B1-grade flame-retardant 105-DEG C irradiation crosslinking halogen-free low-smoke insulated cable material and preparation method thereof

A technology for insulating cables and cable materials, applied in the direction of plastic/resin/wax insulators, insulators, organic insulators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The second aspect of the present invention provides a kind of B described in the present invention 1 A method for preparing a grade flame-retardant 105°C irradiation cross-linked halogen-free low-smoke insulating cable material, the preparation method comprising the following steps:

[0067] First prepare various materials according to the ratio described in the first aspect of the present invention; then add the prepared materials into a high-speed mixer and stir at a high speed for 8-12min (generally about 10min), and the temperature is controlled at 50±2°C; then The mixed material is put into the banbury mixer for banburying, and when the temperature of the banburying material reaches 150-155°C, the material is released, forced to feed through double cones, and granulated by a 75 / 180 double-stage extruder to obtain the above-mentioned B 1 Class flame retardant 105℃ radiation cross-linked halogen-free low-smoke insulating cable material.

[0068] The temperature of ...

Embodiment

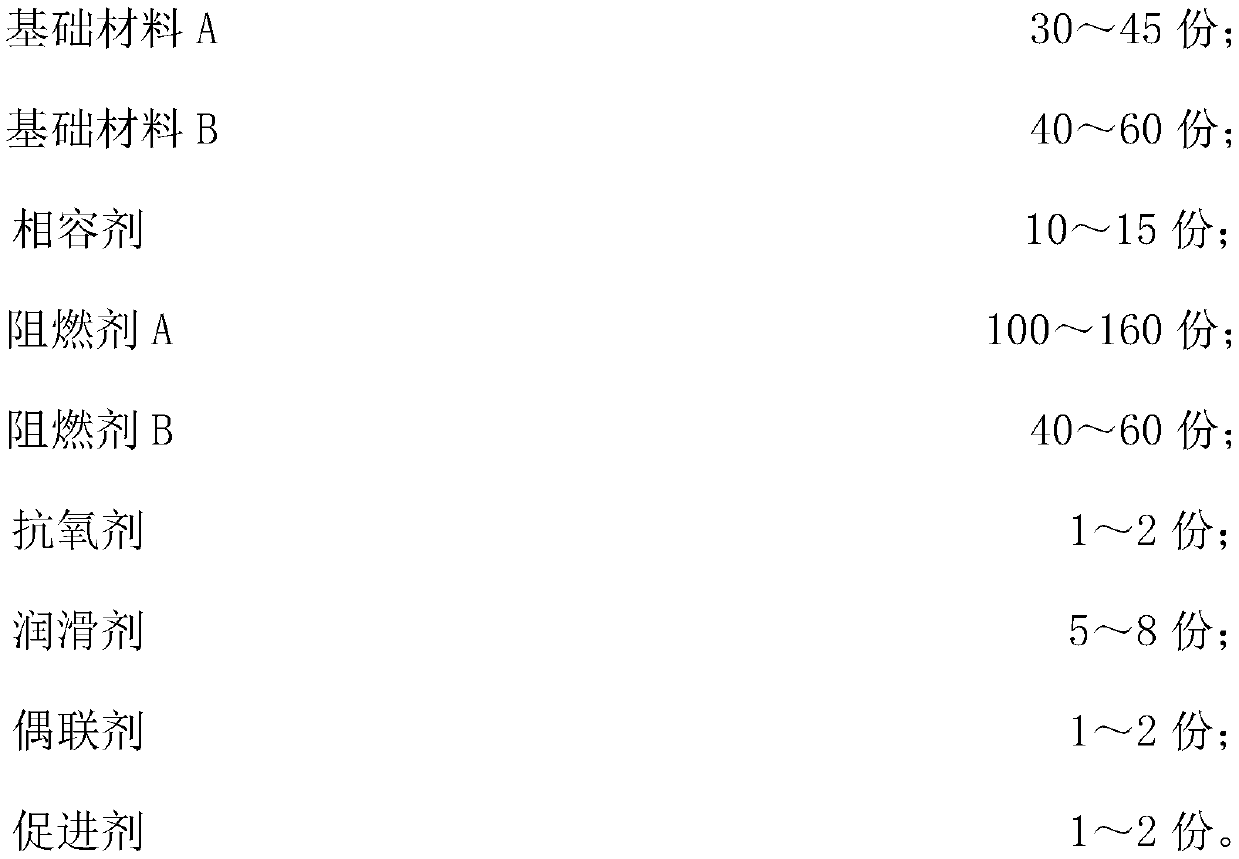

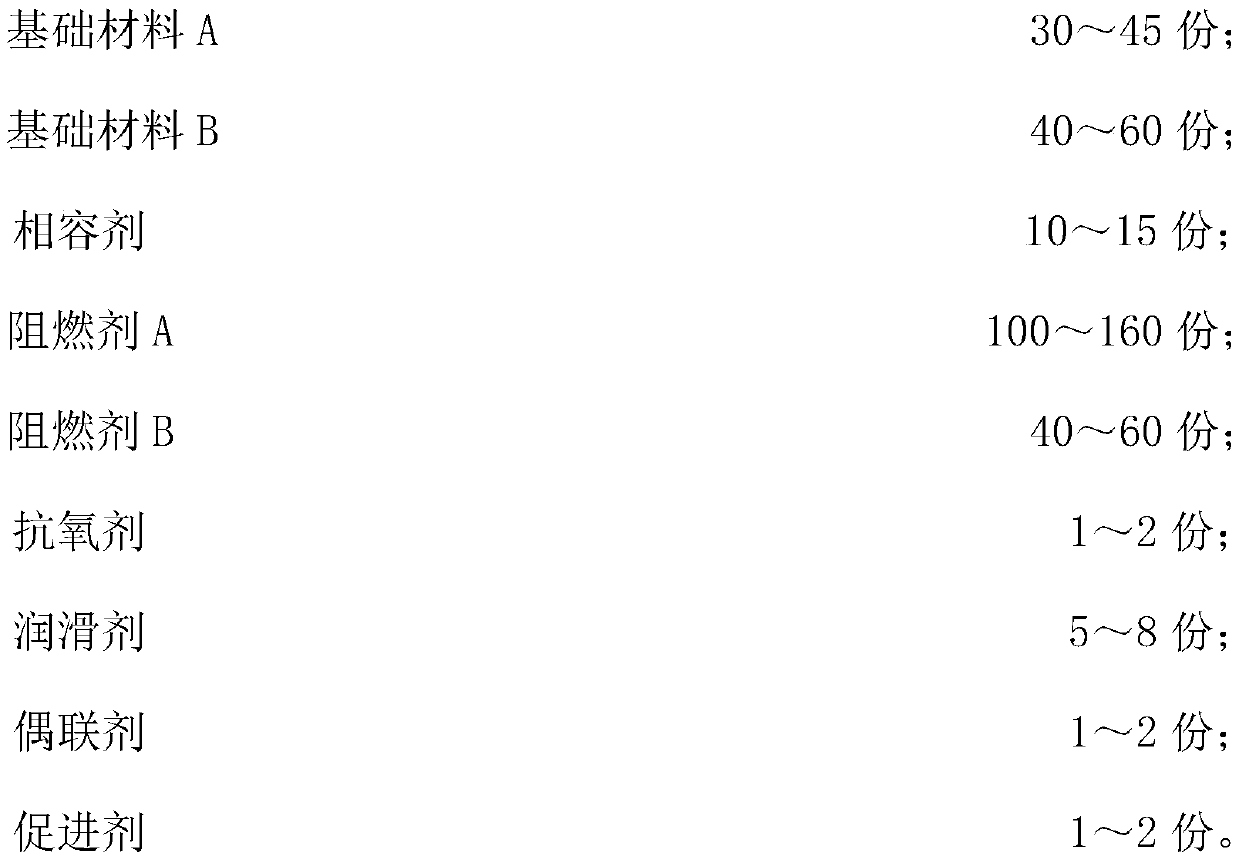

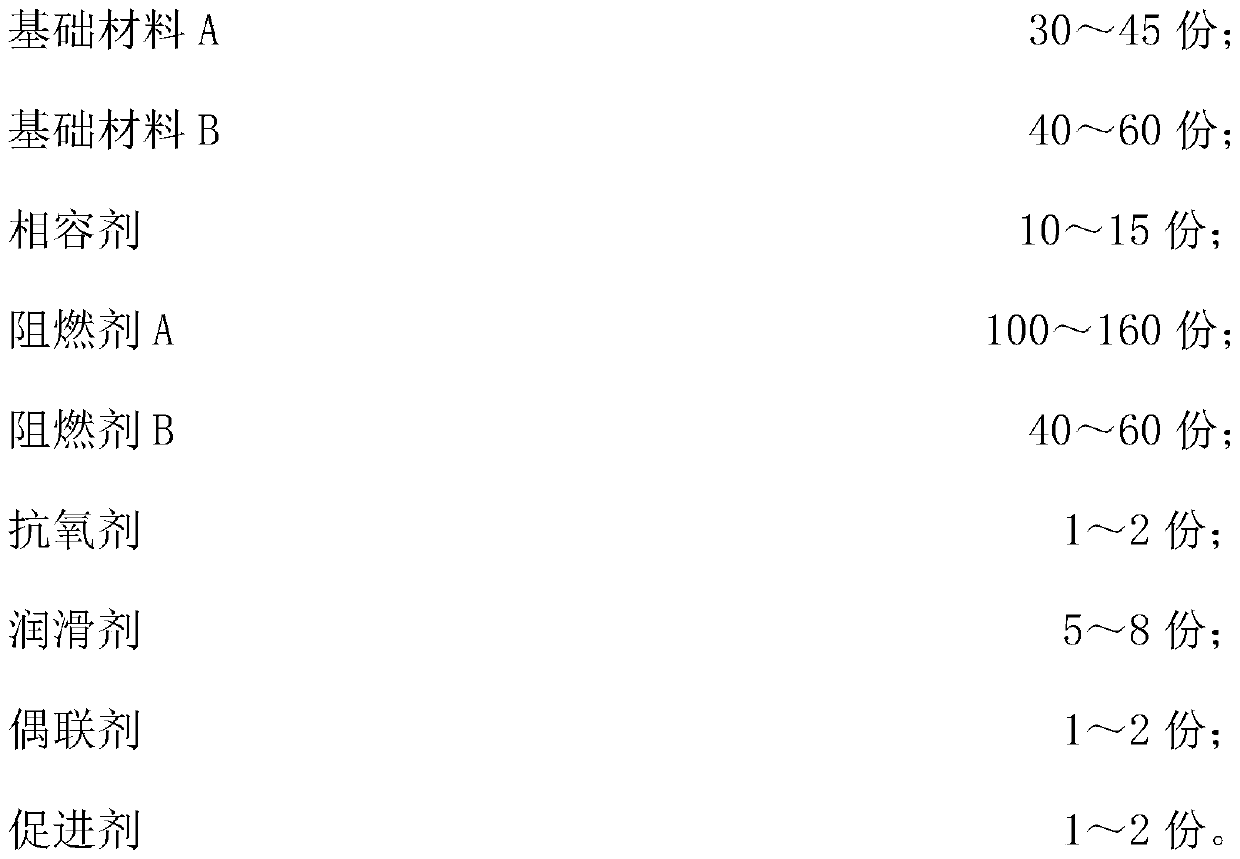

[0073] The name of each component and the parts by weight of each component are shown in Table 1 below:

[0074]

[0075] The preparation method of the above-mentioned invention, it comprises the following processing steps:

[0076] Firstly, prepare various materials according to the parts by weight; then add the prepared materials into a high-speed mixer and stir at a high speed for about 10 minutes, and control the temperature at about 50°C; When the temperature of the mixing material reaches 150-155 ° C, the material is discharged, forced feeding through the double cone, and granulated by a 75 / 180 double-stage extruder to obtain the B 1 Class flame retardant 105℃ radiation cross-linked halogen-free low-smoke insulating cable material.

[0077] The temperature of each section of the extruder starts from the twin-screw feed inlet, and is sequentially 145-150°C, 140-145°C, 130-140°C, 120-130°C, 115-125°C, 105-115°C, 100°C ~105℃, 95~100℃, 110~120℃, 120~130℃, 130~140℃, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com