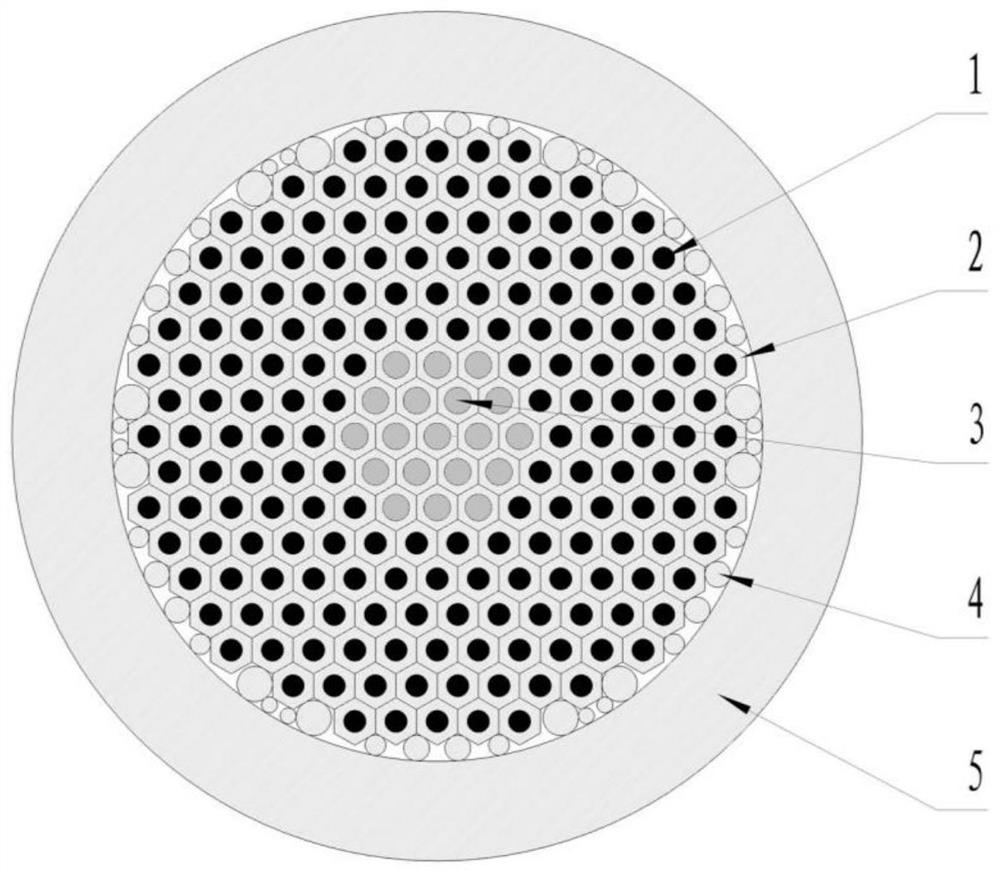

Preparation method of superfine core wire multi-core MgB2 superconducting wire strip

A superconducting wire, thin core technology, applied in the usage of superconducting elements, the manufacture/processing of superconducting devices, superconducting devices, etc., can solve the problems of increased process cost, unfavorable process promotion, inability to realize, etc., to reduce AC loss performance, solving broken cores, and ensuring the effect of synergistic deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

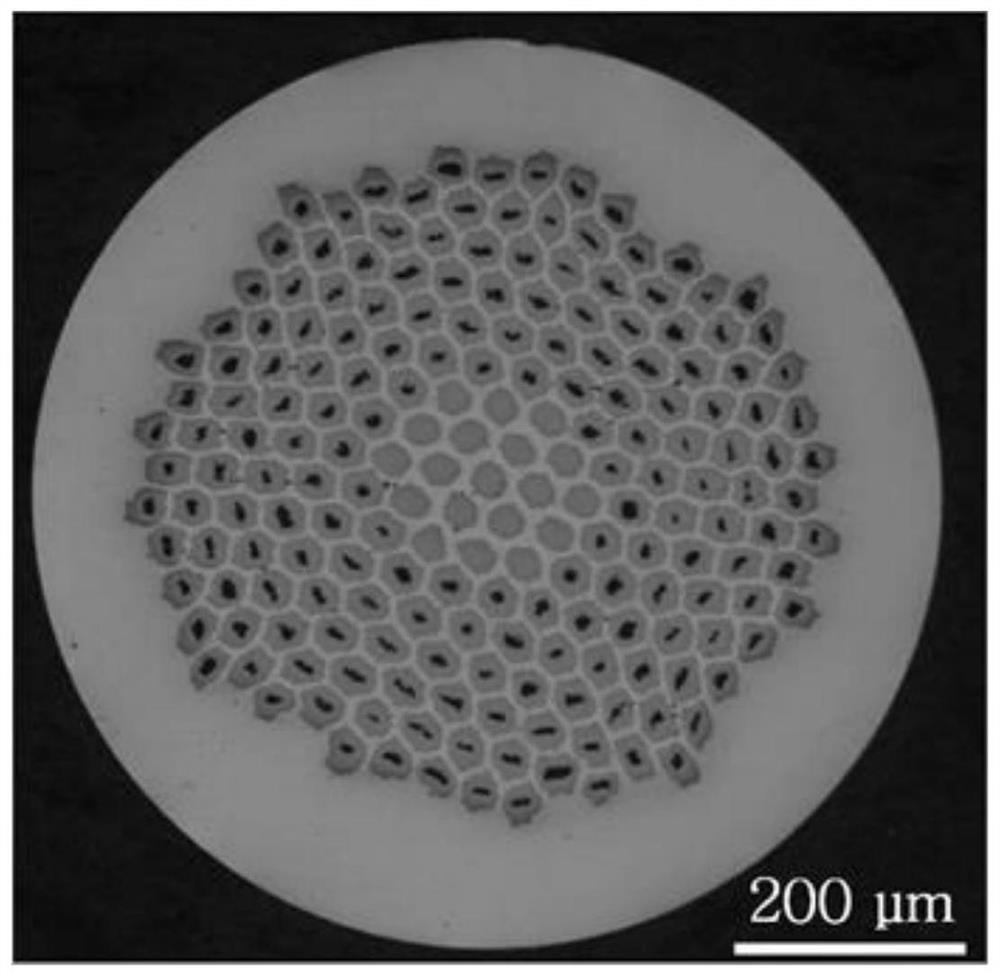

[0030] This embodiment includes the following steps:

[0031] Step 1. Calculate and weigh the amorphous B powder with a particle size of 300nm and a mass purity of 99% and the Mg powder with a particle size of 5 μm and a mass purity of 99.5% according to the molar ratio of Mg:B=1:2. After mixing Grind to obtain mixed powder, and at the same time, carry out surface cleaning on the sheathing materials including the primary sheathing Nb / Cu composite pipe and the secondary sheathing B30 alloy sheathing. ‰ mass concentration of metal cleaning agent aqueous solution in ultrasonic cleaning equipment at 50 ° C for 20 minutes to complete the degreasing treatment, and then use nitric acid aqueous solution to remove surface oxides;

[0032] Step 2, in a vacuum glove box under the protection of argon with a mass purity of 99.999%, fill the mixed powder obtained in step 1 into the Nb / Cu composite tube after surface cleaning and drying, and then use 10% The single-core wire rod is drawn at...

Embodiment 2

[0038] This embodiment includes the following steps:

[0039] Step 1. Calculate and weigh the amorphous B powder with a particle size of 200nm and a mass purity of 99% and the Mg powder with a particle size of 1 μm and a mass purity of 99.5% according to the molar ratio of Mg:B=1:2. After mixing Grind to obtain mixed powder, and at the same time, carry out surface cleaning on the sheathing materials including the primary sheathing Nb / Cu composite pipe and the secondary sheathing B30 alloy sheathing. ‰ mass concentration of metal cleaning agent aqueous solution in ultrasonic cleaning equipment at 60 ° C for 15 minutes to complete degreasing treatment, and then use nitric acid aqueous solution to remove surface oxides;

[0040] Step 2, in a vacuum glove box under the protection of argon with a mass purity of 99.999%, fill the mixed powder obtained in step 1 into the Nb / Cu composite tube after surface cleaning and drying, and then use 10% The single-core wire rod is drawn at a p...

Embodiment 3

[0045] This embodiment includes the following steps:

[0046] Step 1. Calculate and weigh the amorphous B powder with a particle size of 400nm and a mass purity of 99% and the Mg powder with a particle size of 10 μm and a mass purity of 99.5% according to the molar ratio of Mg:B=1:2. After mixing Grind to obtain mixed powder, and at the same time, carry out surface cleaning on the sheathing materials including the primary sheathing Nb / Cu composite pipe and the secondary sheathing B30 alloy sheathing. ‰ mass concentration of metal cleaning agent aqueous solution in ultrasonic cleaning equipment at 30 ° C for 30 minutes to complete degreasing treatment, and then use nitric acid aqueous solution to remove surface oxides;

[0047] Step 2, in a vacuum glove box under the protection of argon with a mass purity of 99.999%, fill the mixed powder obtained in step 1 into the Nb / Cu composite tube after surface cleaning and drying, and then use 10% The single-core wire rod is drawn at a pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com