Method for integrally winding pressurized-water reactor nuclear power plant winding connectionless point stick location probe coil

A technology for pressurized water reactor nuclear power plants and rod position detectors, applied in coil manufacturing, inductance/transformer/magnet manufacturing, nuclear power generation, etc., can solve incomplete insulation treatment, threats to safe and stable operation of power plants, high temperature resistance and radiation resistance Very poor and other problems, to solve the problem of coil disconnection and insulation drop, ensure long-term safe and stable operation, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

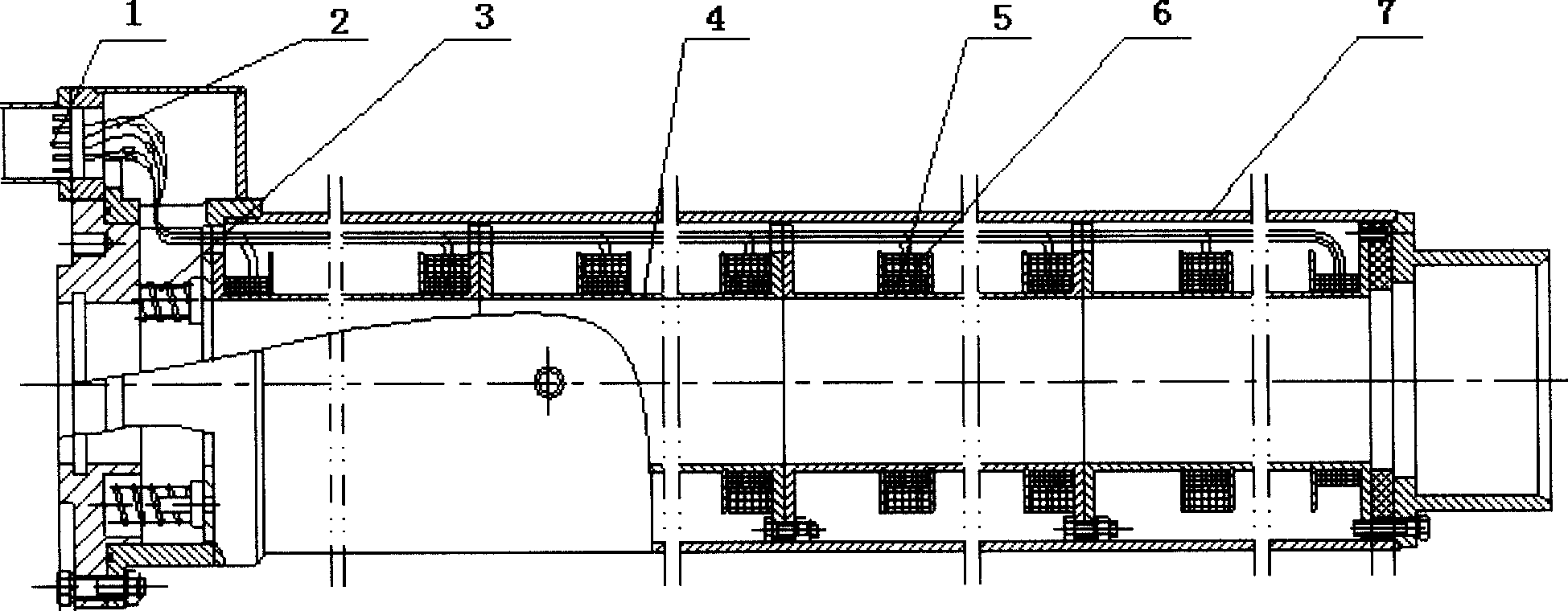

[0032] A PWR nuclear power plant winding non-connection point rod position detector coil overall winding method, the method includes the following steps:

[0033] (1) Use a numerical control winding machine to wind out the primary coil at one time;

[0034] The CNC winding machine is an XFR-1C programmable automatic winding machine, which can automatically counter to ensure accurate counting of the number of winding coils.

[0035] (2) Set the number of starting turns and winding speed of the CNC winding machine, and wind out each position at a time according to the phase sequence of A-B-F-E-C-D or A-B-E-F-C-D stage coil;

[0036] Set the appropriate starting number of turns and winding speed of the CNC winding machine: the number of starting turns of the winding machine (from static to normal speed) should be as many as possible, preferably set to 4 turns; the winding speed should be as low as possible, preferably set to 55r / min.

[0037] (3) The rod position detector coi...

Embodiment 2

[0043] A PWR nuclear power plant winding non-connection point rod position detector coil overall winding method, the method includes the following steps:

[0044] (1) Use a numerical control winding machine to wind out the primary coil at one time;

[0045] The CNC winding machine is an XFR-1C programmable automatic winding machine, which can automatically counter to ensure accurate counting of the number of winding coils.

[0046] (2) Set the number of starting turns and winding speed of the CNC winding machine, and wind out each position at a time according to the phase sequence of A-B-F-E-C-D or A-B-E-F-C-D level coil;

[0047] Set the appropriate starting number of turns and winding speed of the CNC winding machine: the number of starting turns of the winding machine (from static to normal speed) should be as many as possible, preferably set to 4 turns; the winding speed should be as low as possible, preferably set to 55r / min.

[0048] (3) The rod position detector coi...

Embodiment 3

[0054] A PWR nuclear power plant winding non-connection point rod position detector coil overall winding method, the method includes the following steps:

[0055] (1) Use a numerical control winding machine to wind out the primary coil at one time;

[0056] The CNC winding machine is an XFR-1C programmable automatic winding machine, which can automatically counter to ensure accurate counting of the number of winding coils.

[0057] (2) Set the number of starting turns and winding speed of the CNC winding machine, and wind out each position at a time according to the phase sequence of A-B-F-E-C-D or A-B-E-F-C-D level coil;

[0058] Set the appropriate starting number of turns and winding speed of the CNC winding machine: the number of starting turns of the winding machine (from static to normal speed) should be as many as possible, preferably set to 4 turns; the winding speed should be as low as possible, preferably set to 55r / min.

[0059] (3) The rod position detector coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com