Light-emitting diode structure and method for manufacturing the same

A technology for light-emitting diodes and a manufacturing method, which is applied to electrical components, electrical solid-state devices, circuits, etc., can solve the problems of reducing the aspect ratio of the interconnection layer and the disconnection of the interconnection layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

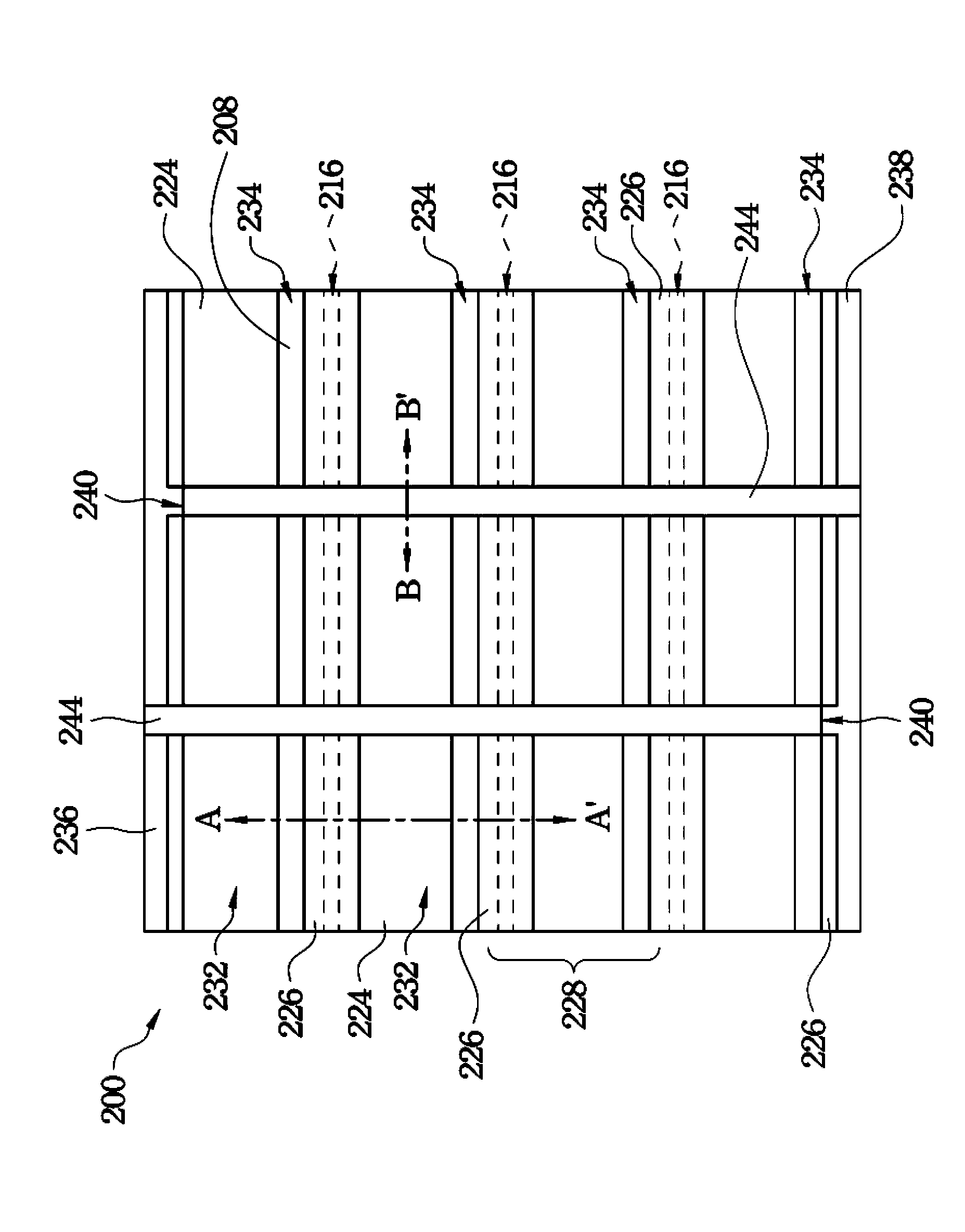

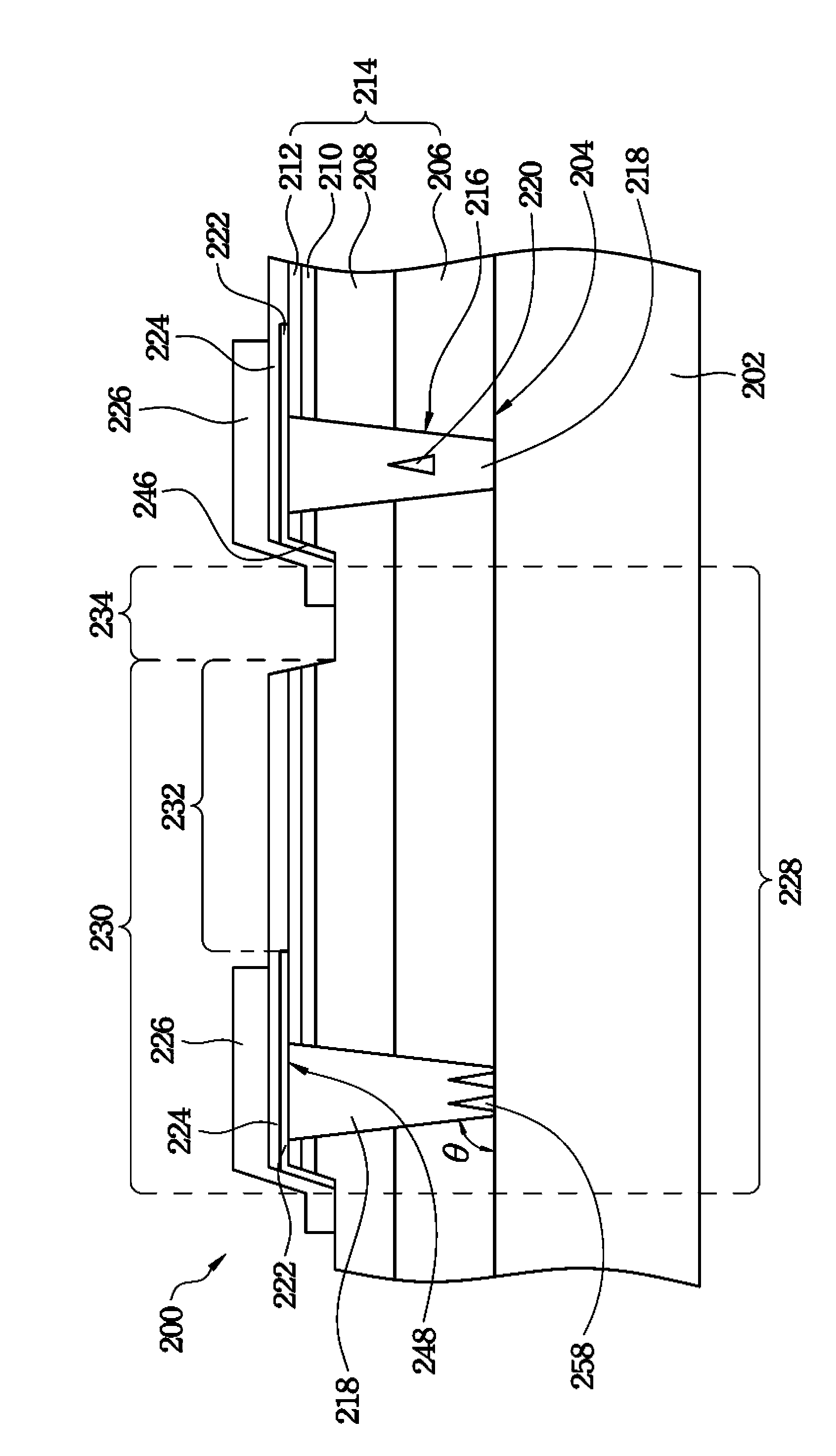

[0088] Please refer to Figure 2 to Figure 4 ,in figure 2 A top view showing a light emitting diode structure according to an embodiment of the present invention, Figure 3A drawn along figure 2 The cross-sectional view of the light-emitting diode structure obtained by the AA' section line, Figure 4 drawn along figure 2 The cross-sectional view of the LED structure obtained by the BB' section line. In this embodiment, the light emitting diode structure 200 may be a high voltage light emitting diode (High Voltage LED; HV LED).

[0089] like figure 2 As shown, the LED structure 200 is formed by connecting several LED chips 228 in series. exist figure 2 In the illustrated embodiment, the LED structure 200 is composed of 12 LED chips 228 connected in series. Isolation trenches 216 and 240 are provided around each LED chip 228 to electrically isolate these LED chips 228 . In addition, the adjacent LED chips 228 are electrically connected through the conductive interc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com