Yarn feeding device for computer flat machine

A technology of yarn feeding device and computerized flat knitting machine, which is applied in textiles and papermaking, weft knitting, knitting, etc. It can solve problems affecting the design of knitting patterns, complex transmission mechanism, and quantity limitation, and achieve superior knitting performance and simple transmission structure. , the effect of force balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with embodiment.

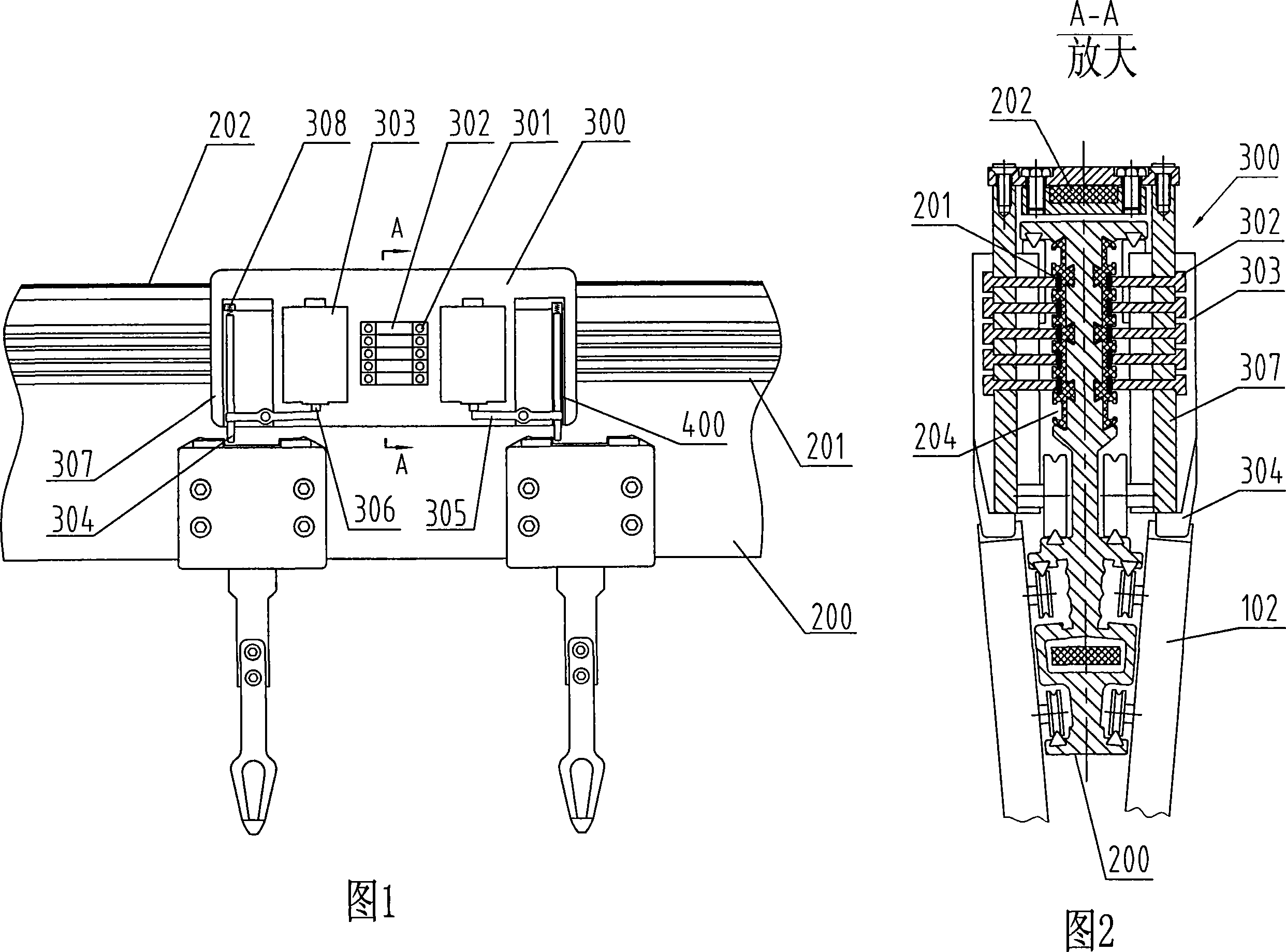

[0016] 1 and 2, the shuttle box control mechanism 300 is placed on both sides of the upper part of the shuttle bar 200, the shuttle box 102 is placed on the lower side of the shuttle bar 200, and the shuttle box control mechanism 300 is connected to the shuttle box 102 through the latch 304 on it , so that it moves along the shuttle bar 200 together.

[0017] Shuttle box control mechanism 300 is mainly made up of carbon brush 301, electromagnet 303, tab 304, tab shift fork 305, return spring 308, and base plate 307 etc. The electromagnet 303 is fixed inside the bottom plate 307 . The tab 304 is slidably connected to a slot 400 inside the bottom plate 307 . One end of the return spring 308 is connected to the bottom of the slot, and the other end is in contact with the upper end of the tab 304 . The carbon brush 303 is fixed on the bottom plate 307 through a carbon brush seat 301 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com