A method and apparatus for controlling a jet loom

A technology of jet loom and control unit, applied in looms, textiles, papermaking, textiles, etc., to improve weaving quality and reduce fluid consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

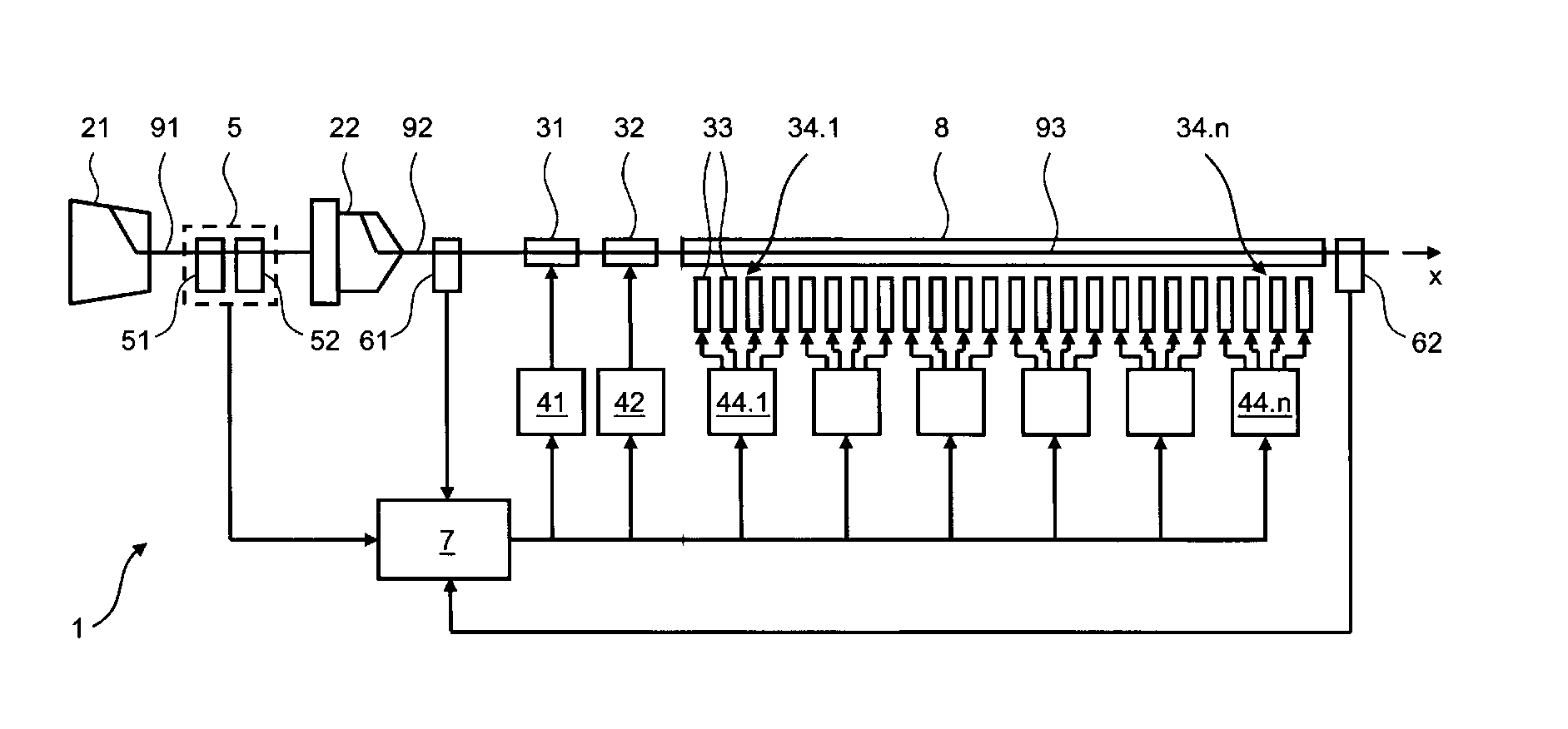

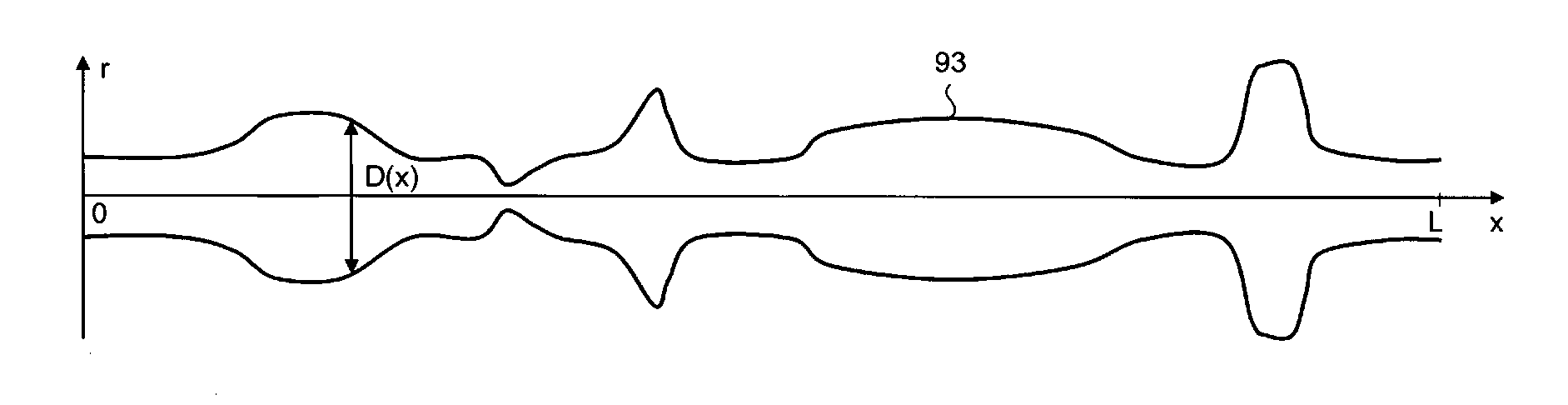

[0035] figure 1An air-jet loom jet loom 1 with a control device according to the invention is shown schematically. In this embodiment, the air-jet loom The jet loom 1 is designed as an air-jet loom. A yarn 91 designated as a weft yarn is provided on the bobbin 21 . The yarn 91 is transported from the bobbin 21 to the weft yarn storage unit 22, which may be designed as a drum-type storage unit. The weft yarn 92 extracted from the weft yarn storage unit 22 is accelerated by one or more accelerating nozzles 31, 32 (also referred to as main nozzles) and supplied to the air supply pipe 8, which is arranged in a shed forming device (not shown) formed in the shed. A specific weft yarn segment 93 inserted into the air supply tube 8 along its longitudinal direction x is called a pick 93 . The pick yarn 93 is conveyed through the air supply pipe 8 by a plurality of auxiliary nozzles 33 . The auxiliary nozzles 33 are preferably divided into a plurality of nozzle groups 34.1, . . . ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com