Warp feeding device of lint air jet loom

An air-jet loom and velvet warp technology, which is applied to looms, textiles, textiles, and papermaking, can solve the problems of manual tight yarn feeding, poor tension control accuracy, and uneven warp let-off, so as to avoid the phenomenon of high and low velvet, The effect of precise tension control and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

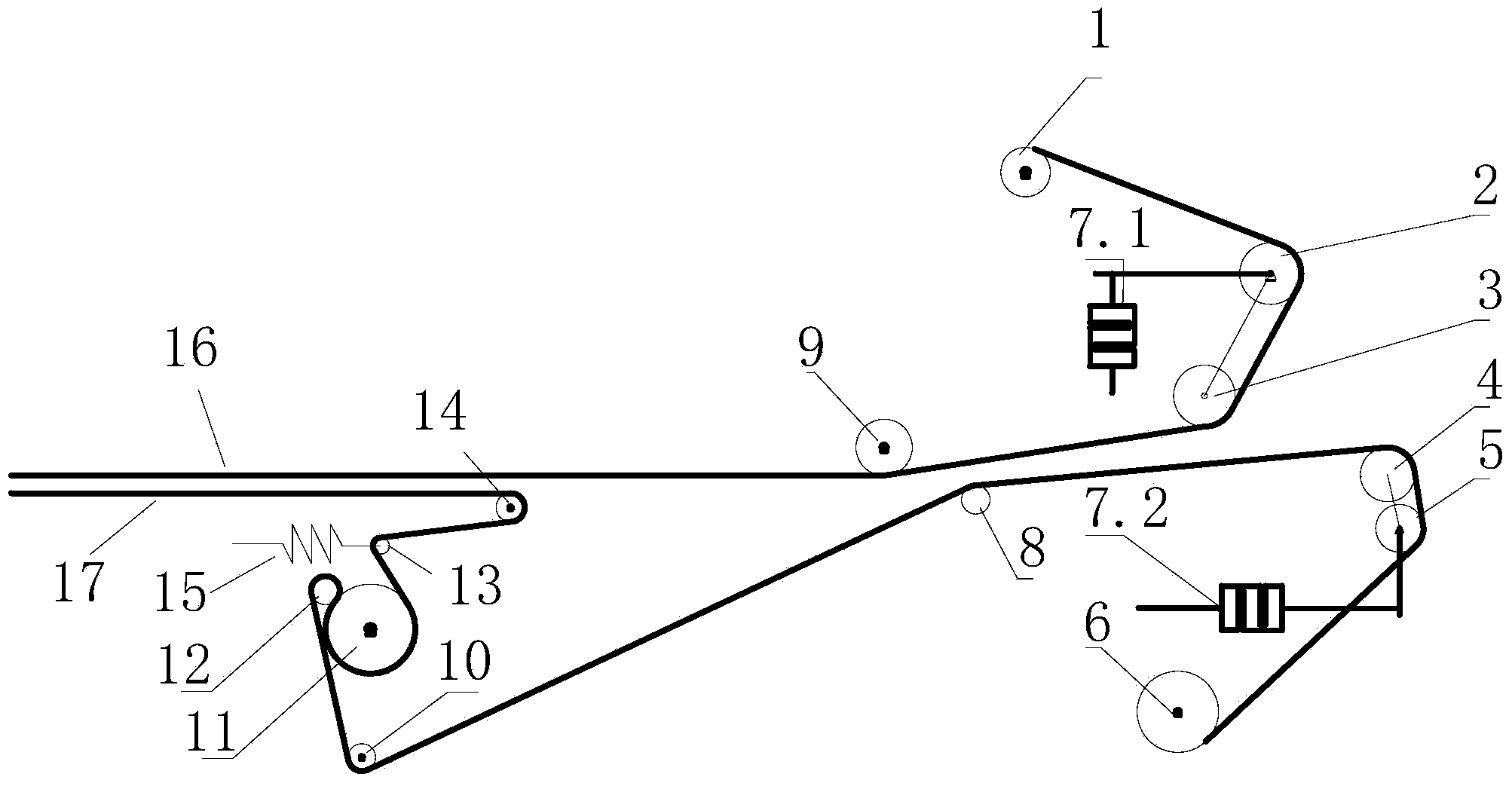

[0021] Such as figure 1 As shown, a warp let-off device for flannelette air-jet loom includes a frame and a servo control system. There is a main shaft of the loom; the ground warp let-off mechanism is sequentially provided with a ground warp loom shaft 1, a ground warp fixed back beam 2, a ground warp let-off tension roller 3 and a ground warp adjustment roller 9 along the ground warp transmission direction. 1 is driven by the ground warp servo motor and provides the ground warp for the air-jet loom. The ground warp sending tension roller 3 is connected with the ground warp tension sensor 7.1. The ground warp adjusting roller 9 is used to adjust the height of the ground warp. The ground warp adjusting roller 9 passes through the first A height adjustment component is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com