Low voltage home line pay-off stand

A technology of pay-off frame and household wire, which is applied in the field of new devices, can solve the problems of time-consuming and laborious work, delay of construction progress, easy knotting of wires, etc., and achieve the effect of convenient use, improved work efficiency, and wires are not scattered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0010] The technical solutions in the embodiments of the present invention will be described and explained clearly and in detail below in combination with the accompanying drawings of the present invention and actual on-site specific embodiments.

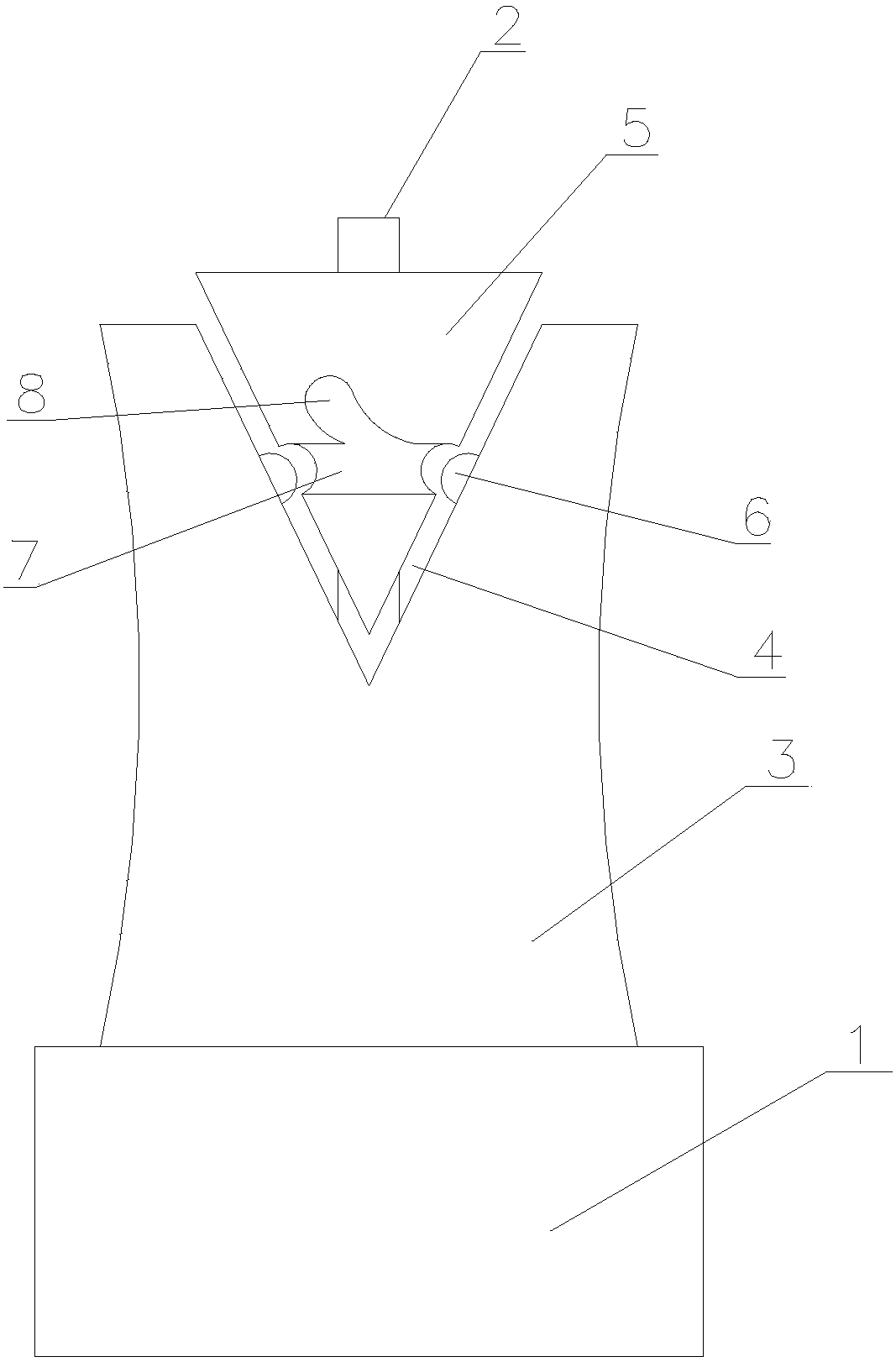

[0011] See attached figure 1 , a low-voltage to-the-house line pay-off rack, including a base frame 1, a vertical column 2 is arranged on the base frame, and a rotor 3 is set on the vertical column. The rotor is a waist-shaped cylinder, and the upper end of the waist-shaped cylinder is provided with There is a tapered groove 4, and a tapered briquetting block 5 is also sleeved on the vertical column, and the tapered briquetting block is stuck in the tapered groove upside down.

[0012] The wall of the tapered groove is provided with a hemispherical projection 6, and the conical pressing block is provided with a groove, and the hemispherical projection is stuck in the groove, wherein the groove is composed of two parts, including an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com