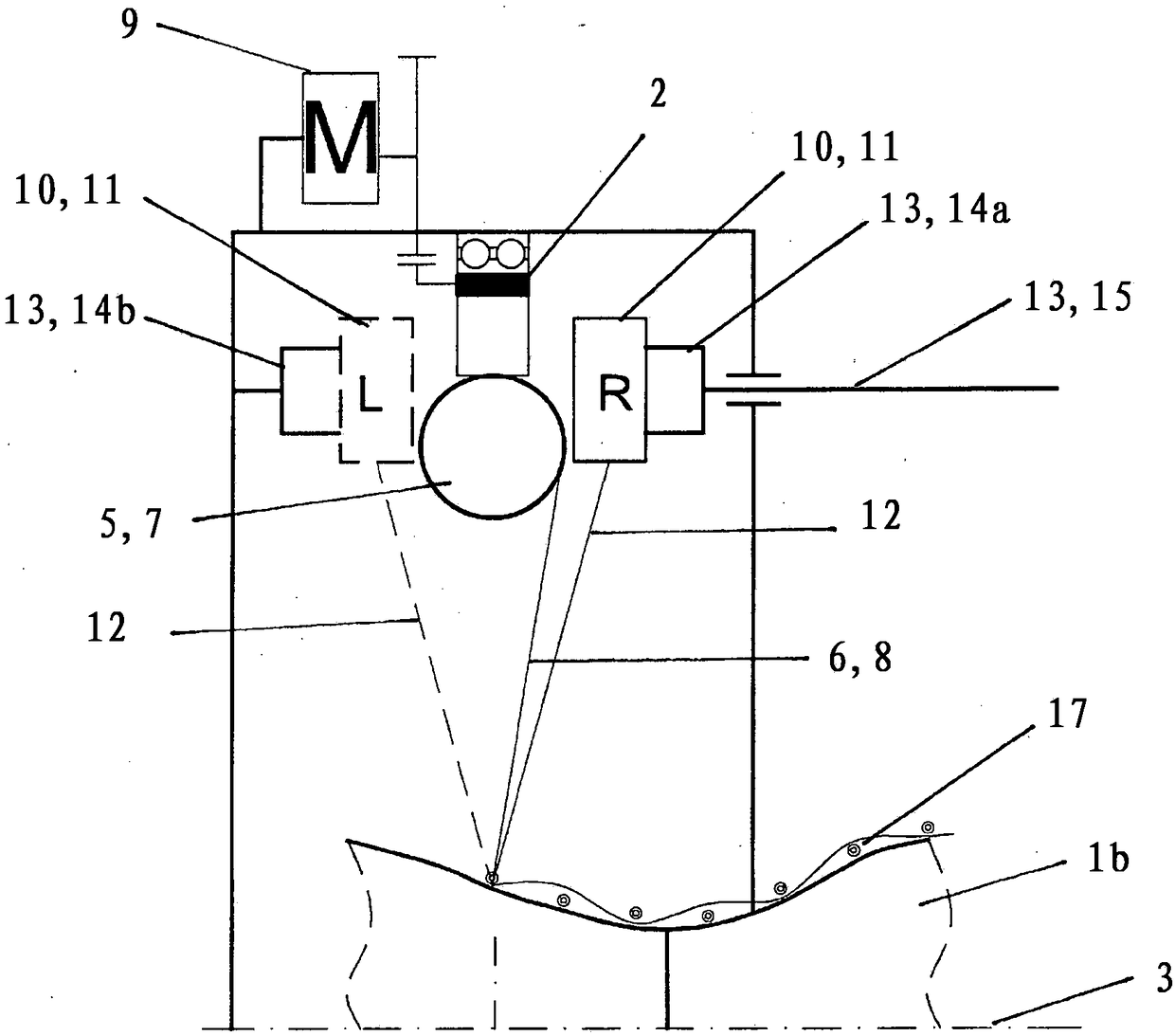

[0128] The circular loom according to the invention according to figure 1 There is a centrally arranged core 1a, which has a cylindrical cross-section, and an annular rotating part (swivel) 2 . The core 1 a is mounted rotatably about a weaving axis 3 and displaceable along this weaving axis 3 on a hollow cylindrical housing 4 of the circular loom. The swivel 2 is likewise mounted rotatably on the housing 4 and rotates concentrically around the core 1a.

[0129] Fastened to the swivel 2 are two weaving shuttles 5 offset from one another by 180° and thus arranged opposite one another, which follow the circle formed by the swivel 2 at the same distance from each other due to the swivel movement of the swivel 2 The surrounding route (conveyor route) 2 is conveyed around the core 1a, and the conveyer route of the weaving shuttle 5 is determined by the configuration shape of the swivel (conveyor route). In this embodiment, the radial extension of the inner space of the swivel 2 de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com