Patents

Literature

61results about How to "Solve disconnection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

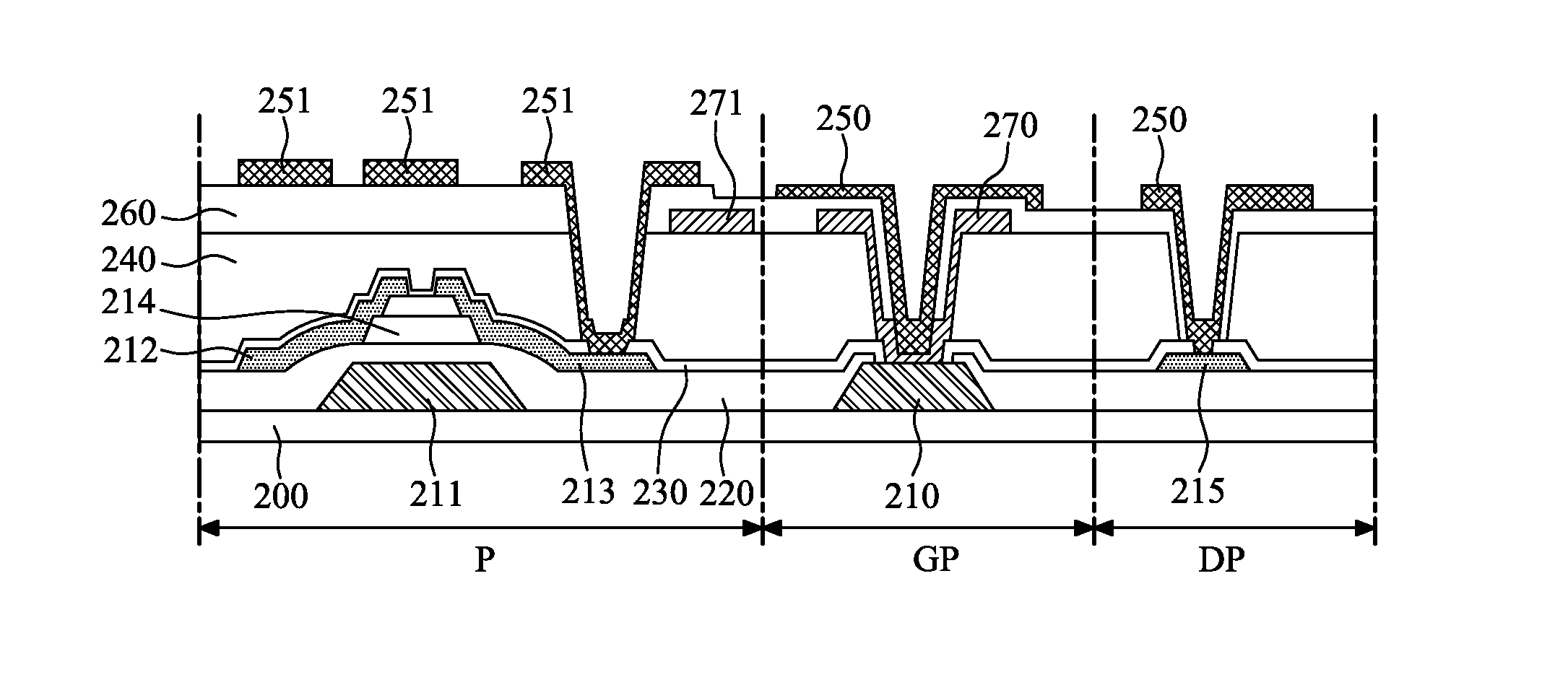

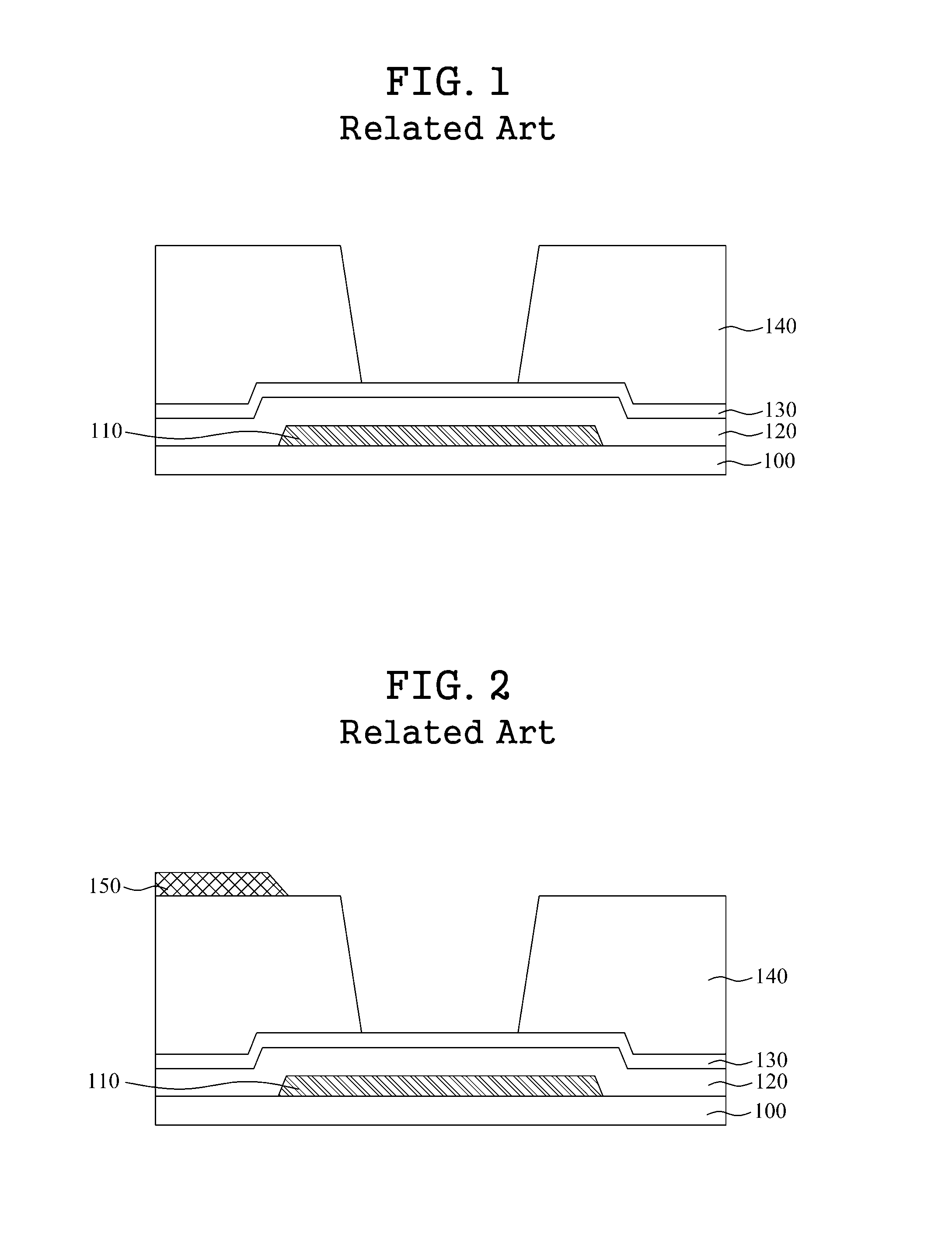

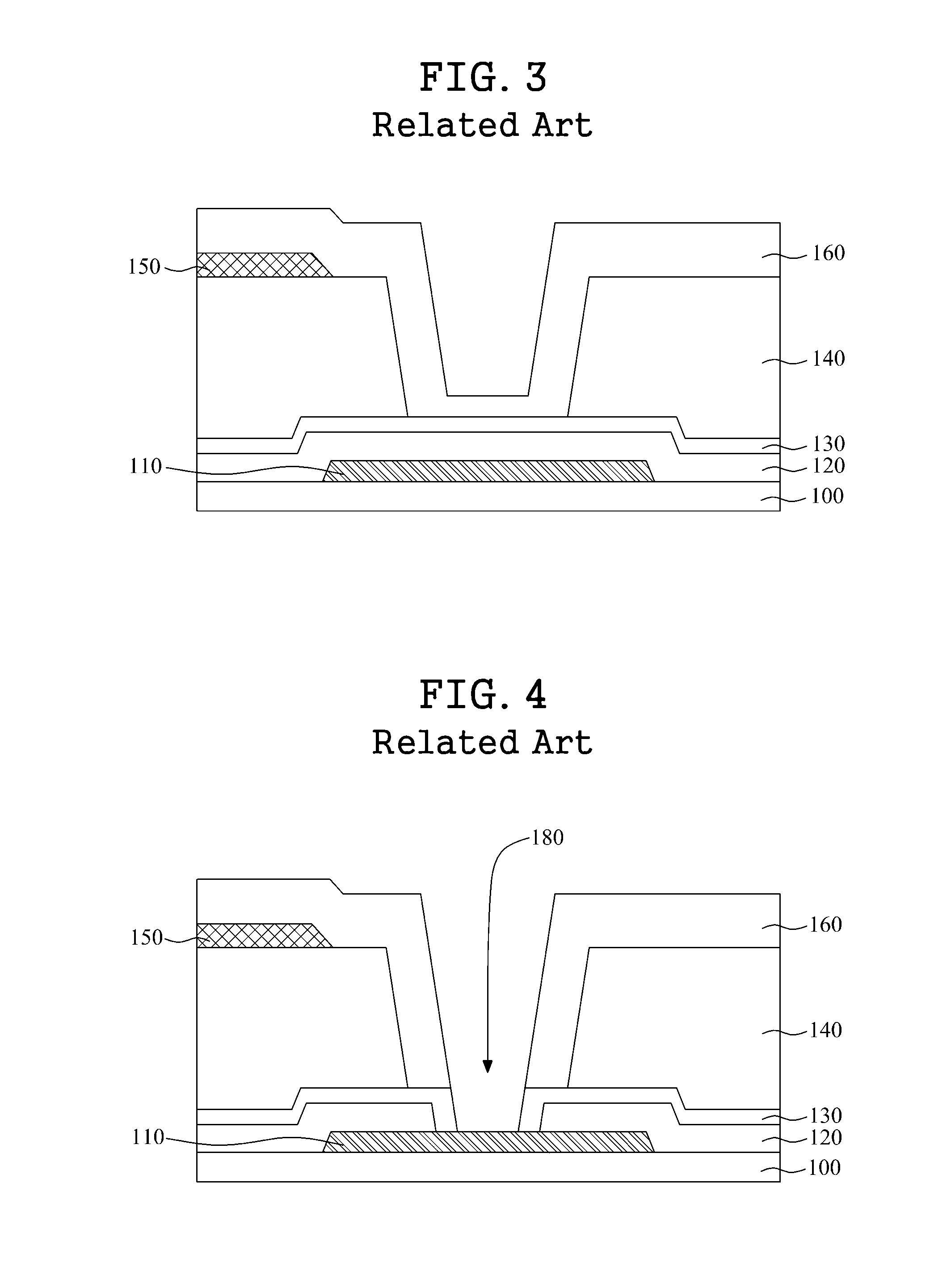

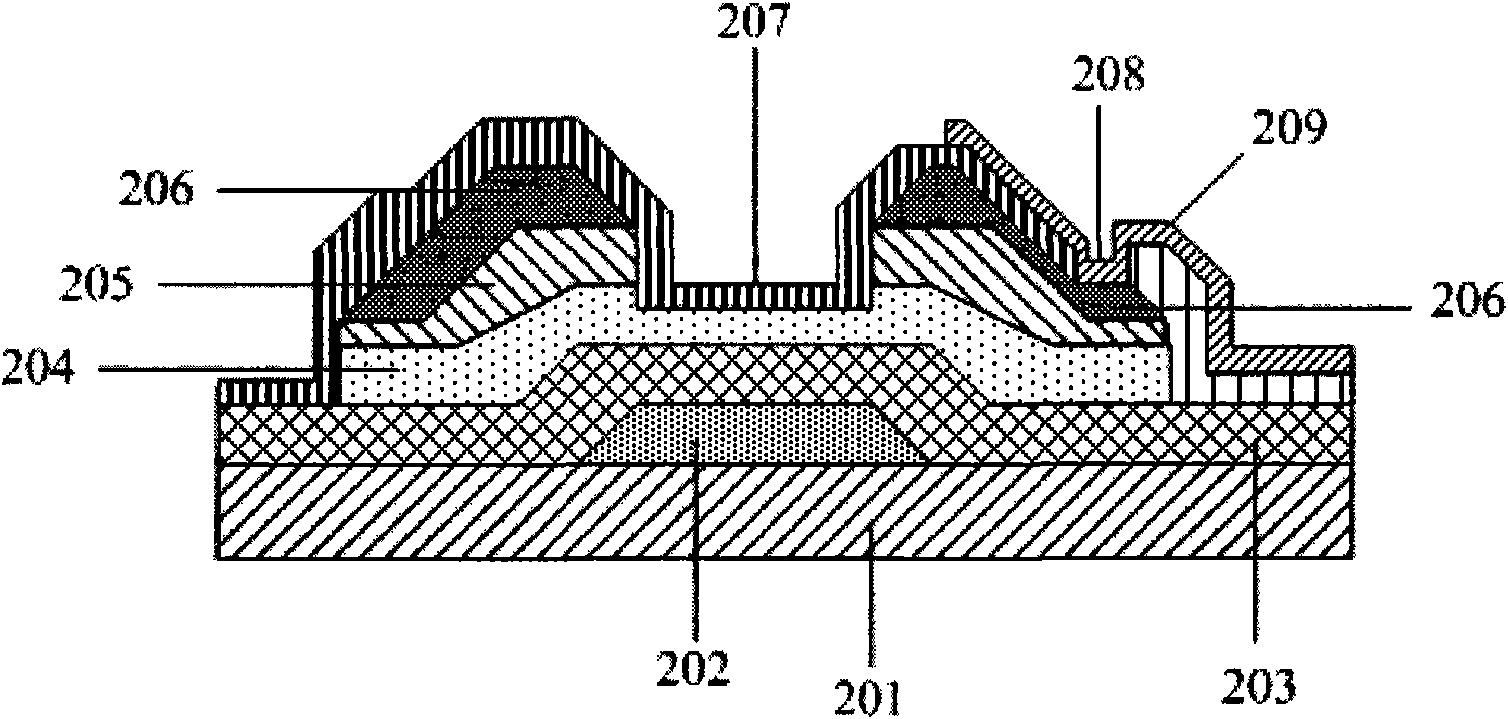

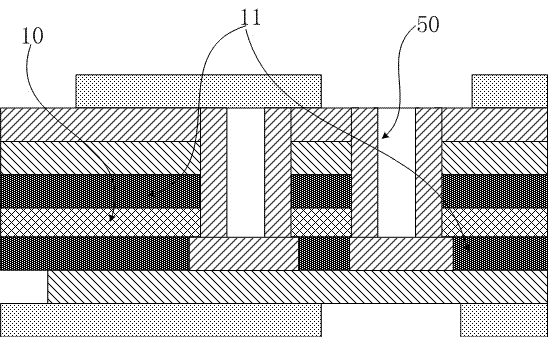

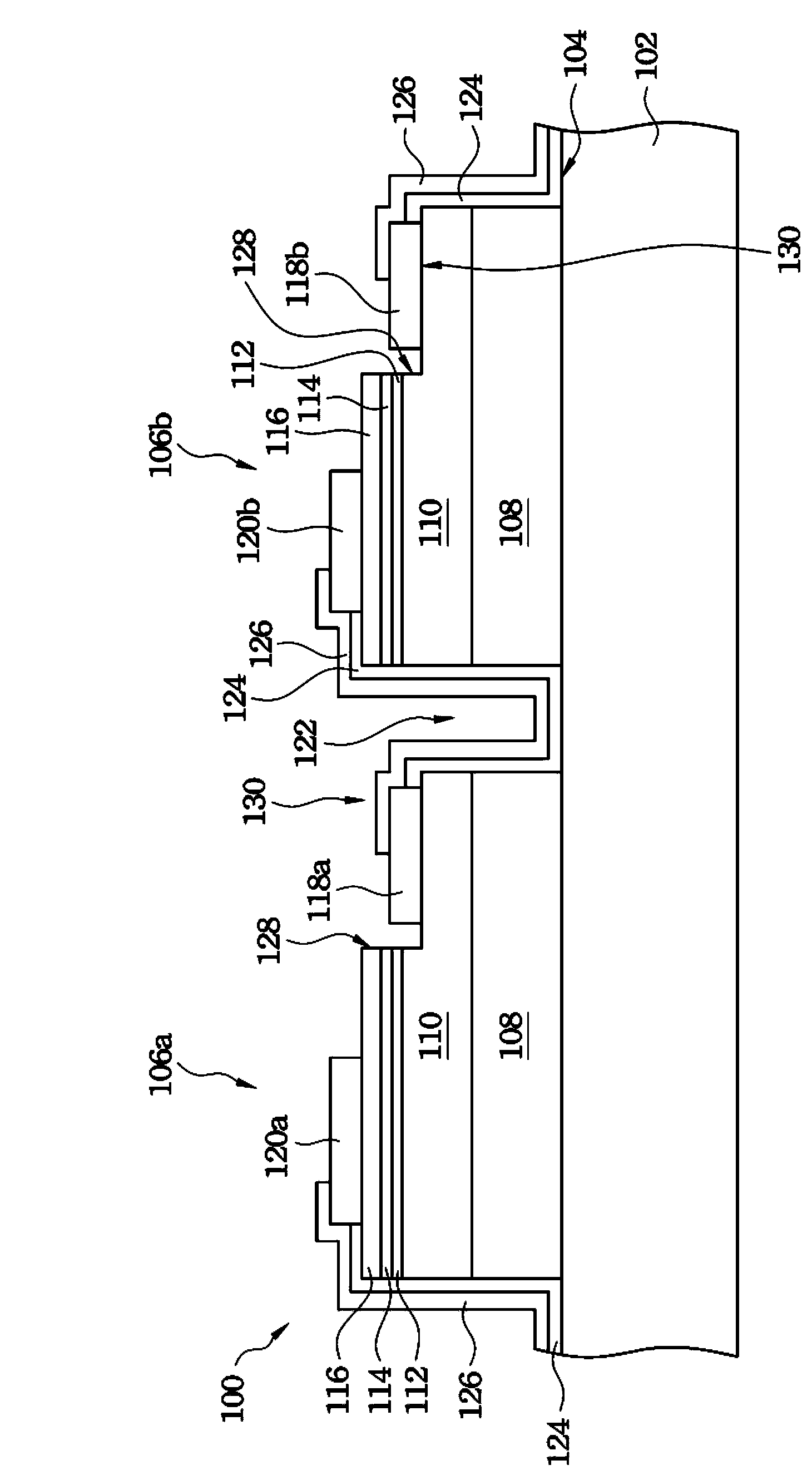

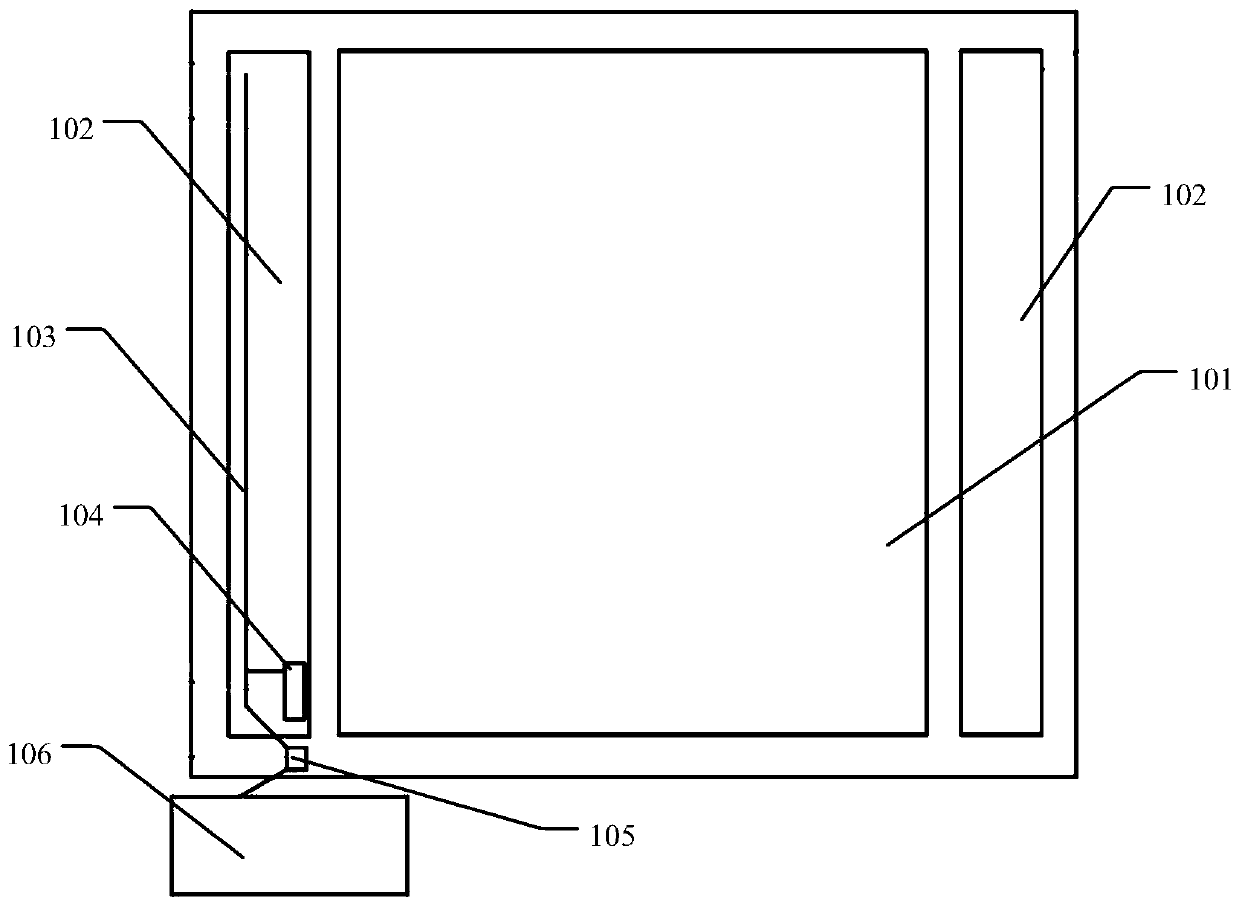

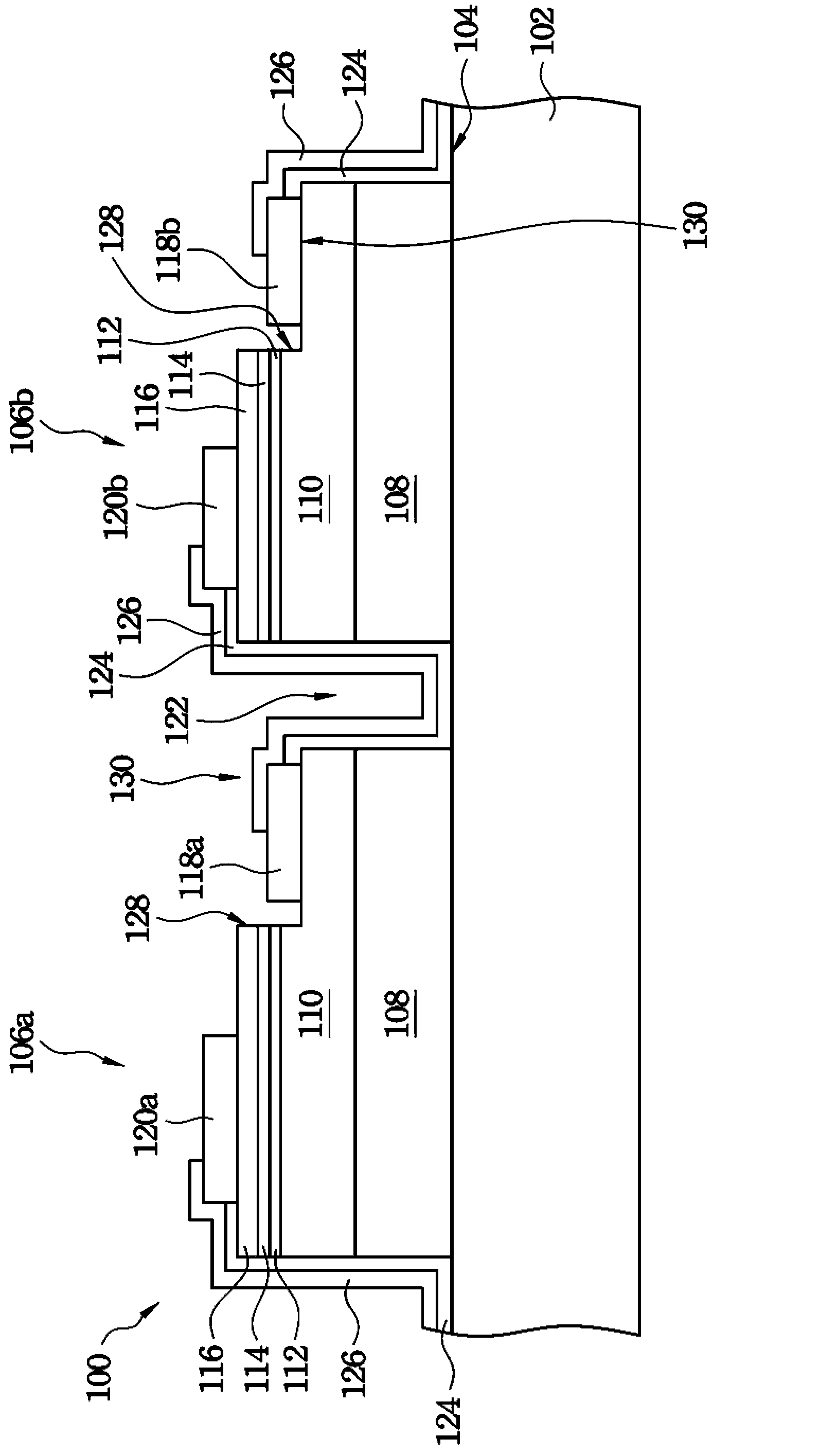

Array substrate for liquid crystal display and manufacturing method thereof

ActiveUS20130320346A1Solve disconnectionSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

An array substrate for a liquid crystal display (LCD) and manufacturing method thereof are provided. The array substrate for a liquid crystal display (LCD) includes: a substrate, including: a gate electrode, a pixel electrode, and a common electrode, a gate pad formed on the substrate, and connected to the gate electrode, a gate insulating layer formed on the gate pad, a first protective layer formed on the gate insulating layer, a second protective layer formed on the first protective layer, a first metal layer formed on the second protective layer, and connected to the gate pad through a first contact hole which exposes the gate pad, a third protective layer formed on the first metal layer and the second protective layer, and a second metal layer formed on the third protective layer, and connected to the first metal layer through a second contact hole which exposes the first metal layer.

Owner:LG DISPLAY CO LTD

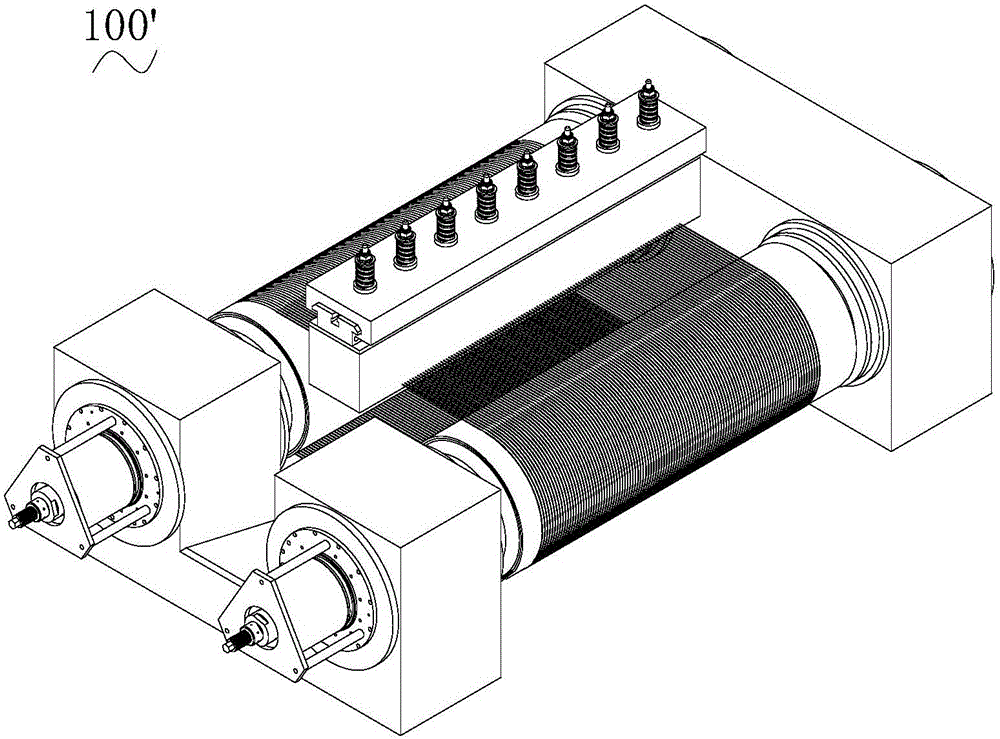

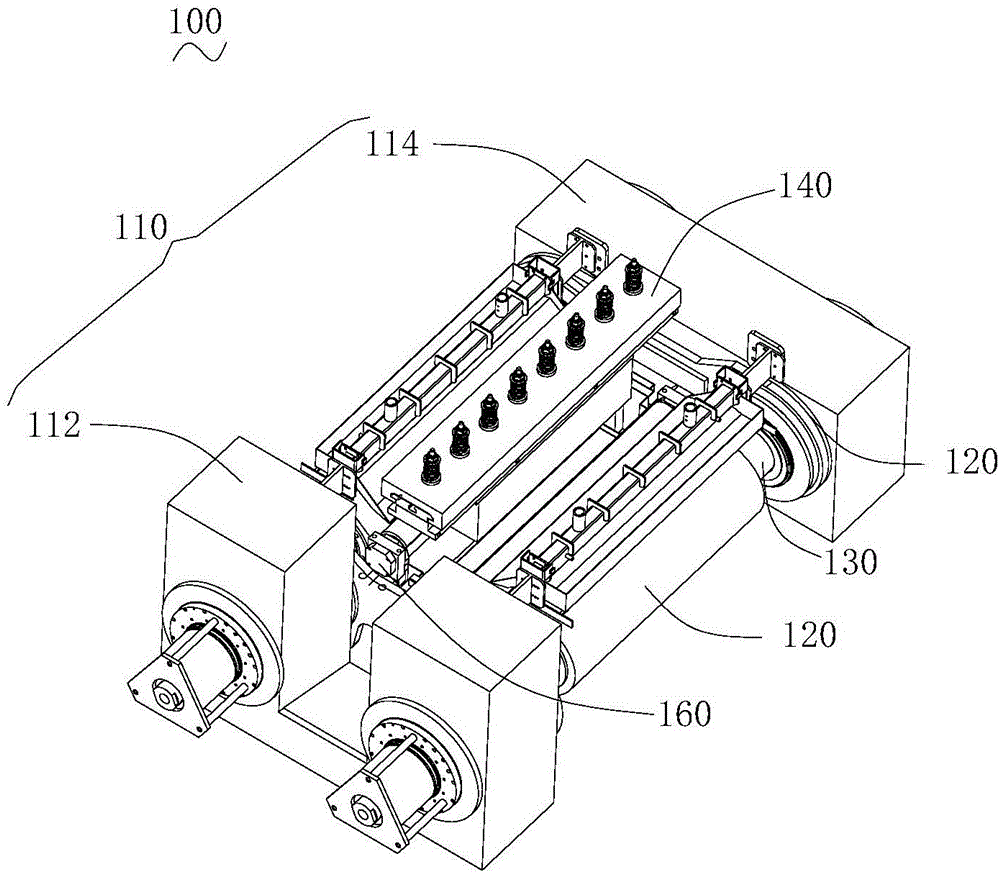

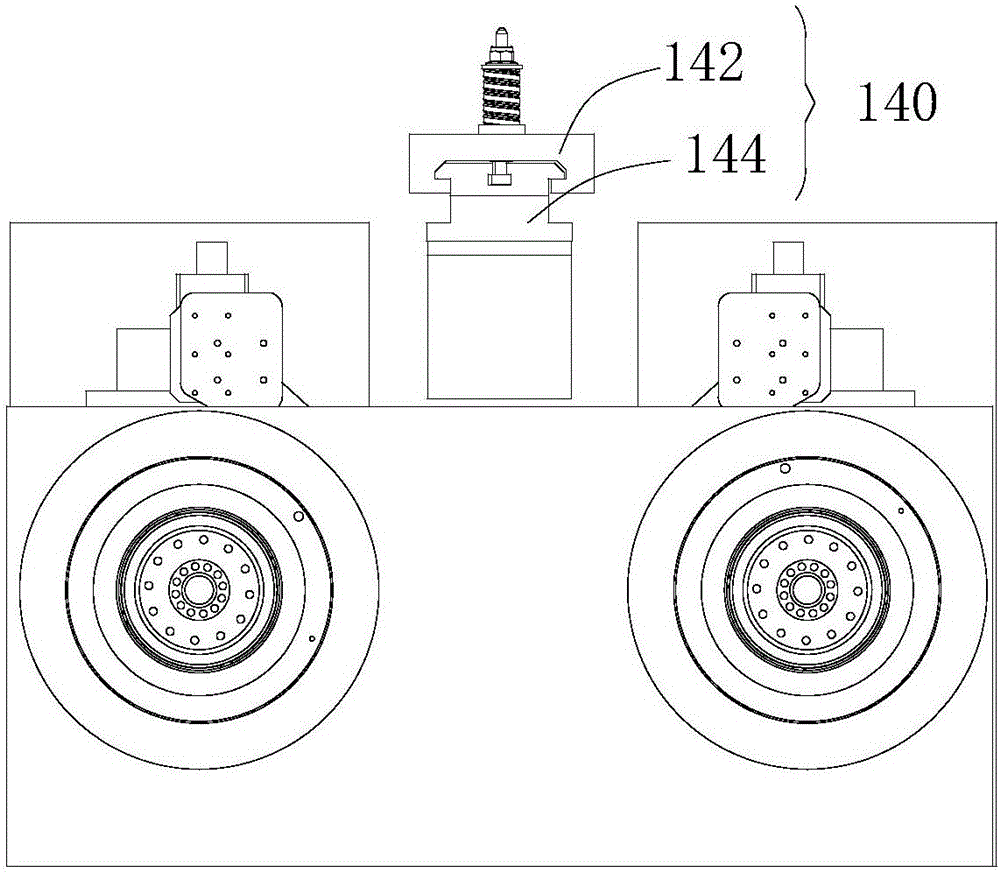

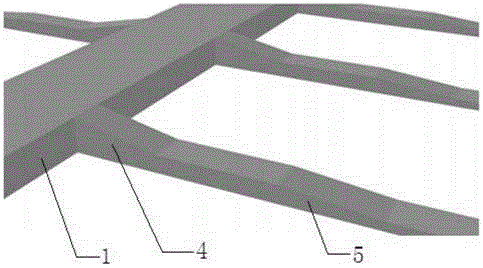

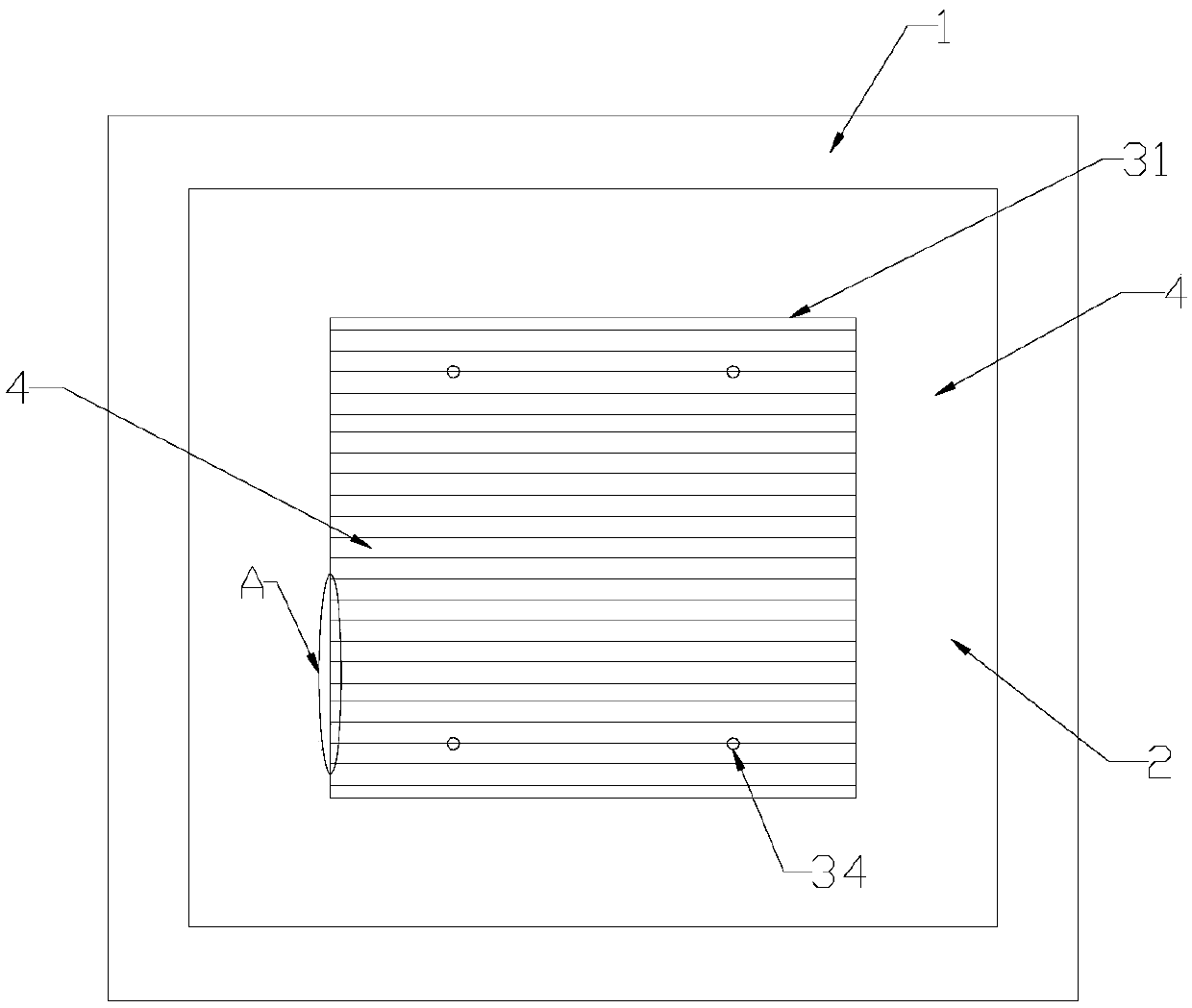

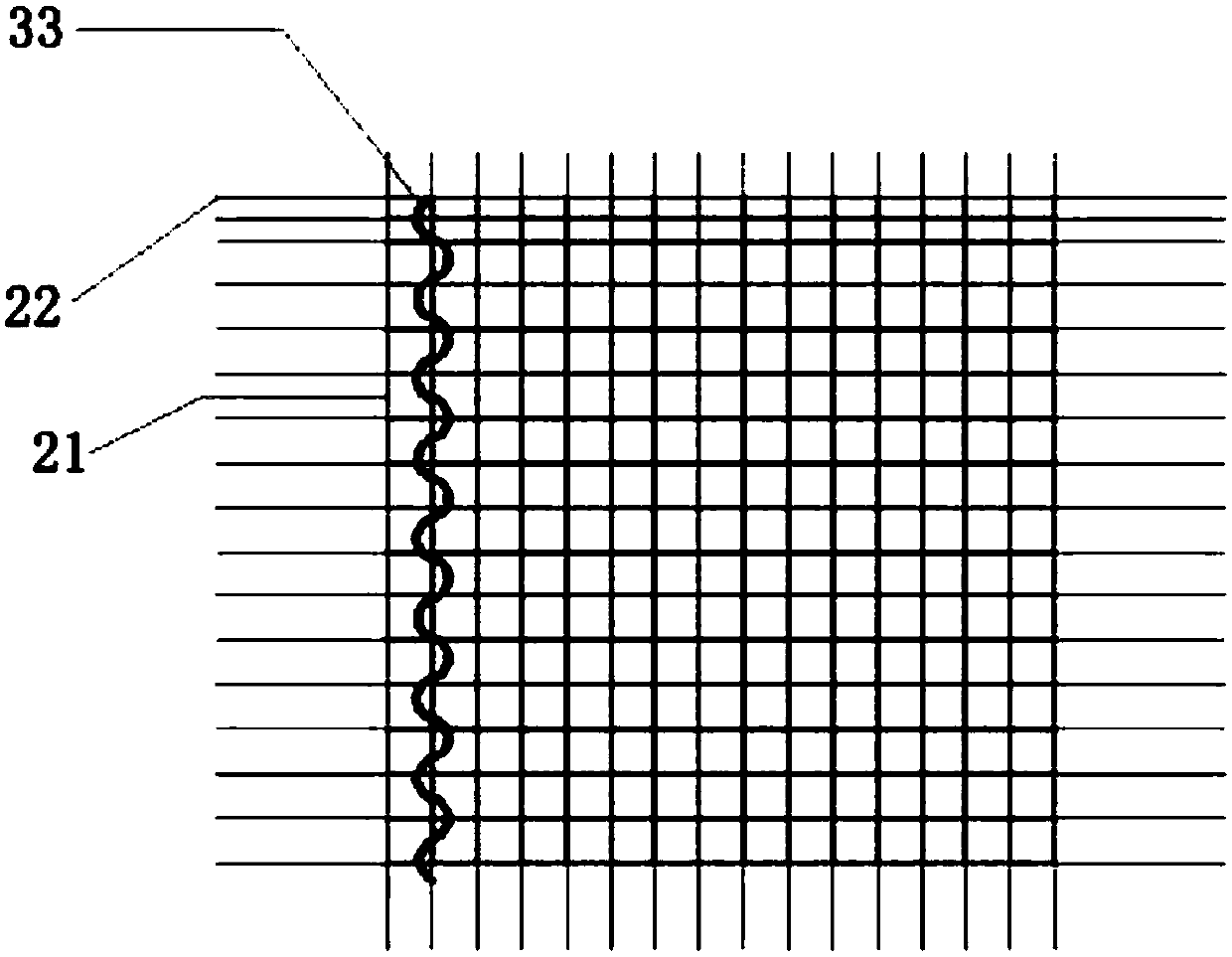

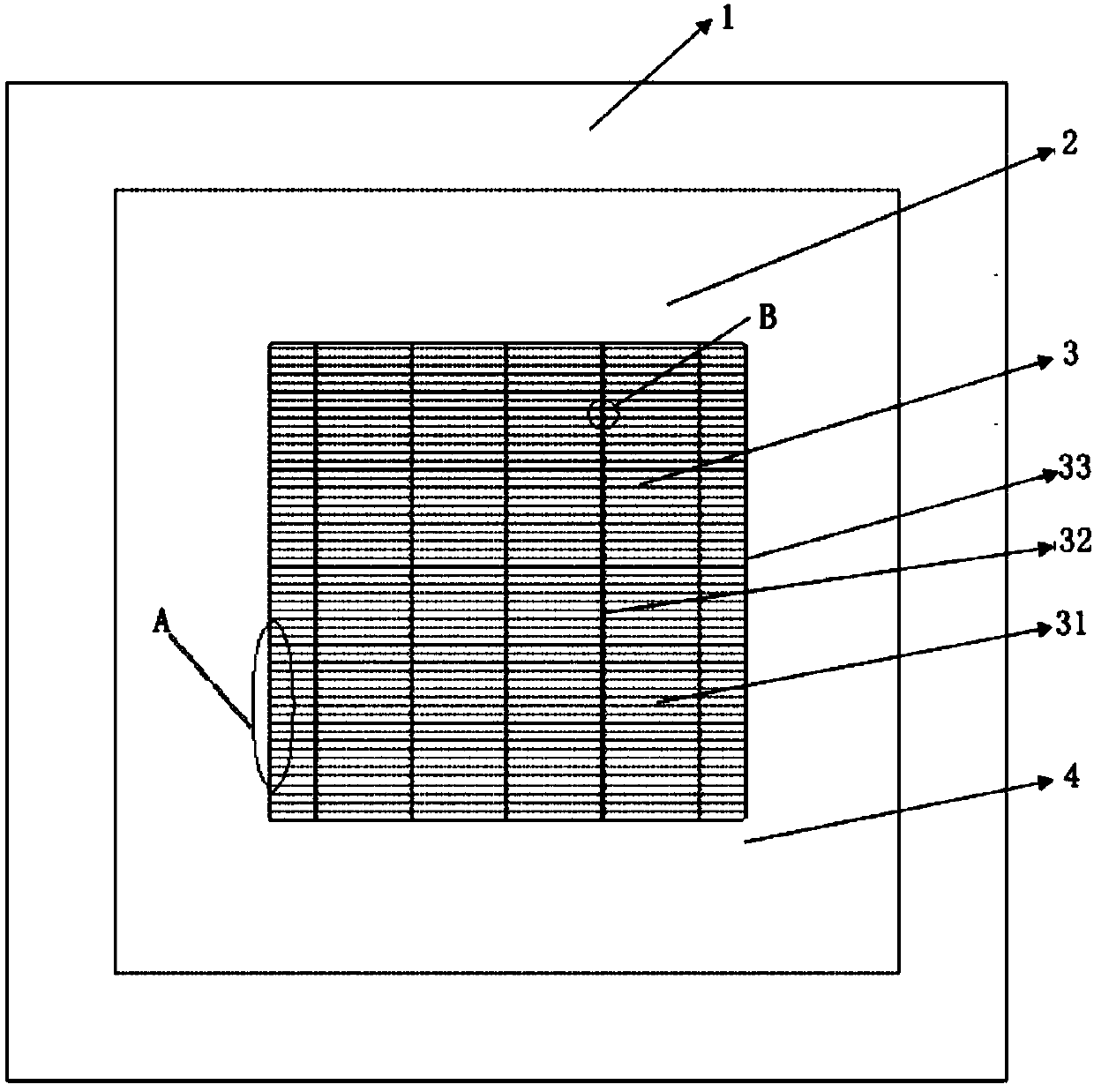

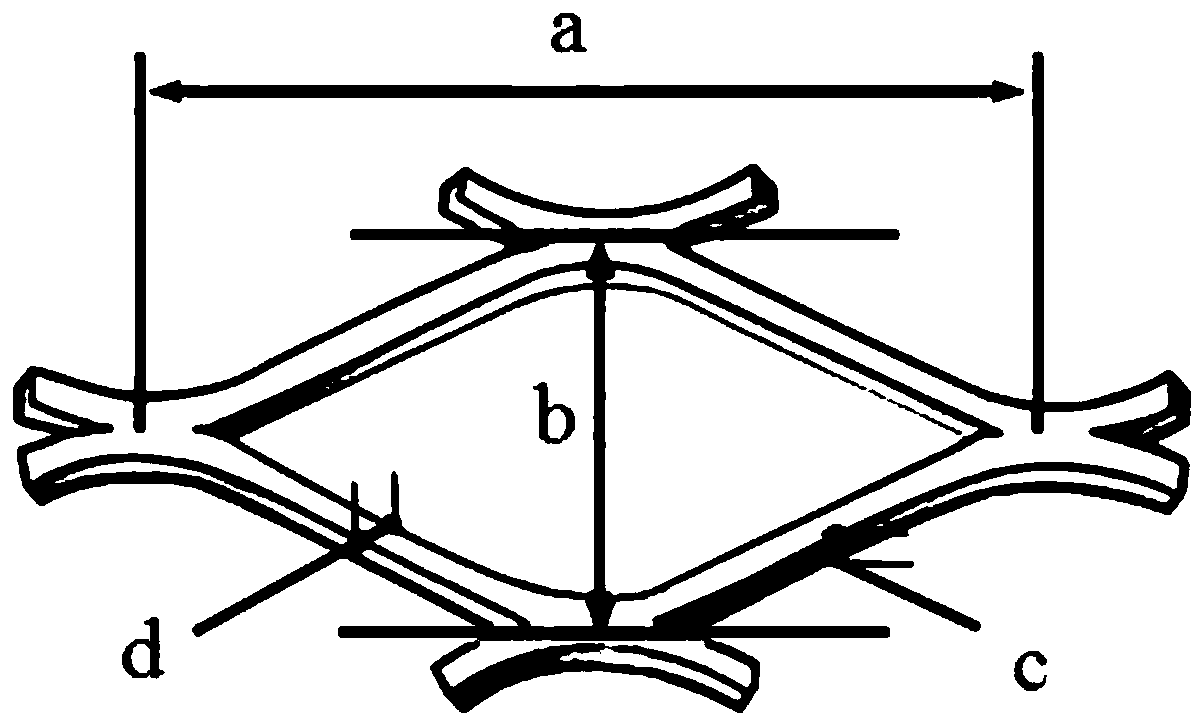

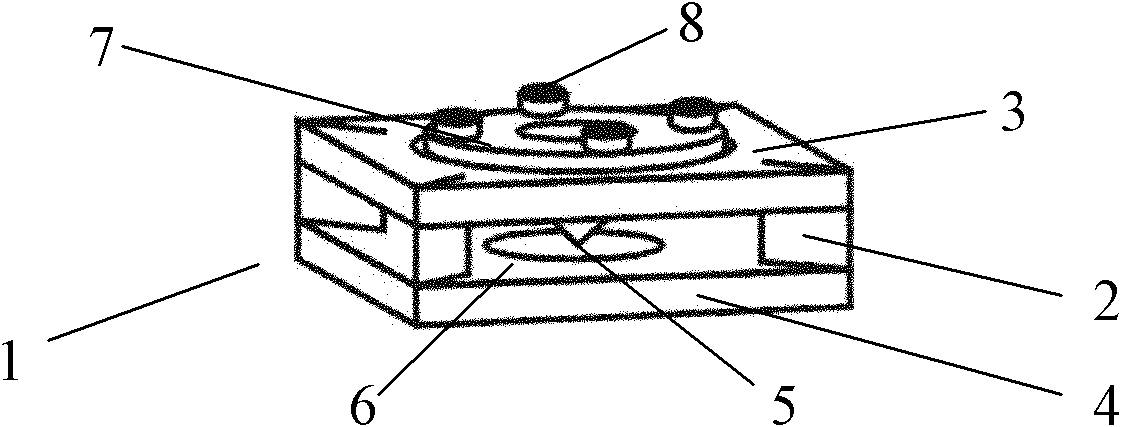

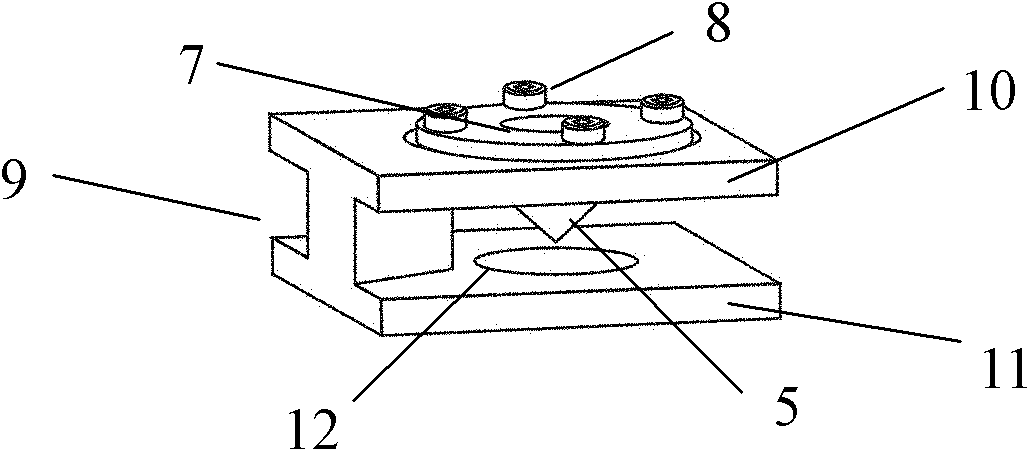

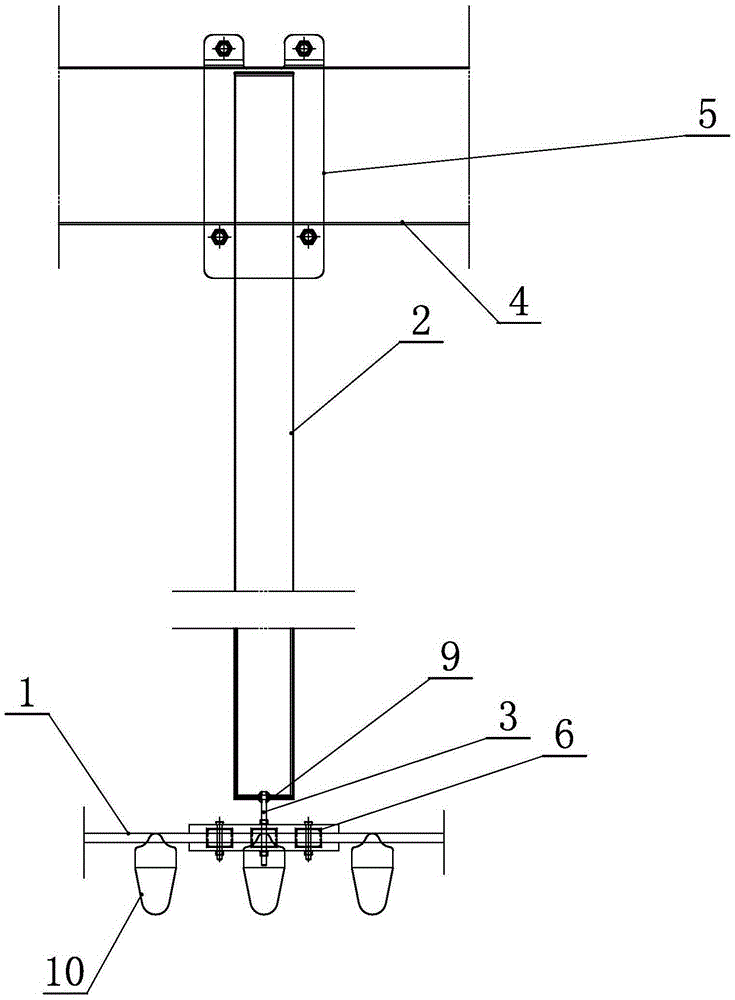

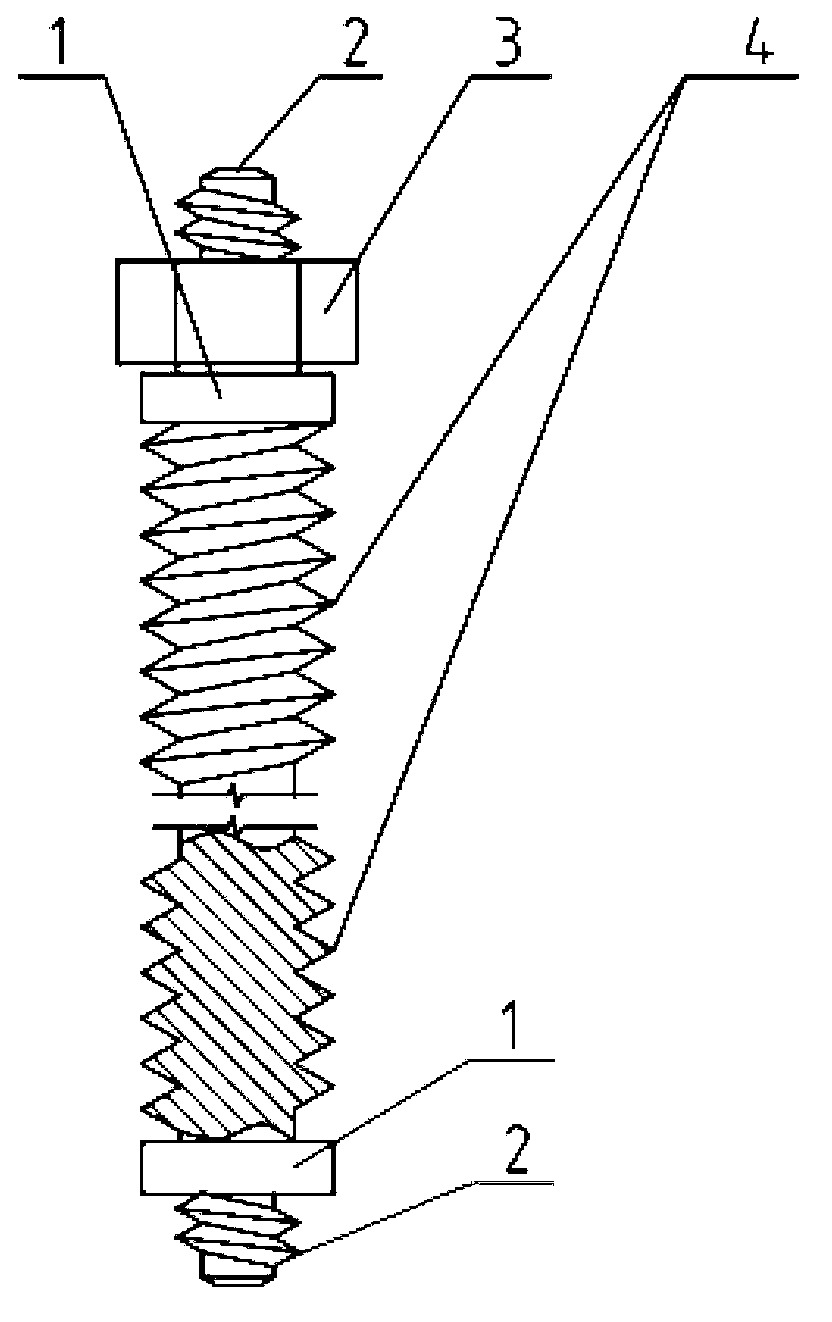

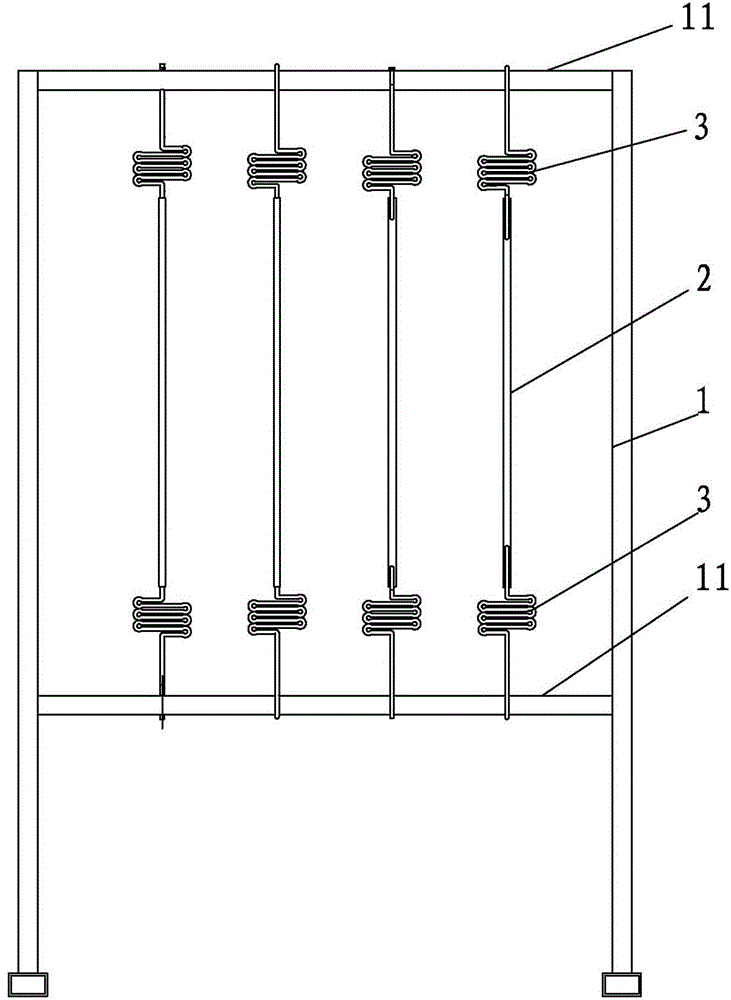

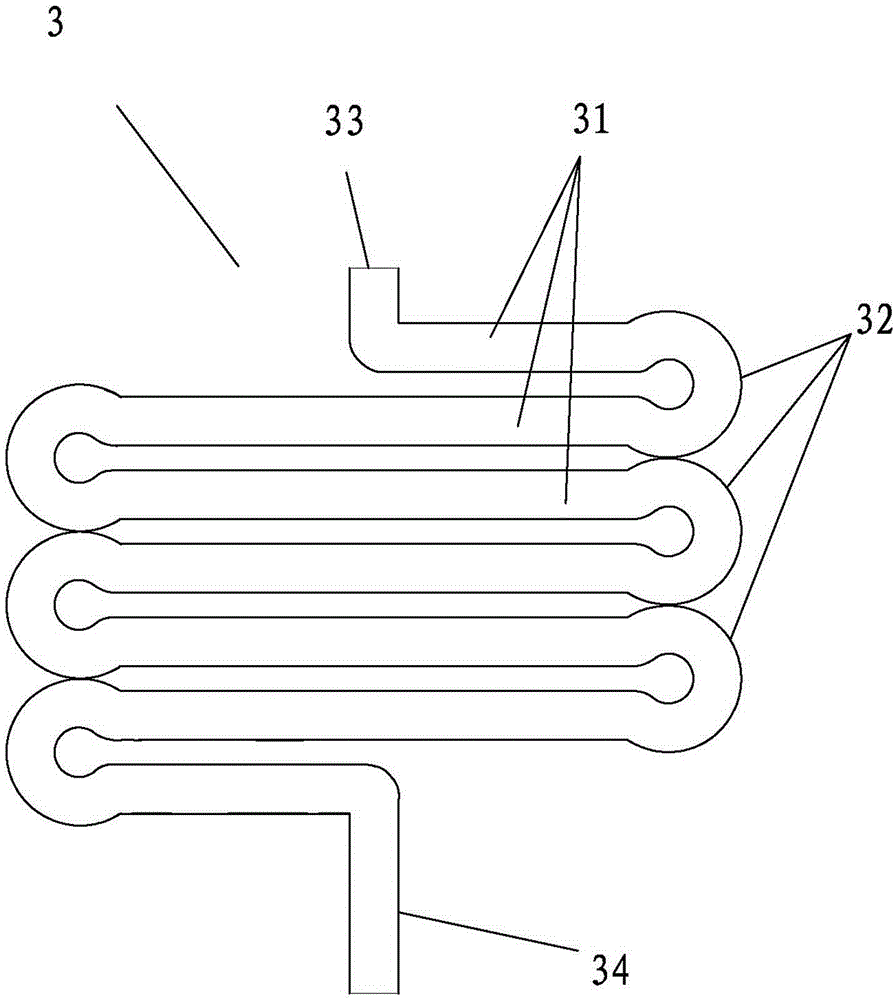

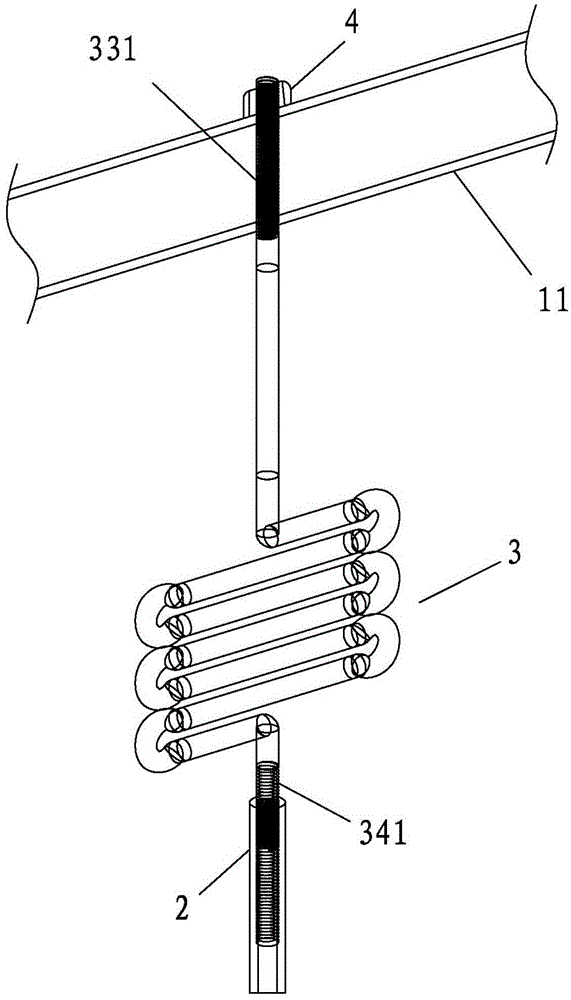

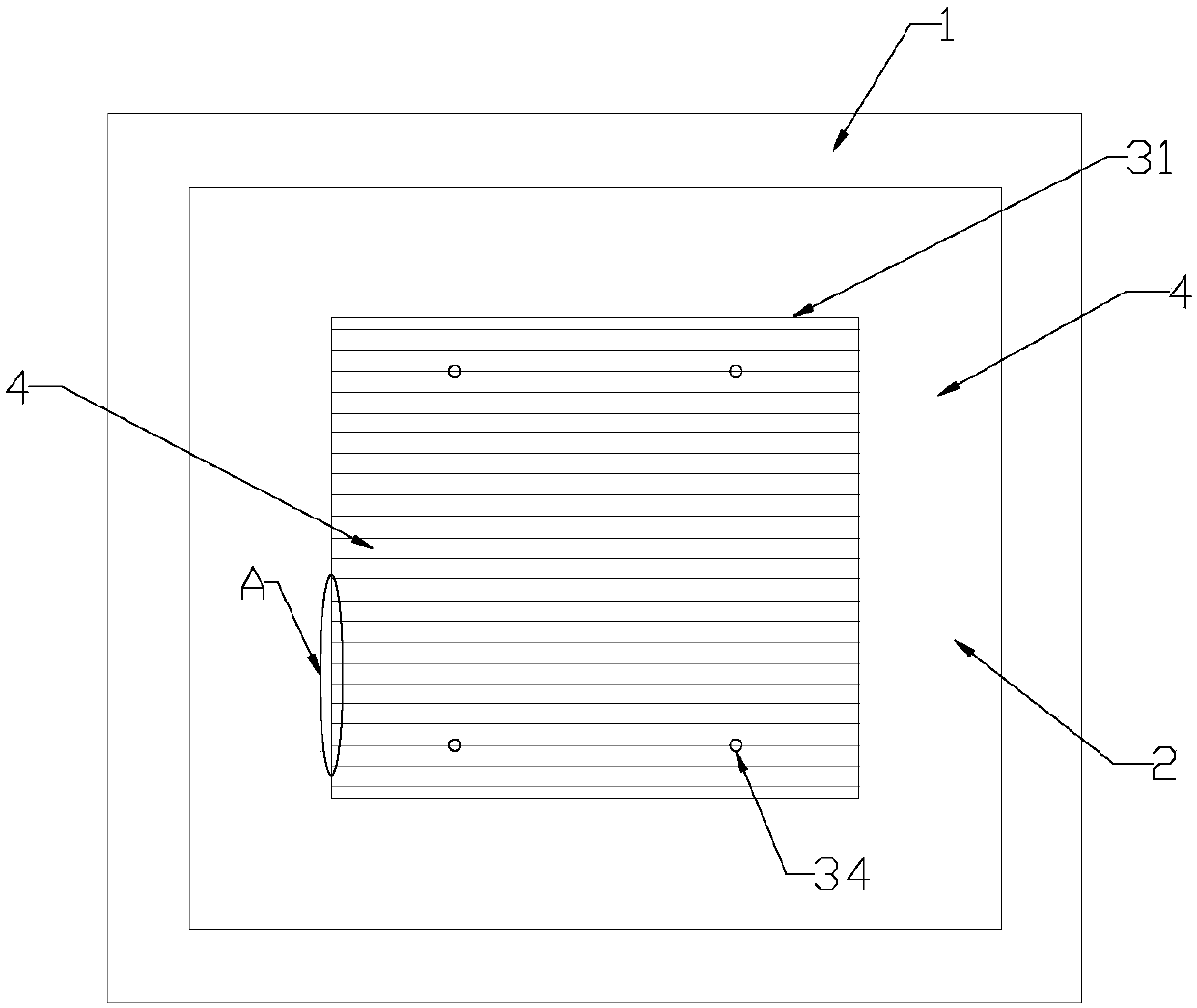

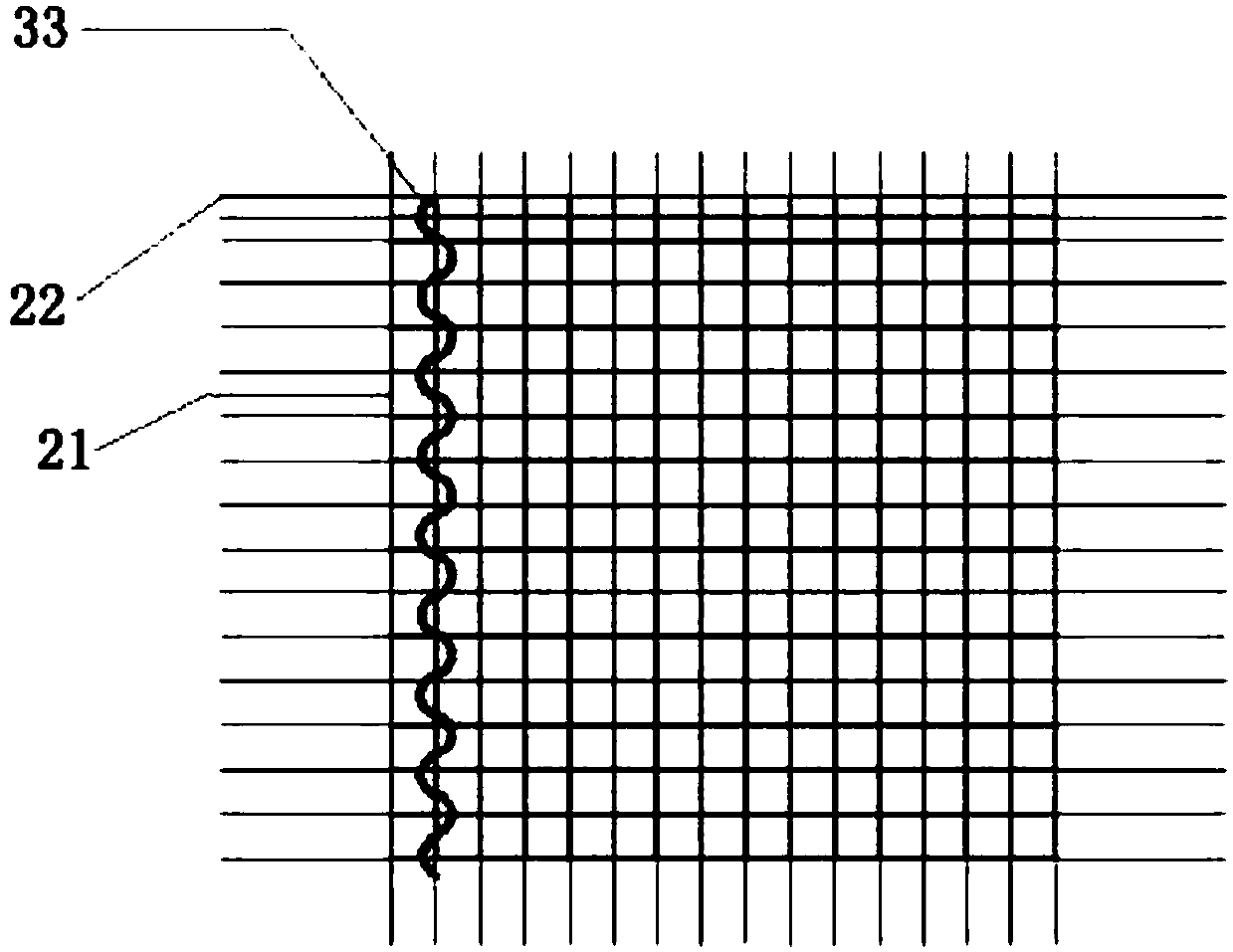

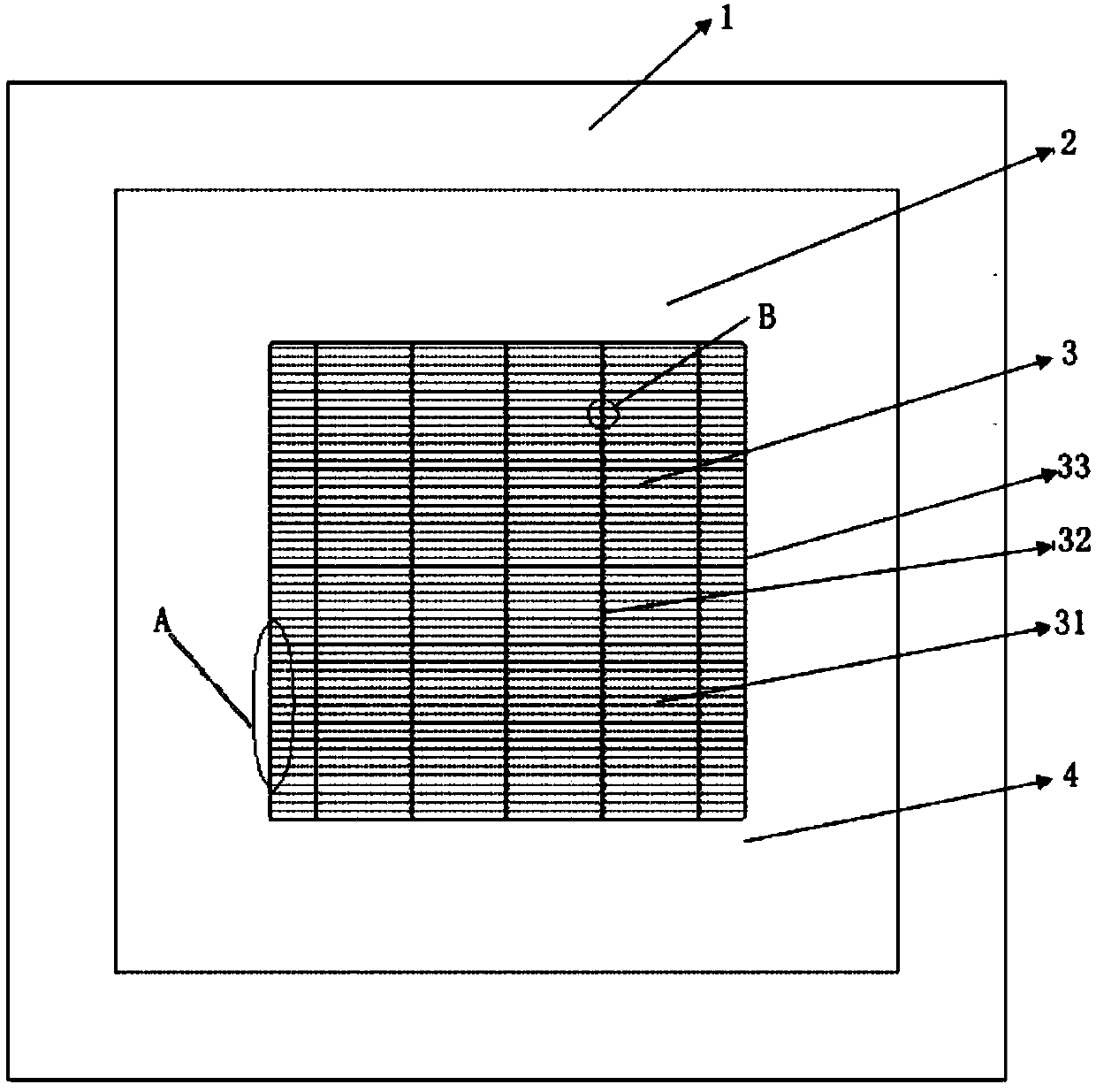

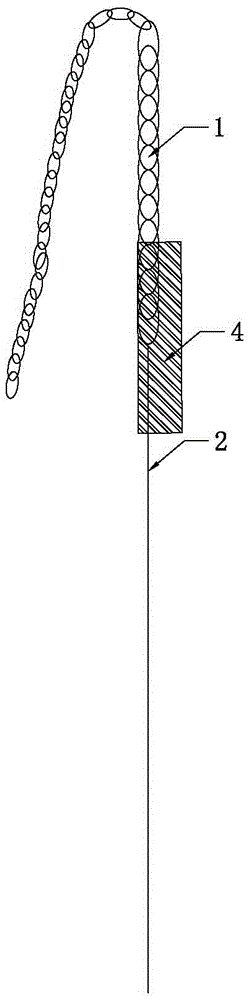

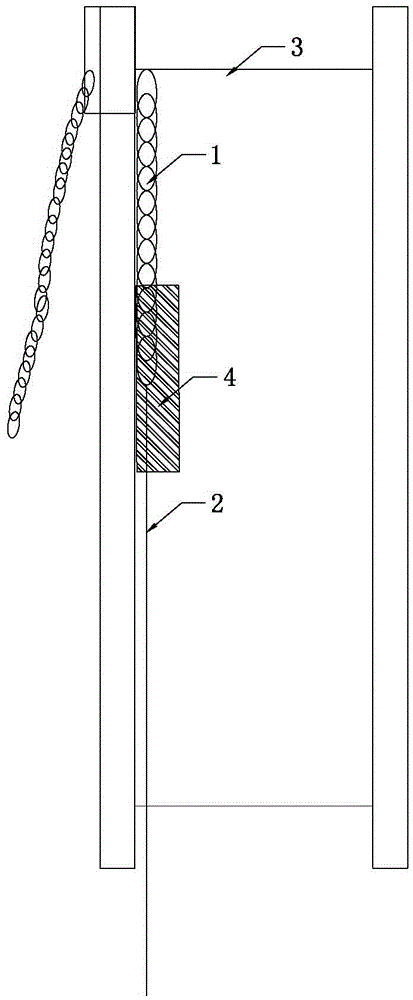

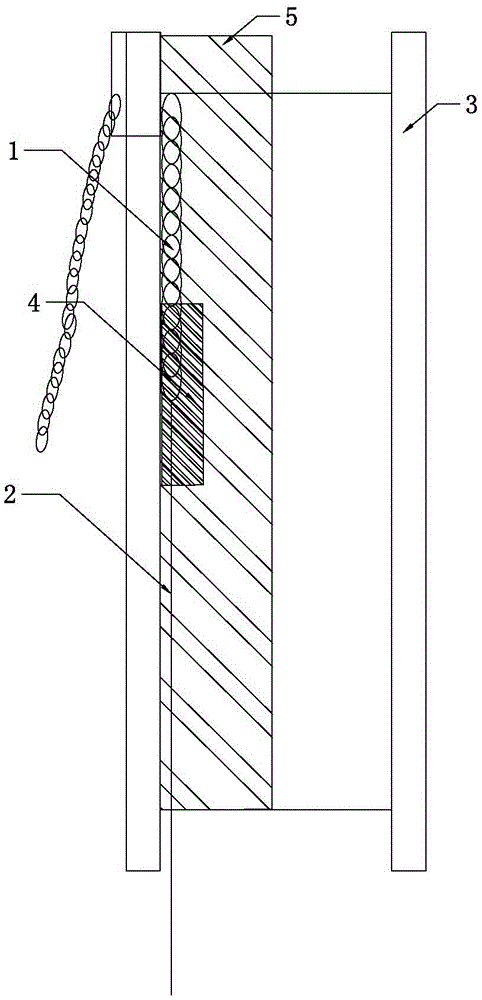

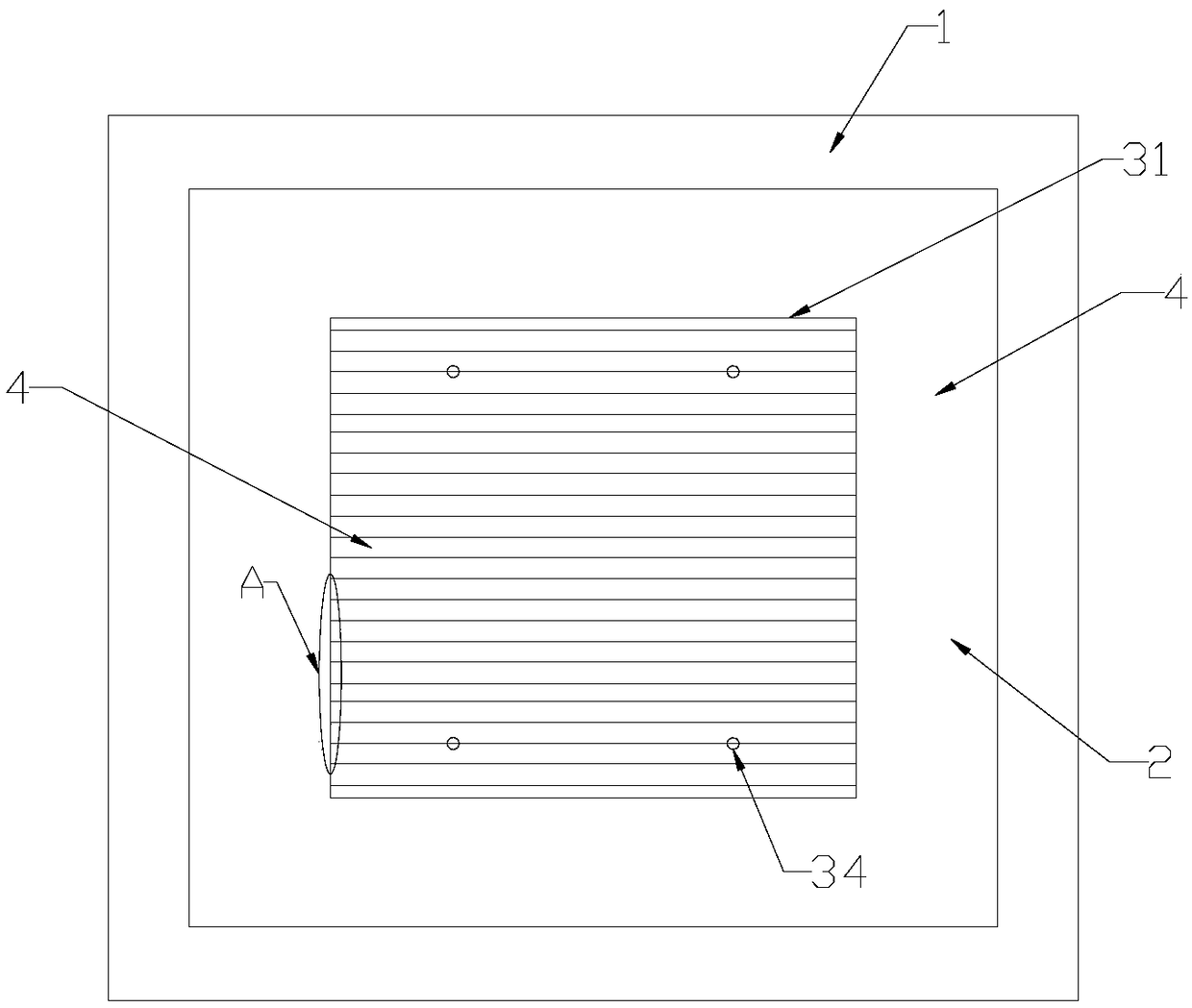

Multi-wire sawing machine for silicon wafers

InactiveCN106426585AShorten the fulcrum distanceReduce the amplitudeGrinding machine componentsWorking accessoriesEngineeringPatch cable

The invention relates to a multi-wire sawing machine for silicon wafers. The multi-wire sawing machine comprises a rack, a guide wheel assembly fixed to the rack, a crystal supporting assembly, a wire net and a vibration damper, wherein the guide wheel assembly comprises a plurality of sets of guide wheels which are arranged in pairs; the crystal supporting assembly is located on the outer side of the part between at least one pair of guiding wheels; the net wire surrounds the multiple sets of guiding wheels which are arranged in pairs; the vibration damper is located between the guiding wheels and comprises a roller structure and a supporting structure used for supporting the roller structure, the roller structure is connected with the wire net in an abutted manner, and the supporting structure is fixedly connected with the rack; and the crystal supporting assembly and the vibration damper are installed on the two sides of the wire net. According to the multi-wire sawing machine for the silicon wafers, on one hand, the fulcrum distance of the wire net is shortened, the amplitude of the wire net is reduced, and therefore the probability that the wire net jumps out of a guide wheel groove is reduced, and the wire breaking problem caused by wire jumping is solved; and on the other hand, the wire arch of the wire net is correspondingly reduced, the sawing efficiency of the wire net can be improved, and therefore the production efficiency is improved, the probability of edge breaking caused when the silicon wafers go out of a cutter edge is reduced, and the yield of products is improved.

Owner:GCL POLY ENERGY HLDG

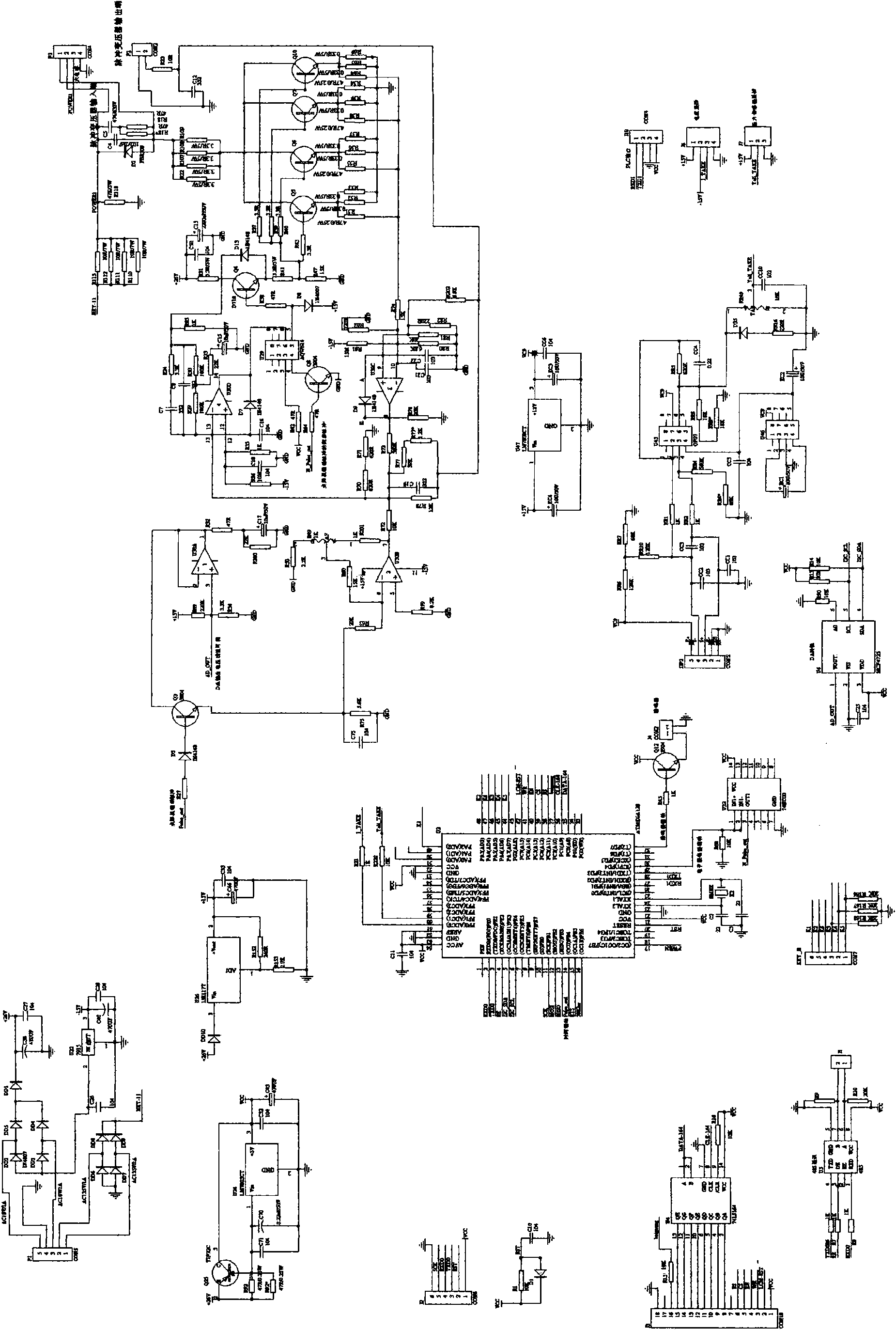

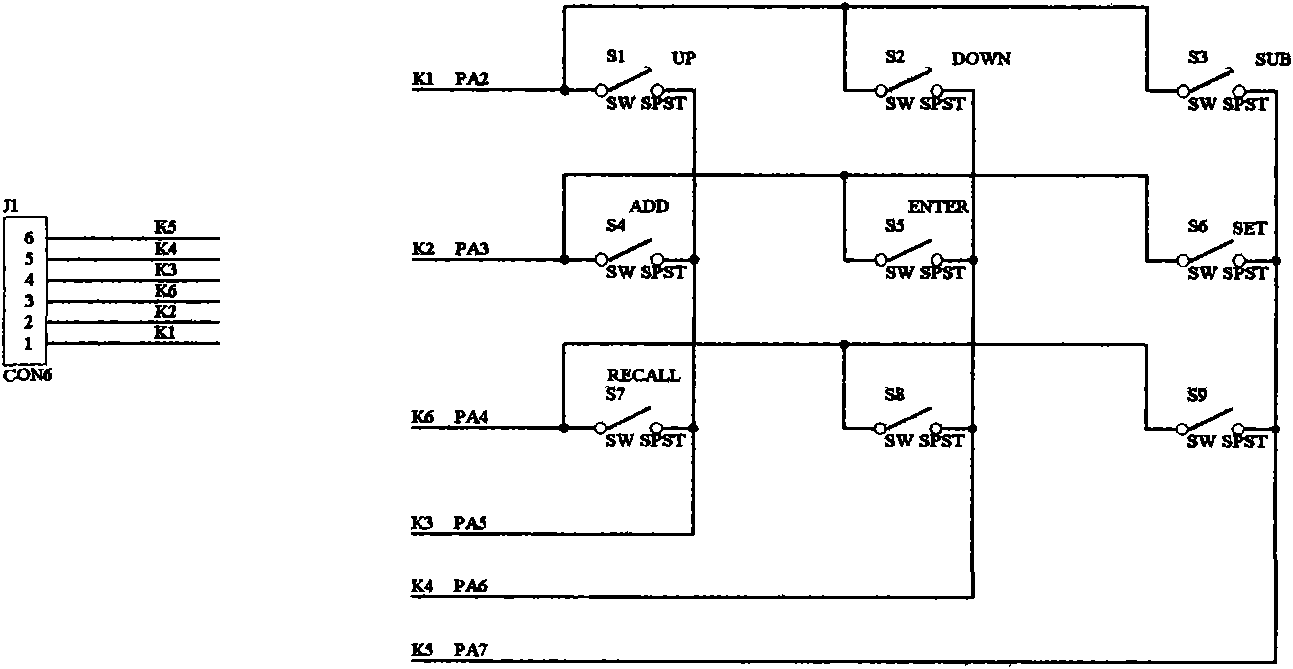

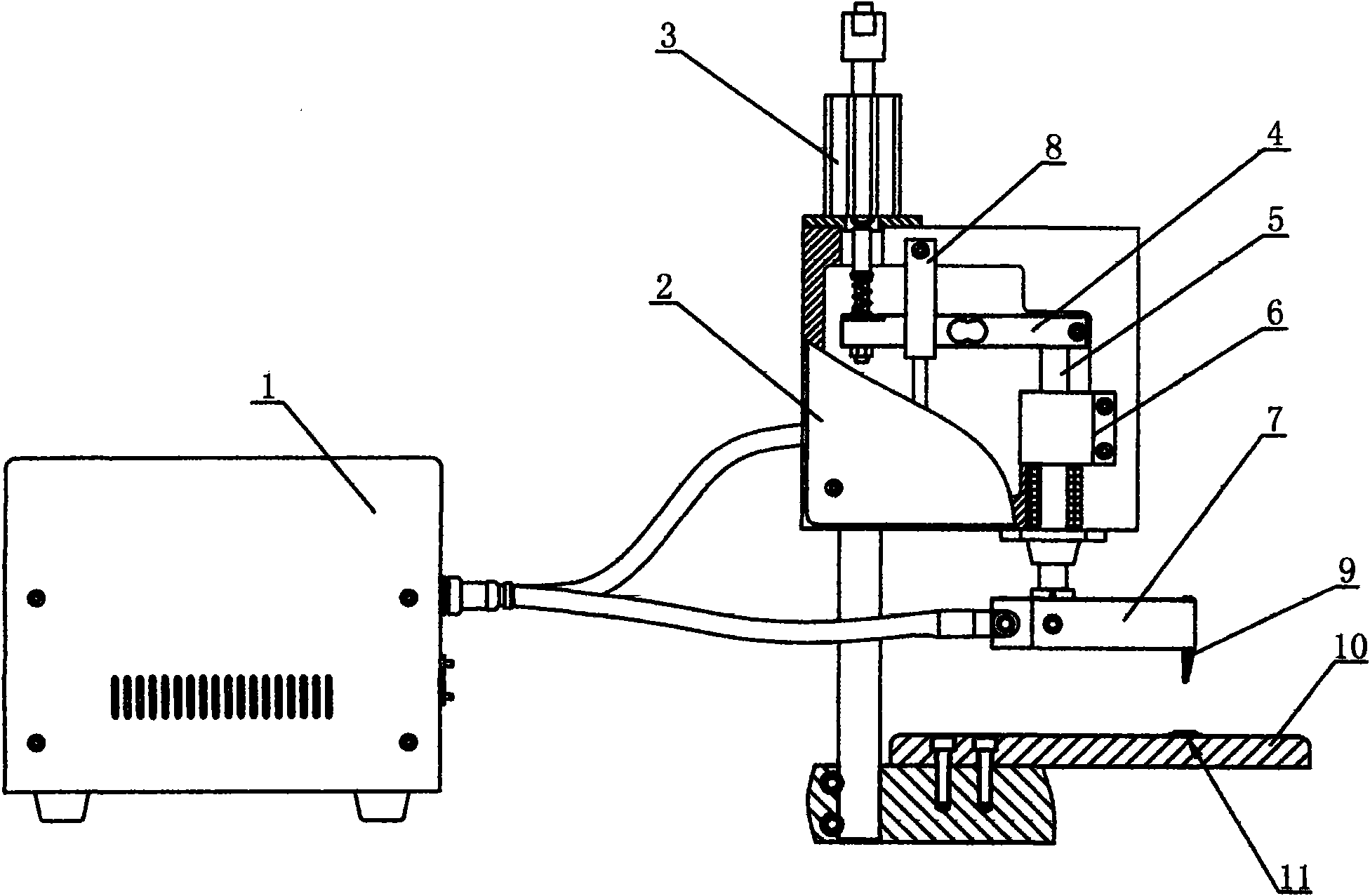

Intelligent electronic spot welder and spot welding method thereof

ActiveCN101890565ASolve only spot weldingSolve quality problemsElectrode featuresWelding monitoring devicesMicrocontrollerAviation

The invention relates to an intelligent electronic spot welder and a spot welding method thereof. The spot welder comprises a host machine provided with a singlechip and a welding database, and a machine head; the machine head comprises a driving device, a front shaft and a welding head; and a detector and a braking device are respectively connected with the front shaft. The detector transmits the acquired data to the singlechip so as to make the welding head automatically perform welding action through the host machine. The intelligent electronic spot welding method comprises the following steps of: (1) establishing a welding parameter database; (2) measuring the diameter of an enameled wire to be processed; (3) outputting a paint-removing pulse for paint removal; (4) outputting a welding pulse for welding; (5) and measuring or performing repair welding. The Intelligent electronic spot welder has real-time detection and repair welding function, namely synchronously welds and detects welding spot quality, and detects a welding spot once the welding spot is welded to form a closed-loop automatic detection system, solves the problems of no detection of the welding spot quality afterwelding, and insufficient welding and wire break during spot welding of the conventional spot welder, and improves the reliability of processing electronic components in the industries of communication, aviation and aerospace and advanced medical equipment.

Owner:珠海精易焊接设备有限公司

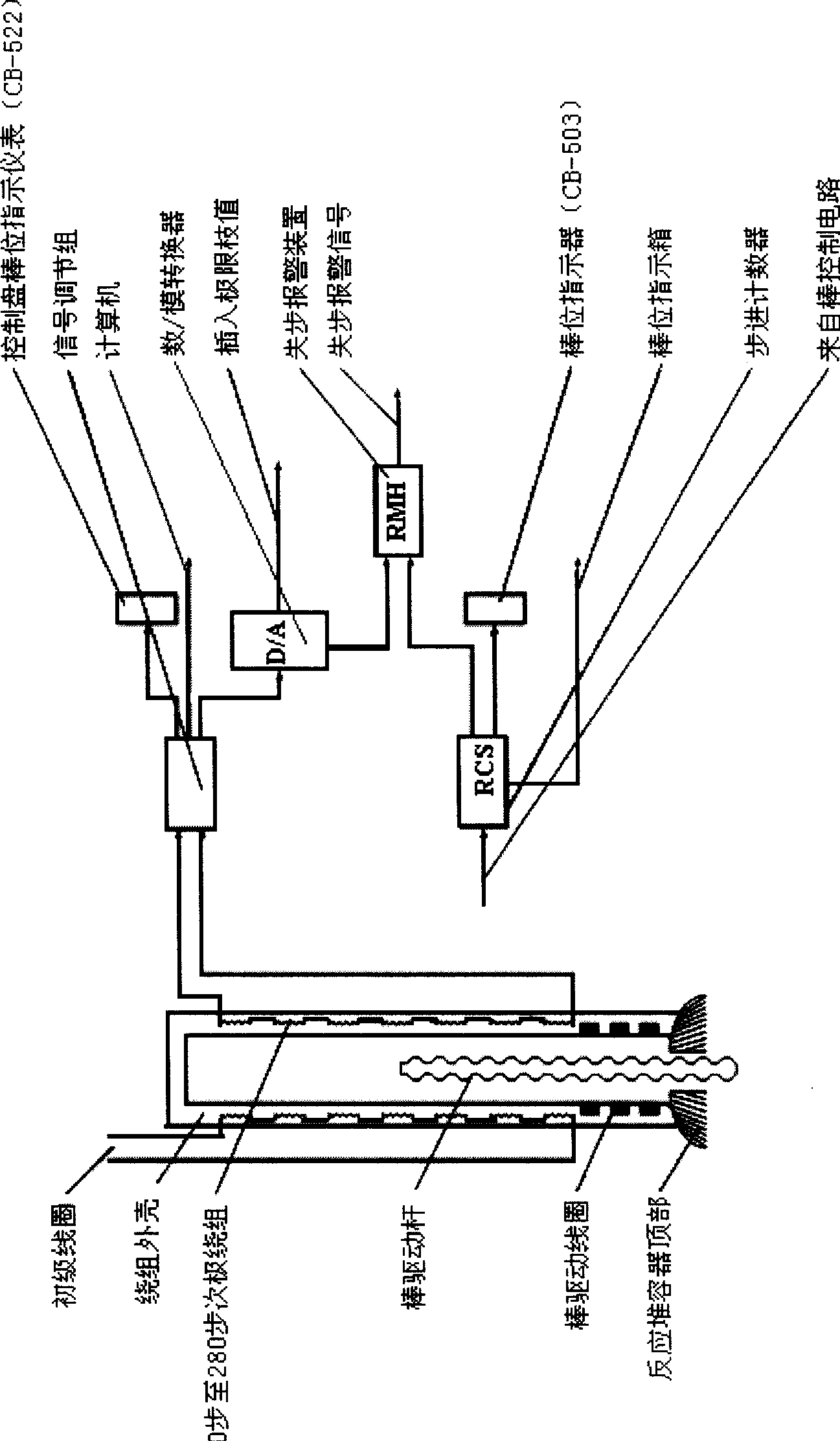

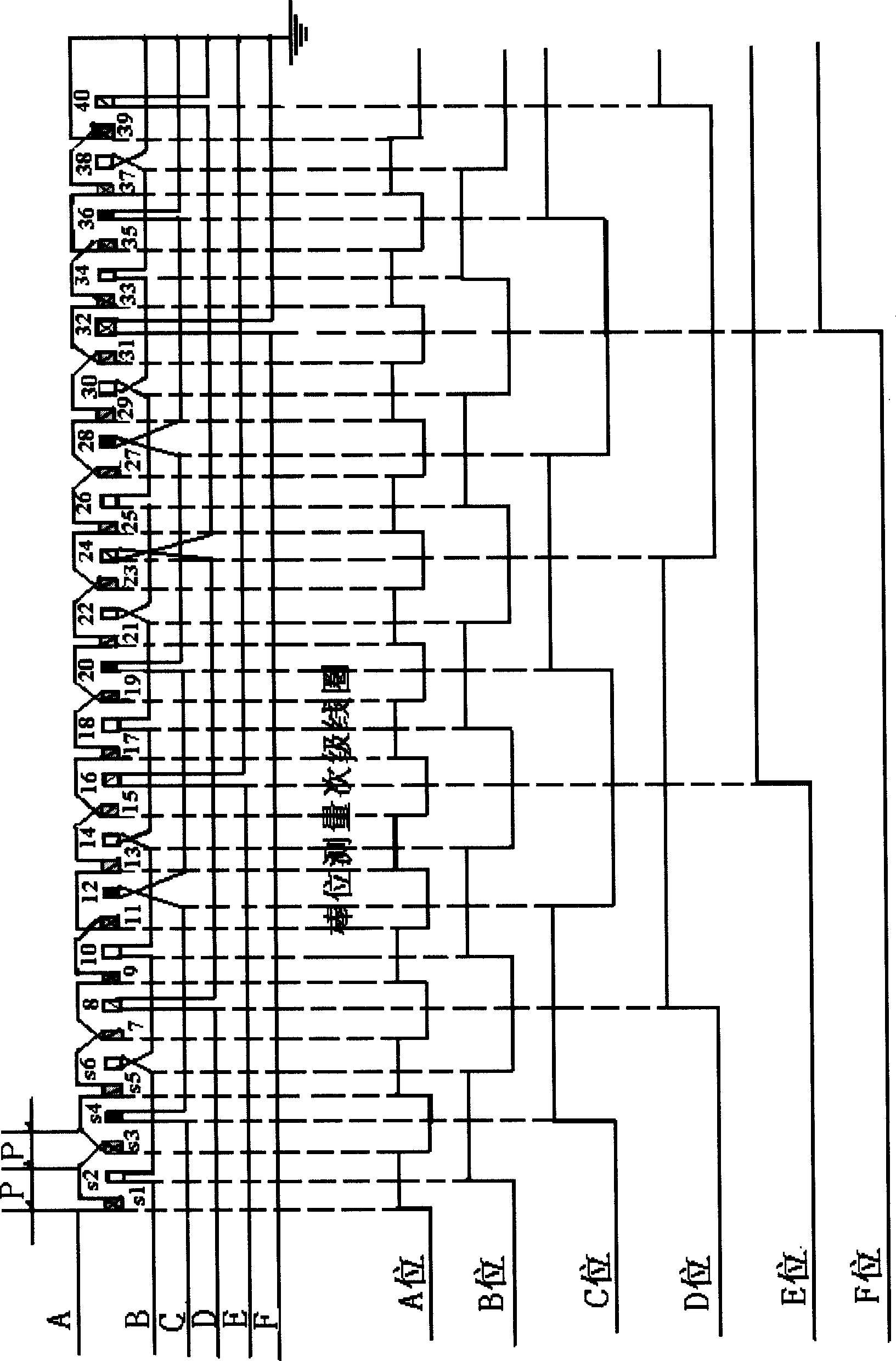

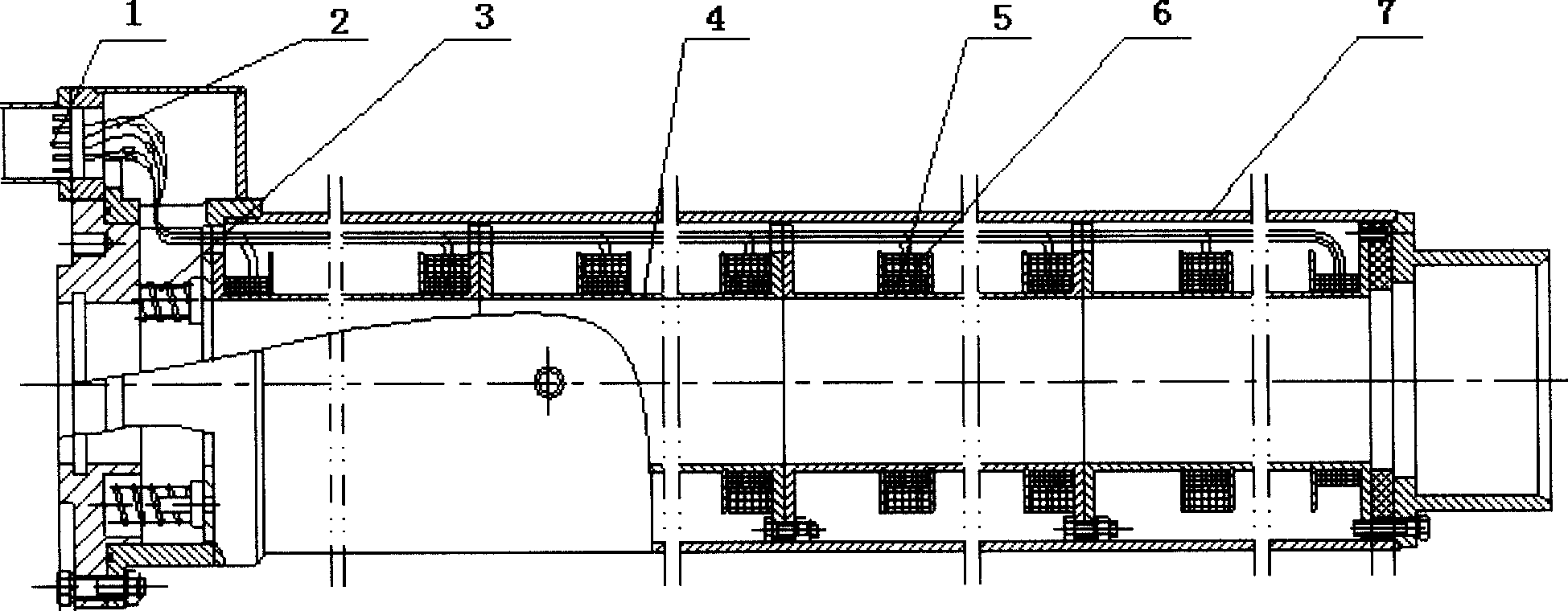

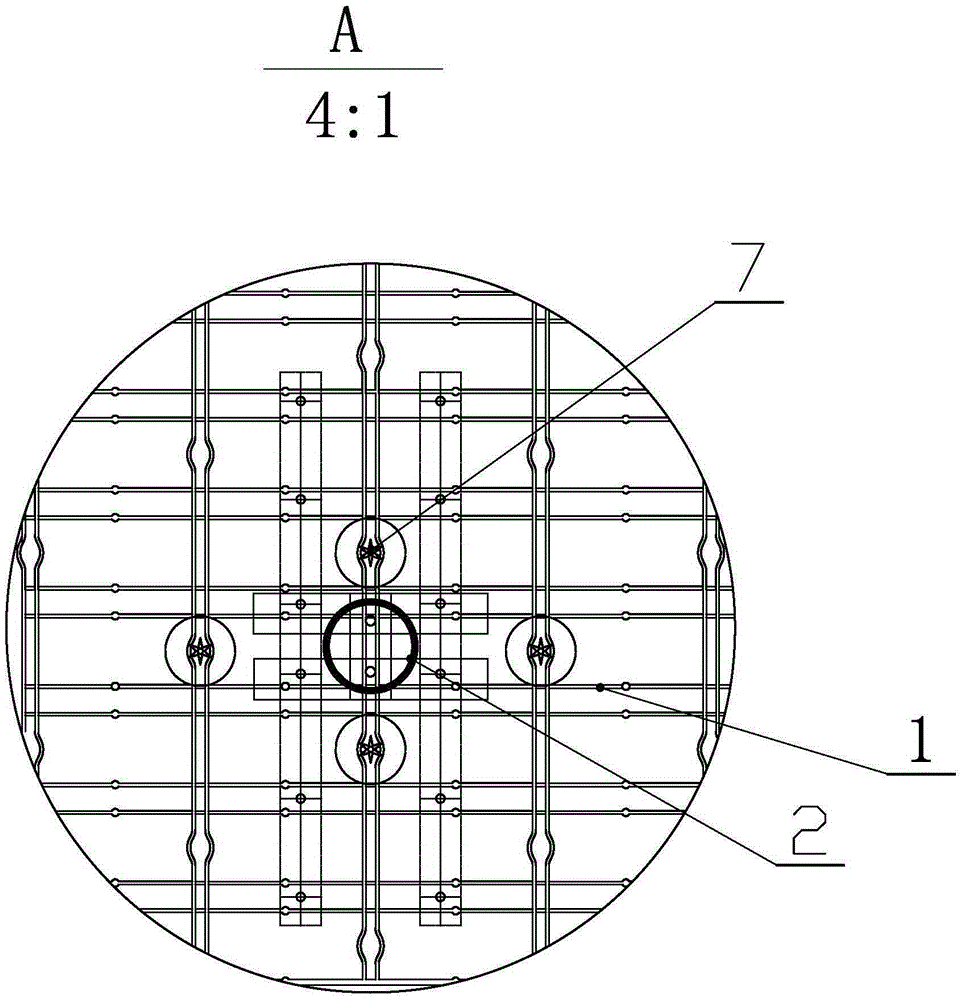

Method for integrally winding pressurized-water reactor nuclear power plant winding connectionless point stick location probe coil

ActiveCN101465201ASolve disconnectionSolve insulation problemsNuclear energy generationNuclear monitoringNuclear powerPressurized water reactor

The invention belongs to the field of pressurized water reactor nuclear power plants and particularly discloses a pressurized water reactor nuclear power plant control rod position detector coil overall winding method, which comprises the following steps: (1) using an NC winding machine wind out the primary windings at one time; (2) setting the start-up circle number and winding speed of the NC winding machine, and winding out each phase secondary winding at one time in accordance with the A-B-F-E-C-D or A-B-E-F-C-D phase order; (3) adopting the entire dual-vacuum impregnating process to impregnate the entire rod position detector coil winding; (4), welding the coil winding with the coil lengthening leading wire through resistance melting welding; (5),and carrying out dual-vacuum impregnating on the connecting points between the coil winding and the coil lengthening leading wire after an organosilicon casing is sleeved. The method solves the problems of insulation reduction and coil breaking of the rod position detector in the high-temperature and high-radiation environment and enables the service life of the detector to reach 40 years.

Owner:QINSHAN NUCLEAR POWER +1

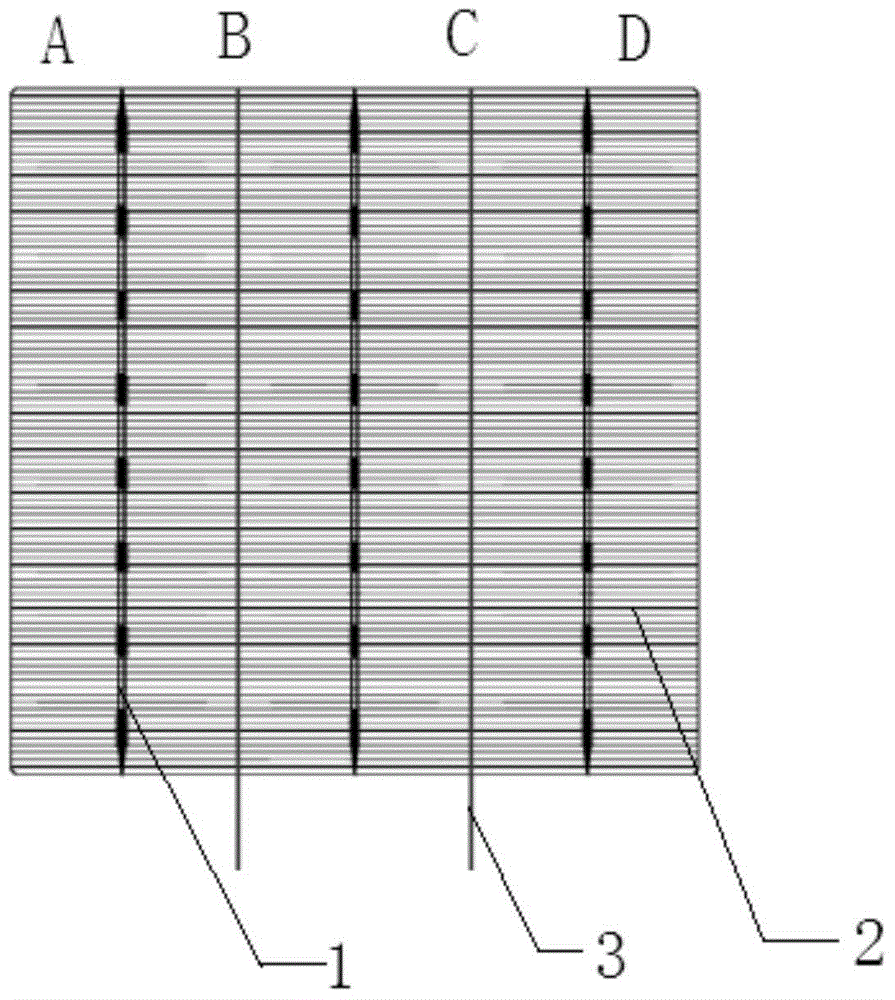

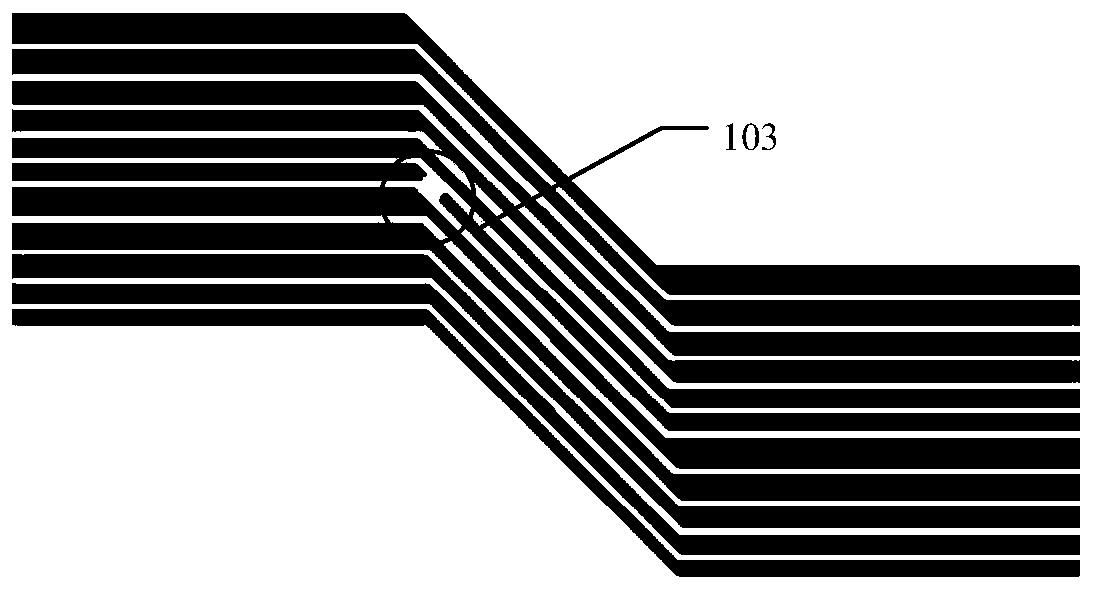

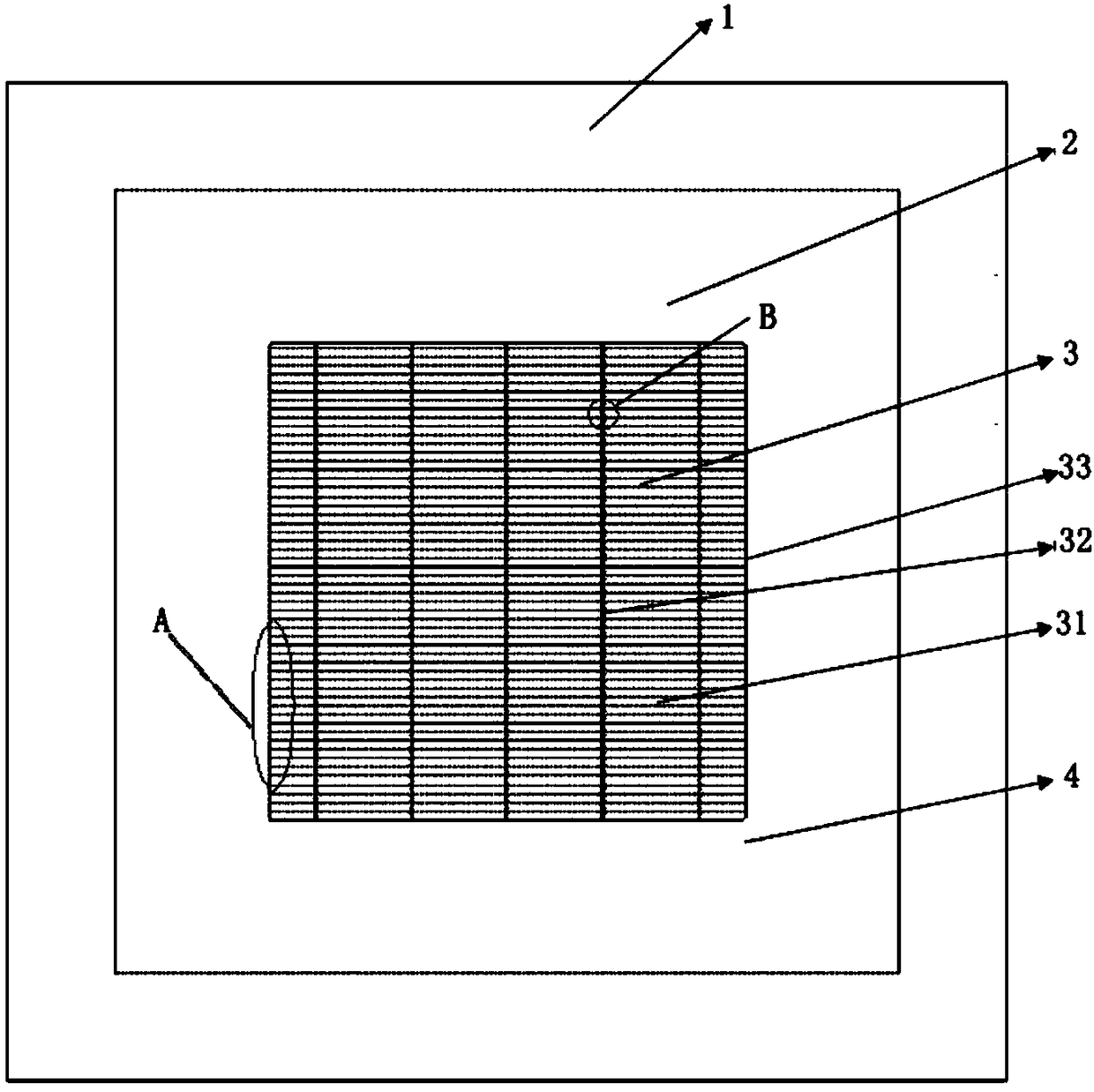

Positive electrode grid line of solar cell, solar cell and manufacturing method of solar cell

InactiveCN104638032AIncrease light receiving areaImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationEngineeringSolar cell

The invention discloses a positive electrode grid line of a solar cell, comprising at least three main grid lines and a plurality of auxiliary grid lines; the main grid lines are arranged in a mutual parallel manner; the auxiliary grid lines are parallel to each other and perpendicular to the main grid lines; every two adjacent central axial lines between the two main grid lines are main grid central lines; the widths of the auxiliary grid lines are distributed in a stepped reduction manner from the main grid lines to the main grid central lines or edges of a positive electrode of the cell. According to the positive electrode grid line of the solar cell, the solar cell and the manufacturing method of the solar cell, the broken lines due to jump cut problem are avoided and the problem of EL (electroluminescence) broken lines is solved; meanwhile, the light interception area of the cell can further be increased, the current conduction capability is enhanced and the conversion efficiency of the cell is improved.

Owner:CHINA SUNERGY CO LTD

Liquid crystal display device and repairing method thereof

The invention discloses a liquid crystal display device and a repairing method thereof. The liquid crystal display device comprises an array substrate which is provided with a plurality of data wires, a plurality of scanning lines, a plurality of public electrode wires and a plurality of pixel electrodes, wherein a plurality of display units are spaced on the data wires, the public electrode wires and the scanning lines; two public electrode wires are arranged at a crossed area of each public electrode wire and each data wire; and the two public electrode wires are combined into one public electrode wire at the crossed area of each public electrode wire and each pixel electrode. With the design, the data wires can be repaired under the conditions of short circuit of the data wires and superposition of a short-circuit area and the scanning lines, and the problem that the scanning lines are broken after the data wires are repaired is solved.

Owner:SHANGHAI SVA LIQUID CRYSTAL DISPLAY

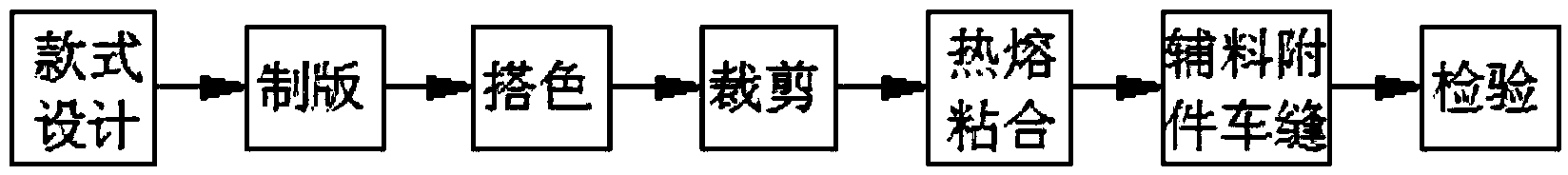

Method for manufacturing seamlessly spliced leather wear

InactiveCN104223548AQuality improvementSolve pinholesClothes making applicancesAdhesion processEngineering

The invention discloses a method for manufacturing seamlessly spliced leather wear. The method comprises the following steps of 1) designing a product, namely designing a fashion style according to characteristics of a seamless splicing process; 2) producing a sample, namely producing the sample in a given size according to a fashion style design; 3) marking off, namely matching required leather according to luster and texture of leather; 4) tailoring, namely tailoring the leather after marking off according to the provided sample; 5) performing hot melt adhesion, namely setting parameters such as temperature, speed and pressure of hot melting equipment according to a requirement, and performing hot melt adhesion operation on the leather according to an operational process; 6) sewing accessories and attachments, namely sewing the accessories and the attachments such as zippers, decoration and buttons, or installing the accessories and the attachments on the spliced leather wear by using other equipment; 7) inspecting, namely performing quality inspection on the spliced finished product. According to the method, parts of the wear are spliced through a hot melt adhesion process, the firmness of the leather wear is improved, potential safety hazards brought by needle breakage and glue water are avoided, and the leather wear is more tidy and smooth in overall appearance.

Owner:ZHEJIANG GLM GARMENT

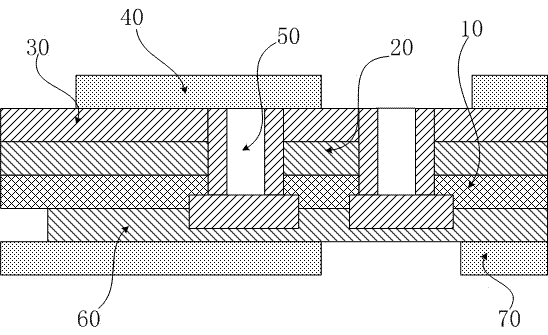

High-density flexible circuit board and manufacturing method thereof

ActiveCN102209438ASolve the problem of wrinkled boardSolve disconnectionPrinted circuit manufactureEtchingHigh density

The invention discloses a manufacturing method of a high-density flexible circuit board. The method comprises the following steps of: attaching a dry film to the surface of a conductive layer after a flexible substrate is cut; exposing and etching; pressing and laminating a covering film; and drilling a blind hole by using laser, depositing copper and plating copper. By using structural design and the manufacturing process, the problems of buckling of the high-density flexible circuit board, and wire break and short circuiting of the high-density flexible circuit board during circuit etching are effectively solved, and the yield of a product can be greatly increased.

Owner:博罗县精汇电子科技有限公司

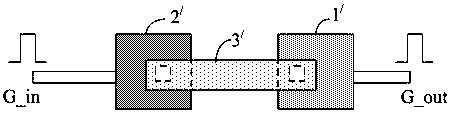

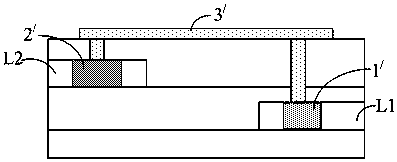

Electrostatic protection circuit structure, display panel and display device

PendingCN107833883AGuaranteed connectivitySolve disconnectionTransistorSolid-state devicesState of artDisplay device

The invention provides an electrostatic protection circuit structure arranged in a display panel. The circuit structure comprises a first through-hole conductive layer and a thin film transistor (TFT). The first through-hole conductive layer is in bridge connection between a second signal line which inputs input signals and a first signal line which outputs output signals, and the second signal line is connected with the first signal line via the first through-hole conductive layer. The gate electrode of the TFT is connected with the drain electrode of the TFT, the gate electrode and / or drainelectrode of the TFT is connected with the second signal line, and the source electrode of the TFT is connected with the first signal line. The invention also provides the display panel and a displaydevice. According to the electrostatic protection circuit structure, display panel and display device, the problems that line break due to too high electrostatic level in the signal input end occurs in the display panel and signals cannot be output normally in the prior art are solved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

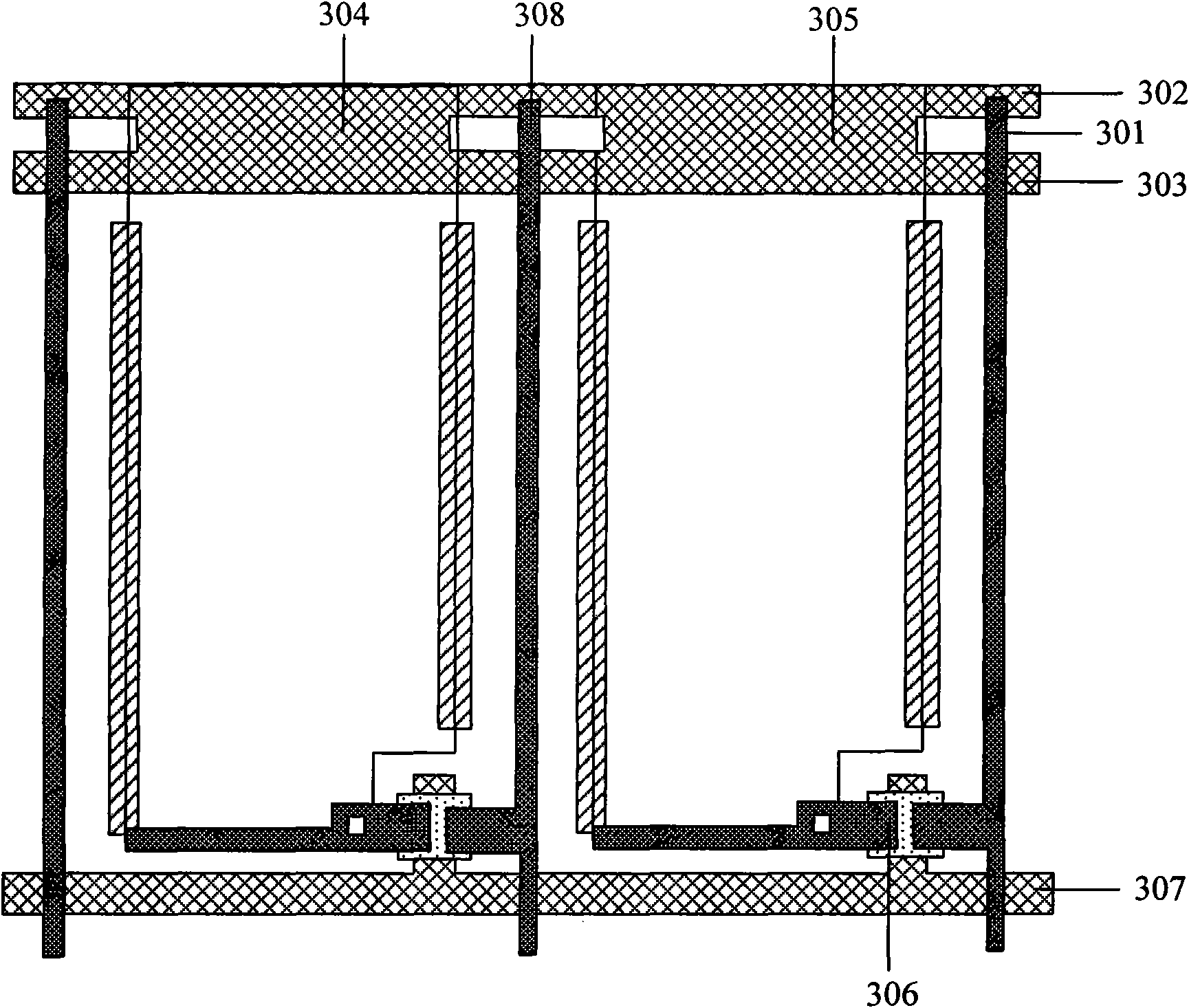

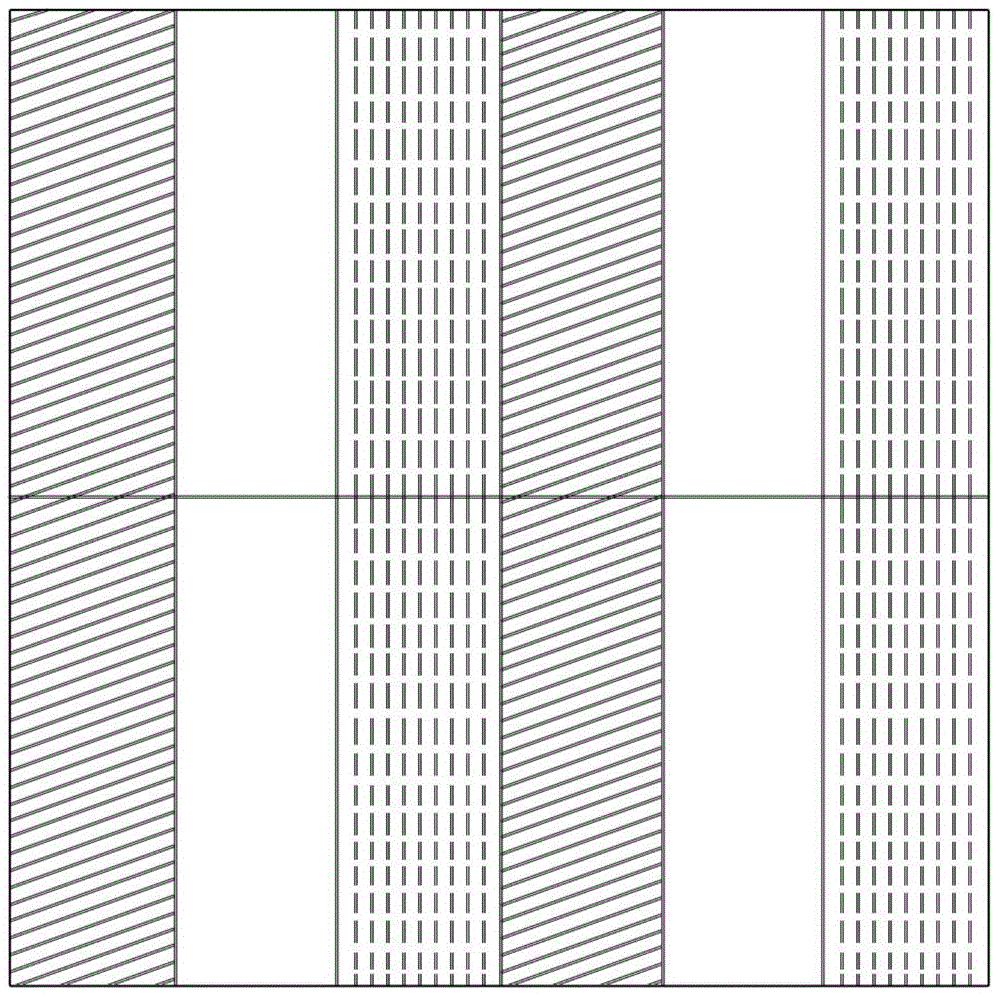

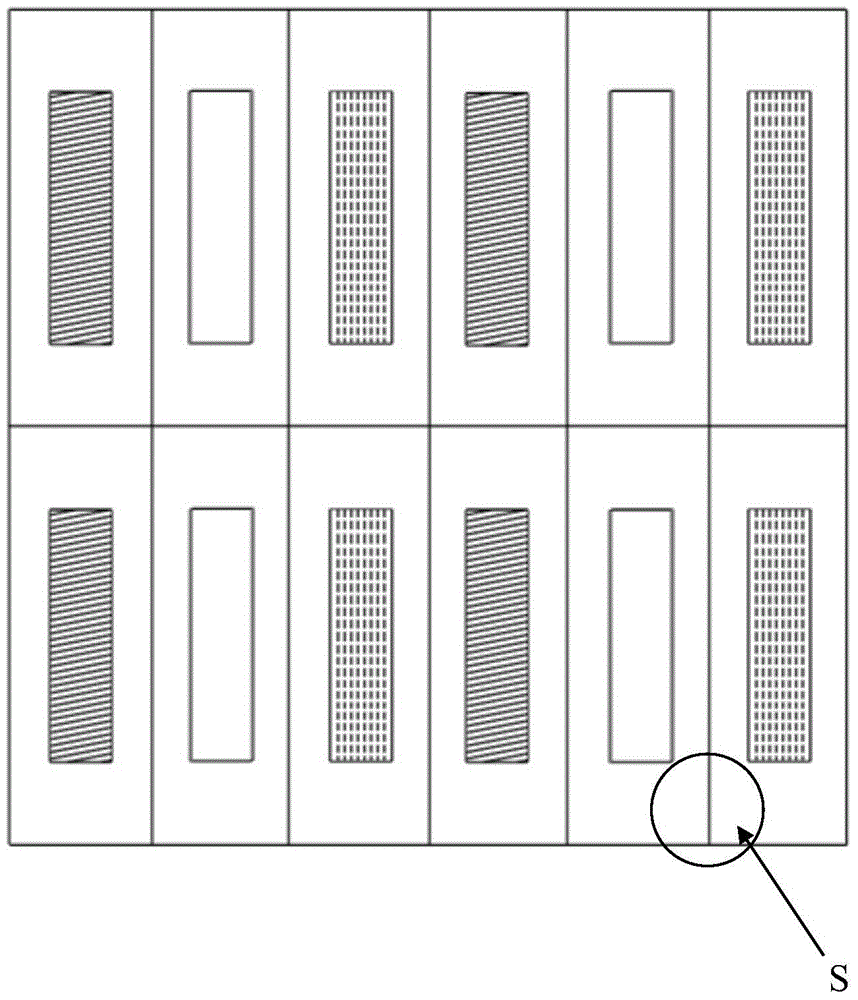

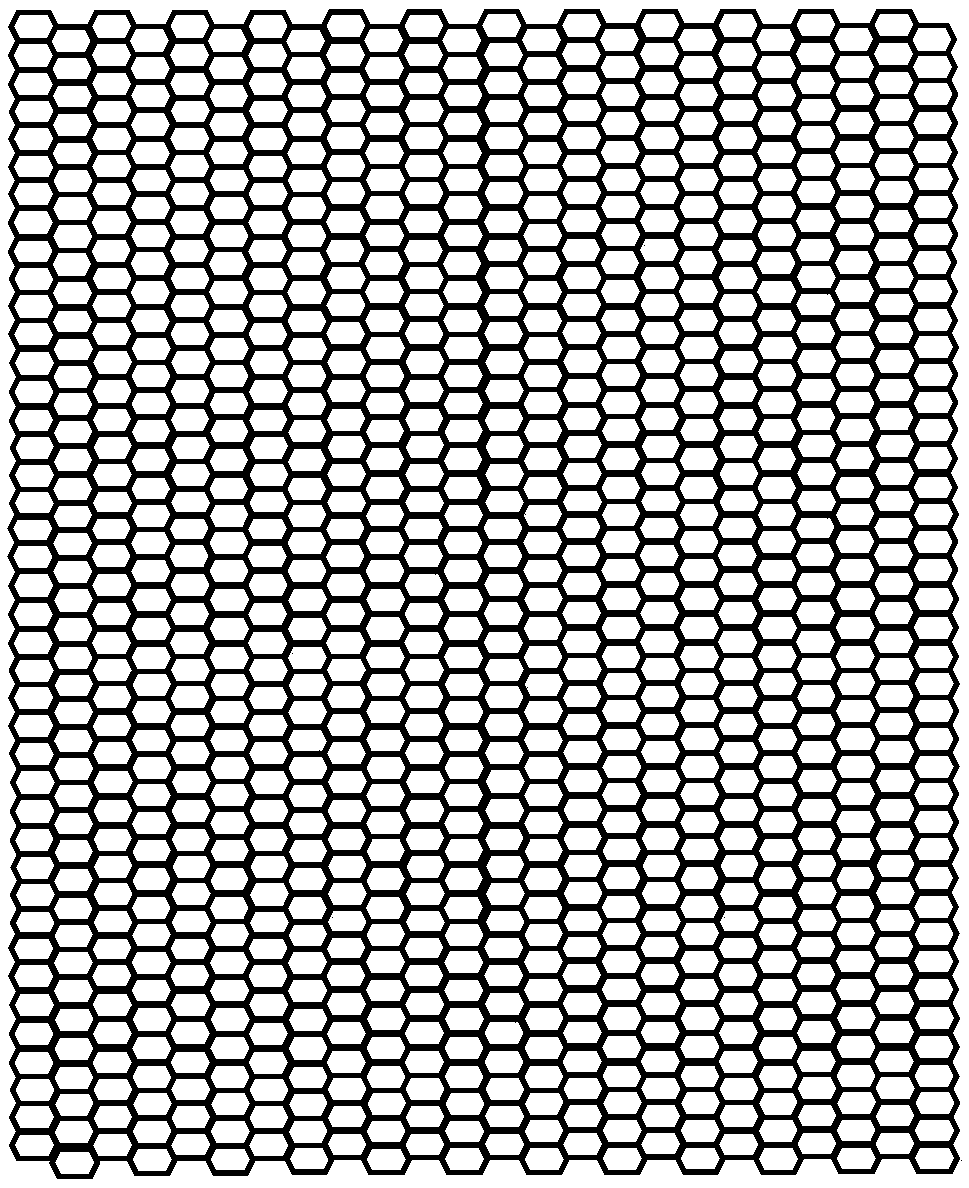

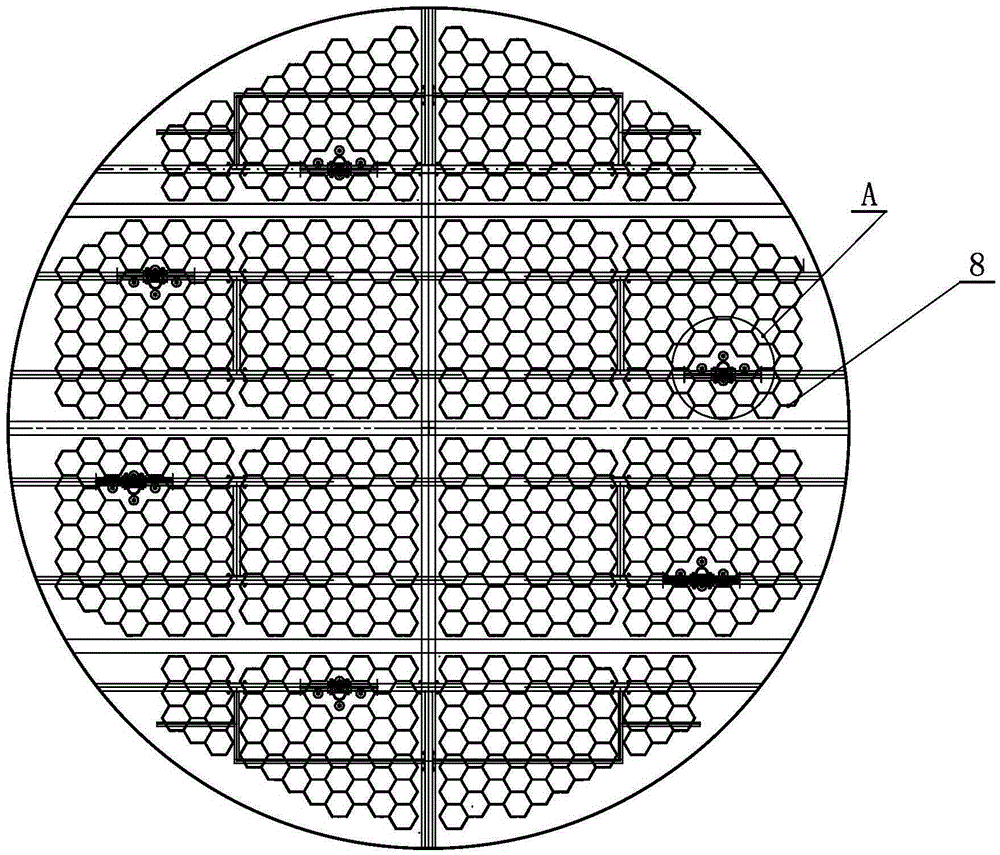

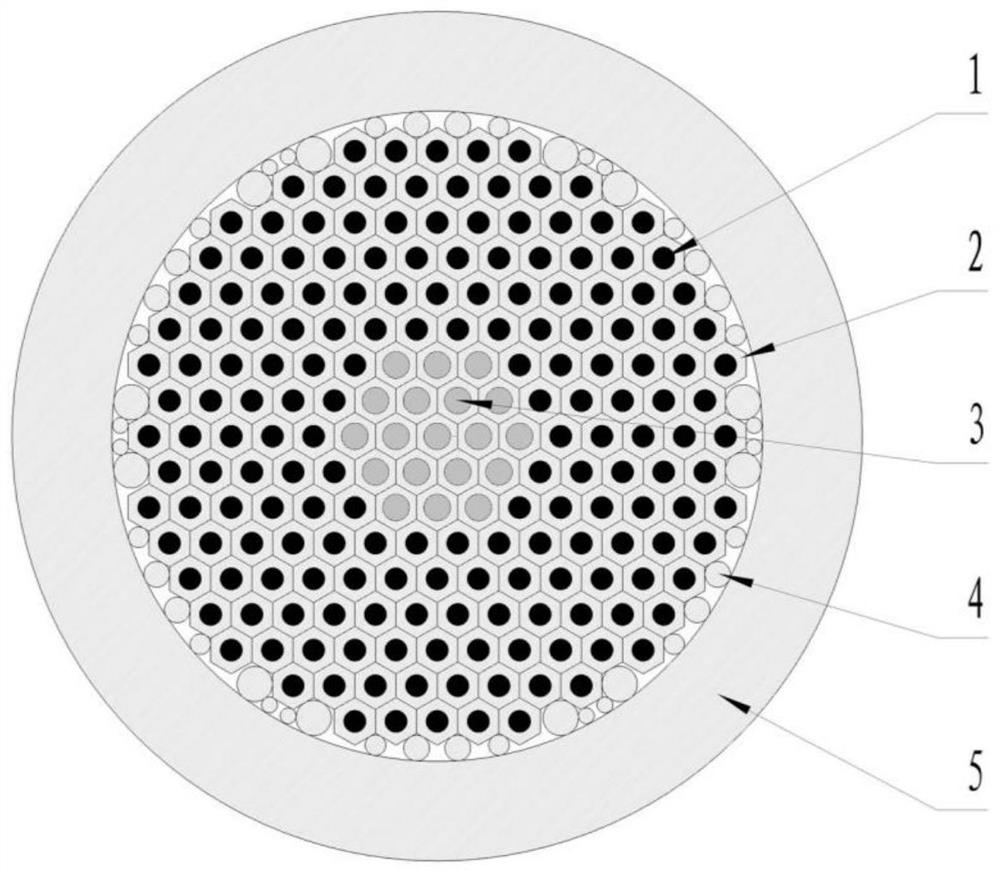

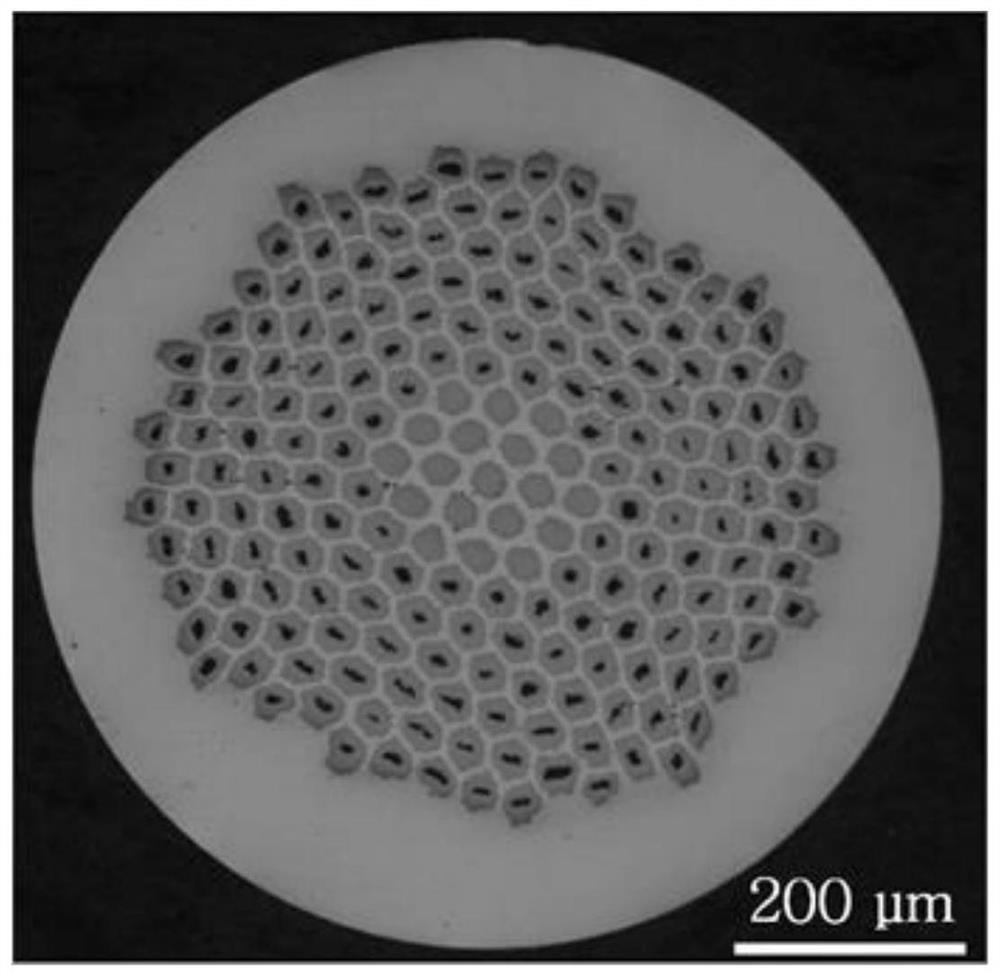

OLED pixel arrangement structure and vapor-deposition mask of pixel arrangement structure

InactiveCN105762169ASolve disconnectionSolve the problem of unable to open the networkSolid-state devicesVacuum evaporation coatingHoneycombComputer science

The invention relates to an OLED pixel arrangement structure and a vapor-deposition mask of the pixel arrangement structure, which belongs to the technical field of electronic equipment. RGB sub-pixels in the pixel array of the OLED pixel arrangement structure are hexagonal and are in a honeycomb distribution. One sub-pixel of any color in each pixel forms a same-color sub-pixel group together with two same-color sub-pixels just adjacent to the above sub-pixel. Based on the above novel pixel arrangement mode, the distance between different-color sub-pixels is maximized in the condition of high resolution. Therefore, the problem that the line of a mask is broken or the mask cannot be expanded can be solved. Based on the vapor-deposition mask, one through hole is shared by the same-color sub-pixel group, so that the spacing between the through holes of the mask is enlarged. Therefore, the alignment space is expanded, and the process difficulty is reduced. The occurrence of color-mixing defects is avoided. Furthermore, the product yield is improved and the production cost is lowered.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

Preparation method for PERC double printing polycrystalline solar cell

InactiveCN109599456ALight attenuation (LID reductionReduced light decay (LID)Final product manufacturePhotovoltaic energy generationEngineeringOxygen

The invention discloses a preparation method for a PERC double printing polycrystalline solar cell. The PERC double printing polycrystalline solar cell is obtained by taking a polycrystalline siliconwafer as a base material and sequentially performing the steps, namely flocking, diffusion, etching, annealing, back passivation, antireflection film plating, back laser grooving, printing, sinteringand light attenuation reduction; in the annealing step, oxygen-free annealing is adopted, in the back passivation step, Al2O3 and SiNX are plated on the back of the silicon wafer, in the antireflection film plating step, SiNX is plated on the front of the silicon wafer, during positive electrode printing, a silk screen printing machine is adopted for printing twice, namely DP1 and DP2, a secondarygrid line is printed during the DP1, a main grid line and the secondary grid line are overprinted during the DP2, and a silk screen printing plate used in the printing DP1 and the printing DP2 is a knotless silk screen printing plate. The preparation method provided by the invention and for the PERC double printing polycrystalline solar cell can reduce LID of the solar cell to be about 1%, powerof a module finished product can be increased, conversion efficiency is high, and grade and electrical properties are obviously improved.

Owner:TONGWEI SOLAR ENERGY CHENGDU CO LID

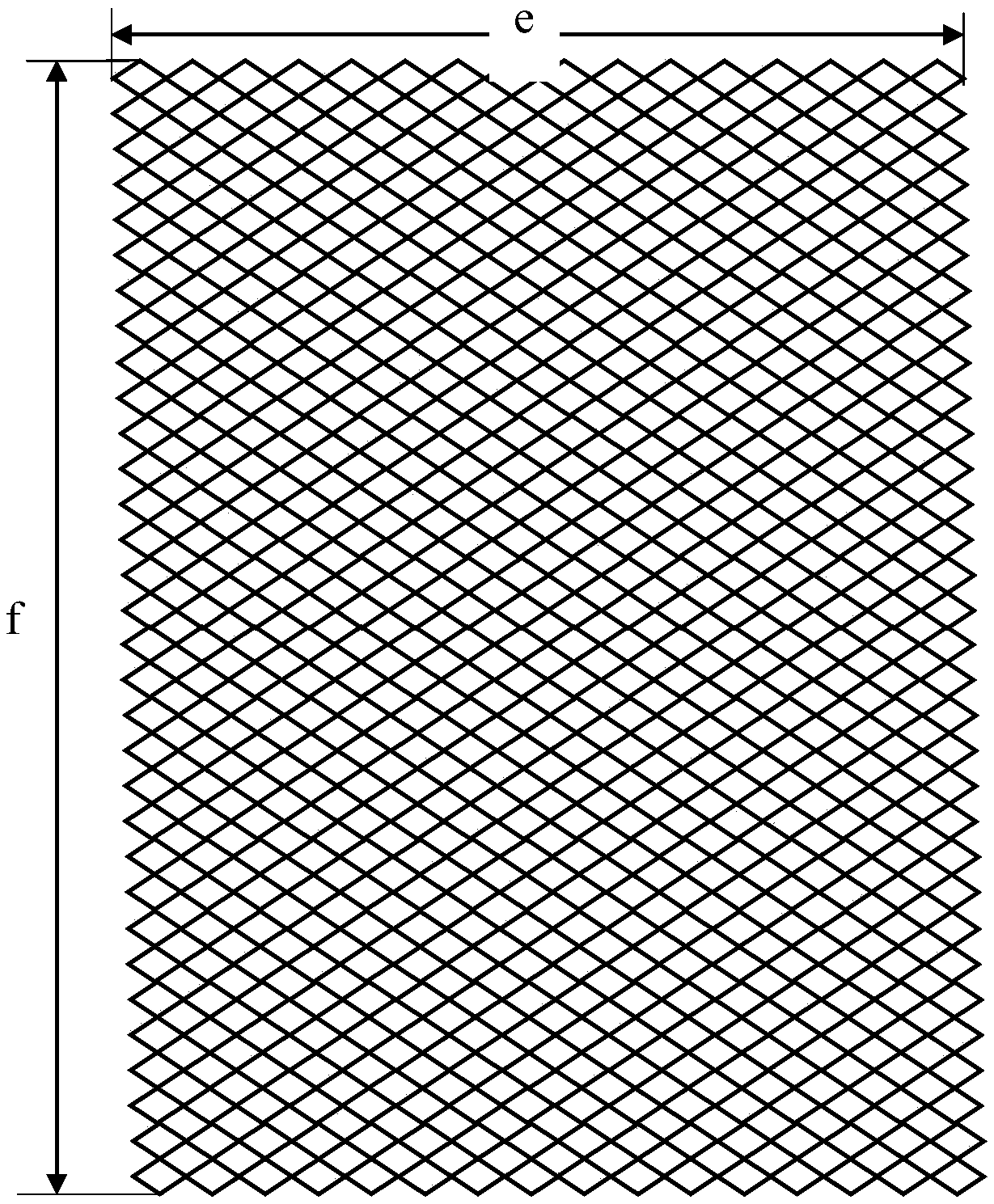

Ultrathin wide microporous aluminum net for thunder and lightning protection and preparation method thereof

PendingCN109457145AHigh strengthImprove plasticityAircraft lighting protectorsAircraft static dischargersUltimate tensile strengthAluminum foil

The invention discloses an ultrathin wide microporous aluminum net for thunder and lightning protection and a preparation method thereof and belongs to the technical field of microporous metal nets. The microporous aluminum net comprises, by weight percent, 0.1% to 0.3% of Sc, 0.05% to 0.15% of Zr and the balance Al. The thickness of the microporous aluminum net ranges from 0.05 mm to 0.13 mm, thewidth of the microporous aluminum net ranges from 600 mm to 1000 mm, the length of the microporous aluminum net is larger than 100 m, the long pitch of the microporous aluminum net ranges from 1.8 mmto 2.2 mm, and the short pitch of the microporous aluminum net ranges from 0.7 mm to 1.4 mm. Specifically, the ultrathin wide microporous aluminum net is obtained by carrying out stamping, stretchingand precision bump-cutter machine planishing on an aluminum foil material. The ultrathin wide microporous aluminum net for thunder and lightning protection is good in conductivity, high in strength,high in plasticity and low in mass, and the problem that when a wide ultrathin metal aluminum stretching net is produced in the prior art, net breaking, edge cracking and other continuous conduction failing problems are caused is solved.

Owner:有研金属复材技术有限公司

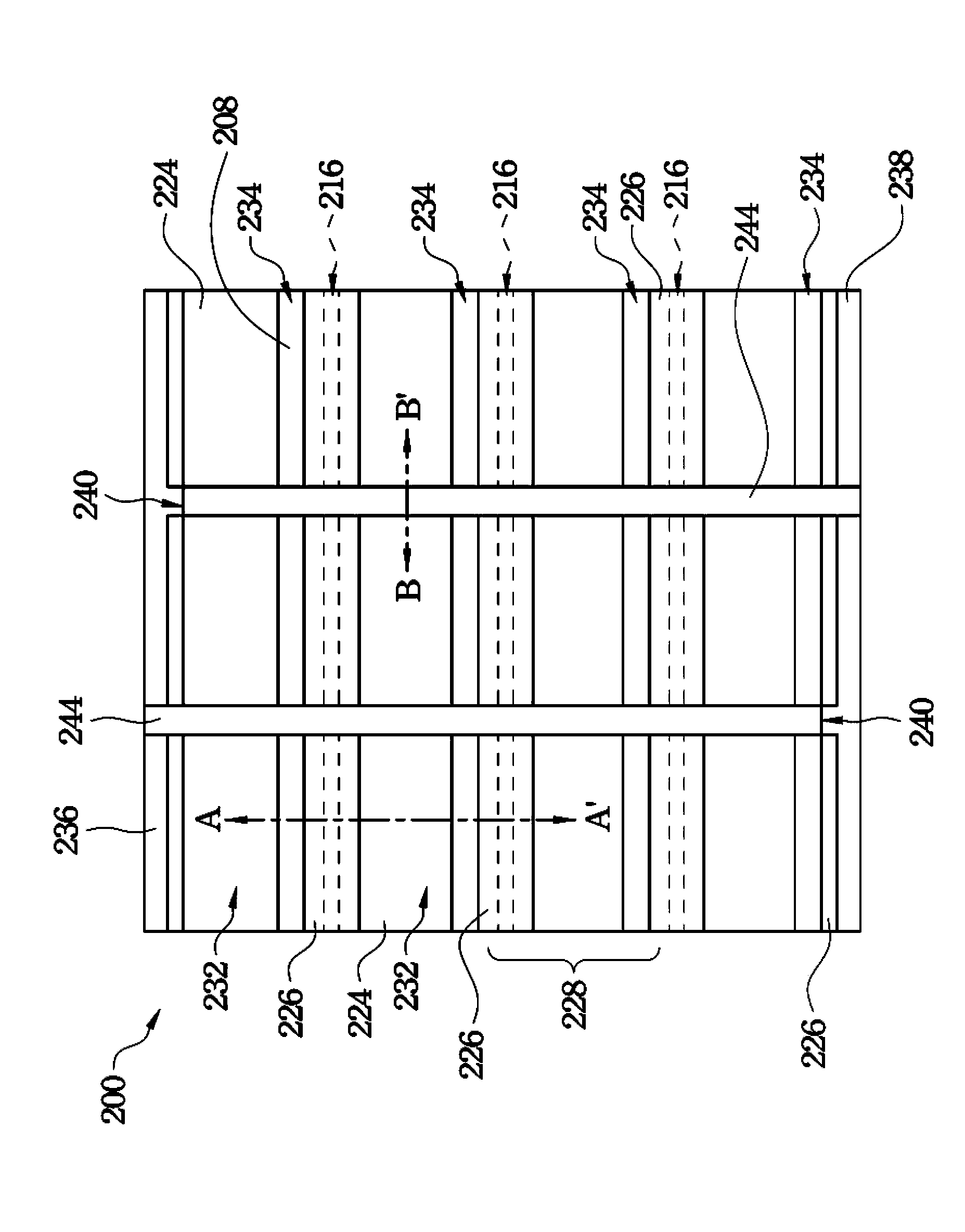

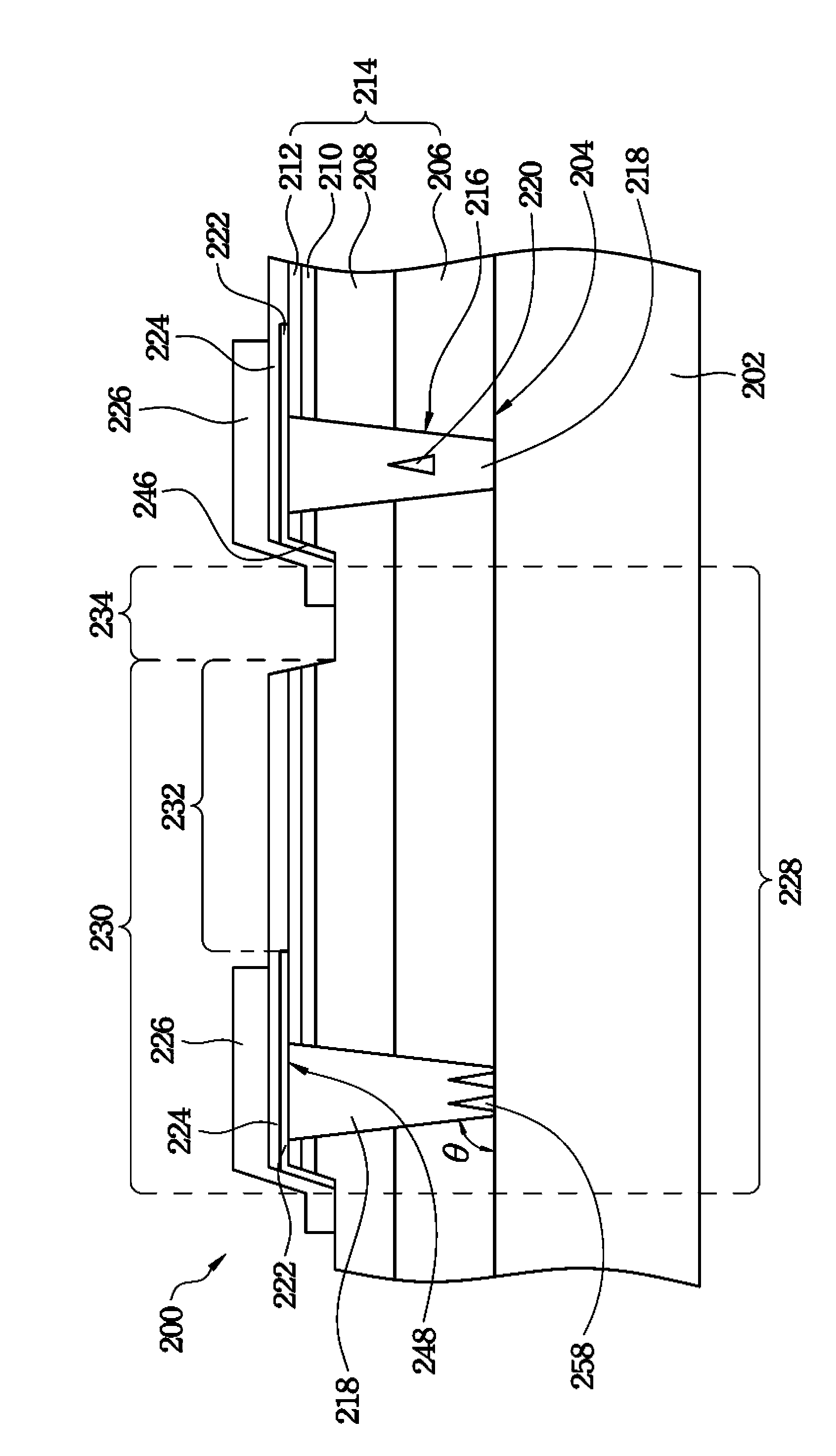

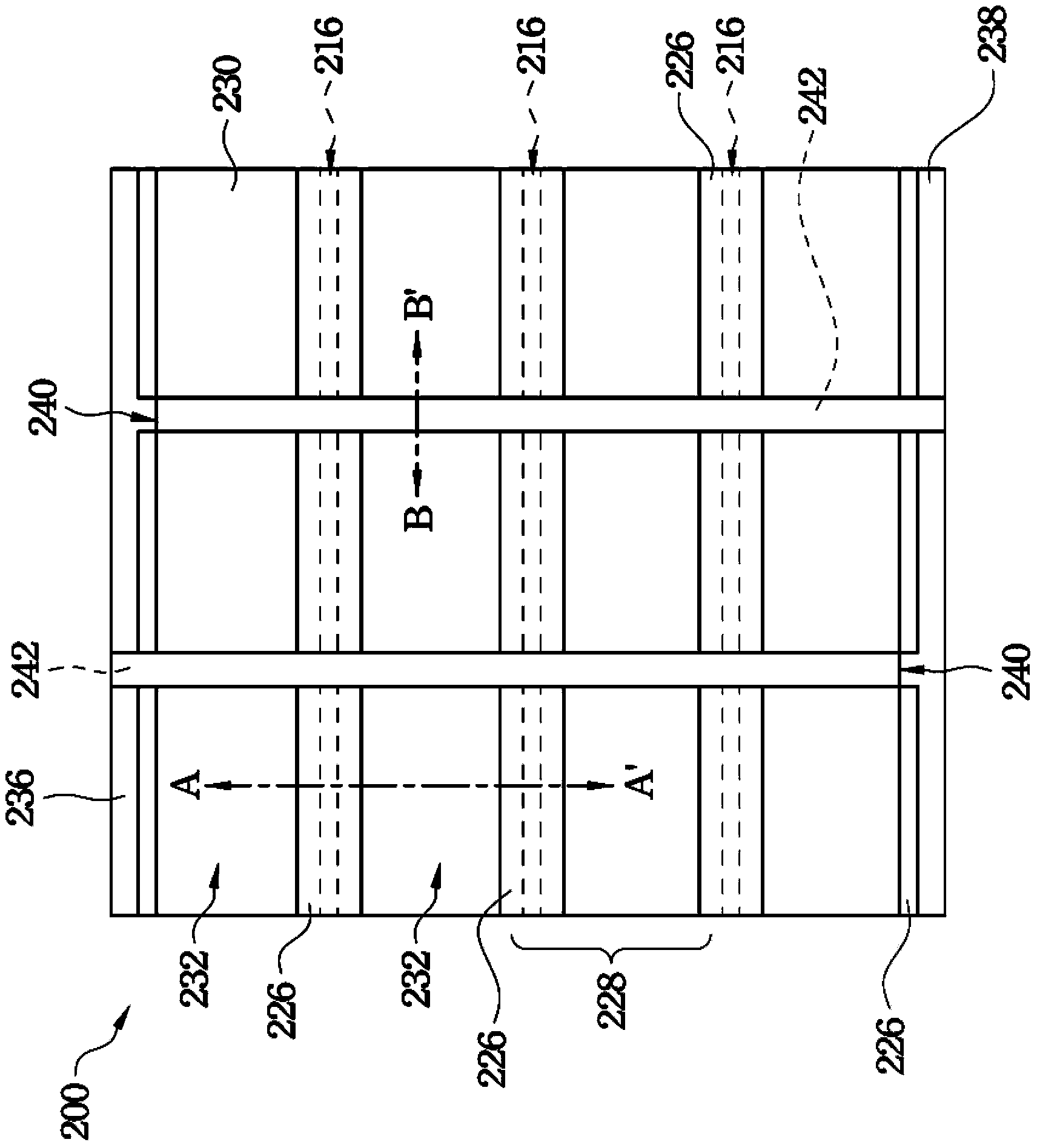

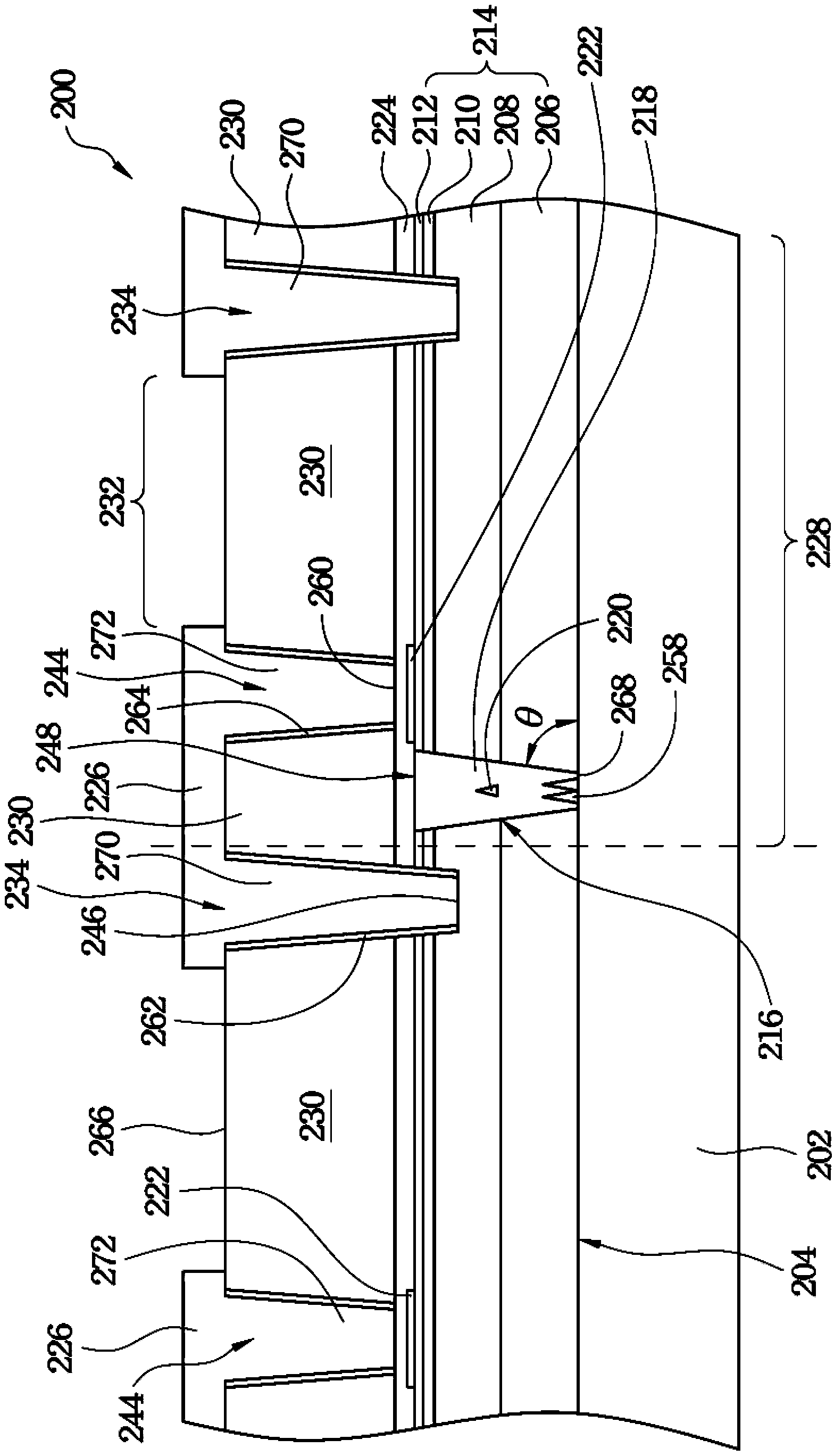

Light-emitting diode structure and method for manufacturing the same

InactiveCN103383949AImprove production yieldSolve disconnectionSolid-state devicesSemiconductor devicesInterconnectionEngineering

A light-emitting diode (LED) structure and a method for manufacturing the same. The LED structure comprises an insulating substrate, a plurality of LED chips (228) and a plurality of interconnection layers. Each LED chip comprises a first conductivity type semiconductor layer, an active layer and a second conductivity type semiconductor layer stacked in sequence on a surface of the insulating substrate. Each LED chip includes a mesa structure, an exposed portion of the first conductivity type semiconductor layer adjacent to the mesa structure, and a first isolation trench (216,240). The first isolation trench is disposed in the mesa structure. The interconnection layers (226) respectively connect neighboring two of the LED chips.

Owner:CHI MEI LIGHTING TECHNOLOGY CORP +1

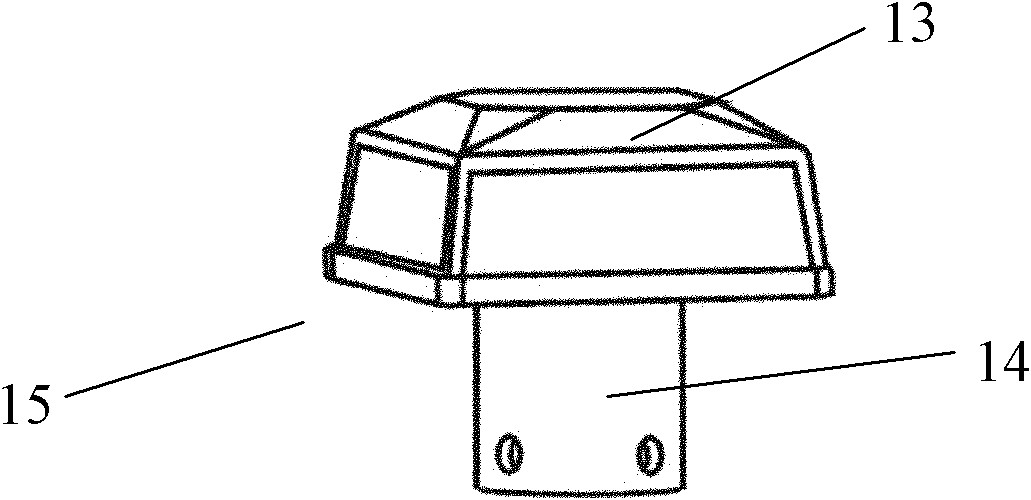

Reflective laser level with common-point three-dimensional beam splitting prism

ActiveCN102095415AReduce the amount usedSolve Laser Line DistortionReference line/planes/sectorsPrismOptoelectronics

The invention relates to a reflective laser level with a common-point three-dimensional beam splitting prism. The reflective laser level with a common-point three-dimensional beam splitting prism comprises a prism reflection module, a temperature-controlled single light source system, and a common-point three-dimensional beam splitting module, wherein the common-point three-dimensional beam splitting module is arranged in the emergent light path of the temperature-controlled single light source system; and the prism reflection module is arranged on the emergent light path of the common-point beam splitting module. The reflective laser level with a common-point three-dimensional beam splitting prism provided in the invention can effectively solve the technical problems of prism support, singe light source three-dimensional beam splitting, outlaid automatic leveling and the like.

Owner:XIAN HUANIC OPTOELECTRONICS CORP

Adjustable cathode fixing device for high-voltage wet electrostatic precipitator

InactiveCN105396697AEasy to fixLow failure rateElectrode carrying meansExternal electric electrostatic seperatorEngineeringHigh voltage

The invention discloses an adjustable cathode fixing device for a high-voltage wet electrostatic precipitator. A cathode frame is provided with groove steel for a cathode fixing pile to be connected with the frame. A cathode girder is located above an anode pipe of the cathode frame and is fixed through two clamping flanges and clamping bolts. The cathode fixing pile is arranged between the cathode girder and the cathode frame and is installed in a connection channel between the cathode girder of an upper air chamber and the cathode frame of a lower air chamber. A cathode wire is laid in the anode pipe in the channel. An adjusting bolt is fixed to the bottom of the cathode fixing pile, a screw rod of the adjusting bolt penetrates through the groove steel and the cathode frame, and an adjusting nut matched with the adjusting bolt is arranged below the cathode frame. The adjustable cathode fixing device is suitable for treatment of exhaust gas of large power stations, exhaust gas of sintering machines, pellets, cement and chemical engineering of the iron and steel industry and a large amount of exhaust gas of the nonferrous metallurgy industry. Ultra-low emission improvement is carried out on existing power plants and steel mills and is of great significance in high efficiency and energy conservation advocated by the country and long-term safe, stable and standard operation of a system.

Owner:SHANDONG GUOSHUN CONSTR GRP

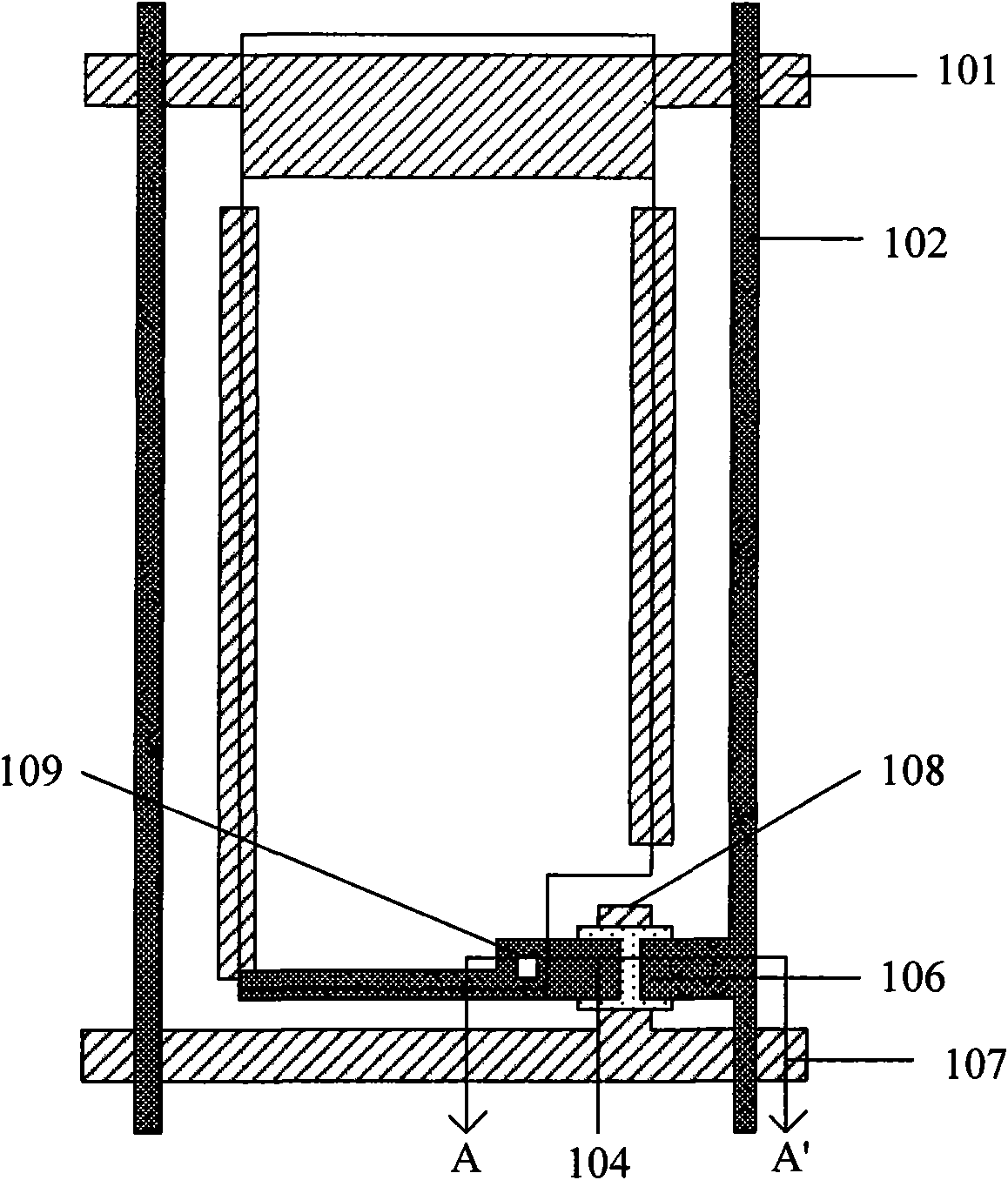

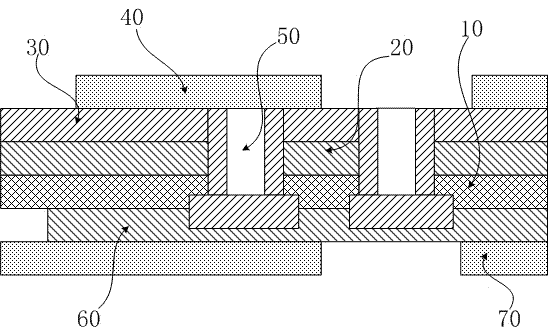

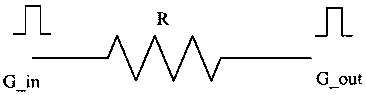

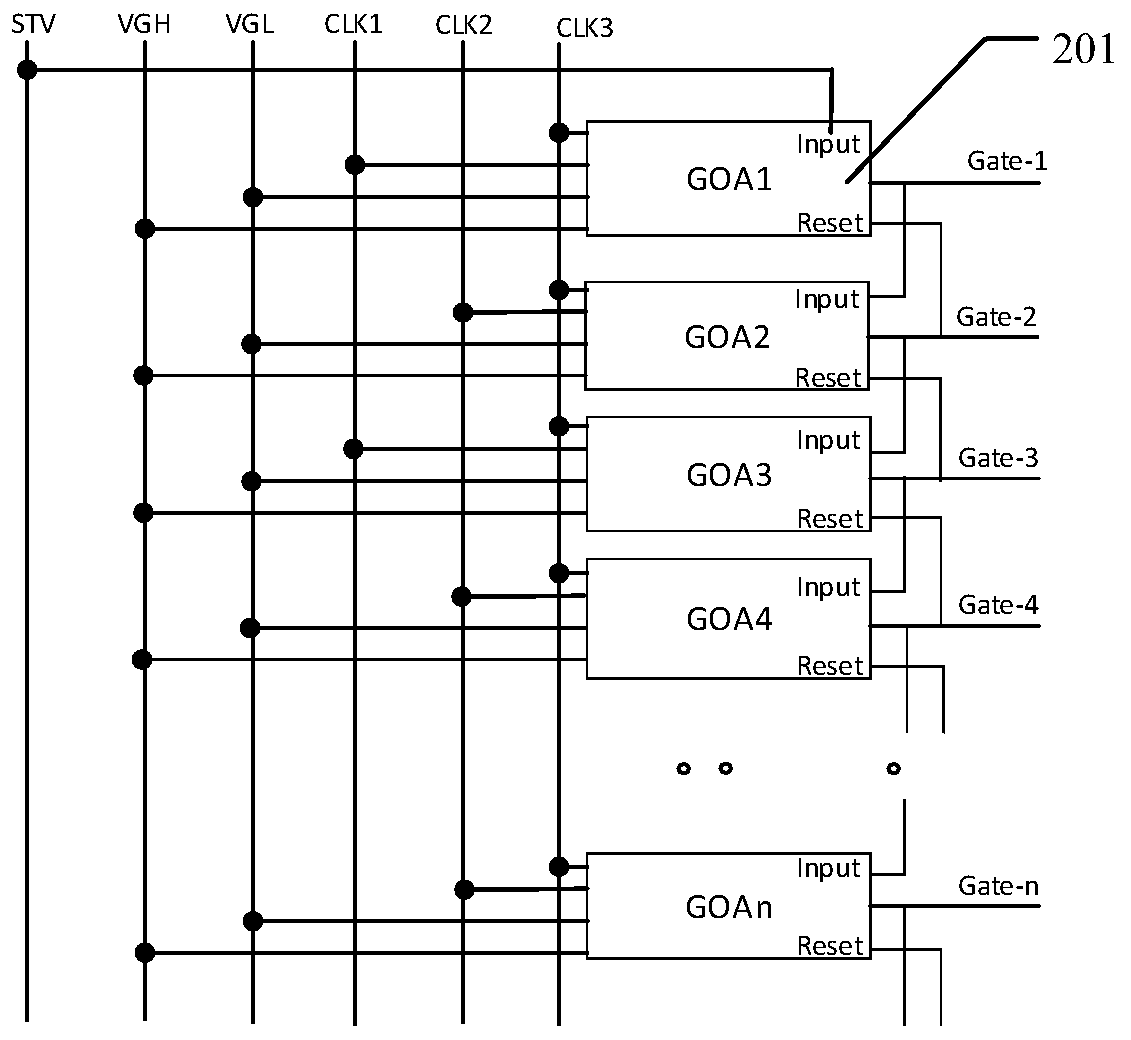

Gate drive circuit, display device and repair method

ActiveCN110767149ASolve disconnectionAvoid disconnectionStatic indicating devicesEmbedded systemSignal lines

The invention discloses a gate drive circuit, a display device and a repair method. The gate drive circuit comprises a plurality of cascaded GOA units, a plurality of clock signal lines, a plurality of clock signal lines for repair and a plurality of electrostatic protection sub-circuits, wherein each clock signal line is used for providing various clock signals for the GOA unit; the clock signalline for repairing is used for replacing the broken clock signal line to transmit a corresponding clock signal when any clock signal line is broken; each electrostatic protection sub-circuit is connected with the corresponding clock signal line and the corresponding clock signal line for repair through connecting lines, and is used for preventing the clock signal line and each clock signal line for repair from electrostatic damage; the connecting lines, the clock signal lines and the clock signal lines for repairing are arranged on different layers of the circuit board, and the orthographic projections of the connecting lines on the planes where the corresponding clock signal lines or the corresponding clock signal lines for repairing are located intersect with the corresponding clock signal lines and the corresponding clock signal lines for repairing respectively.

Owner:HEFEI BOE ZHUOYIN TECH CO LTD +1

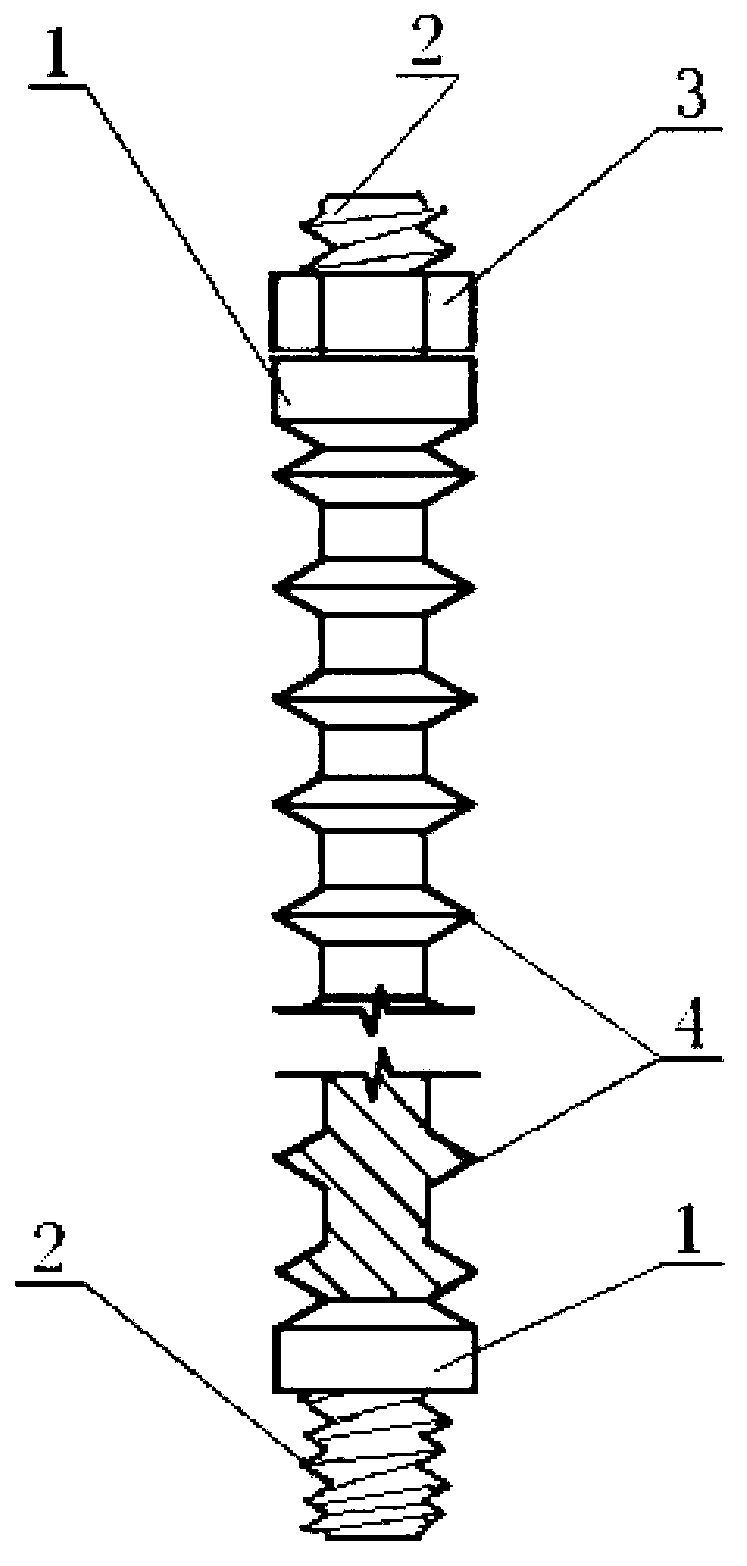

Spiral needle electric demisting cathode ray

The invention discloses a spiral needle electric demisting cathode ray which comprises a cathode bar, wiring terminals, nuts and a spiral discharging body. The spiral needle electric demisting cathode ray is characterized in that the cathode bar is made of solid round metal, the interval of spiral tooth blades of the spiral discharging body arranged on the cathode bar is 20-50mm, the interval between the spiral tooth blades of the spiral discharging body and the cathode bar is 2-5mm, the wiring terminals positioned at two ends of the cathode bar are of threaded structures, and the wiring terminals are provided with the fastening nuts. The spiral discharging body of the electric demister cathode ray and the cathode bar are integrally connected, are extremely firm and are easy to process, the running time is long, and efficient running of an electric demister is guaranteed. Besides, a spiral blade discharging structure is adopted, discharging points are many, and the spiral needle electric demisting cathode ray discharges electricity evenly, is good in demisting effect and has good economic benefit, social benefit and ecological benefit.

Owner:GUANGXI MINGLI CHEM

Pure spinning yarn made of polyamide staple fibers and spinning process thereof

InactiveCN108950770AMeet downstream production needsSolve poor lap formationCarding machinesYarnFiberYarn

The invention belongs to the technical field of spinning and relates to pure spinning yarn made of polyamide staple fibers and a spinning process thereof. The process includes the following steps of healthcare pretreatment of the polyamide staple fibers, manual feeding, treatment on an FA106 cotton opener, treatment on an FA046 type vibrating cotton box cotton feeding machine, treatment on an A076F single beater scutcher, treatment on an FA201B type carding machine, treatment on an FA317A first drawing frame, treatment on an FA317A last drawing frame, treatment on an FA415A type roving frame,treatment on an EJM128K type spinning frame and treatment on a NO.21C type automatic winder.

Owner:WEIQIAO TEXTILE

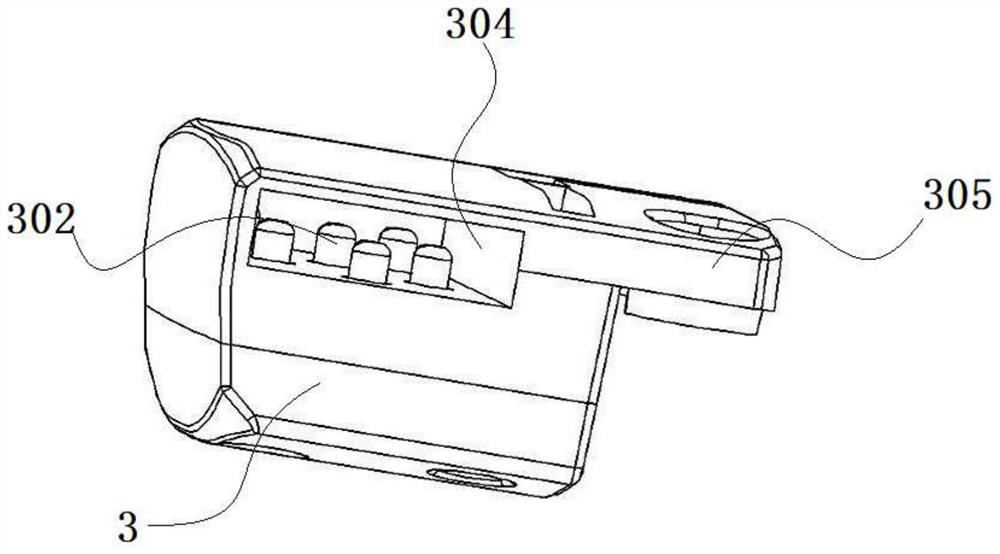

Flexible sliding power supply assembly, massage back cushion and control method of massage back cushion

ActiveCN112510458AImprove adaptabilityStructural specificationProgramme controlPhysical therapies and activitiesMassageElectrical connection

The invention discloses a flexible sliding power supply assembly, a massage back cushion and a control method of the massage back cushion. Two or more fixing grooves are formed in a flexible conductive rail, and conductive strips are installed in the fixing grooves in an embedded mode; a sliding conductive assembly is installed on the flexible conductive rail, the sliding conductive assembly is slidably and electrically connected with the conductive strip, and the conductive strip is correspondingly and electrically connected to the power supply and the controller. The flexible conductive railcan be unidirectionally bent in a large arc manner to adapt to massage chairs in different shapes, is good in adaptability, and can be used for a common back cushion and a curved back cushion; the flexible conductive rail and the tunnel type sliding power transmission assembly can be made into standard parts, and can be universally used for various back cushions, so that the development cost is reduced, and the assembly is convenient; the flexible conductive rail is connected by adopting a tunnel type probe control sleeve structure, and is fixed reliably during sliding guide; and one controller can be connected with a plurality of massage machine cores with tunnel sliding electricity transmission assemblies, the number of wires is reduced, and the problems that wires of a massage cushionare broken and massage heads are twisted are thoroughly solved.

Owner:SHENZHEN MONDIAL TECH CO LTD

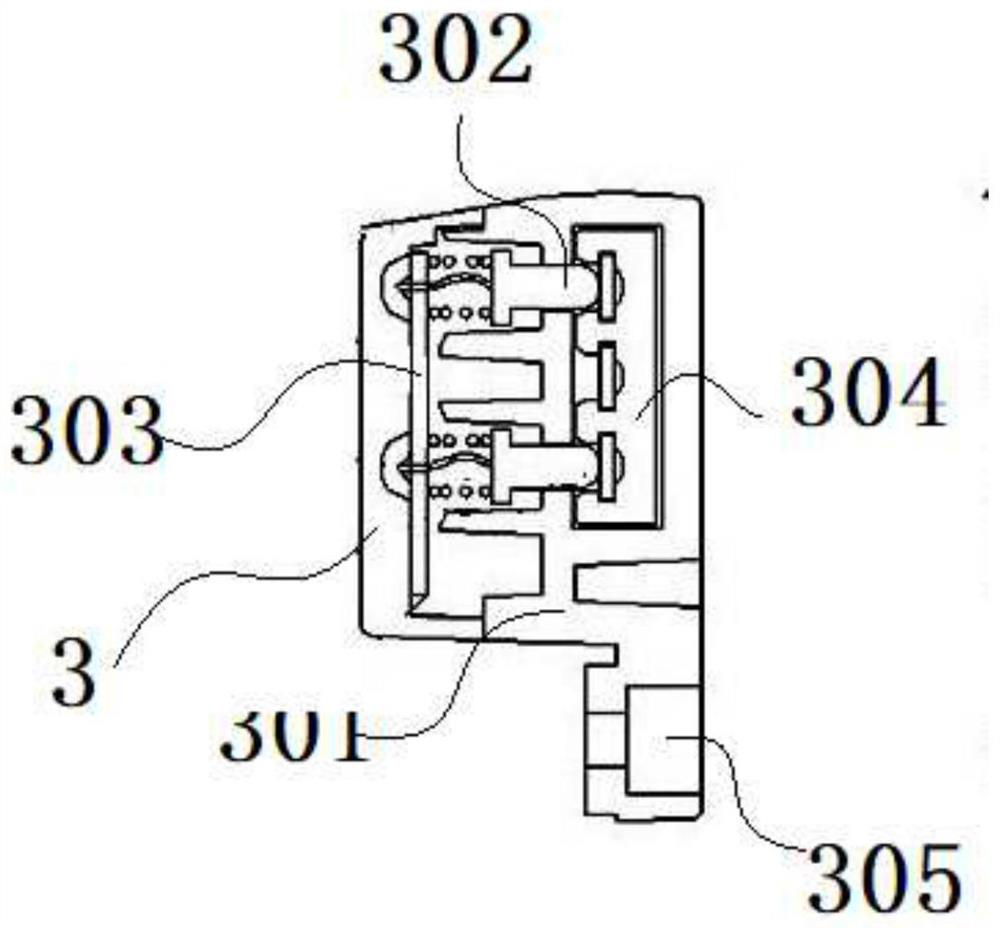

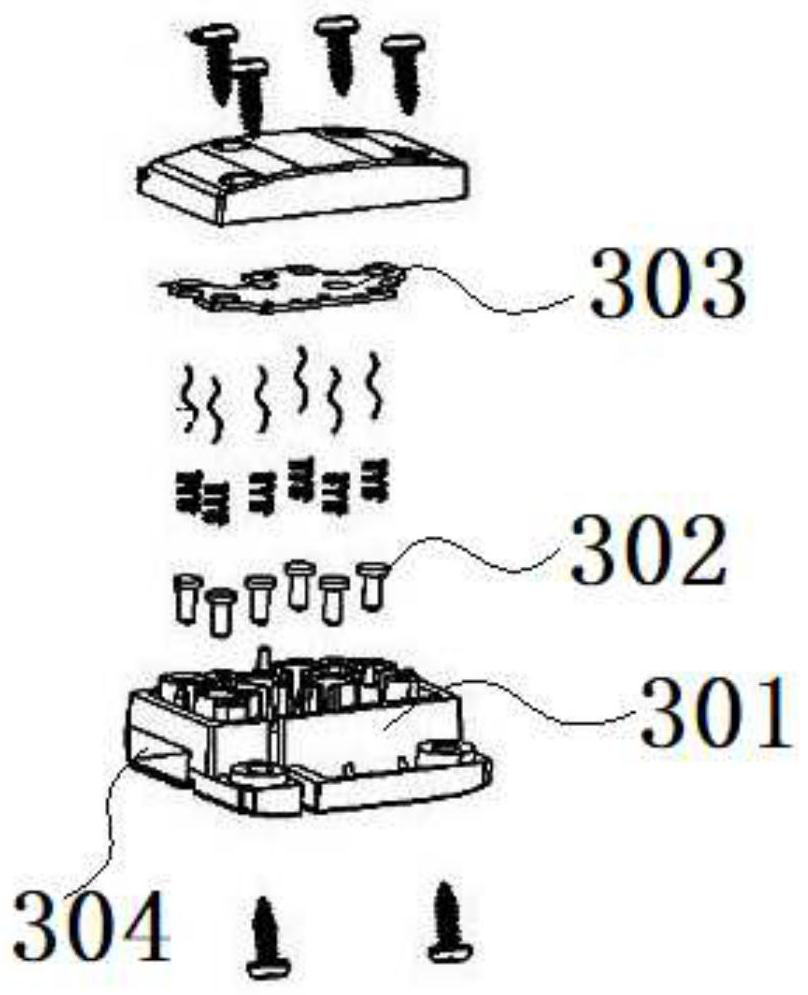

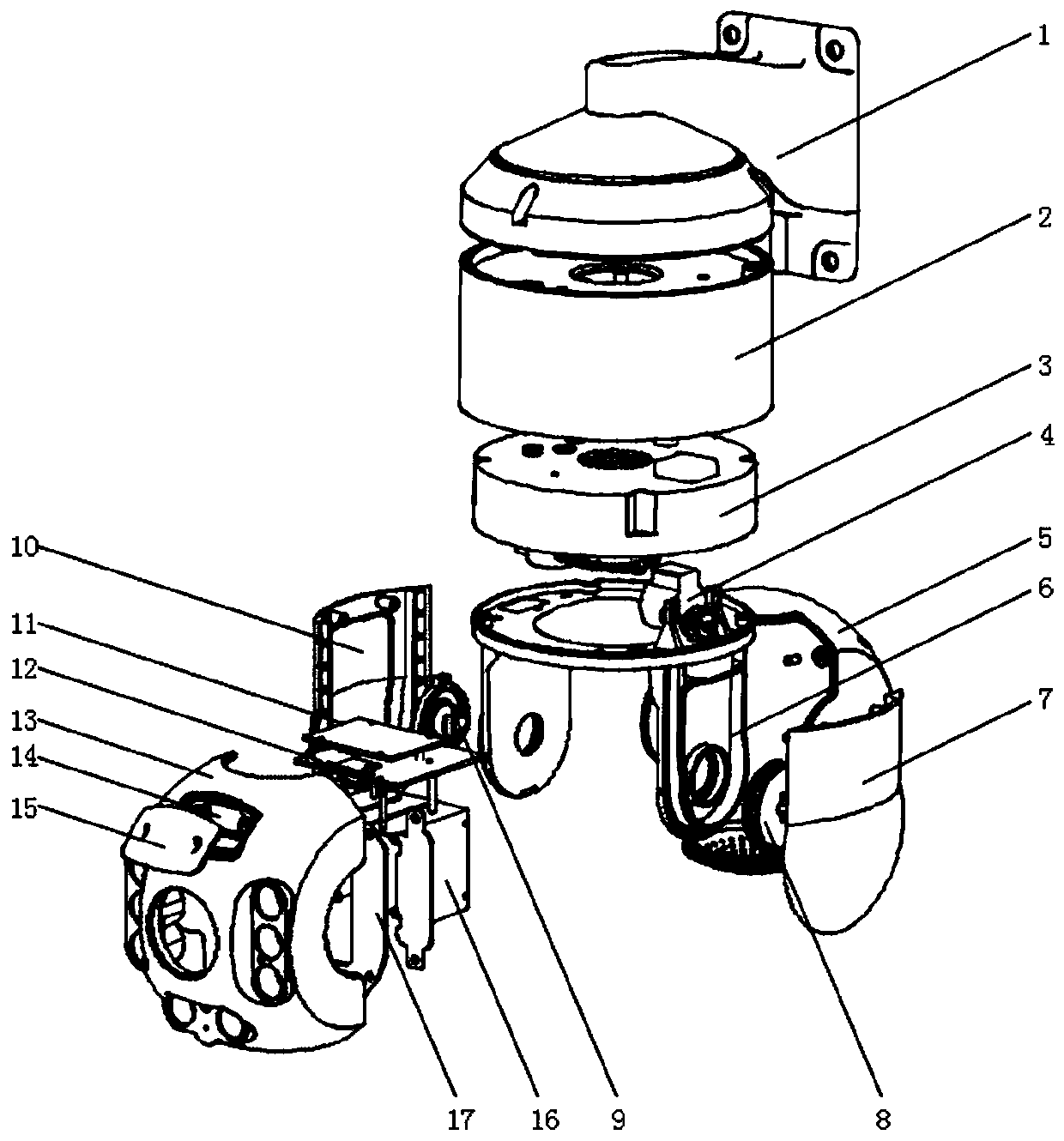

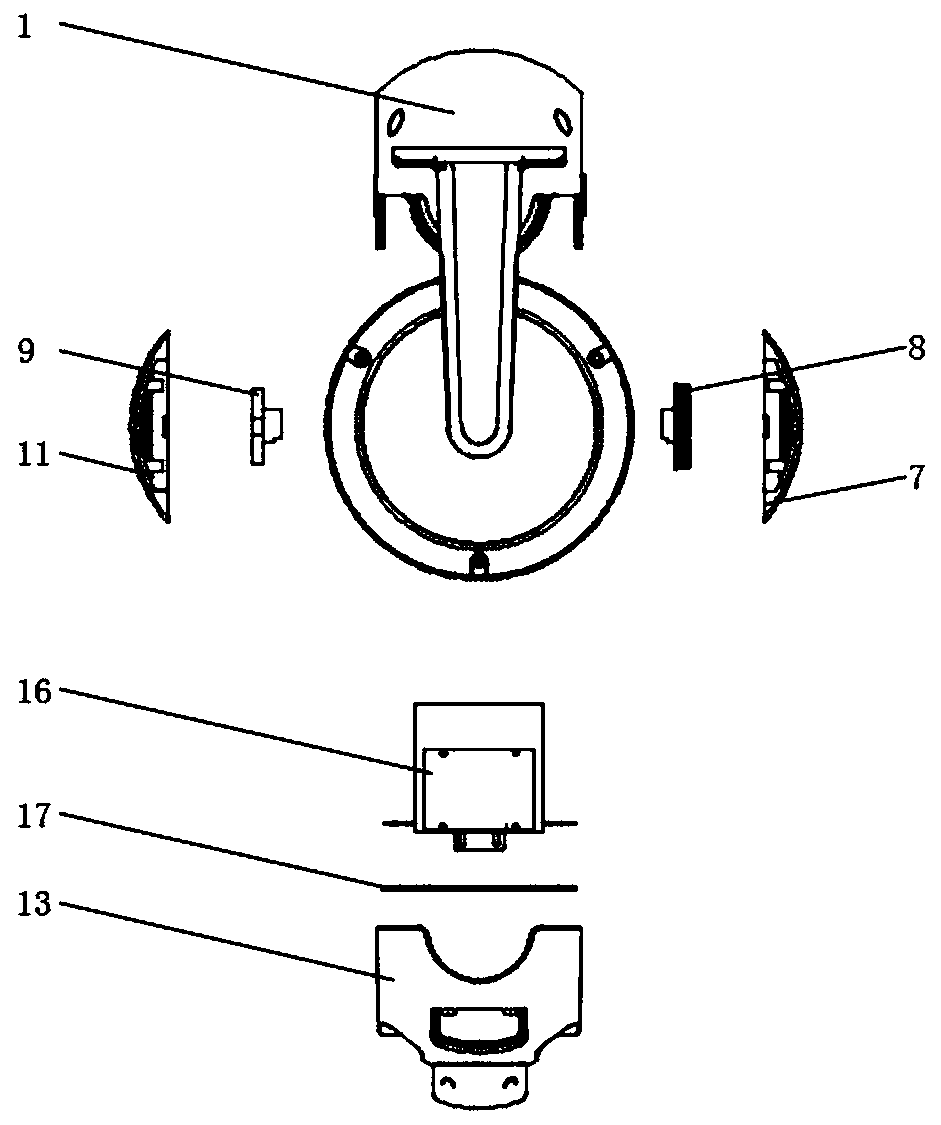

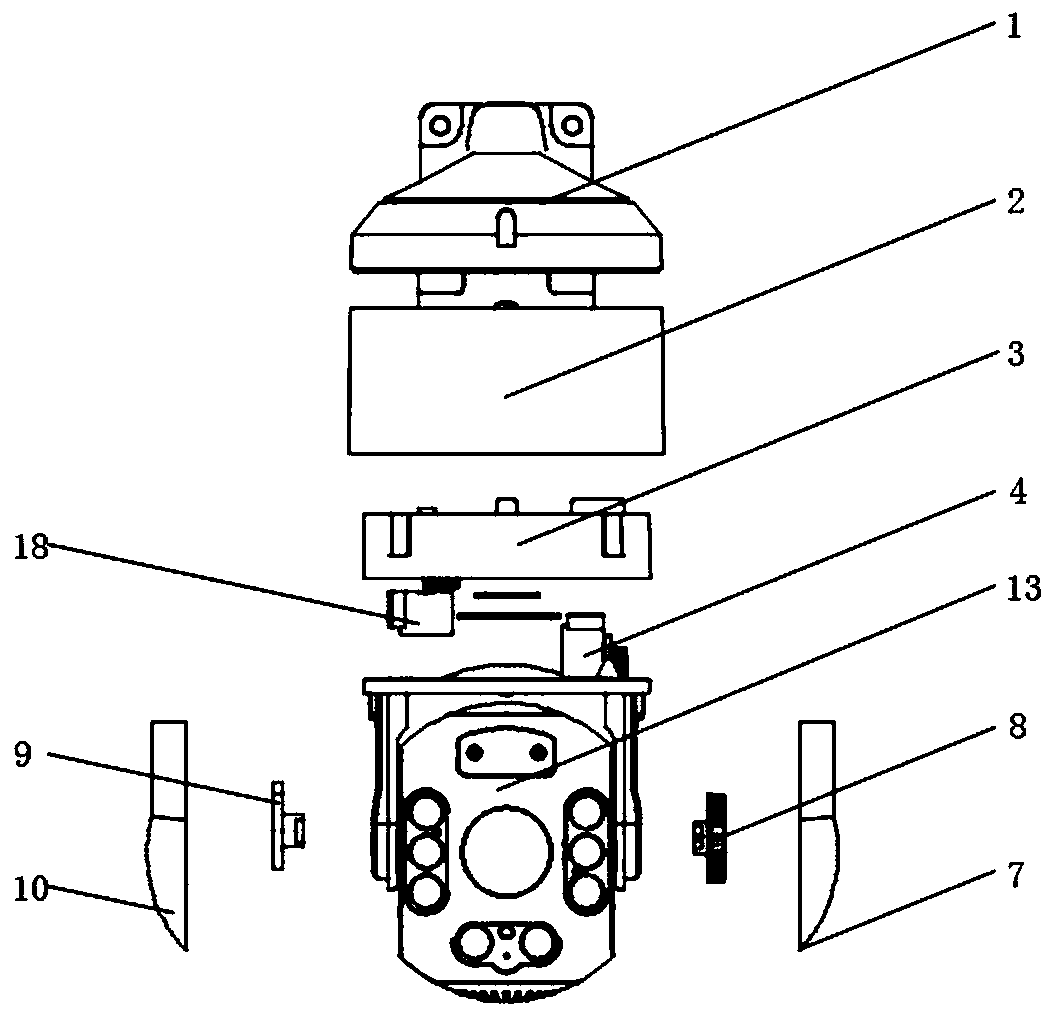

Million high-definition wireless network video variable-magnification pan-tilt monitoring camera

PendingCN110035261AExtended service lifeSolve disconnectionTelevision system detailsColor television detailsMagnificationMechanical engineering

The invention discloses a million high-definition wireless network video variable-magnification pan-tilt monitoring camera. The camera comprises a ball machine body, the ball machine body comprises asupport, a base, a horizontal motor support and a holder support. A power supply is arranged in the ball machine body; the bottom of the support is fixedly connected with the base; wherein the horizontal motor support is installed below the base, a horizontal motor installation position is arranged in the horizontal motor support, a horizontal motor is installed at the position, located at the horizontal motor installation position, in the horizontal motor support, and the holder support is installed below the horizontal motor support. According to the million-high-definition wireless networkvideo-recording zoom holder monitoring camera, a ball machine can circularly rotate by 360 degrees, the problem that the tail line of a 355-degree ball machine on the market is broken is solved, the service life of the ball machine is longer, the ball machine is not prone to damage, mounting is faster, the structure is simple, assembling is quick, after-sales maintenance is simple, the productionefficiency is improved, and maintenance is more convenient.

Owner:深圳市华安邦数字技术有限公司

Wet electrostatic precipitator cathode wire weldless connection structure

InactiveCN104858065ASolve disconnectionAdjustable distanceElectrode constructionsElectricityThermal expansion

The invention discloses a wet electrostatic precipitator cathode wire weldless connection structure which comprises a frame, a cathode wire, and two elastic pieces which are arranged in pair, wherein one ends of the elastic pieces are connected with two ends of the cathode wire in a disassembling manner; the other ends of the elastic pieces are connected with corresponding cross bars of the frame in the disassembling manner. The cathode wire and the elastic pieces are in up-down tight connection in a disassembling manner; the original elastic pieces are used for achieving an integrated connection structure, elastic force of the elastic pieces can be used for tightly fastening the cathode wire and the frame, the connection manner is simple, the disassembling and the assembling are convenient and fast, and the connection is fastened and reliable while the function of heat expansion and cold contraction can be reduced, so that the problem that the wire breakage is caused in the running process as materials of the cathode wire are changed and the percentage of contraction of the cathode wire is increased after the cathode wire are welded can be extremely solved; the distance between the cathode wire and the frame can be adjusted, so that if only the connection part of the cathode wire is damaged, the cathode wire can also be used continuously, and further the wet electrostatic precipitator cathode wire weldless connection structure has the very high application value and prospect.

Owner:XIAMEN UNIV OF TECH

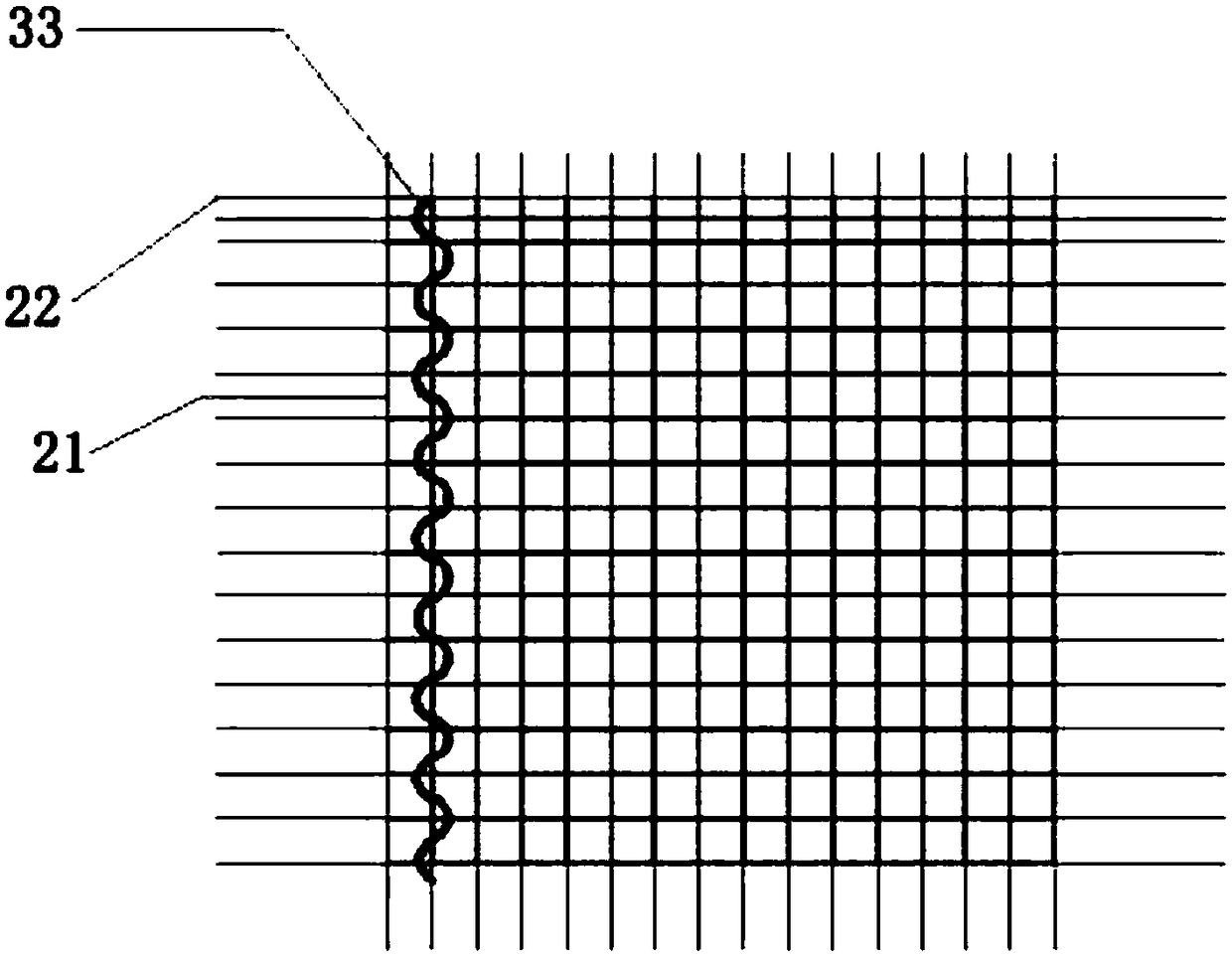

Preparation method of conventional single-crystal secondary-printed solar battery piece

InactiveCN109616544AReduce surface impurity concentrationReduce concentrationFinal product manufacturePhotovoltaic energy generationEngineeringSingle crystal

The invention discloses a preparation method of a conventional single-crystal secondary-printed solar battery piece. The preparation method comprises the following steps of A, texturing; B, diffusion;C, etching; D, annealing; E, plating of an antireflection film; and F, printing, wherein annealing in the step D adopts oxygen-free annealing; and a non-net-knot secondary printing mode is adopted for printing in the step F.

Owner:TONGWEI SOLAR ENERGY CHENGDU CO LID

Winding technology of transformer and transformer manufactured with winding technology

ActiveCN106024373AImprove reliability and longevityImprove production efficiencyCoils manufactureManufacturing efficiencyWinding machine

The invention discloses a winding technology of a transformer and the transformer manufactured with the winding technology, and relates to the technical field of transformers. The winding technology of the transformer includes the steps that stranded parts of stranded wires are wrapped with first insulation tape; the stranded wires penetrate through the inner side of a wire feeding groove from the outer side of the wire feeding groove; the stranded wires are pressed on the inner side of the side wall of a rubber core; the stranded wires located on the inner side of the wire feeding groove are fixed on the rubber core through second insulation tape. The hidden danger problem of incompact parts of the stranded wires and the hidden danger problem of inter-turn short circuits are solved, the previous problem that as the tape is not fixed and also moves when a winding machine rotates, winding wires are broken is solved, the reliability of the transformer is improved, and the service life of the transformer is prolonged; meanwhile, the manufacturing efficiency of the transformer is higher, and the reject ratio is lower.

Owner:DONGGUAN DAZHONG ELECTRONICS

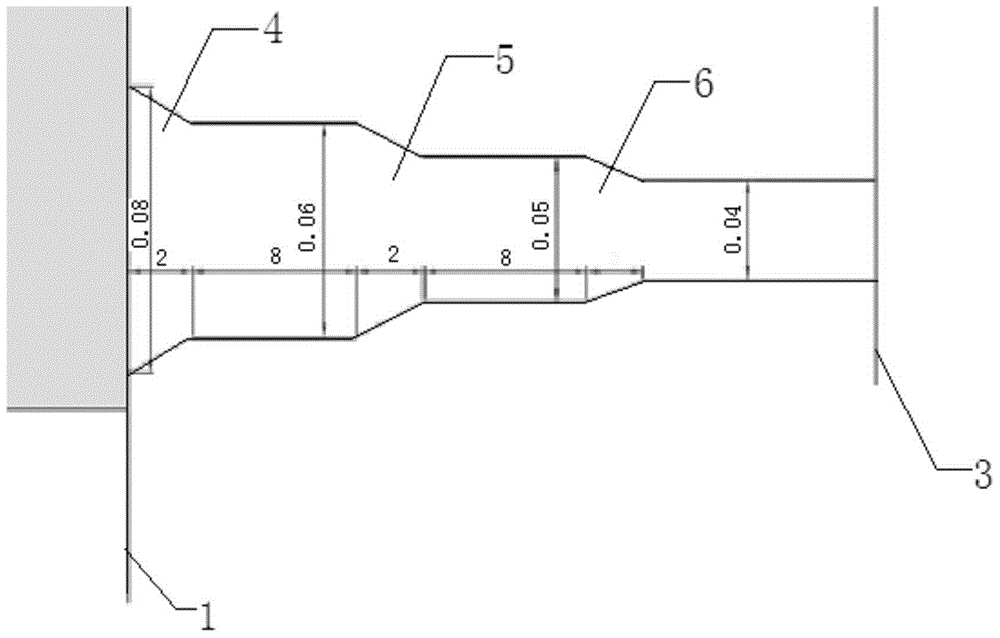

Screenless secondary printing method for positive electrode of crystalline silicon solar cell

InactiveCN109427919ALower transfer resistanceHigh aspect ratioPhotovoltaic energy generationSemiconductor devicesScreenlessSilicon solar cell

The present invention discloses a screenless secondary printing method for a positive electrode of a crystalline silicon solar cell. The method comprises that: a silk-screen printing machine is used to perform two times of printing of DP1 and DP2, wherein the sub-grid line is printed in the DP1, the main grid line and the sub-gate are printed in the DP2, and the silk-screen printing plate used forDP1 and DP2 printing is a screenless silk-screen printing late; the sub-grid line and the positioning points are printed onto the cell sheet by using the slurry through the DP1 screenless silk-screenprinting plate; four solid positioning points on the cell sheet is captured by using the HD camera, and the cell sheet is automatically adjusted to the appropriate position to achieve precise contrast with the alignment point on the DP2 screenless silk-screen printing plate; and the main grid line and the sub-grid line are printed onto the cell sheet by using the slurry through the DP2 screenlesssilk-screen printing plate. According to the method disclosed by the present invention, the limitations of the traditional printing process is broken through, the aspect ratio of the sub-grid printing is improved, the printing quality of the grid line is improved, and the electrical performance and the excellent product rate of the cell sheet are improved.

Owner:TONGWEI SOLAR ENERGY (CHENGDU) CO LID

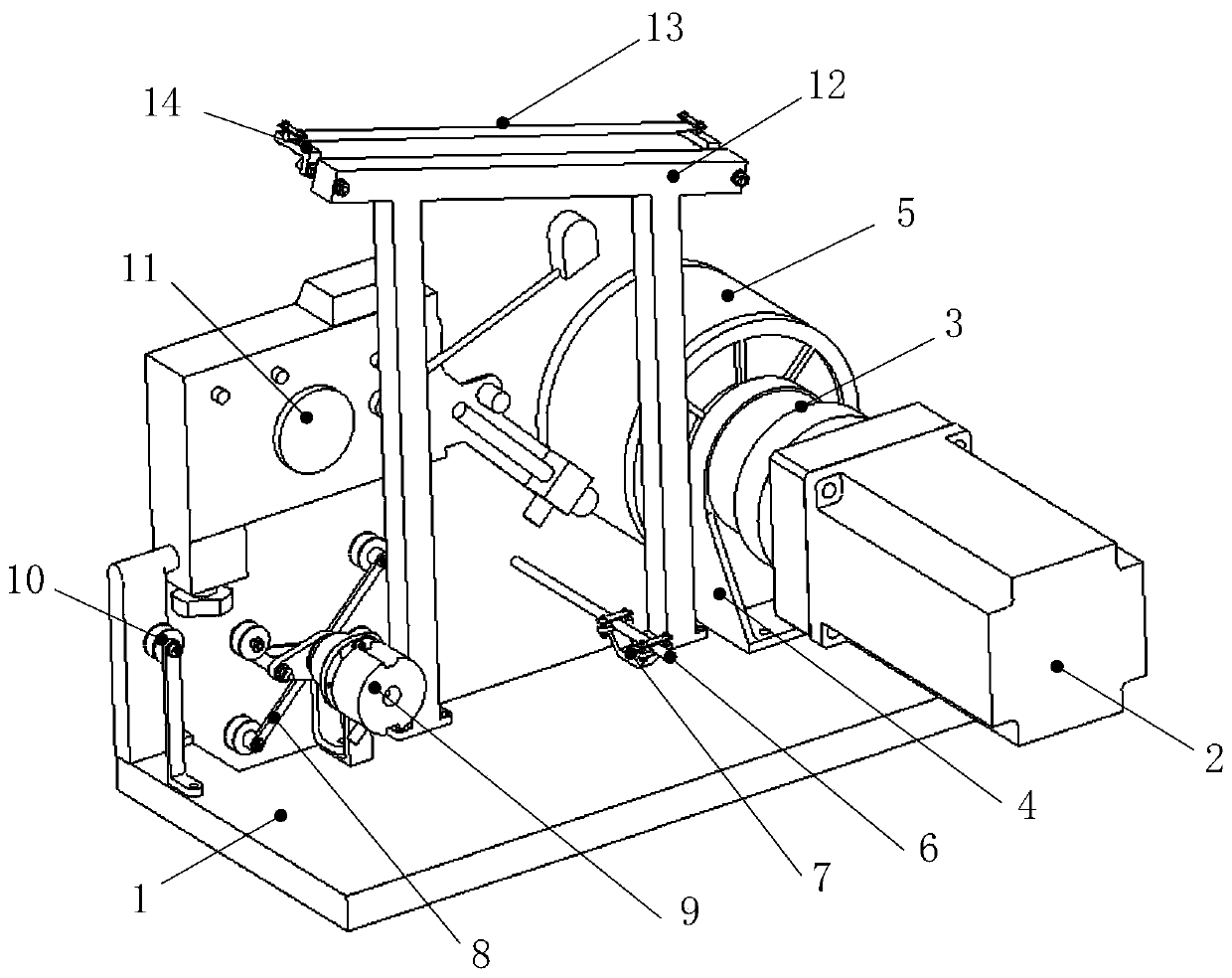

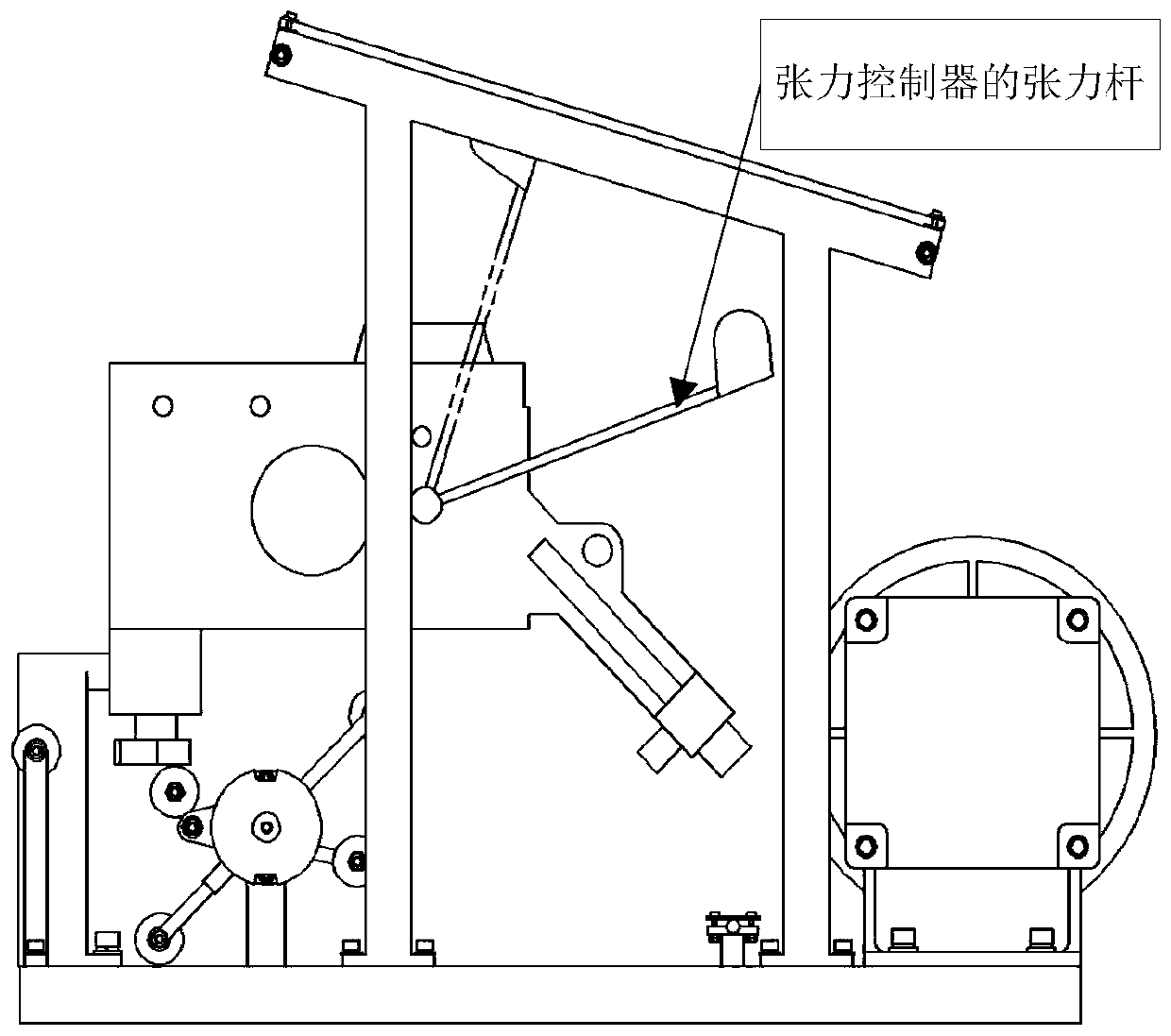

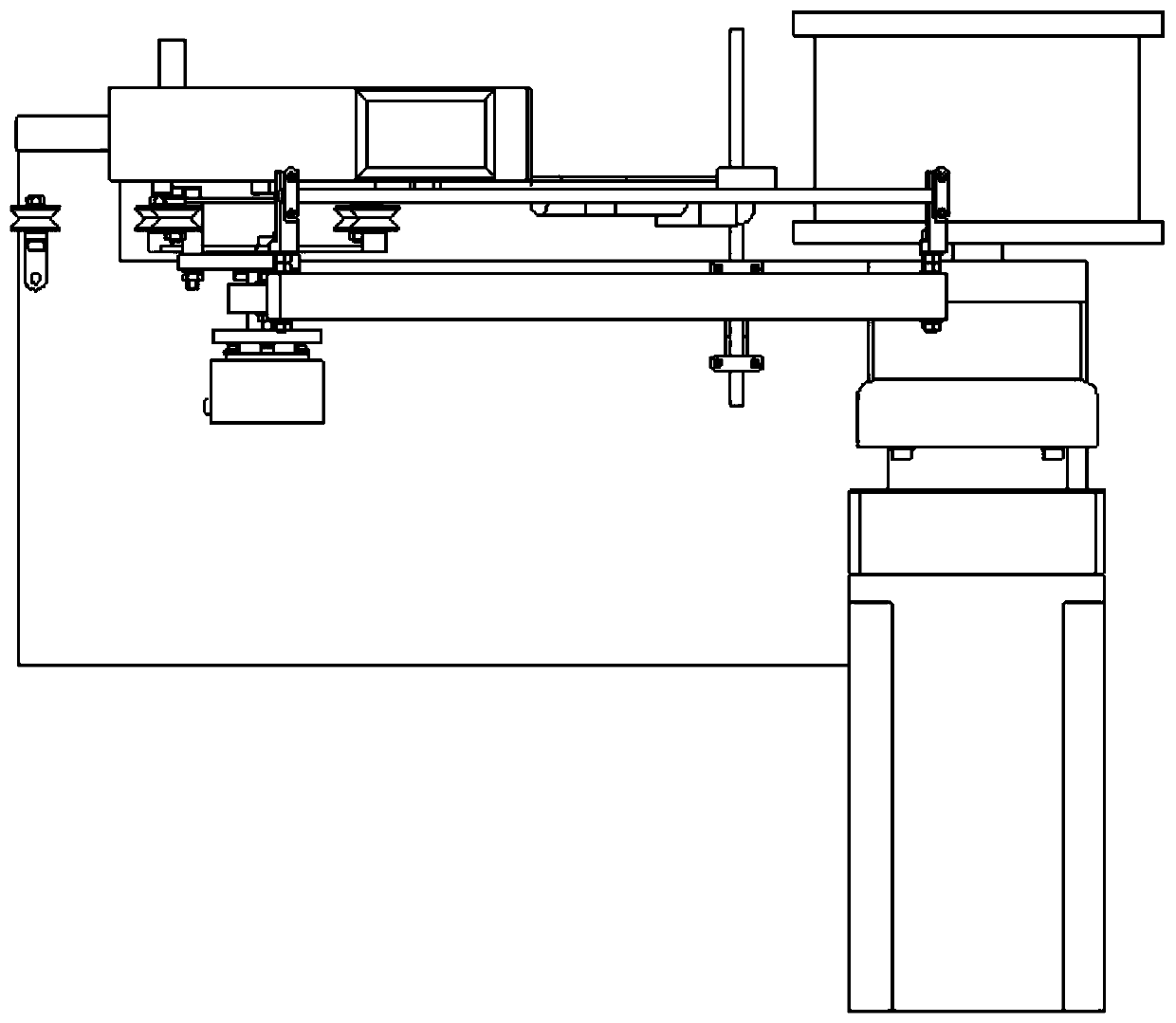

Active pay-off system with variable thread speed and constant tension

The invention provides an active pay-off system with variable thread speed and constant tension. The active pay-off system with variable thread speed and constant tension comprises a platform, a thread tray, a motor drive device, a thread pressing rod, a double-guide-wheel thread tightener, a shaft angle sensor, a guide wheel, a tension controller, a thread guiding rod and a pay-off tension control system. The motor drives the device to drive the thread tray to rotate, a silk thread is wound on the thread tray, the silk thread drawn from the thread tray passes through the thread pressing rod so as to form a wrap angle and enters the double-guide-wheel thread tightener, the silk thread is drawn from the double-guide-wheel thread tightener and then passes through the guide wheel so as to enter the tension controller, and the silk thread passing through the tension controller is drawn through the thread guiding rod. According to the active pay-off system with variable thread speed and constant tension provided by the invention, through the joint action of the motor drive device, the double-guide-wheel thread tightener and the shaft angle sensor, the closed-loop control of the pay-offspeed can be realized. Compared with a passive pay-off system characterized by fixing the thread tray on a non-driving device, active pay-off can be realized, and the control system controls the drivedevice to actively adjust the pay-off speed according to an angle value detected by the shaft angle sensor, so that the occurrence of thread breaking or silk thread loosening can be prevented.

Owner:CHINA ELECTRONICS TECH GRP NO 39 RES INST

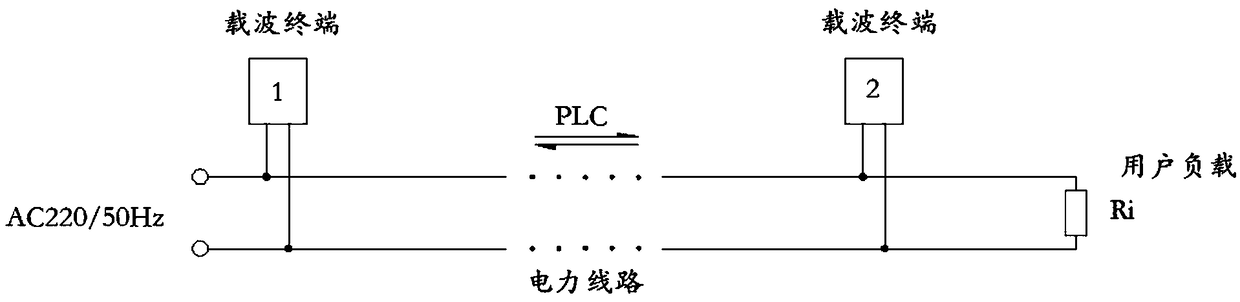

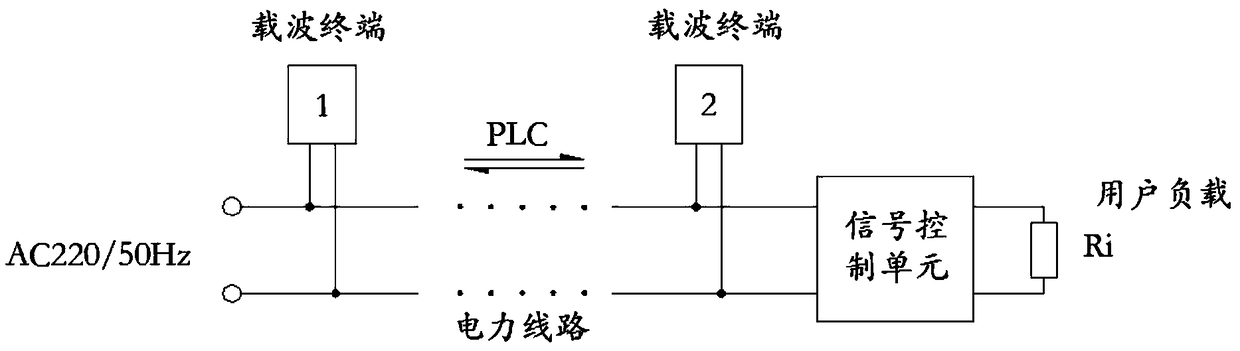

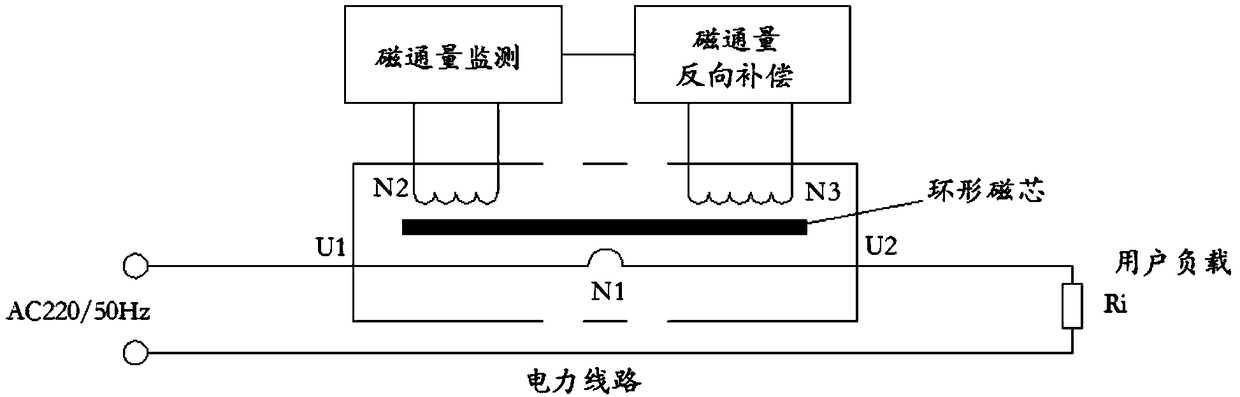

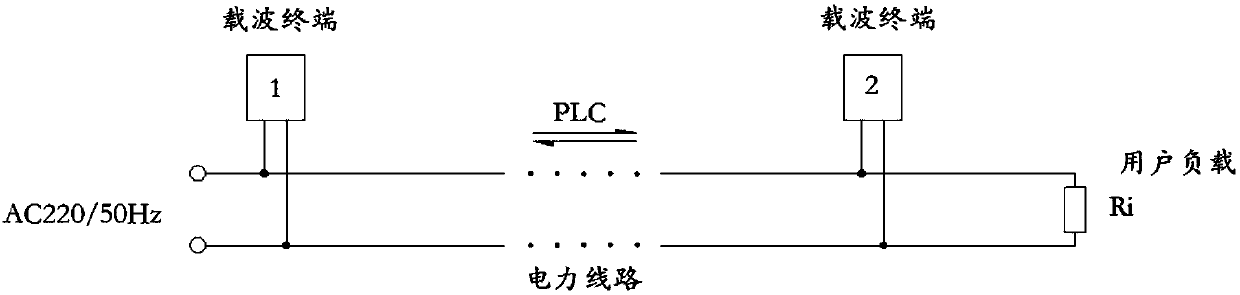

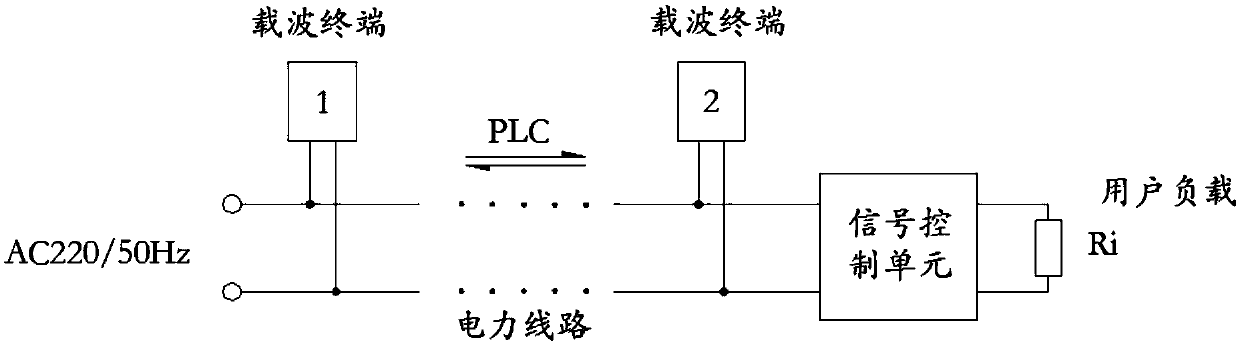

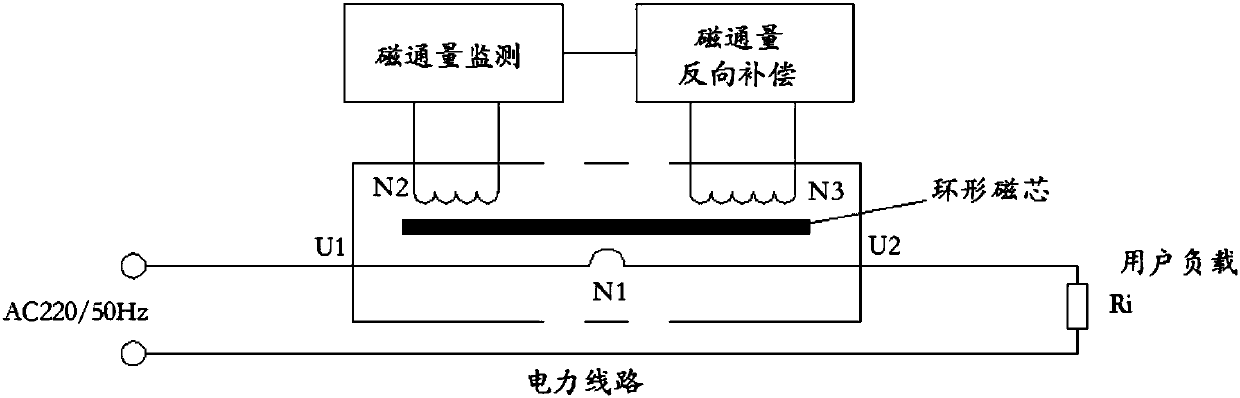

System capable of suppressing attenuation of power carrier signal

ActiveCN108923823AInhibition attenuationStable deliveryElectric signal transmission systemsPower distribution line transmissionUltrasound attenuationReliable transmission

The invention discloses a system capable of suppressing attenuation of a power carrier signal, which comprises a power line and a user load connected to a power line terminal, wherein the power line is used for transmitting an AC power supply signal and a power carrier signal simultaneously. The system capable of suppressing attenuation of the power carrier signal is characterized in that the power line is connected with a signal control module; the signal control module is normally open for the AC power supply signal and is normally disconnected for the power carrier signal, so that the userload is disconnected with the carrier signal to suppress attenuation of the user load to the carrier signal. The system capable of suppressing attenuation of the power carrier signal in the inventionensures smooth and reliable transmission of the carrier signal between the carrier terminals.

Owner:ZHUHAI KEHUI ELECTRICAL APPLIANCE CO LTD

Preparation method of superfine core wire multi-core MgB2 superconducting wire strip

ActiveCN113571254AHigh bonding strengthGuaranteed co-morphing capabilitySuperconductors/hyperconductorsSuperconductor device manufacture/treatmentWire rodEngineering

The invention discloses a preparation method of a superfine core wire multi-core MgB2 superconducting wire strip, which comprises the steps of 1, mixing tubing precursor powder, grinding to obtain mixed powder, and cleaning the surface of a wrapping material; 2, filling the mixed powder into a primary sheath, and drawing to obtain a single-core wire; 3, bundling and assembling a plurality of single-core wires, a central plunger and an edge plunger into a secondary sheath for vacuum seal welding; 4, sequentially carrying out hot extrusion, groove rolling and drawing, and matching an intermediate heat treatment process; and 5, performing phase forming heat treatment to obtain the superfine core wire multi-core MgB2 superconducting wire strip. According to the invention, through structural design and hot extrusion of the multiple single-core wires after bundling and assembling, the bonding strength between the sub-components is improved, the cooperative deformation capacity between the sub-components is guaranteed, the number of the superconducting core wires is increased, the diameter of the superconducting core wires is reduced, the alternating current loss performance of the multi-core MgB2 superconducting wire strip is reduced, and the requirement of alternating current transmission application is met.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Light-emitting diode structure and method for manufacturing the same

InactiveCN103579148ASolve disconnectionImprove production yieldSemiconductor/solid-state device detailsSolid-state devicesInterconnectionEngineering

A light-emitting diode (LED) structure and a method for manufacturing the same. The LED structure includes an insulation substrate, a plurality of LED chips and a plurality of interconnection layers. Each LED chip includes an epitaxial layer and a dielectric layer stacked on a surface of the insulation substrate in sequence. Each LED chip is formed with a first conductivity type contact hole and a second conductivity type contact hole penetrating the dielectric layer, and a first isolation trench disposed in the epitaxial layer and between the second conductivity type contact hole of the LED chip and the first conductivity type contact hole of the neighboring LED chip. Each interconnection layer extends from the second conductivity type contact hole of each LED chip to the first conductivity type contact hole of the neighboring LED chip by passing over the first isolation trench to electrically connect the LED chips.

Owner:CHI MEI LIGHTING TECH +1

Annular needle-shaped electric defogging cathode ray

ActiveCN102989585AGuaranteed uptimeUniform dischargeElectrode constructionsSocial benefitsWhole body

Owner:GUANGXI MINGLI CHEM

Method for suppressing attenuation of power carrier signal

ActiveCN107592139AInhibition attenuationStable deliveryElectric signal transmission systemsPower distribution line transmissionUltrasound attenuationElectricity

The invention discloses a method for suppressing the attenuation of a power carrier signal. The power carrier signal is transmitted by a power line; the power line is used for transmitting a second electrical signal; a terminal of the power line is connected with a user load; a signal control unit is connected on the power line; and the signal control unit is normally opened for the second electrical signal, and is normally closed for the power carrier signal, so that the user load is not connected with the carrier signal, and suppression of the carrier signal by the user load is suppressed. Through adoption of the method, smooth and reliable transmission of the carrier signal between carrier terminals is ensured. Attenuation caused by a load on the carrier power line can be suppressed effectively.

Owner:ZHUHAI KEHUI ELECTRICAL APPLIANCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com