Active pay-off system with variable thread speed and constant tension

A constant tension, active technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of reduced speed, deterioration of wire arrangement accuracy, broken wires, etc., to improve control accuracy and speed, The function relationship is simple and clear, and the effect of preventing the looseness of the silk thread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

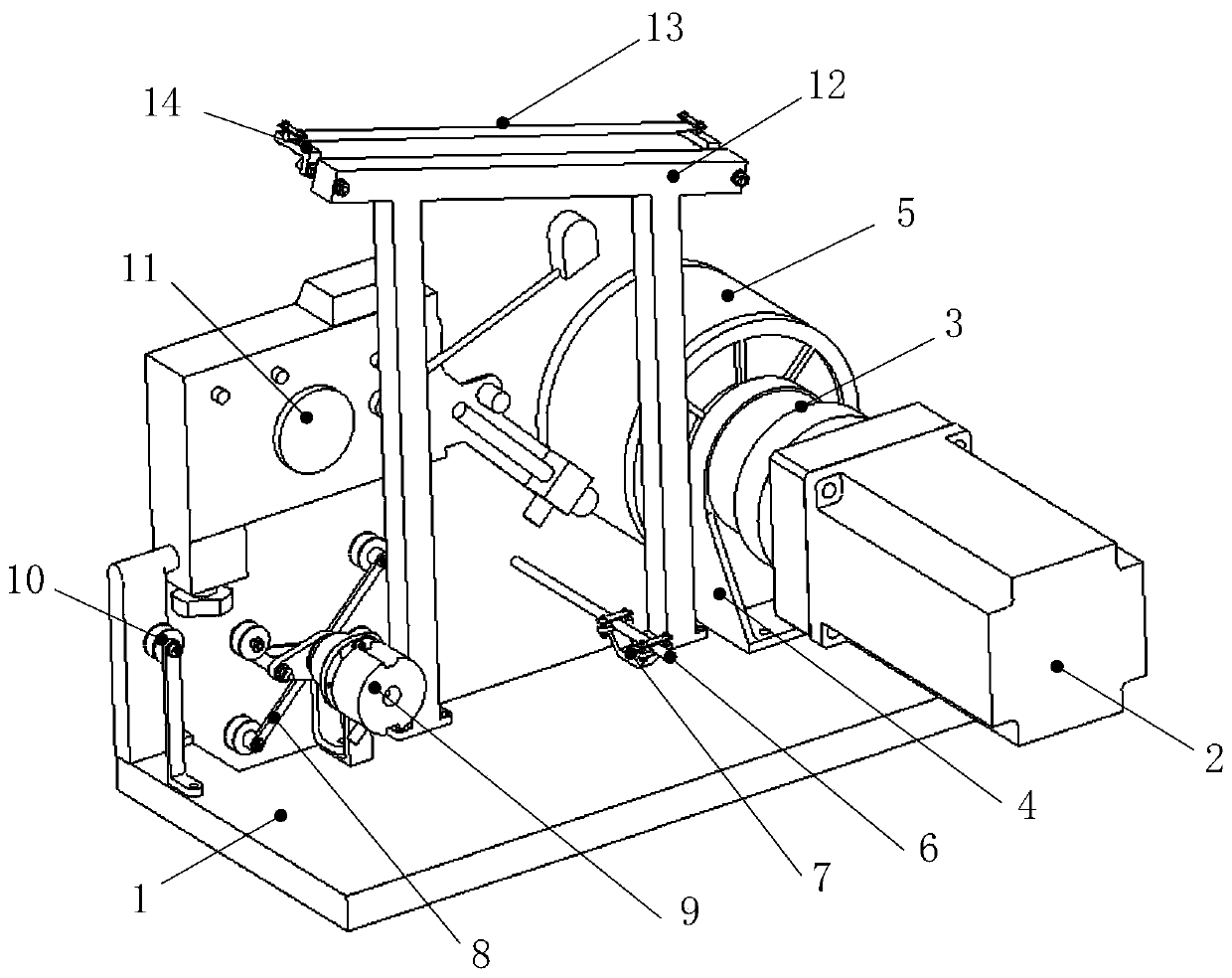

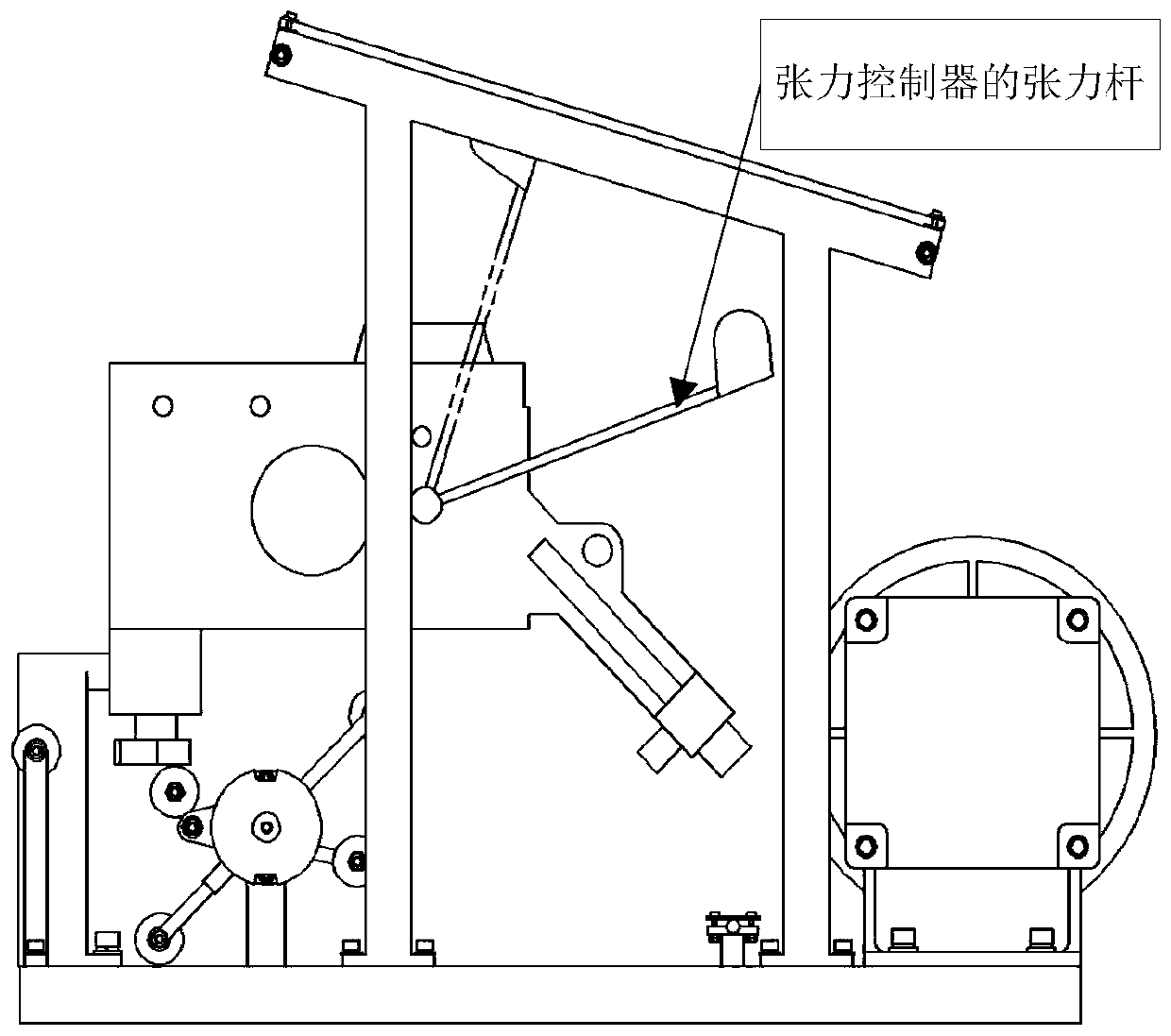

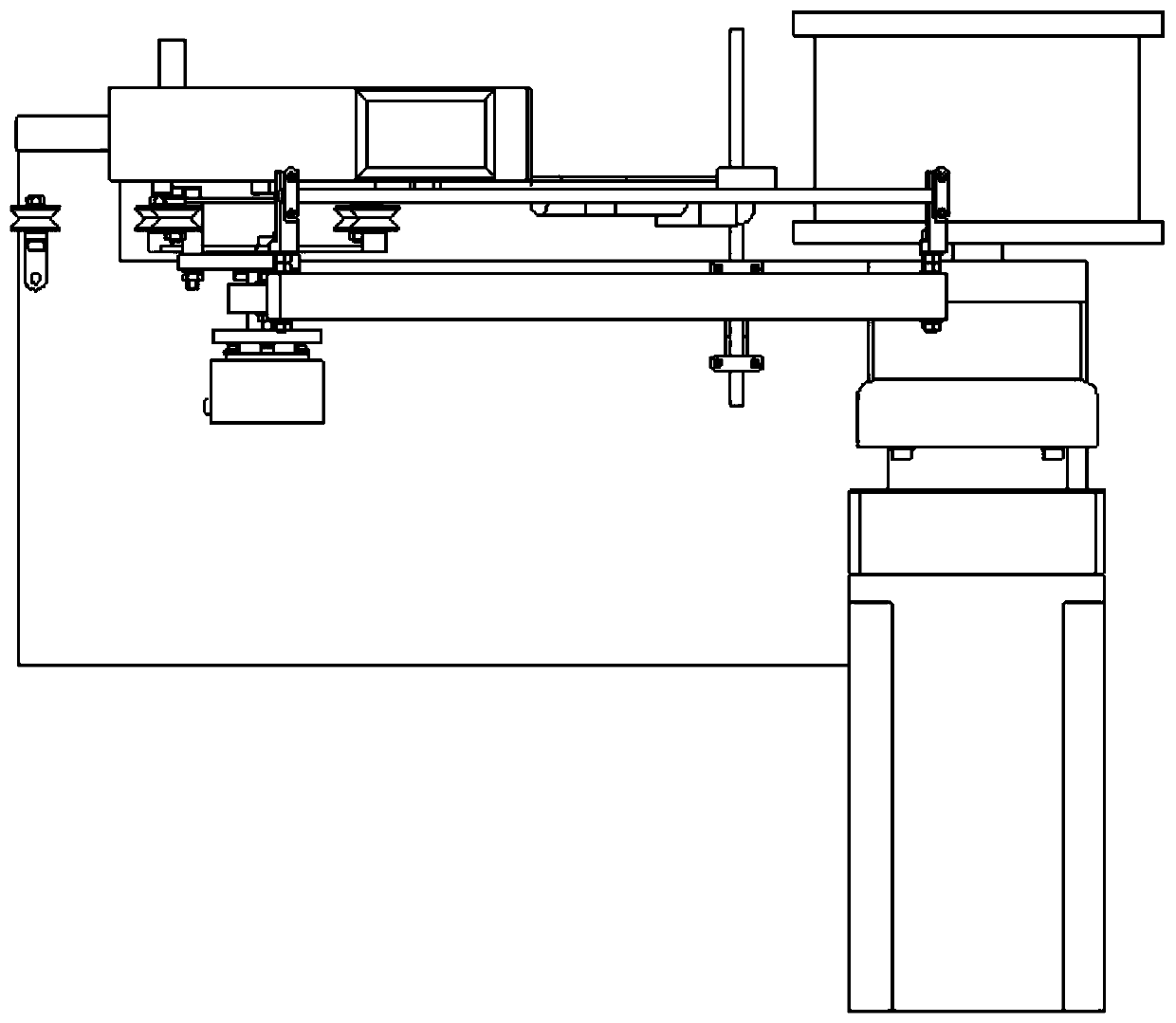

[0037] In this example, first combine Figure 5 ~ Figure 7 Explain the working principle of the double guide wheel tensioner, for the convenience of explanation, Figure 5 ~ Figure 7 Four fixed wheels are adopted in the present embodiment, but in the actual embodiment, the fixed wheels on the outside of both sides are realized by crimping rods and guide wheels.

[0038] Such as Figure 5As shown, the rocker shaft is fixed at the center of the length direction of the rocker, and the rocker shaft is installed on the support. The drive energy is released and stored during the rotation of the direction. Rocker guide wheels are installed at both ends of the rocker.

[0039] Four fixed wheels are arranged in pairs, and among the two fixed wheels in each group of fixed wheels, one is positioned at the outside of the rocker guide wheel's circle of revolution, and one is positioned at the inside of the rocker guide wheel's circle of revolution.

[0040] Such as Figure 5 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com