Reflective laser level with common-point three-dimensional beam splitting prism

A laser line thrower, three-dimensional technology, applied in the direction of instruments, measuring instruments, active optical measuring devices, etc., can solve the problems affecting the realization of the productization of the axicon reflective laser line thrower, and achieve the solution of laser line deformation, high-tech , the effect of reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

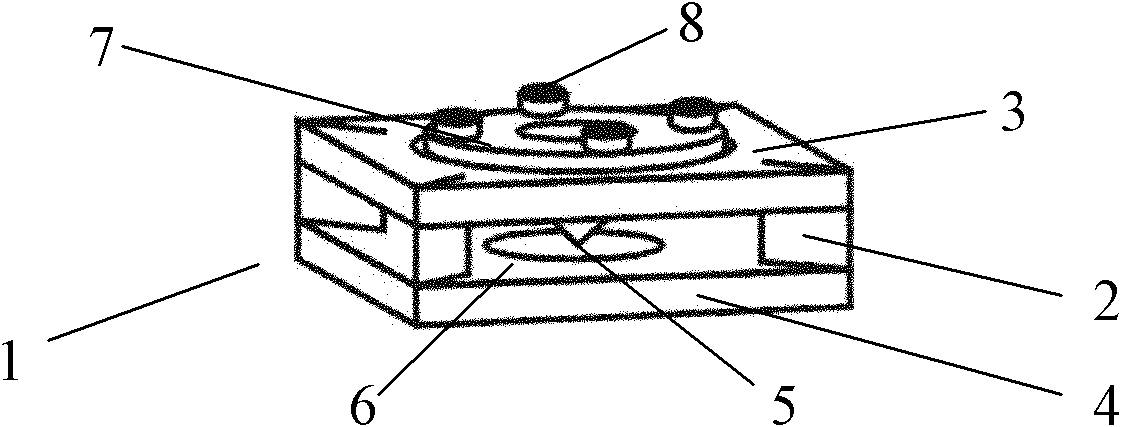

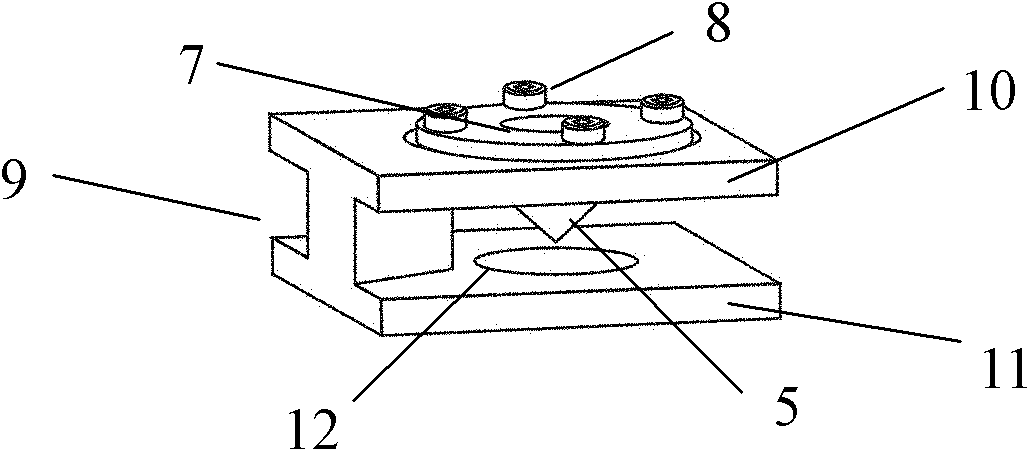

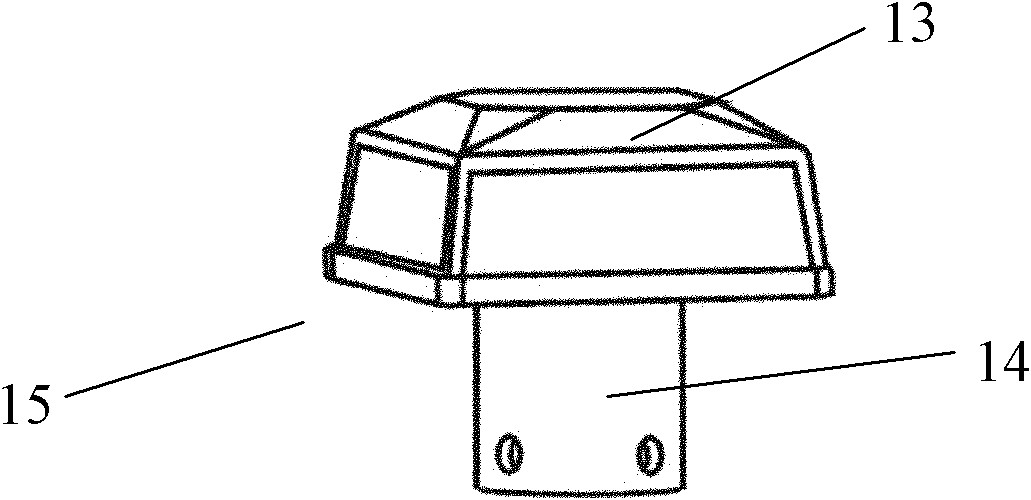

[0041] see Figure 1 to Figure 10 , a co-point three-dimensional beam-splitting cone reflective laser line projector of the present invention is composed of a first axicon reflection module 61, a second axicon reflection module 62, a third axicon reflection module 63, and a co-point three-dimensional light-splitting module 16 or 30 , Temperature-controlled single light source system 45 and Anping adjustment system 53 or 65 and body 44, mounting plate 58, base 59, control circuit board 76, battery box 74, shell 71, operation panel 73 and so on.

[0042] Wherein, the co-point three-dimensional spectroscopic module 16 or 30 and the temperature-controlled single light source system 45 are respectively arranged in the main body 44 .

[0043] see Figure 6 , the temperature-controlled single light source system 45 is composed of a laser module 48 , a semiconductor cooler 47 , a radiator 46 , a first reflector 50 , and a second reflector 52 . The semiconductor cooler 47 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com