High-density flexible circuit board and manufacturing method thereof

A technology of flexible circuit boards and manufacturing methods, which is applied in the fields of printed circuit manufacturing, printed circuits, electrical components, etc., can solve the problems of low yield rate and achieve the effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Specific embodiments of the present invention are described with reference to the above drawings.

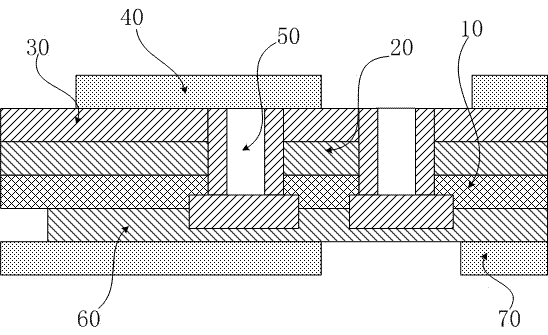

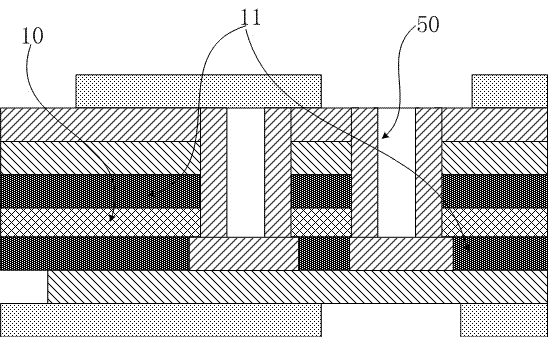

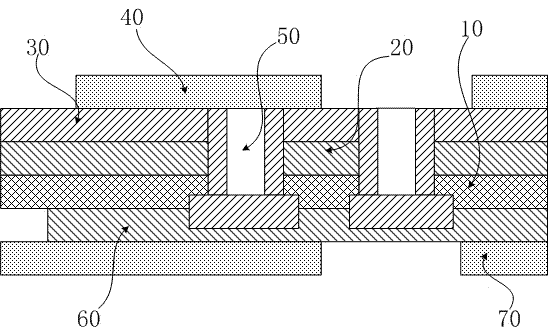

[0010] Depend on figure 1 with figure 2 It can be seen from the figure that this high-density flexible circuit board includes a polyimide base material 10, one side of the base material 10 is provided with a first conductive layer 20, and the first conductive layer 20 is provided with a deposited copper layer 30, The first covering layer 40 is provided on the said sinking copper layer 30, and a blind hole 50 is also drilled on the circuit board, and the said sinking copper layer 30 is along the inner wall of the blind hole 50, and the blind hole 50 The depth of the hole reaches the second conductive layer from the sinker and the copper plating layer 30 . The flexible substrate includes a flexible substrate and a conductive layer covering the flexible substrate, and the flexible substrate is polyimide. The manufacturing process of this high-density flexible circuit boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com