Rapid fixing type paying-off construction process

A construction technology and fast technology, applied in electrical components, transportation of filamentous materials, cable laying equipment, etc., can solve the problems of scattered cable coils, slow cable pay-off speed, and high labor intensity, and reduce labor costs. cost, increase the speed of the pay-off, and facilitate the effect of limiting the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

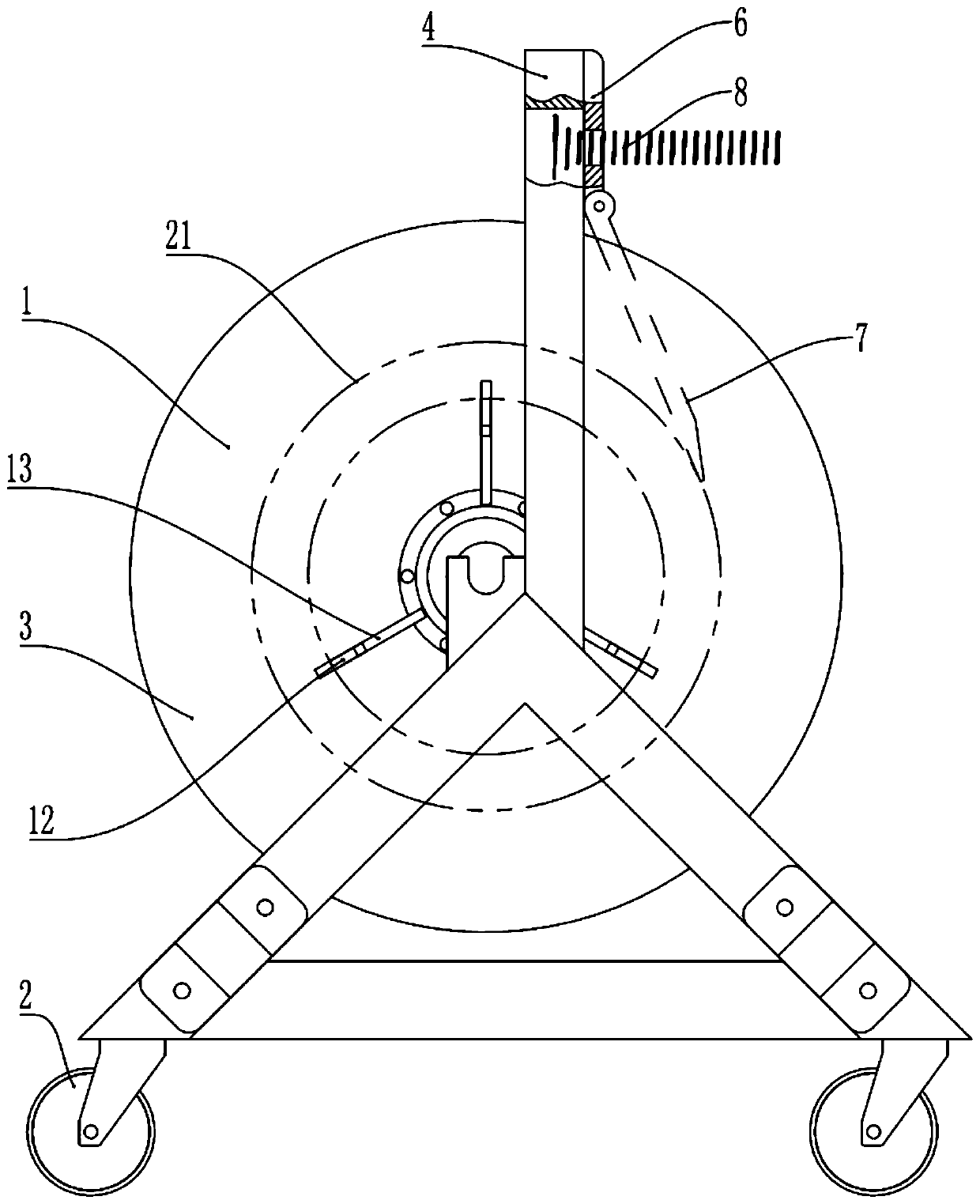

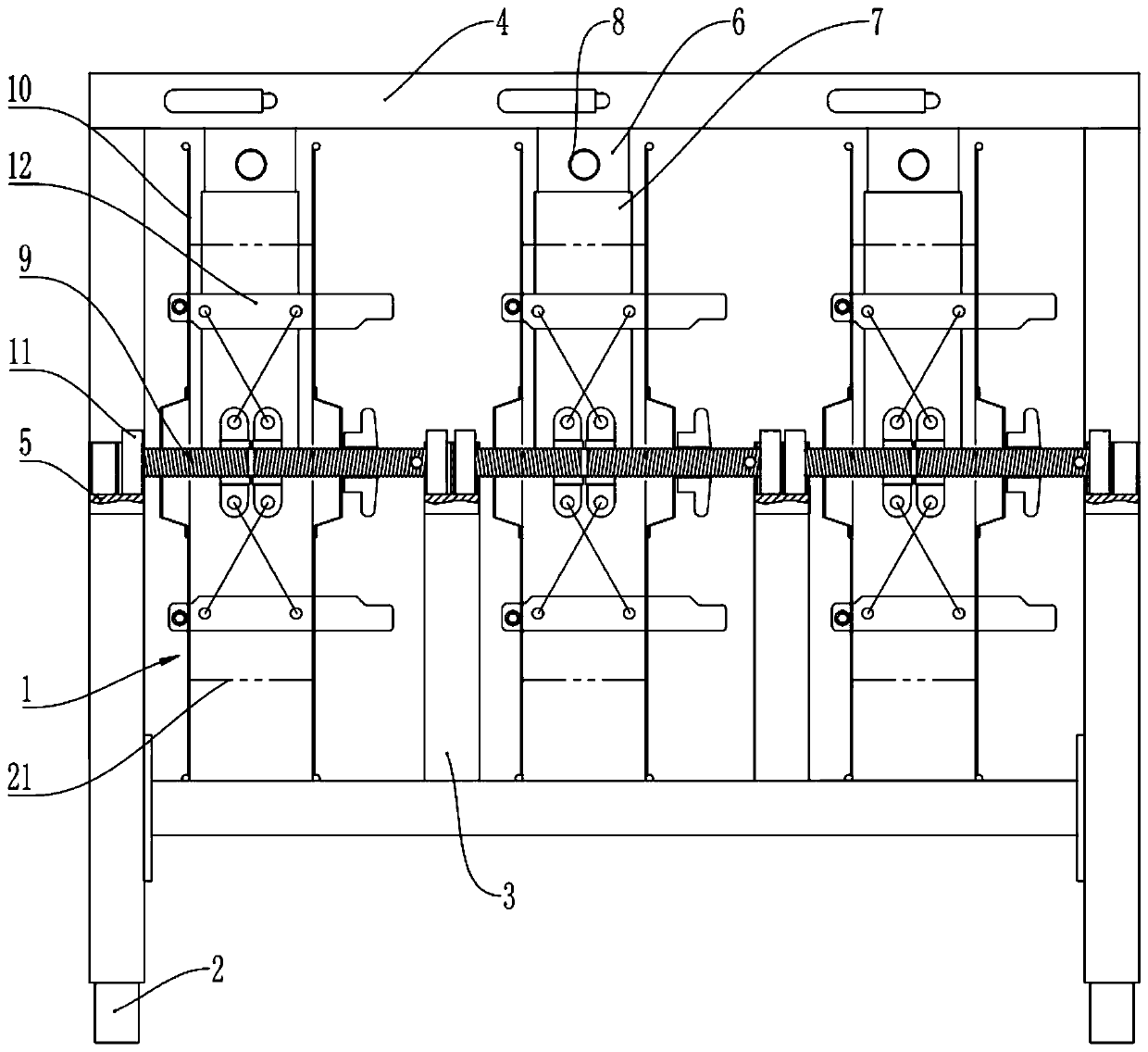

[0046] Embodiment one is basically as Figure 1 to Figure 6 Shown:

[0047] The fast fixing and setting-out construction technology includes the following steps:

[0048] Step 1, take the fast fixed pay-off device:

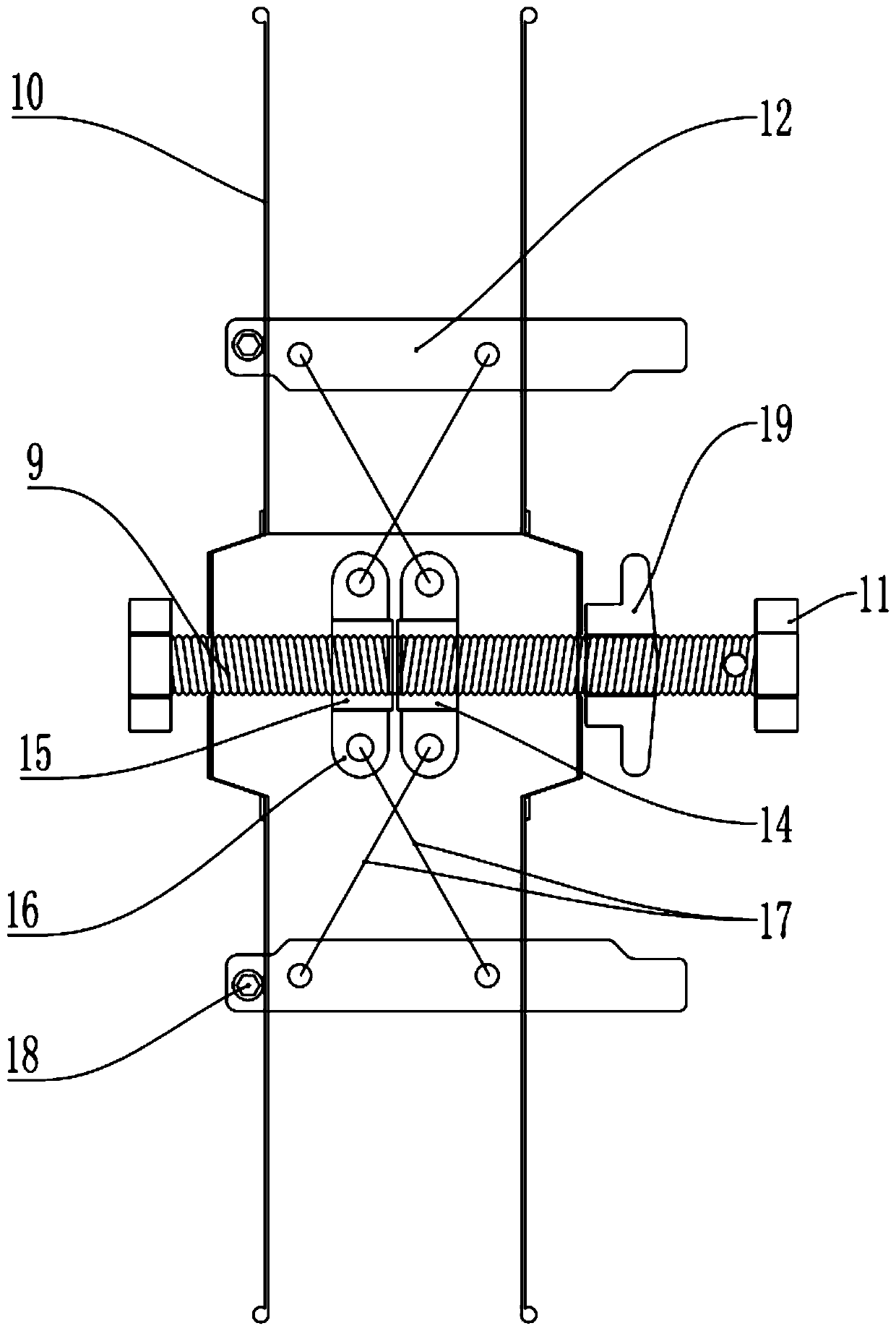

[0049] combine figure 1 and figure 2 , Quickly fix the pay-off device, including a bracket and three wire loading reels 1, the wire loading reels 1 are rotatably connected to the bracket, and casters 2 are installed at the bottom of the bracket. The support includes a main support frame 3 and a cross bar 4. The main support frame 3 is provided with a slot part 5, and a partition is arranged inside the slot part 5, and the partition divides the slot part 5 into two slots.

[0050] The crossbar 4 is connected to the main support frame 3 by bolts, the crossbar 4 is located above the wire loading tray 1, and a waist-shaped hole is opened on the crossbar 4; a brake unit is connected to the crossbar 4, and the brake unit includes a connecting plate 6 and a brake T...

Embodiment 2

[0068] Embodiment two is basically as Figure 7 Shown; Embodiment two is on the basis of embodiment one, has also increased following steps:

[0069] Step 5, increase the number of wiring reels 1:

[0070] Install external brackets 20 through screws at both ends of the cross bar 4, take the wire loading reel 1 where the cable coil 21 is installed in step 2 of the first embodiment, and connect one end of the screw rod 9 on the wire loading reel 1 to the external bracket by rotating On the slot part 5 of the frame 20, the other end of the screw mandrel 9 is rotatably connected to the slot part 5 of the support, for the wire reel 1 that is completed in addition.

[0071] By setting the external bracket 20, on the basis of the existing embodiment one, the external bracket 20 for installing the wire reel 1 can also be added on the left and right sides of the cross bar 4, so that the entire device can be installed. The number of cable reels 1 is increased by two, the utilization r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com