Positive electrode grid line of solar cell, solar cell and manufacturing method of solar cell

A technology of solar cells and manufacturing methods, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of affecting current collection, increasing the risk of disconnection, and affecting battery quality, so as to improve conversion efficiency, Conducive to pooling and cost-increasing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

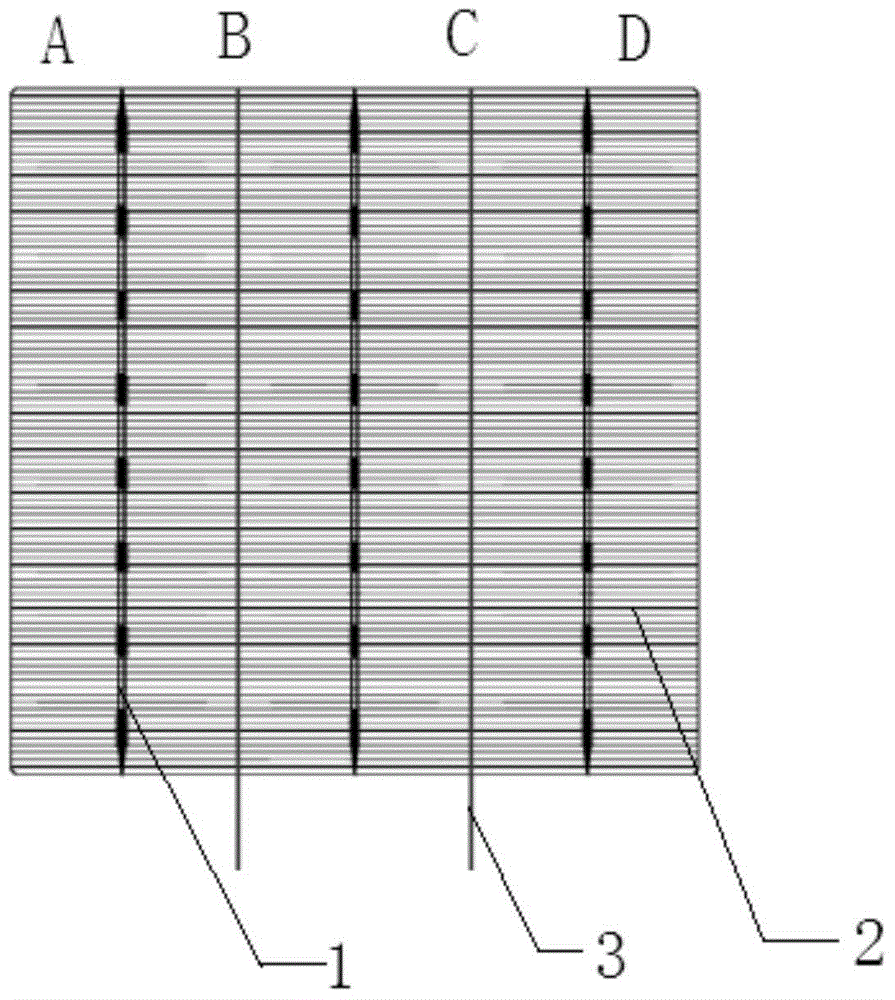

[0027] Embodiment 1: This implementation provides a solar cell positive electrode grid line, including at least 3 main grid lines 1 and a plurality of auxiliary grid lines 2, and the grid line distribution schematic diagram is as follows figure 1 As shown, there are 3 main grid lines, which divide the cell into four areas A, B, C, and D.

[0028] The three main gate lines 1 are arranged parallel to each other, and the auxiliary gate lines 2 are arranged parallel to each other and perpendicular to the main gate lines 1 . The central axis between two adjacent main grid lines 1 is the main grid center line 3, and the width of the auxiliary grid line 2 is from the main grid line 1 to the main grid center line 3 or the positive electrode of the battery The margins are distributed in a stepwise reduction.

[0029] The schematic diagram of the sub-grid width distribution is shown in figure 2 As shown, in the regions B and C, the width of the auxiliary gate line 2 is distributed in...

Embodiment 2

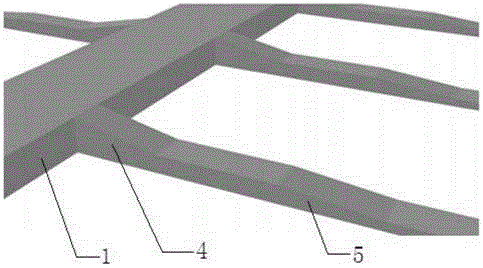

[0034] Embodiment 2: This implementation provides a positive electrode grid wire of a solar cell, and the structural diagram is as follows image 3 As shown, its structure is basically the same as that of Embodiment 1, the difference is that the width of the sub-grid line 2 is reduced in a stepped manner, and its starting position is the connection between the sub-grid line and the main grid line. The width of the starting position is 80 μm, the width of the ending position is 40 μm, and the waistline height of the step is 1 mm. .

[0035] For this embodiment 2 image 3 The positive electrode grid line of the structure was tested, and the test conditions and results are as follows:

[0036] The test items are as follows:

[0037] Test 10,000 cells on two production lines with the same configuration using the newly designed pattern and the original design pattern.

[0038] Every 1 hour, take 24 finished cells for EL test.

[0039] Count the number of EL broken grids, calcu...

Embodiment 3

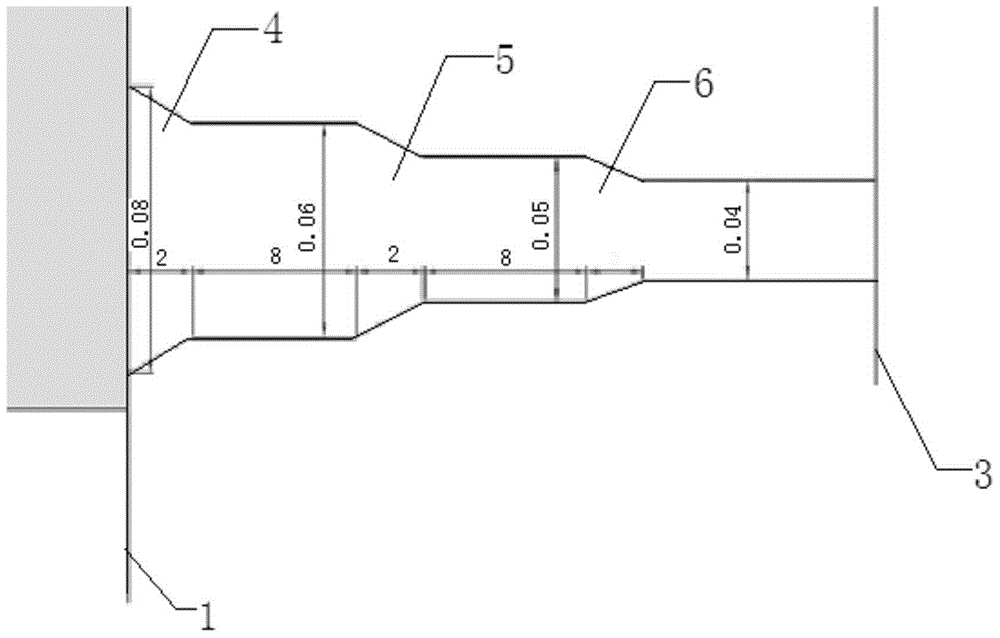

[0043]Embodiment 3: This implementation provides a positive electrode grid line of a solar cell, the structure of which is basically the same as that of Embodiment 1, the difference is that the height of the auxiliary grid line is from the main grid line to the center of the main grid Lines or the edge of the positive electrode of the battery are in a stepwise decreasing distribution, and the width distribution step of the auxiliary grid line corresponds to the height distribution step of the auxiliary grid line, and the height of the auxiliary grid line is in a stepwise decreasing distribution. Such as Figure 4 shown.

[0044] In the embodiment, the width of the sub-grid line 2 is reduced in a three-step manner. Therefore, in this embodiment, the height of the sub-grid line 2 is distributed in a three-step manner. 1 equal height, the height is 25 μm, and the height of the end position is 22 μm; the start position of the second step 5 is equal to the end position of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com