Intelligent electronic spot welder and spot welding method thereof

An electronic point and intelligent technology, applied in the direction of resistance welding equipment, welding power supply, electrode characteristics, etc., can solve the problems of small solder joint thickness, large solder joint thickness, low temperature resistance and low temperature resistance of solder joints, etc., and achieve easy use , high degree of automation, solve the effect of virtual welding and disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

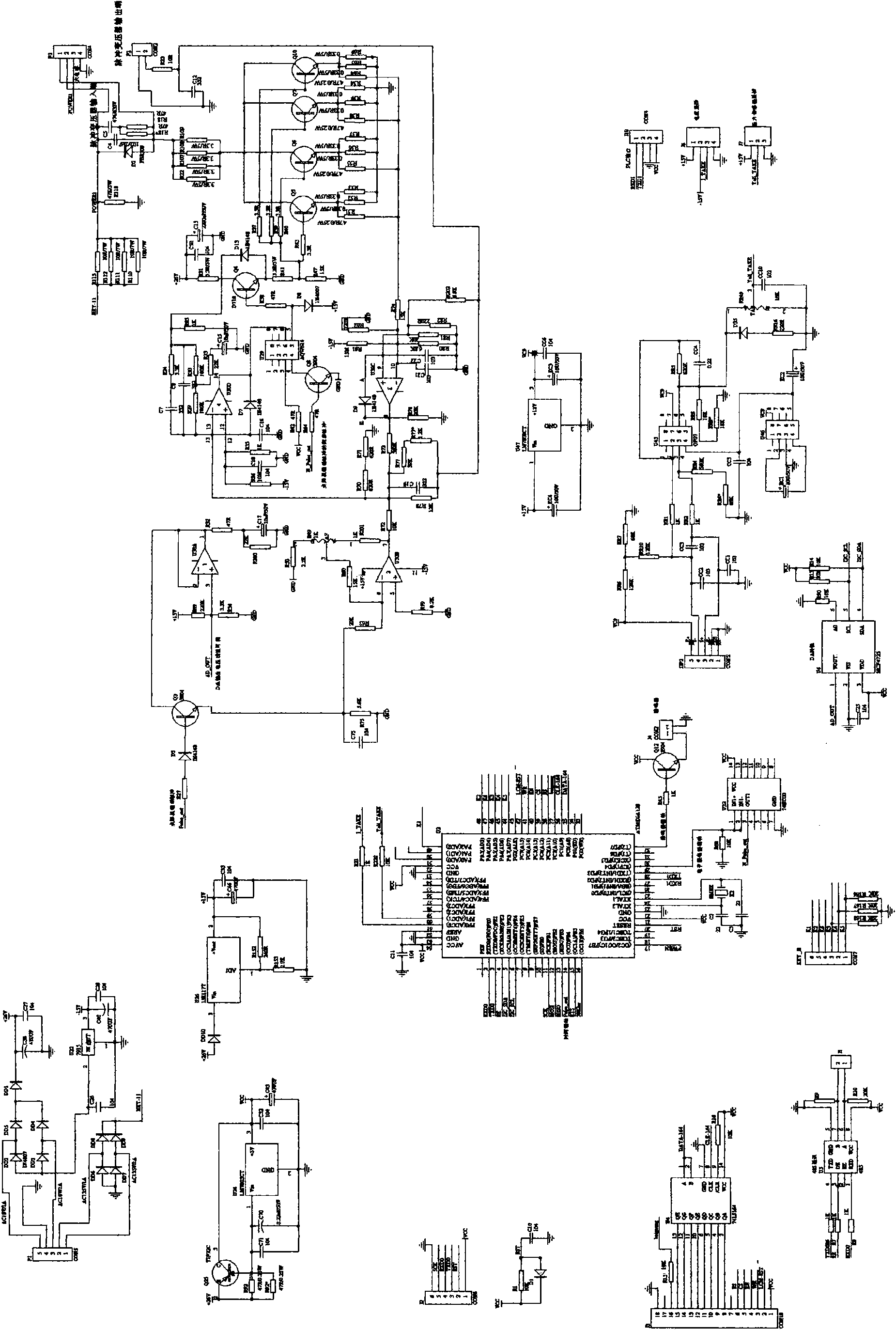

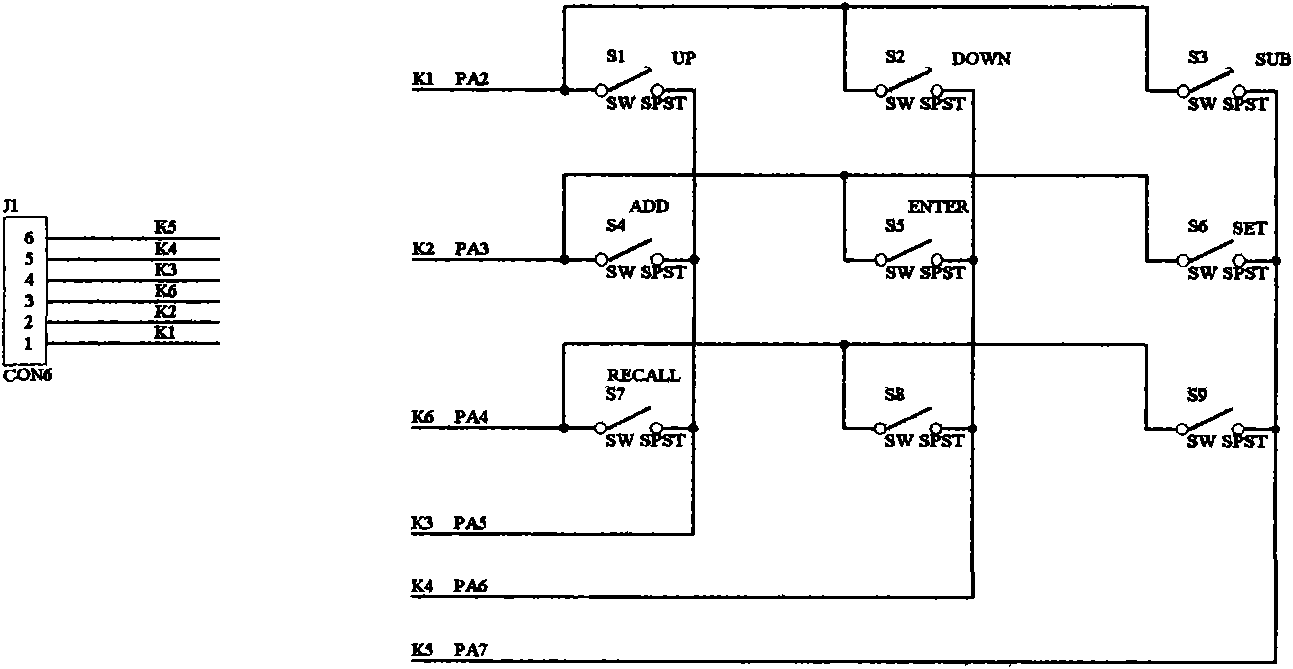

Method used

Image

Examples

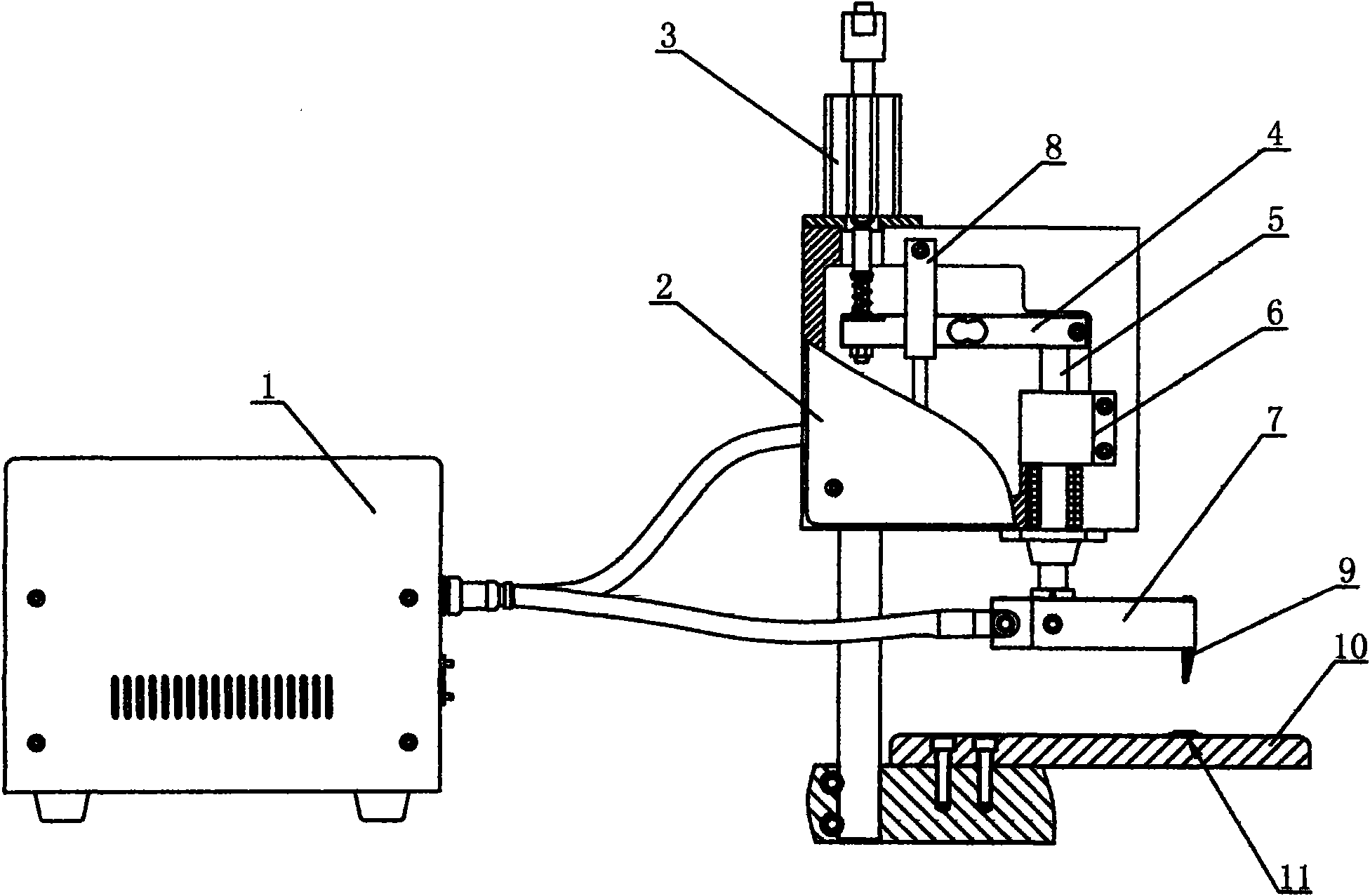

Embodiment 1

[0048] Embodiment one: if Figure 1 to Figure 3 As shown, the intelligent electronic spot welding machine of the present invention comprises a main frame 1, a head 2 and a cylinder 3. The main frame 1 is provided with a single-chip microcomputer control circuit and a welding parameter database management program, and the connecting rod provided with the cylinder 3 and the rear end of the pressure sensor 4 Connected, an electronic grating scale 8 is installed above the pressure sensor 4, the front end of the pressure sensor 4 is linked with the front axle 5, the middle part of the front axle 5 is equipped with an electromagnetic brake device 6, and the welding head clamp 7 is installed at the lower end of the front axle 5, The front end of the welding head clamp 7 is fixed with a spot welding head 9, and below the spot welding head 9 are a workbench 10 and a workpiece 11 to be welded.

[0049] The host 1 controls the cylinder 3, the pressure sensor 4, the electromagnetic brakin...

Embodiment 2

[0050] Embodiment two: if figure 1 , figure 2 and Figure 4 As shown, the intelligent electronic spot welding machine of the present invention comprises a main frame 1, a head 2 and a servo motor 12. The main frame 1 is provided with a single-chip microcomputer control circuit and a welding parameter database management program. The main shaft of 12 is connected to the rear end of the pressure sensor 4 through the flange, and the front end of the pressure sensor 4 is connected to the front shaft 5, and the lower end of the front shaft 5 is equipped with a welding head clamp 7, and the front end of the welding head clamp 7 is fixed with a spot welding head 9, There are 2,000 kinds of welding parameters stored in the memory chip of the host 1, and the paint removal pulse, welding pulse and repair welding pulse are output according to the detected data, and the measurement, welding voltage, current and welding pressure are displayed in real time through the liquid crystal displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com