Adjustable cathode fixing device for high-voltage wet electrostatic precipitator

A technology of wet electrostatic precipitator and cathode fixation, which is applied in the direction of electrode conveying device, external electrostatic separator, electrostatic separation, etc., can solve the problems of uneven electrode spacing, low operating efficiency, and inability to operate at full load, so as to solve the problem of flue gas escape, improve operating efficiency, and solve the effect of insulation failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is attached Figure 1-6 The features and principles of the present invention are described in detail, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

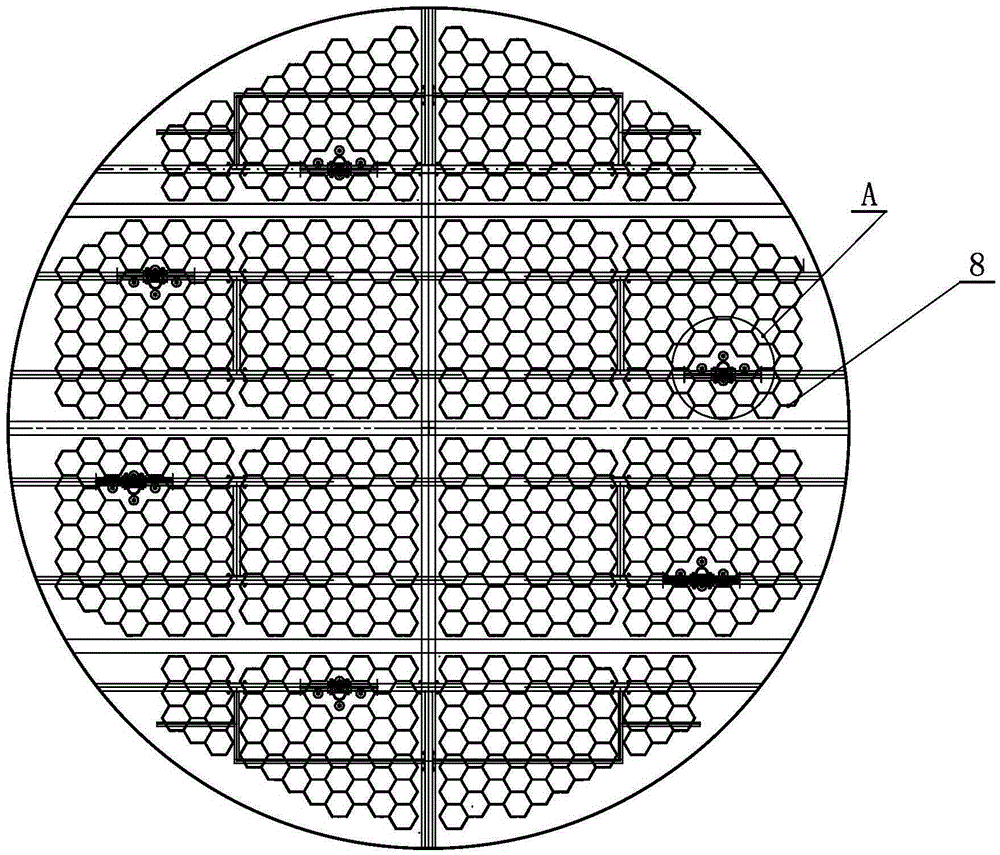

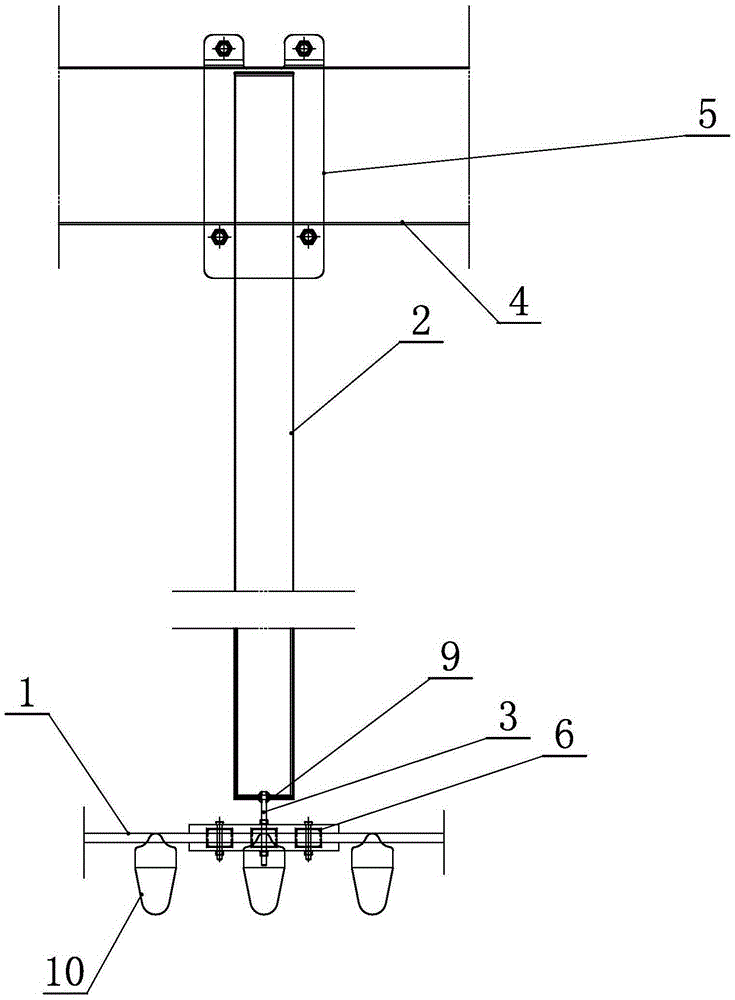

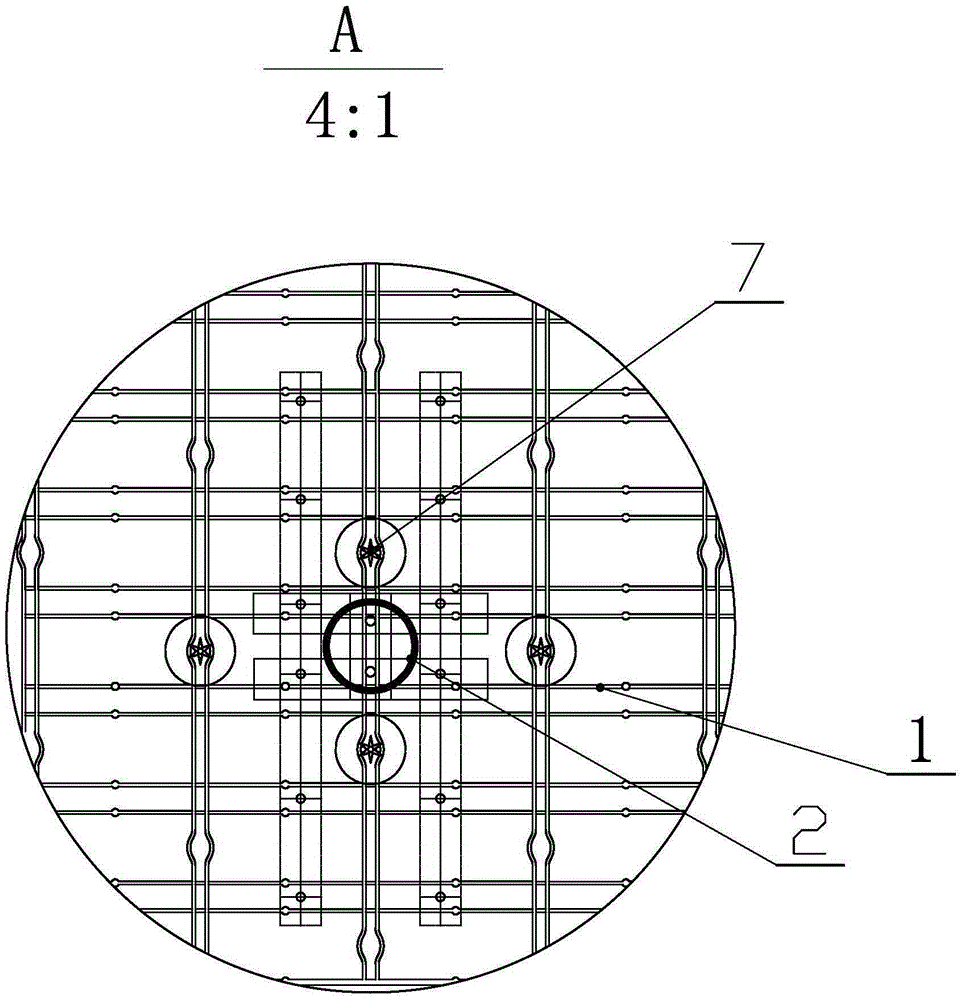

[0027] like Figure 1-6 As shown, the invention includes a cathode frame 1, a cathode fixing pile 2, a connection channel between the cathode frame of the upper air chamber and the cathode frame of the lower air chamber, an adjustment bolt 3, a cathode beam 4 and a cathode beam clamping flange 5.

[0028] The cathode frame is provided with channel steel 6 for connecting the frame with cathode fixing piles, and several cathode wire tensioning weights 10 are provided on the cathode frame. The channel steel is buckled on the cathode frame to increase the connection rigidity between the cathode frame and the adjusting bolt. The cathode girder is located above the cathode frame, and the cathode pile is welded on one of the flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com