Automatic adjustment control device capable of controlling tension and preventing breakage line for cabling equipment of communication cable

A communication cable and tension control technology, applied in the direction of cable/conductor manufacturing, transportation and packaging, electrical components, etc., can solve the problems of affecting the tightness of the cable, the inability to twist the core accurately, and increasing the local stress of the cable, etc. , to achieve wide applicability and social benefits, to avoid the decline of cable quality, and to avoid the effect of wire reel jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

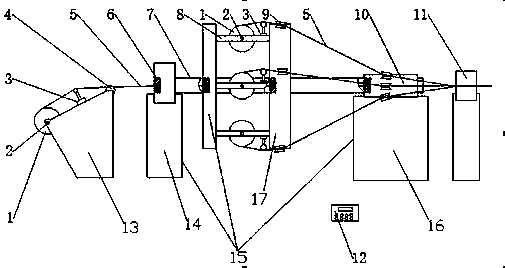

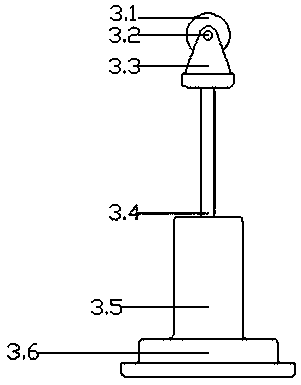

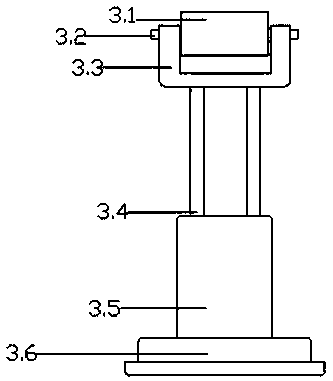

[0020] As attached figure 1 , Attached figure 2 , Attached image 3 , 1. A tension control and anti-breakage automatic adjustment control device for communication cable forming equipment, comprising a stranded wire core 5, a pay-off rack 13, a stranding cage body 15 and a wire mold base 11 connected in turn from left to right And the main control system 12 that controls the entire device. The pay-off rack 13 is equipped with a pay-off reel 1, a brake is provided on the side of the pay-off reel 1, 2 is provided with a support roller 4 on the pay-off rack 13, and the stranding cage body 15 includes the rear seat 14 of the stranding cage body, the stranding core 17, and the front seat 16 of the stranding cage which are connected from left to right. A rotatable support shaft 7 and a support shaft are arranged between the rear seat 14 of the stranding cage body and the front seat 16 of the stranding cage body. 7 A rotatable twisting core 15 is mounted on the rack, and the twisting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com