Wet electrostatic precipitator cathode wire weldless connection structure

A wet electrostatic precipitator, welding-free connection technology, applied in electrode structure, electrostatic separation and other directions, can solve the problems of reduced rapping cleaning effect, large shrinkage rate after welding, and dust removal failure, etc., to achieve high application value and prospects, dismantling Easy to install and easy to connect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

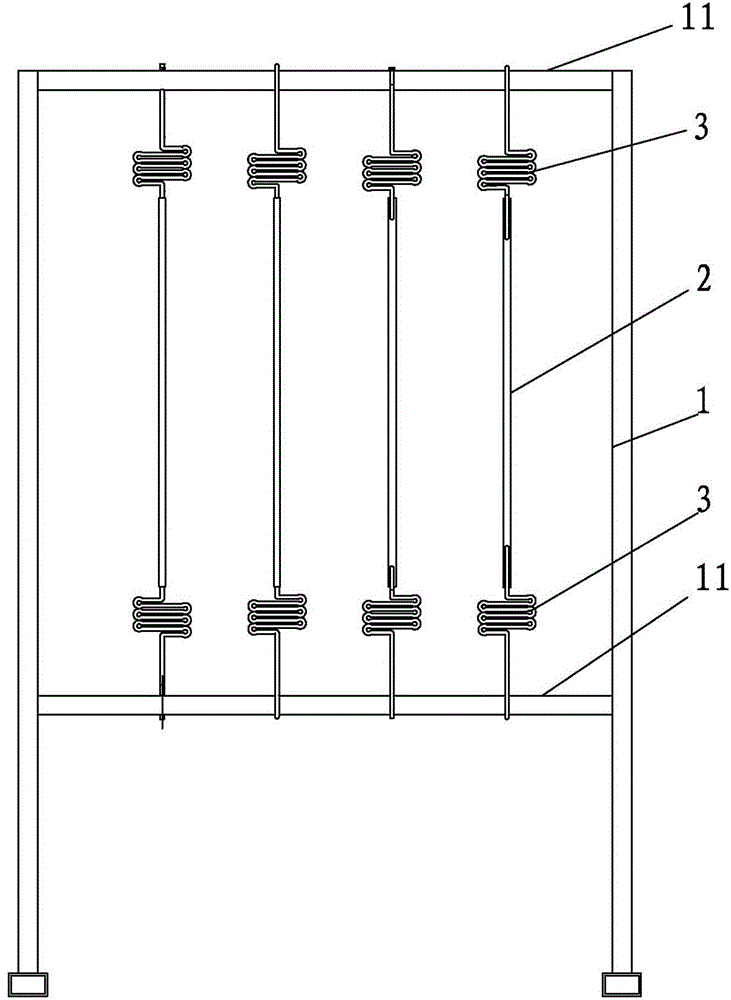

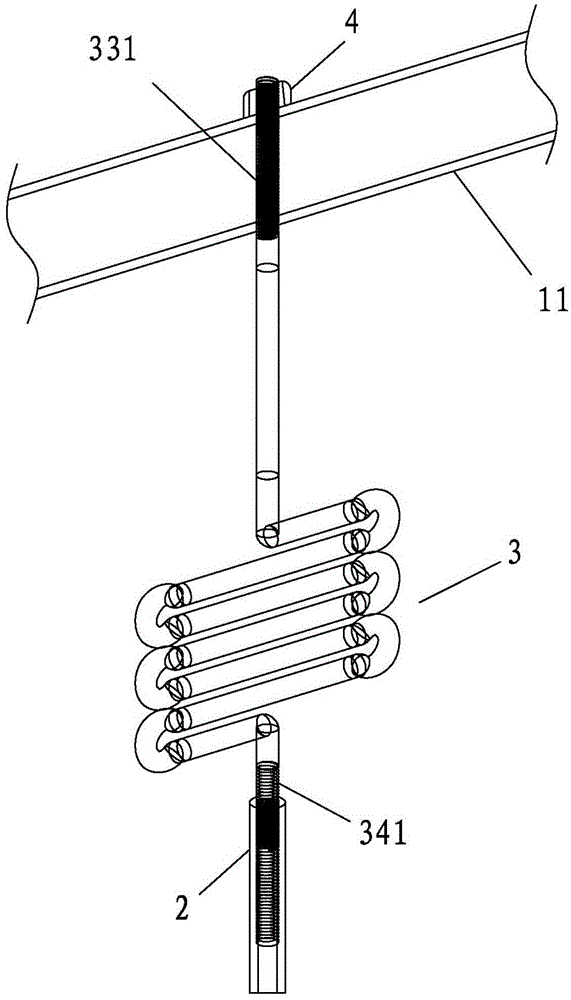

[0031] This case involves a non-welded connection structure for wet electrostatic precipitator cathode wires, such as figure 1 As shown, there is a frame 1 and a cathode wire 2, and the cathode wire 2 is usually provided with several pieces side by side. In particular, it also has two elastic pieces 3 arranged in pairs. The two elastic parts 3 have two upper and lower connecting ends, one of which can be detachably connected to the upper and lower ends of the cathode wire 2, and the other connecting ends of the two elastic parts 3 can be detachably connected to the upper and lower ends of the frame 1 respectively. on the corresponding crossbar 11.

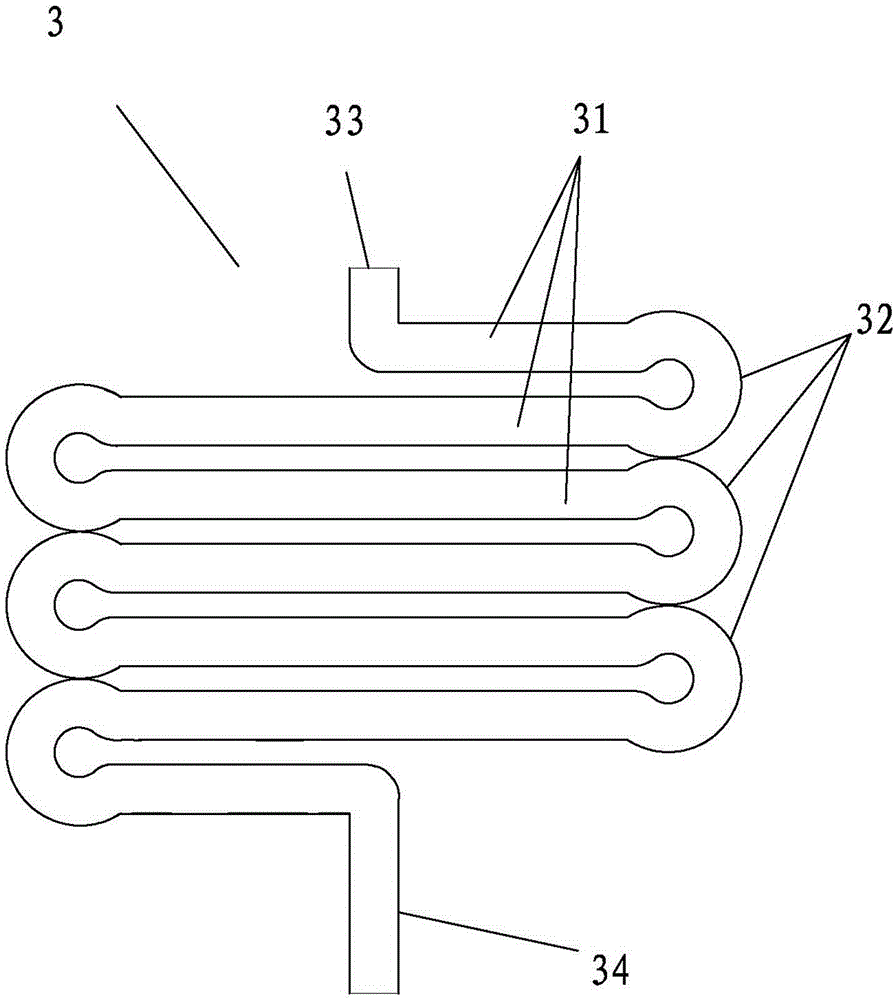

[0032] The present invention also carries out innovative design to elastic member 3, as figure 2 As shown, the elastic member 3 is formed by bending a steel bar (preferably a circular steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com