Automatic weft insertion rate control system for air-jet loom and regulation method of control system

An automatic control system, the technology of air-jet looms, applied in looms, textiles, textiles and papermaking, etc., can solve the problems affecting weaving effect, change of yarn flight time, etc. The effect of weaving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

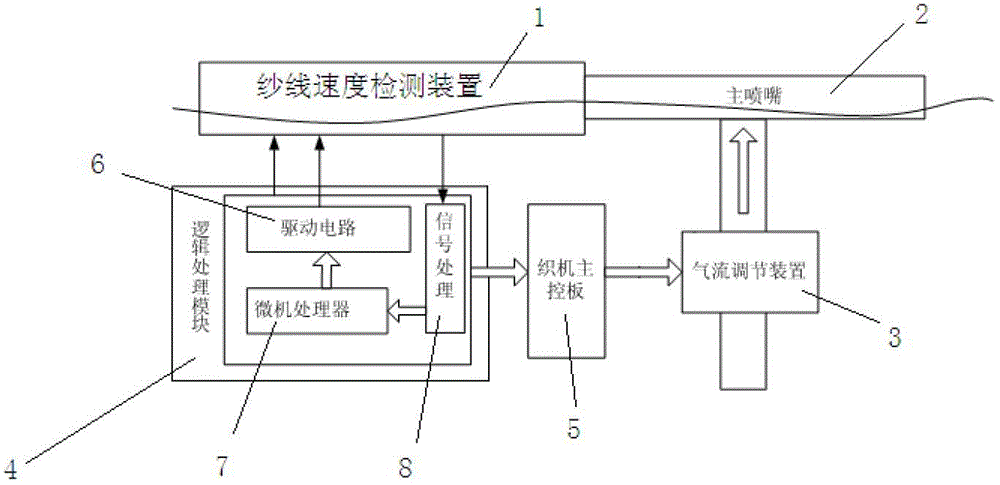

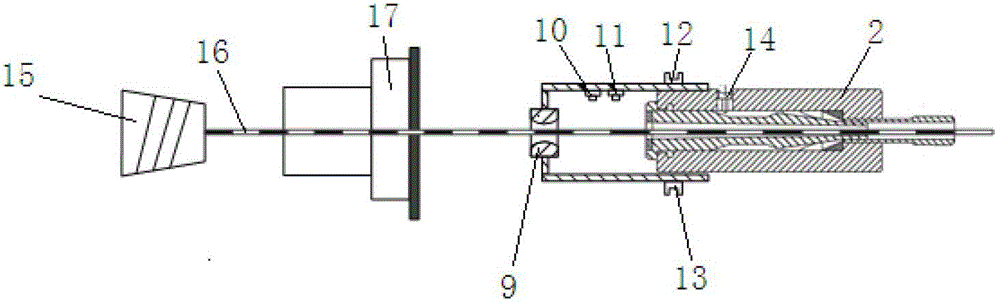

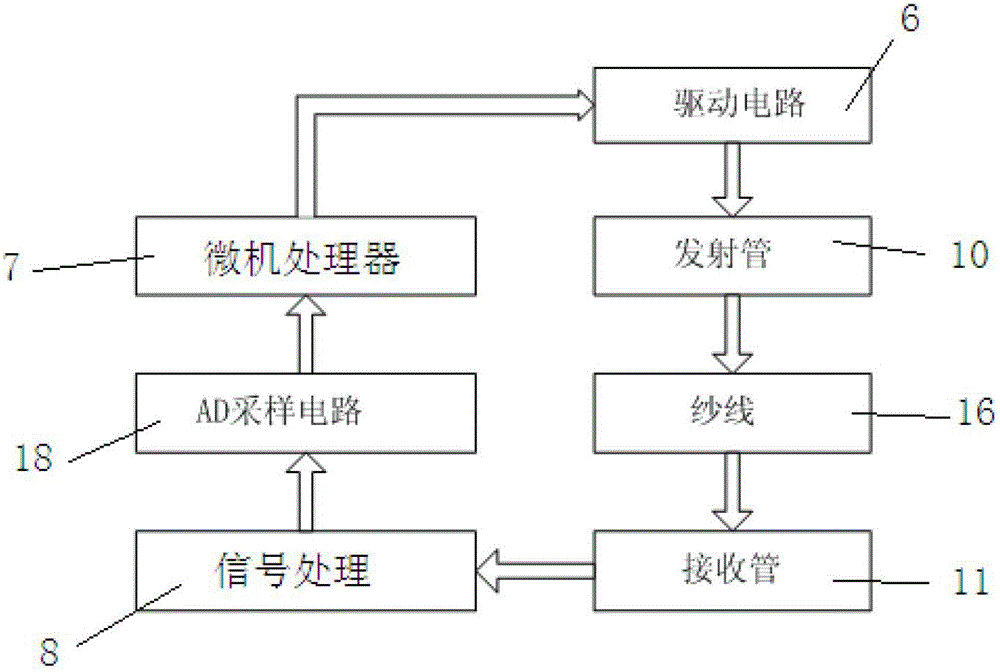

[0020] like figure 1 , figure 2 , image 3 As shown, an automatic control system for weft insertion speed of an air-jet loom in this embodiment includes a yarn speed detection device 1, a main nozzle 2, an airflow adjustment device 3 and a logic processing module 4; wherein the yarn speed detection device 1 fixedly installed with the main nozzle 2 through the first recessed screw 12 and the second recessed screw 13; the main nozzle 2 is equipped with an air intake passage 14; the yarn speed detection device 1 includes a closed tube 9 Infrared emission tube 10 and photoelectric receiving tube 11 are installed in the described closed tube 9; Described logic processing module 4 comprises microcomputer processor module 7, drive circuit module 6 and signal processing module 8; Wherein described microcomputer processing The device module 7 is connected with the drive circuit module 6 through the line; the drive circuit module 6 is connected with the infrared emission tube 10 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com