Method for manufacturing seamlessly spliced leather wear

A production method and seamless splicing technology are applied in the production field of seamless splicing leather garments, which can solve the problems of consumers' human safety hazards, flammability, easy bending of machine needles, etc., so as to solve health hazards, avoid safety hazards, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

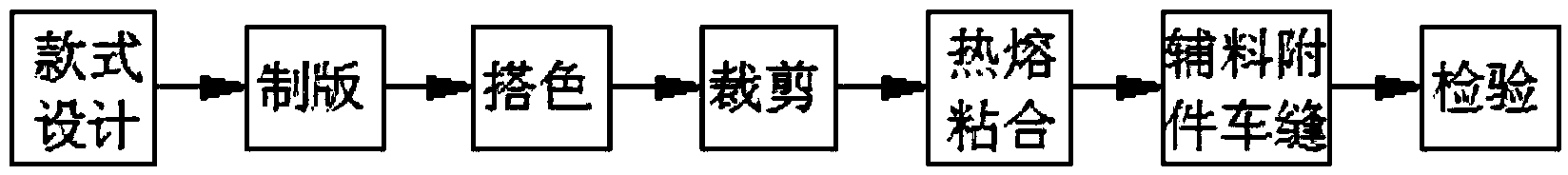

[0035] refer to figure 1 , the present invention includes the following steps:

[0036] a) Product design: According to the characteristics of the seamless stitching process, design novel clothing styles. The design process includes discussion, hand-painting, drawing, and making white blanks;

[0037] b) Plate making: According to the designed style and pattern, plate making is carried out according to the size regulations. The plate making process includes pushing board, typesetting, and cutting board. The template obtained after plate making is accurate, with clear writing and accurate marking;

[0038] c) Color matching: Match the leather materials required for a leather garment according to the color, texture and thickness of the leather materials, and select leather materials with the same thickness and color;

[0039] d) Cutting: According to the sample provided by the technical department, cut the leather material after color matching, and the leather material after cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com