Patents

Literature

90results about How to "Solve processing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

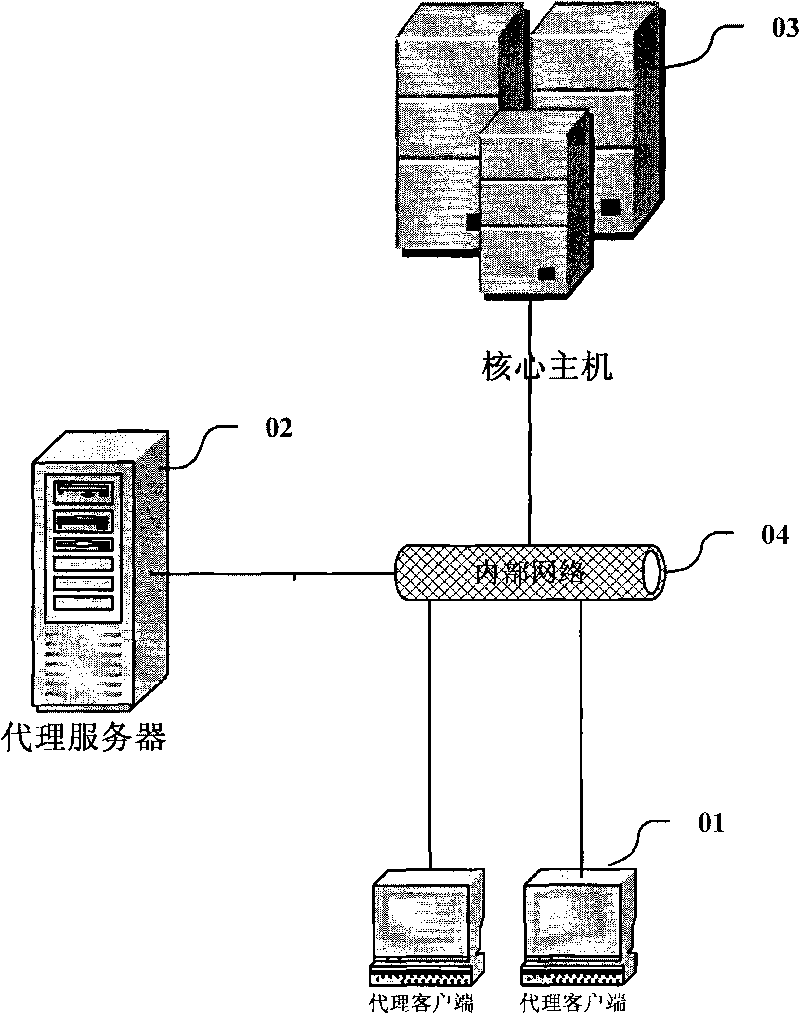

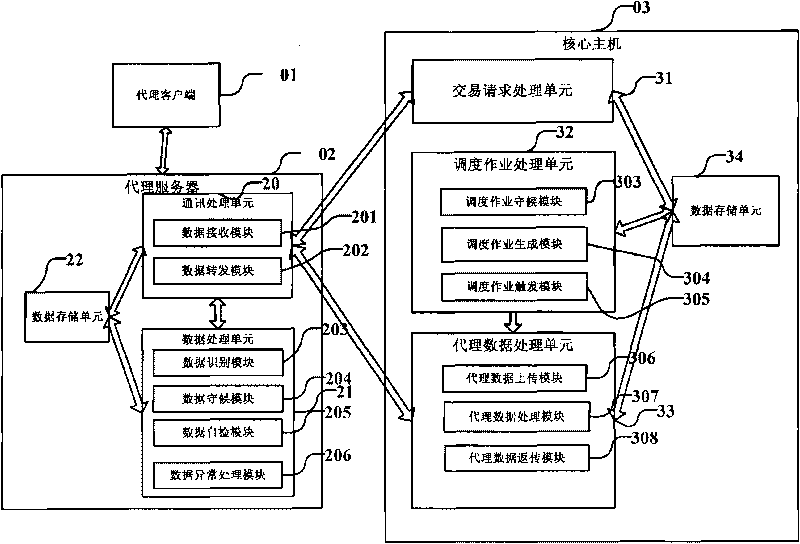

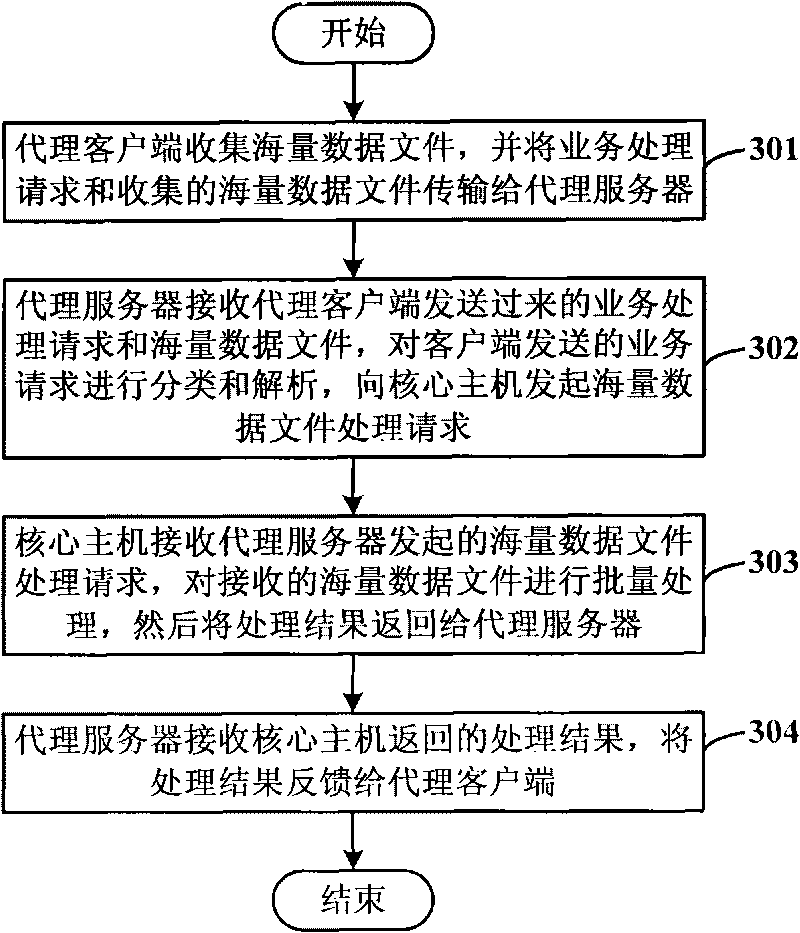

Device and method for carrying out transmission processing on massive data files

InactiveCN101719153ASolve processing efficiencyGeneral supportSpecial data processing applicationsBatch processingData file

The invention discloses a device for carrying out transmission processing on massive data files, comprising an proxy client terminal, a proxy server and a core host computer, wherein the proxy client terminal is used for collecting massive data files and transmitting business processing requests and the collected massive data files to the proxy server; the proxy server is used for receiving the business processing requests and the massive data files transmitted from the proxy client terminal, classifying and resolving the business requests transmitted from the client terminal, initiating a massive data file processing request to the core host computer, receiving a processing result and feeding the result back to the proxy client terminal; and the core host computer is used for receiving the massive data file processing request initiated by the proxy server, carrying out batch processing on the received massive data files and then returning a processing result to the proxy server. The invention discloses a method for carrying out transmission processing on the massive data files. By utilizing the invention, the problem of low transmission processing efficiency on the massive data files is solved.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

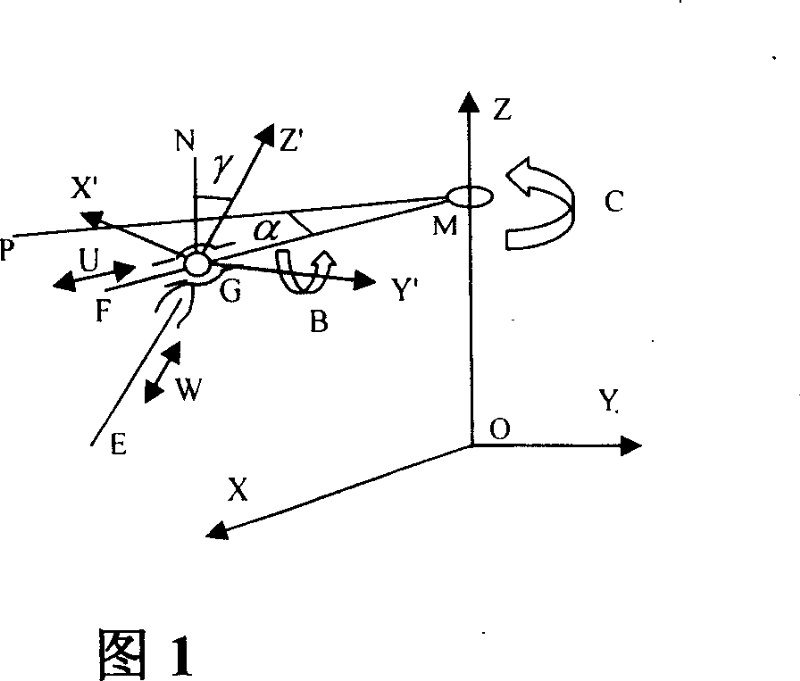

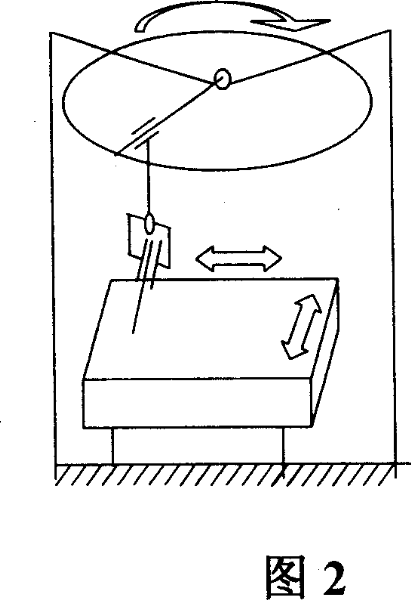

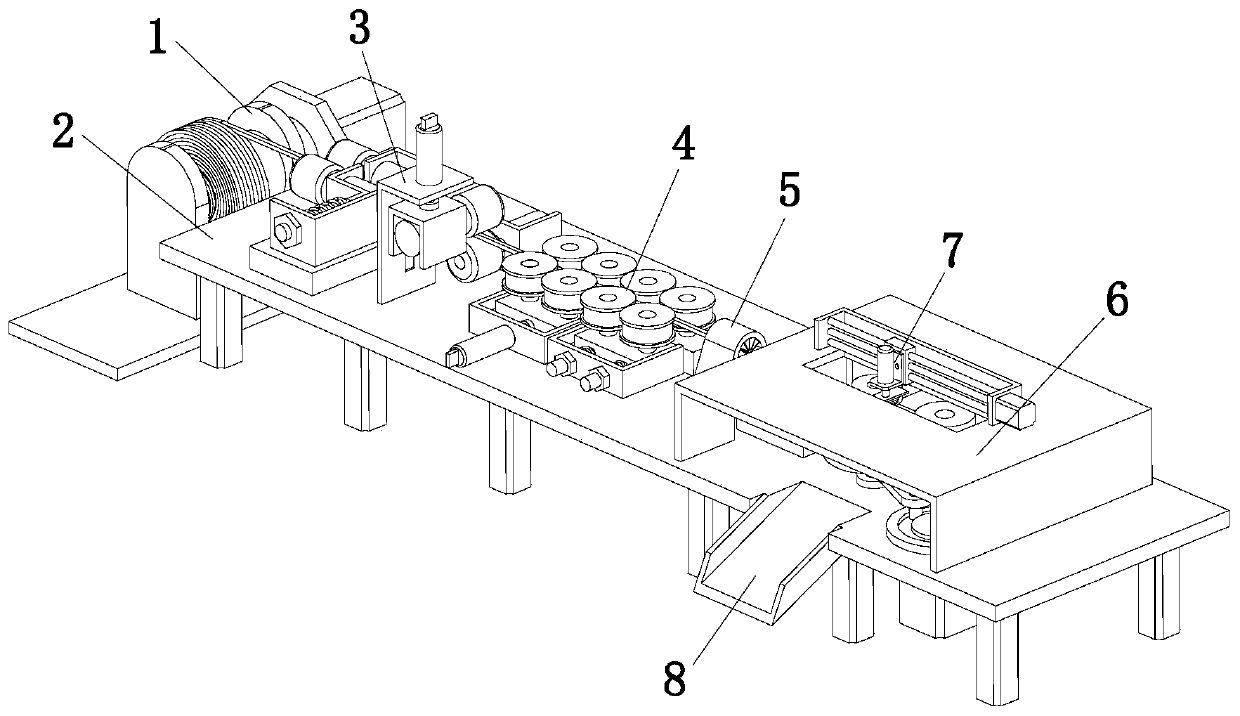

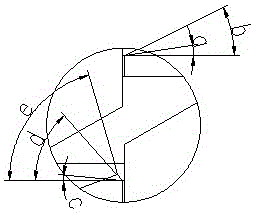

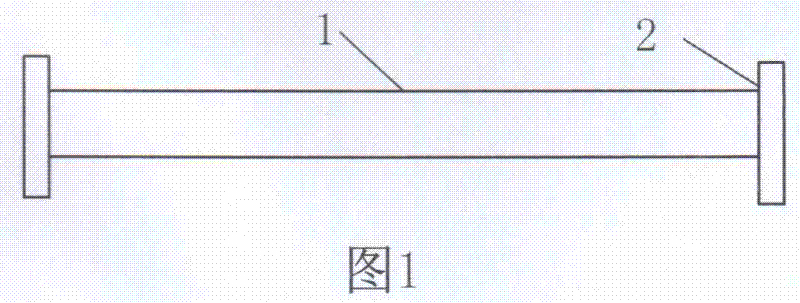

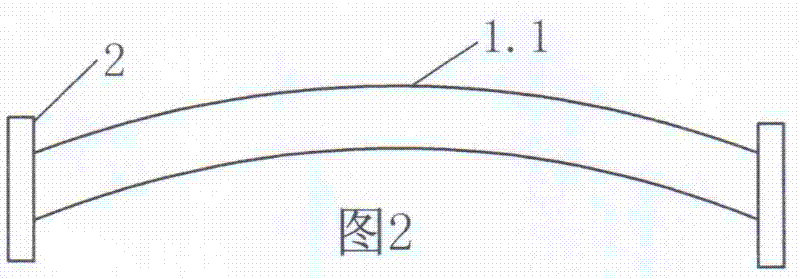

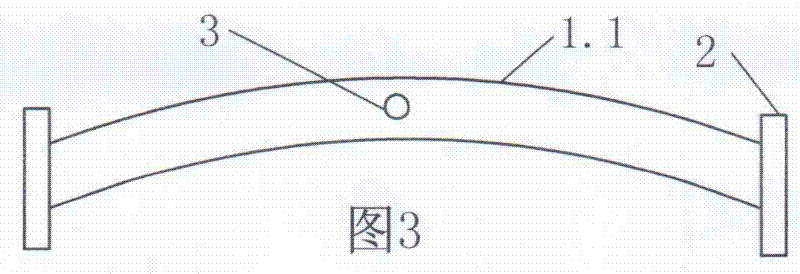

Method and device of processing the contacting surface of the digital controlled lines

InactiveCN101041224ASolve processing efficiencySolve machining errorsAutomatic control devicesGrinding drivesEngineeringMulti axis

The invention relates to a digital-control line-contact surface processing method and the equipment, belonging to the mechanical processing field. The core is four-axis line-contact surface processing device comprising rotating module, translating module, swinging module, expanding module and cutting module. The cutting module is set on the expanding module and it following said four modules moves in space. In the invention NC multi-axis moving coordinate feeding system with four-axis line-contact surface processing device is used; according to the processing demand, multiple multi-axis NC surface processing machine tool can be constituted. The side blade of cutting tool is controlled to machine in tangency with straight generatrix of machining surface always to realize the processing method that a code is used to machine a special surface or any space plane. It is provided with no theoretical profile error, high efficiency and high accuracy. The least linkage axis number and the least NC machining codes are used to realize surface processing. It can be applied in NC milling finishing machining, finish machining, NC turning-milling machining, NC electrochemical machine and NC EDM so on.

Owner:XIAN TECHNOLOGICAL UNIV

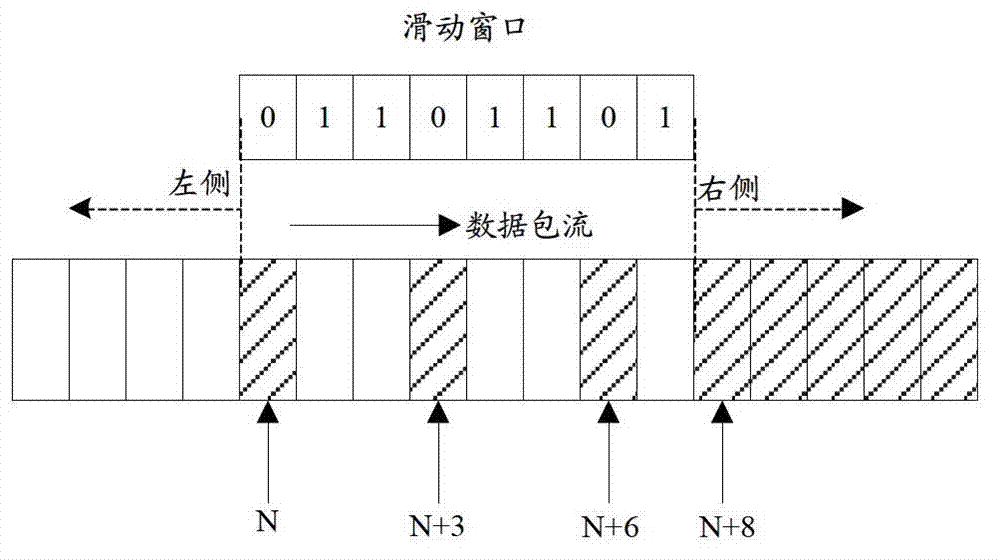

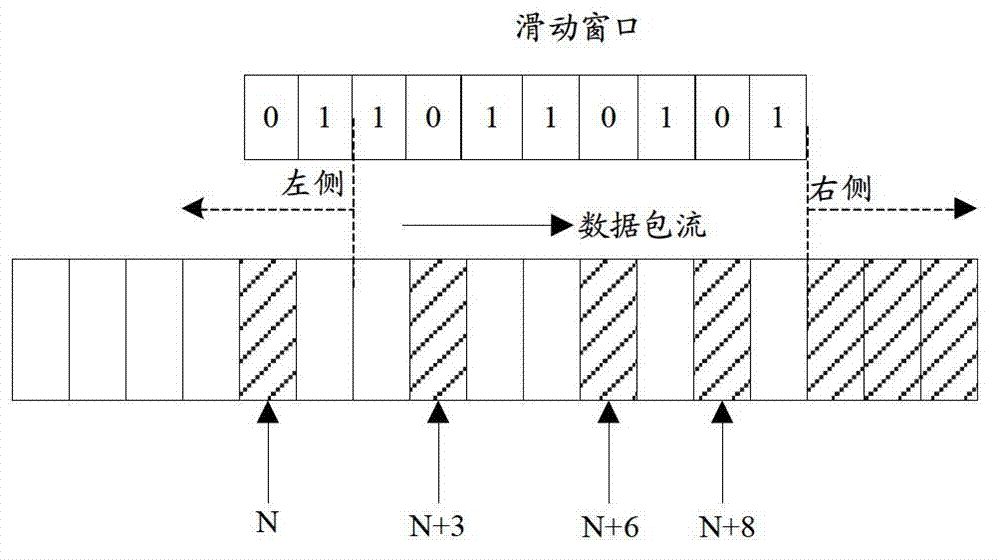

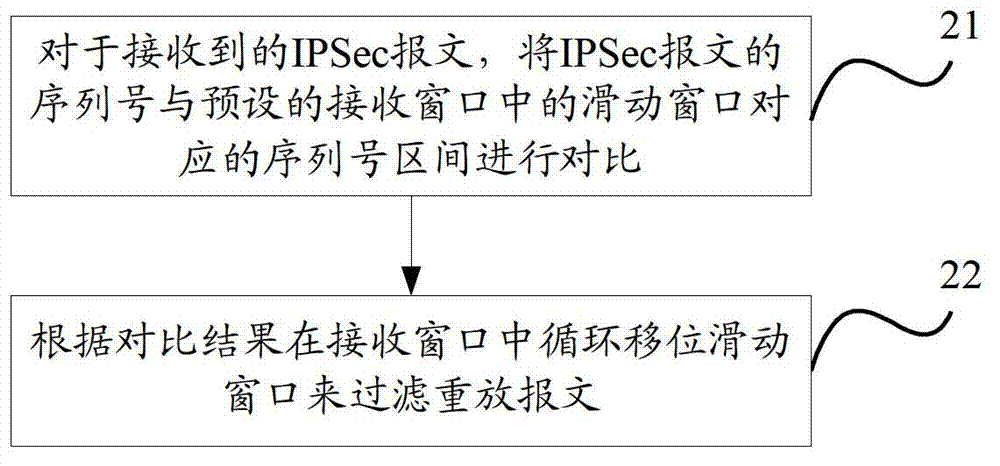

Message anti-replay method, message anti-replay device and network device

ActiveCN102769572AAddressing ComplexitySolve processing efficiencyData switching networksSlide windowIPsec

The invention discloses a message anti-replay method, a message anti-replay device and a network device which are based on IPSec (internet protocol security). The method includes: comparing a serial number of an IPSec message with a preset serial number range corresponding to a sliding window in a receiving window, and filtering the replay message by means of cyclic shift of the sliding window in the receiving window according to a comparison result. Sliding shift of the sliding window can be achieved only by cyclic shift of the sliding window in the receiving window, and the replay message can be filtered by means of cyclic shift of the sliding window, so that processing complexity of shift of the sliding window can be lowered, system overhead is reduced, and processing efficiency is improved. Therefore, the problems of processing complexity and low processing efficiency due to the fact that message anti-replay processing is performed by shifting the sliding window by means of sequential shift in the prior art are solved.

Owner:RUIJIE NETWORKS CO LTD

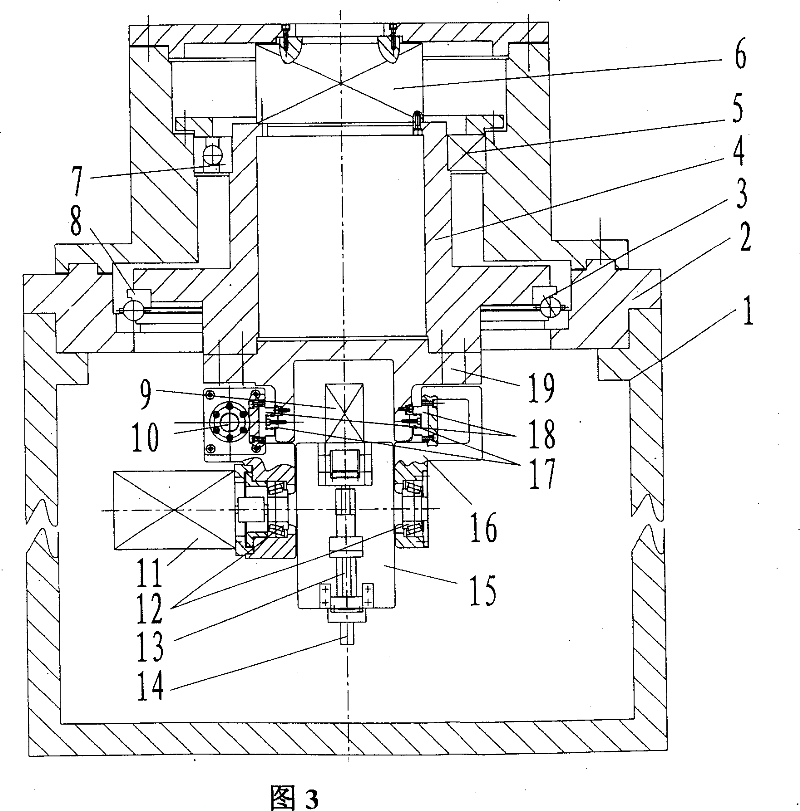

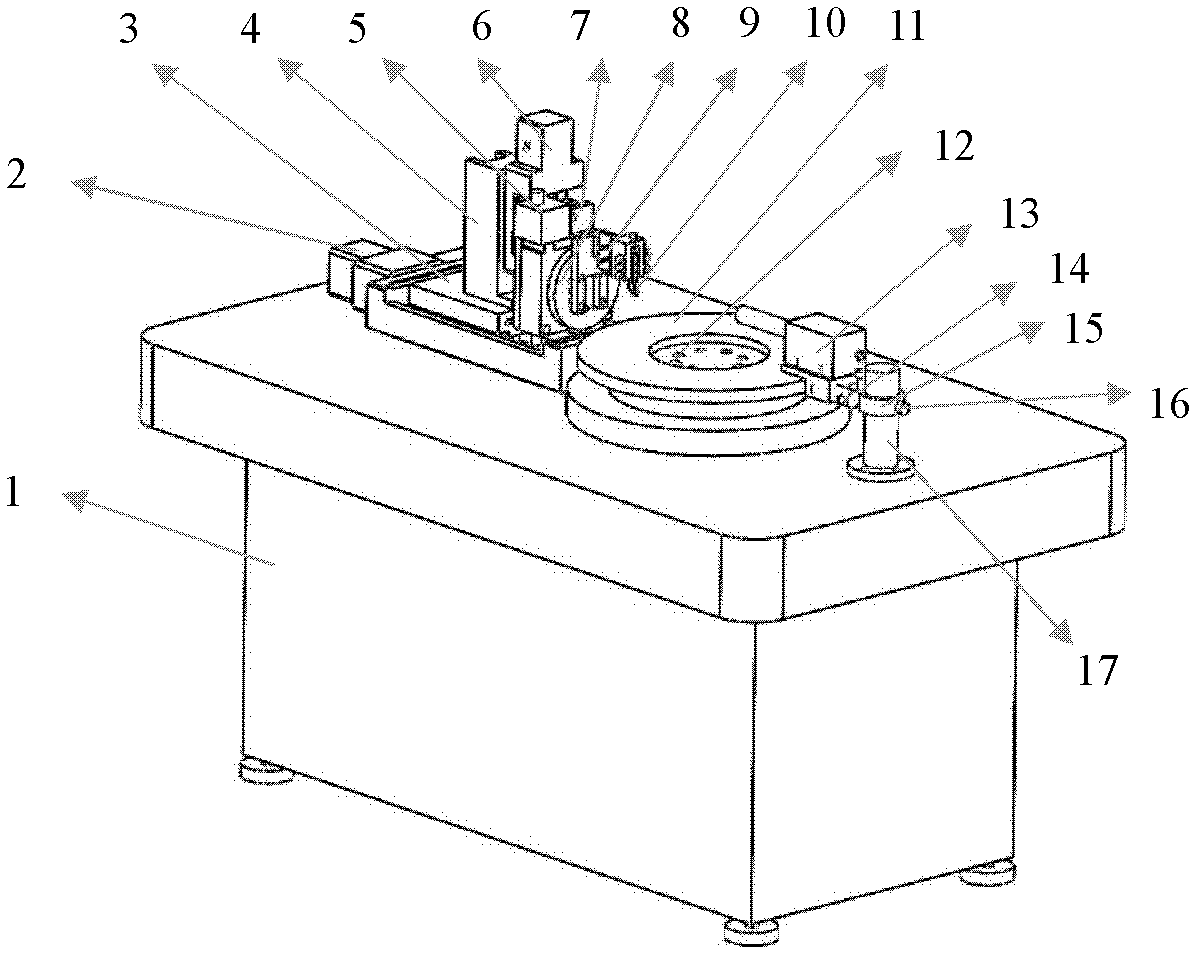

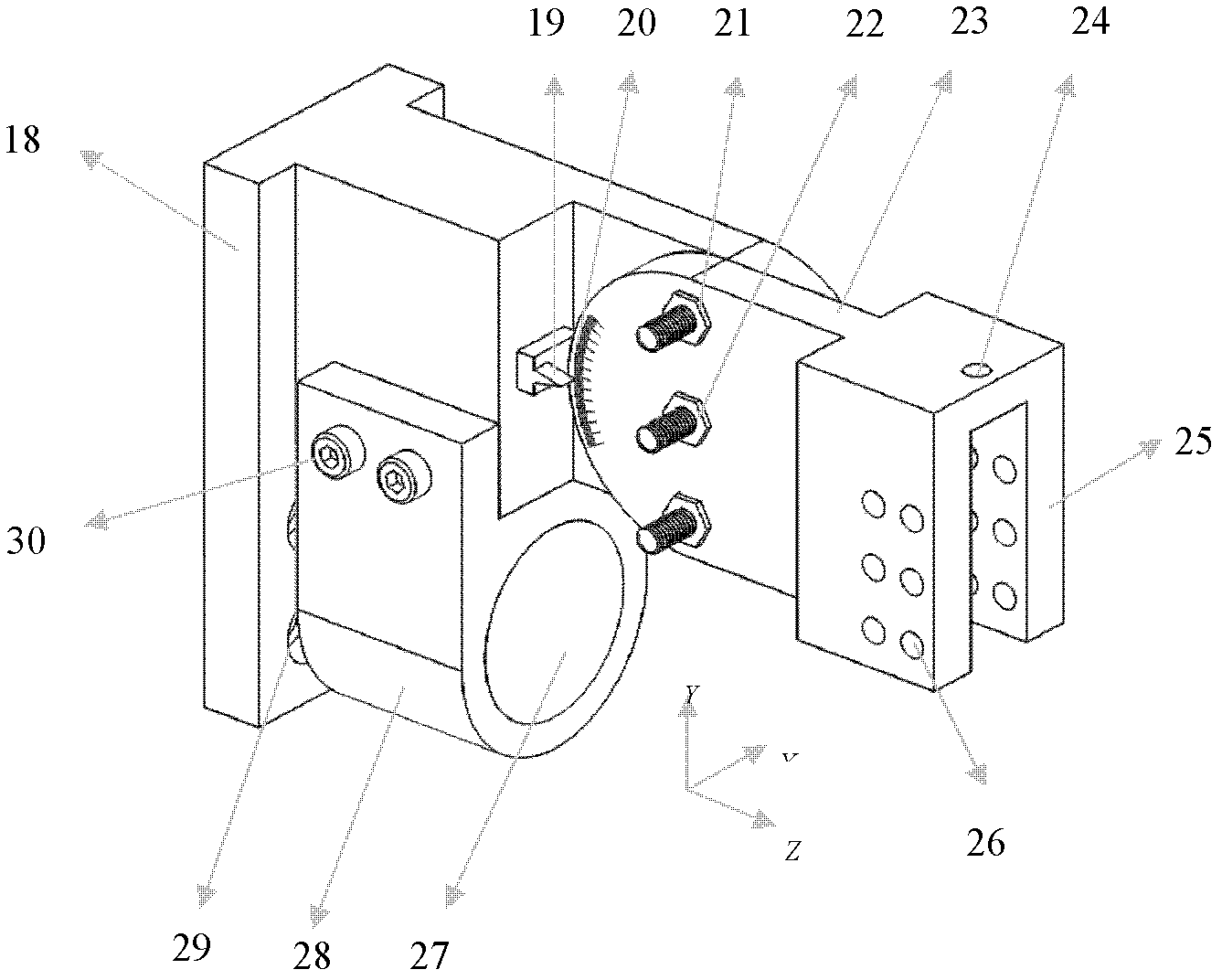

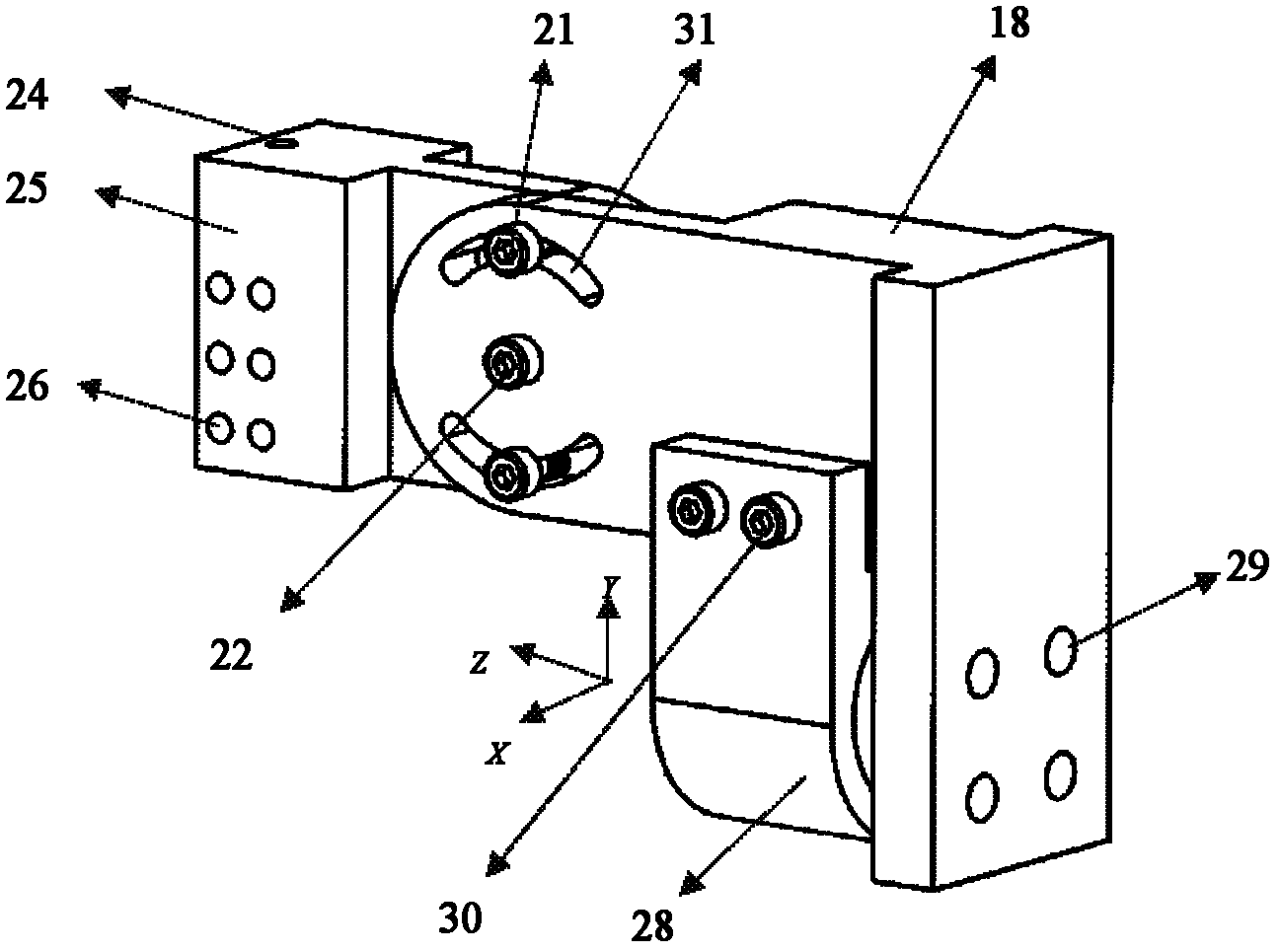

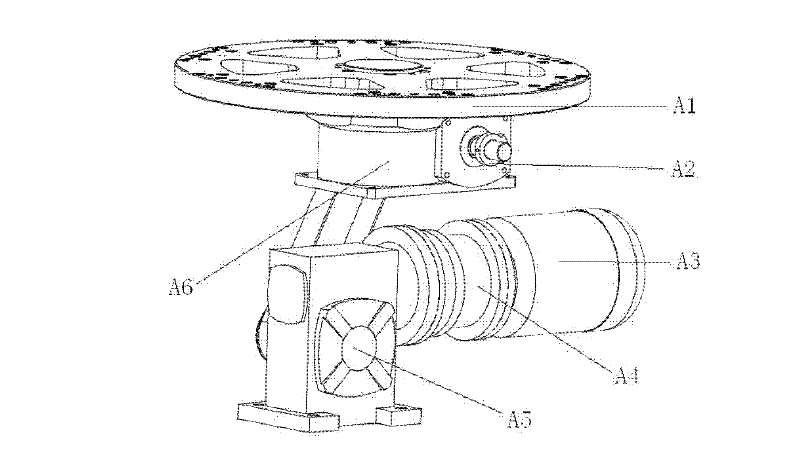

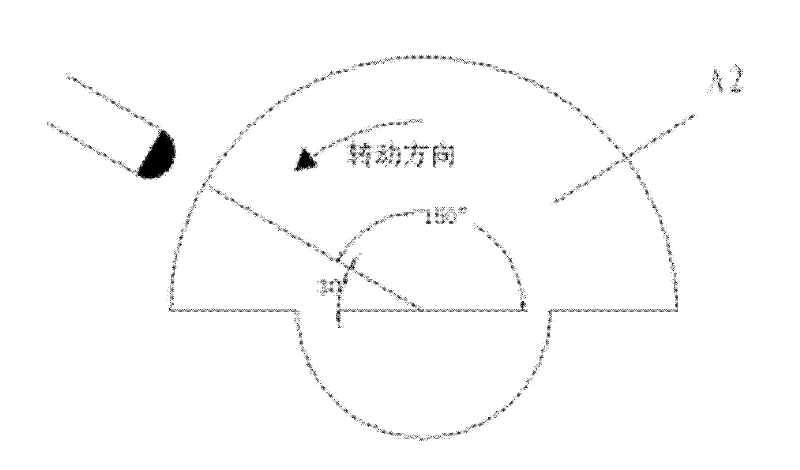

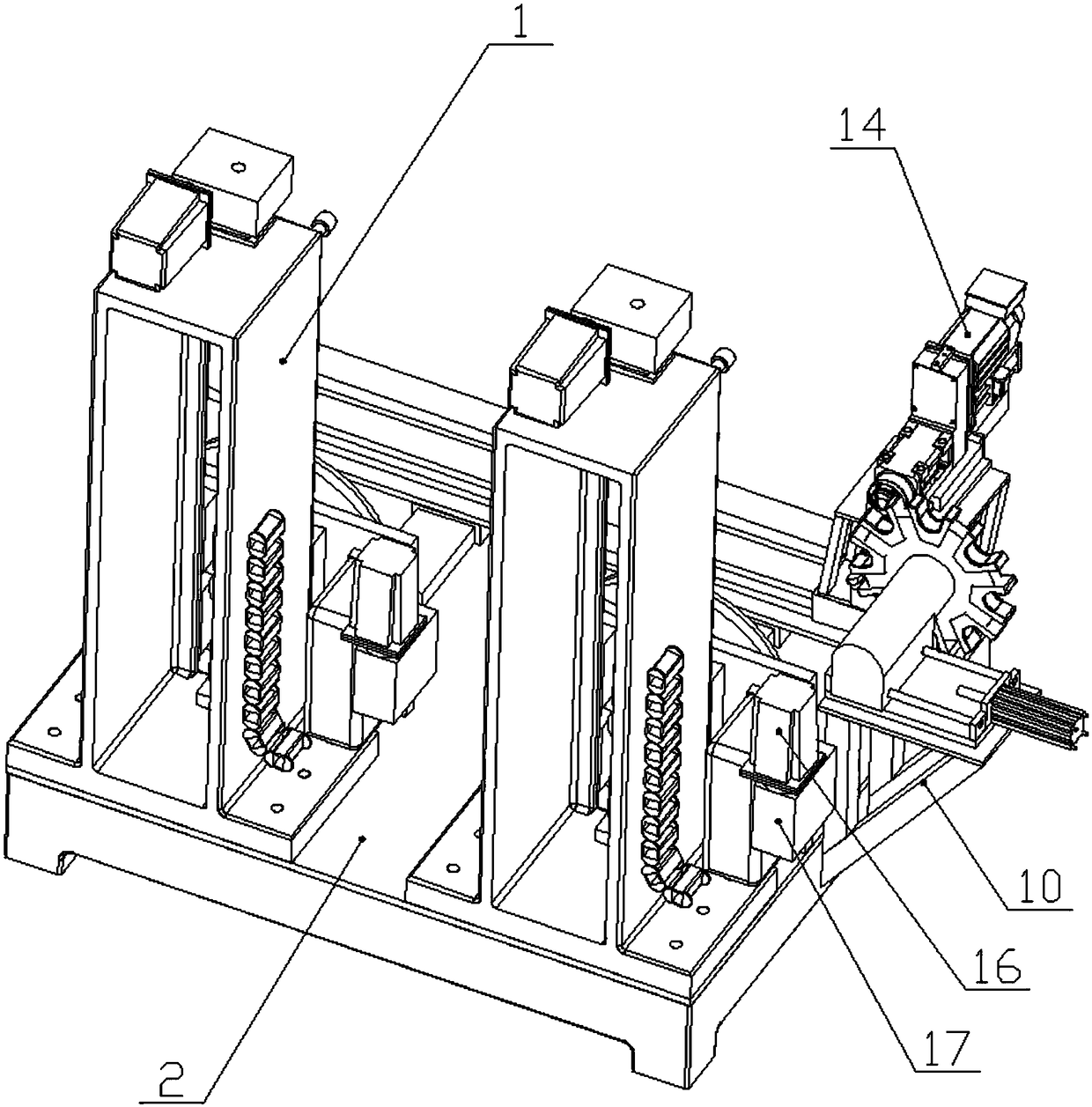

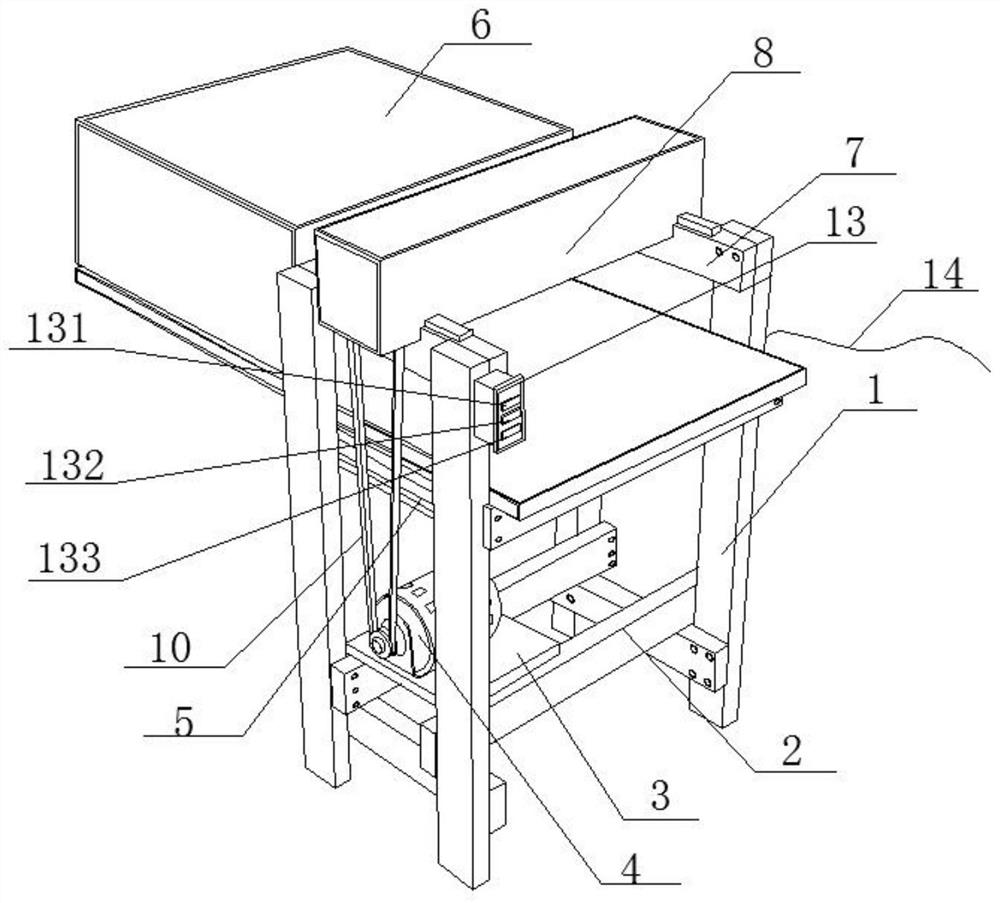

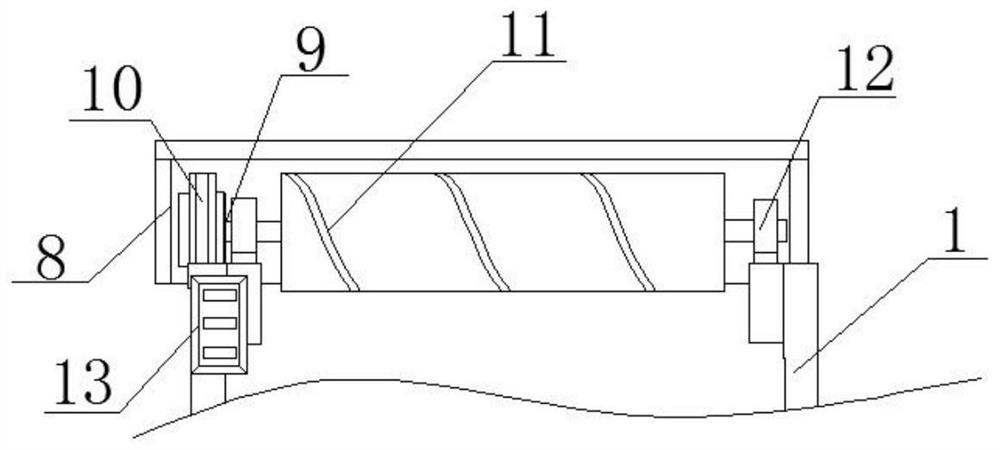

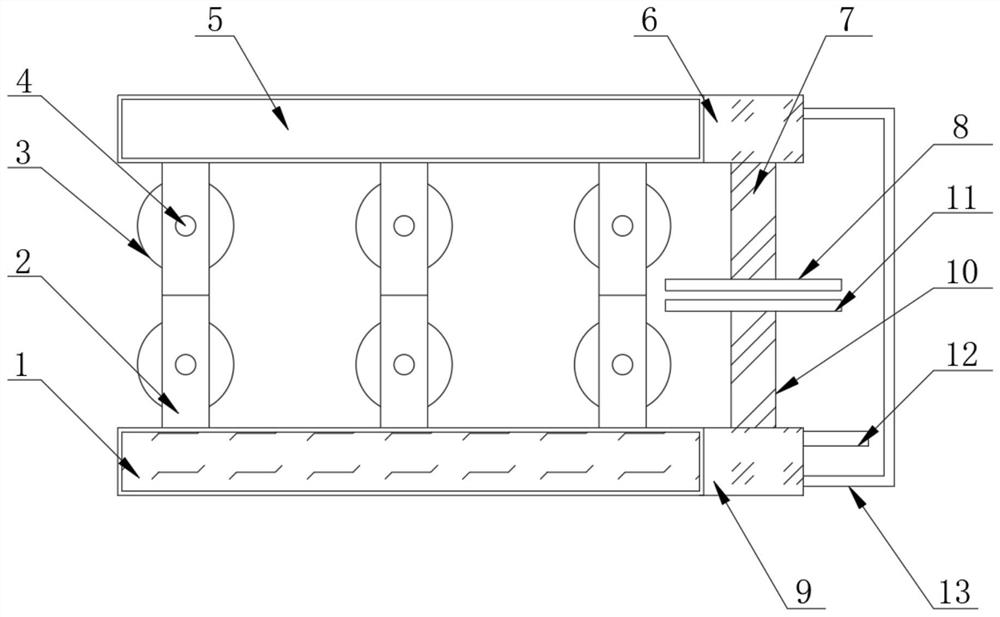

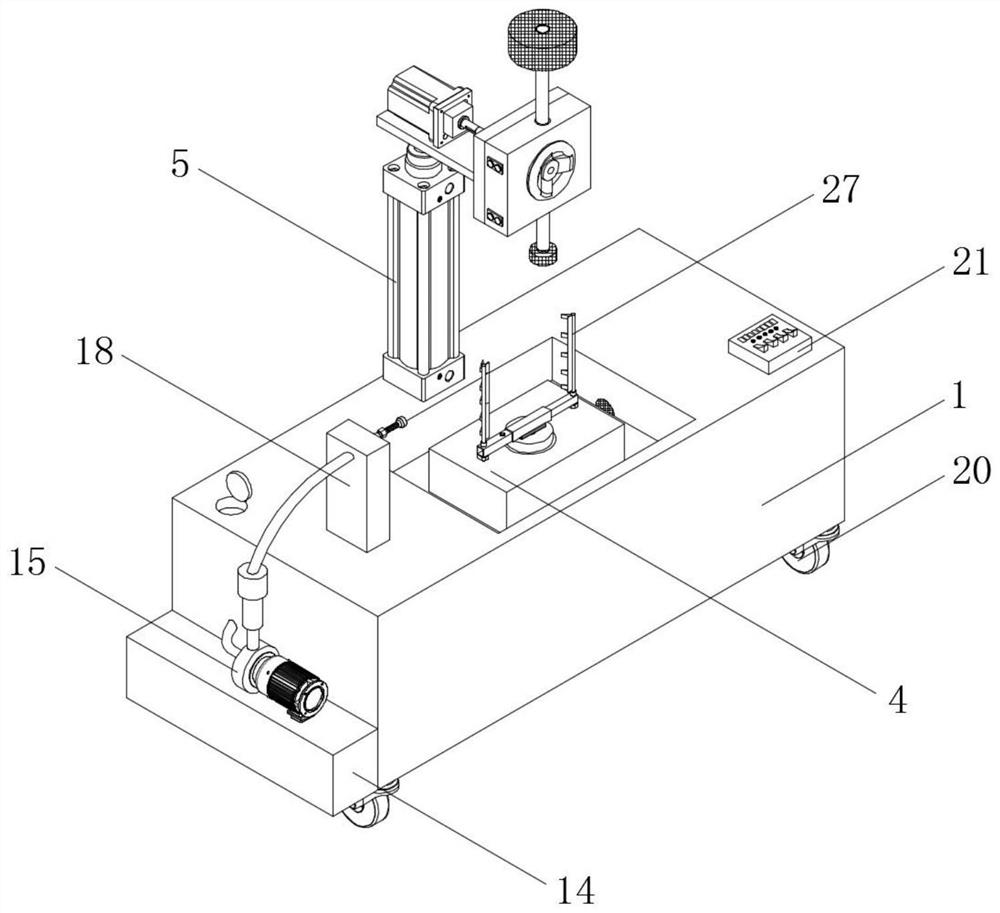

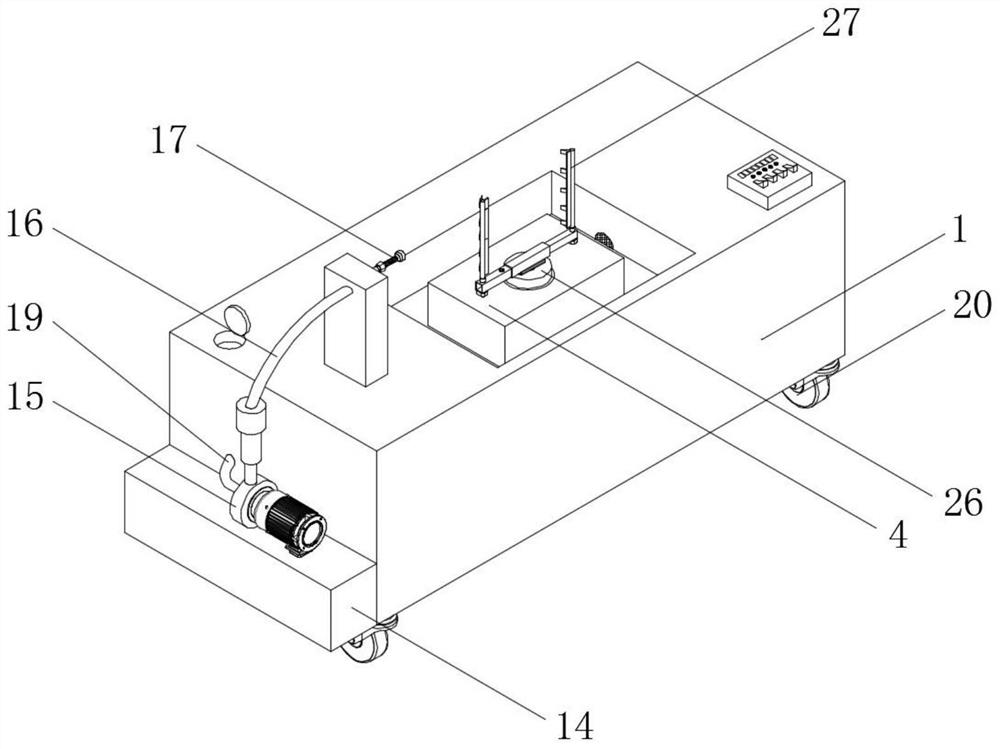

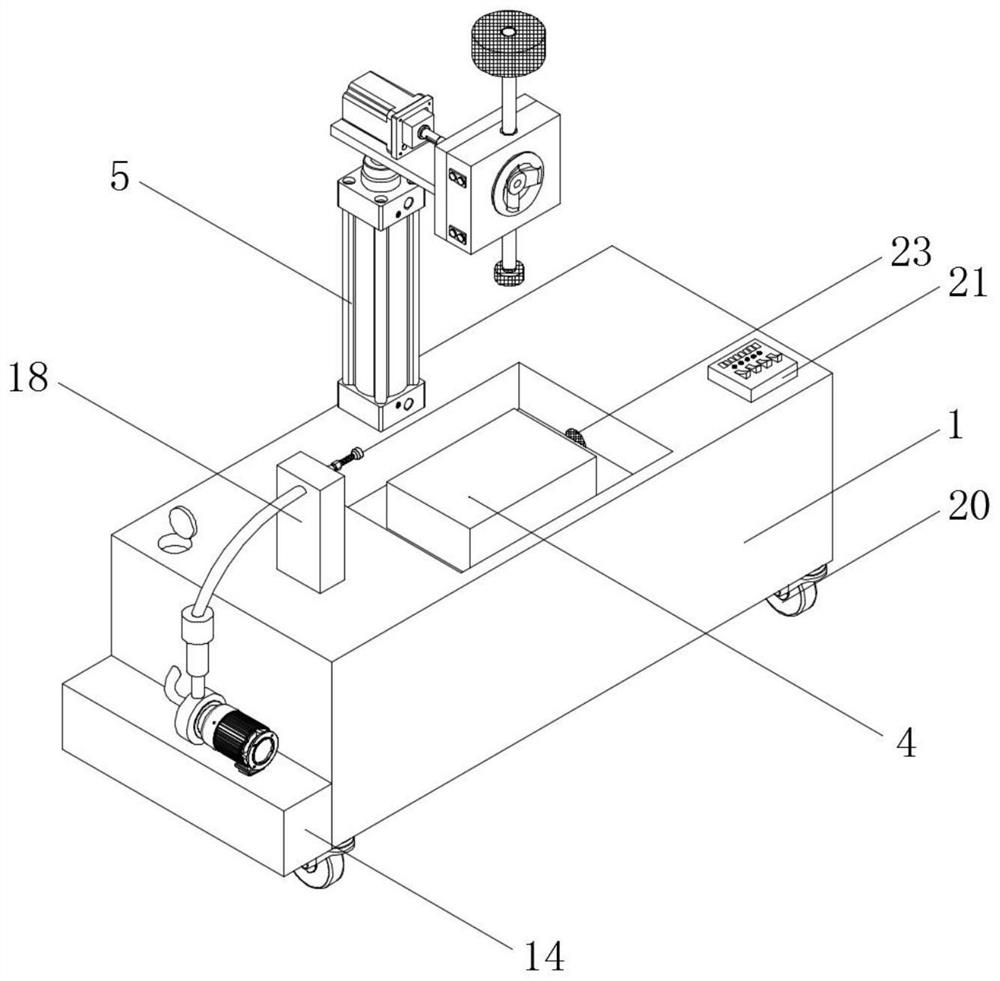

Relief angle adjustable device for automatic grinding of arc-edge diamond lathe tool

InactiveCN102248451AImproving the manufacturing accuracy of blade shapeImprove production efficiencyPlaning/slotting toolsTurning toolsEngineeringDiamond

The invention discloses a relief angle adjustable device for the automatic grinding of an arc-edge diamond lathe tool, comprising a base, wherein a driving device, a grinding disc and a photographing device are sequentially installed on the table board of the base; the driving device comprises a transverse feed device and a longitudinal feed working table connected with the transverse feed device; a longitudinal feed device is arranged on the longitudinal feed worktable; a swing device is connected with the longitudinal feed device; a relief angle adjustable fixture comprises a cantilever part connected with the swing device; the center of one side of an angle adjusting part and the center of the front end of the cantilever part are connected through a shaft and can rotate around the shaft at a certain rotation angle; the rotation angle can be displayed through a reading device; a lathe tool clamping part on which a groove is arranged is connected with one side of the angle adjusting part; and the diamond lathe tool arranged on a tool holder is inserted in and connected with the groove. By utilizing the device provided by the invention, the relief angle of the lathe tool can be accurately adjusted when the arc-edge diamond lathe tool is ground.

Owner:TIANJIN UNIV

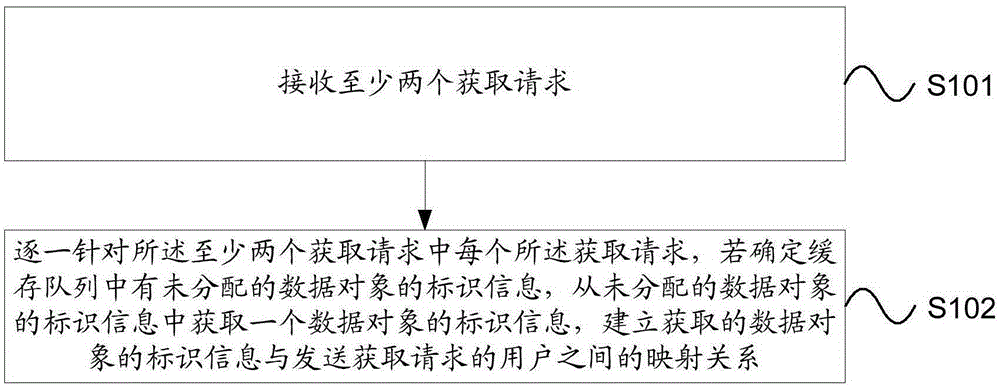

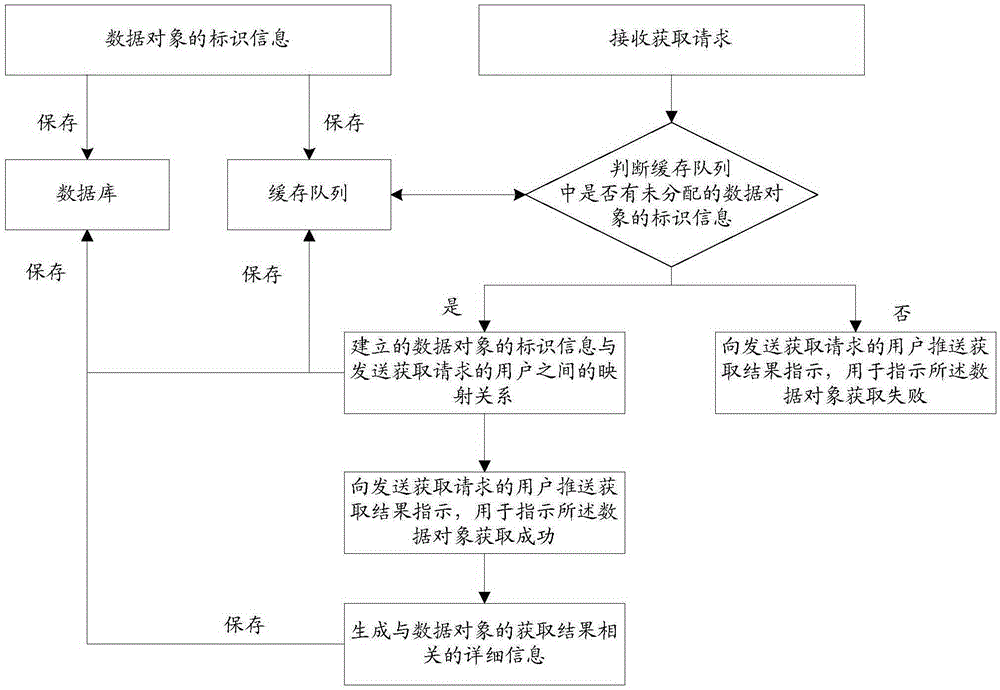

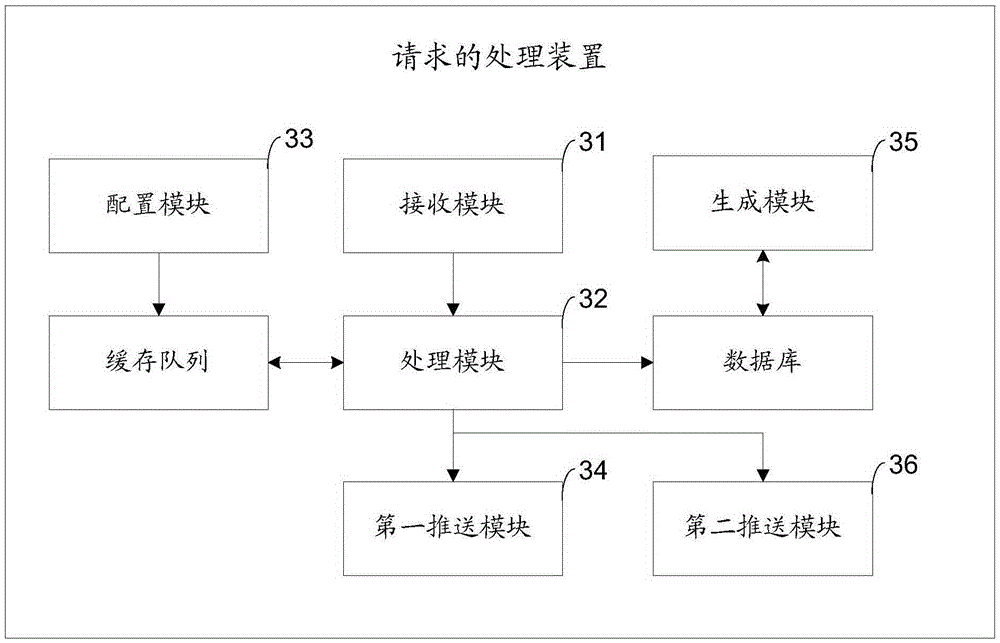

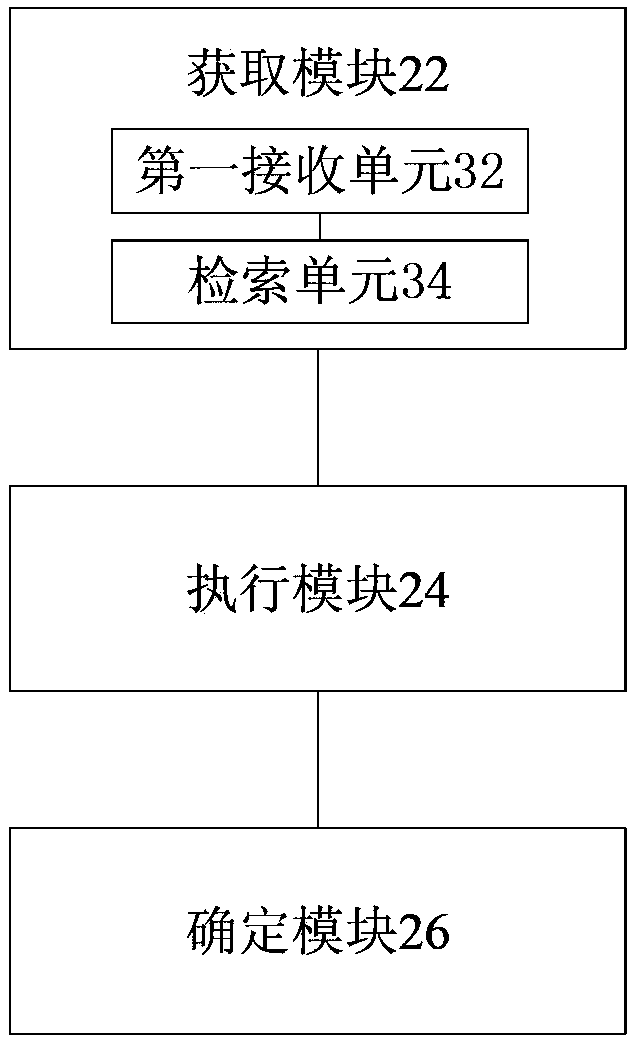

Request processing method and device

InactiveCN105302907AIncreased process reliabilitySolve processing efficiencySpecial data processing applicationsData miningData request

The invention provides a request processing method and device. The method comprises the following steps: receiving at least two acquisition requests; and in allusion to each acquisition request in the at least two acquisition requests, if determining that identification information of undistributed data objects exist in a cache queue, obtaining the identification information of one data object in the identification information of the undistributed data objects and establishing the mapping relationship between the obtained identification information of the data object and the user sending the acquisition requests. Therefore, the request processing method and device provided by the invention can be used for solving the problem that the data request processing manner in the prior art is low in data request processing efficiency and reliability.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

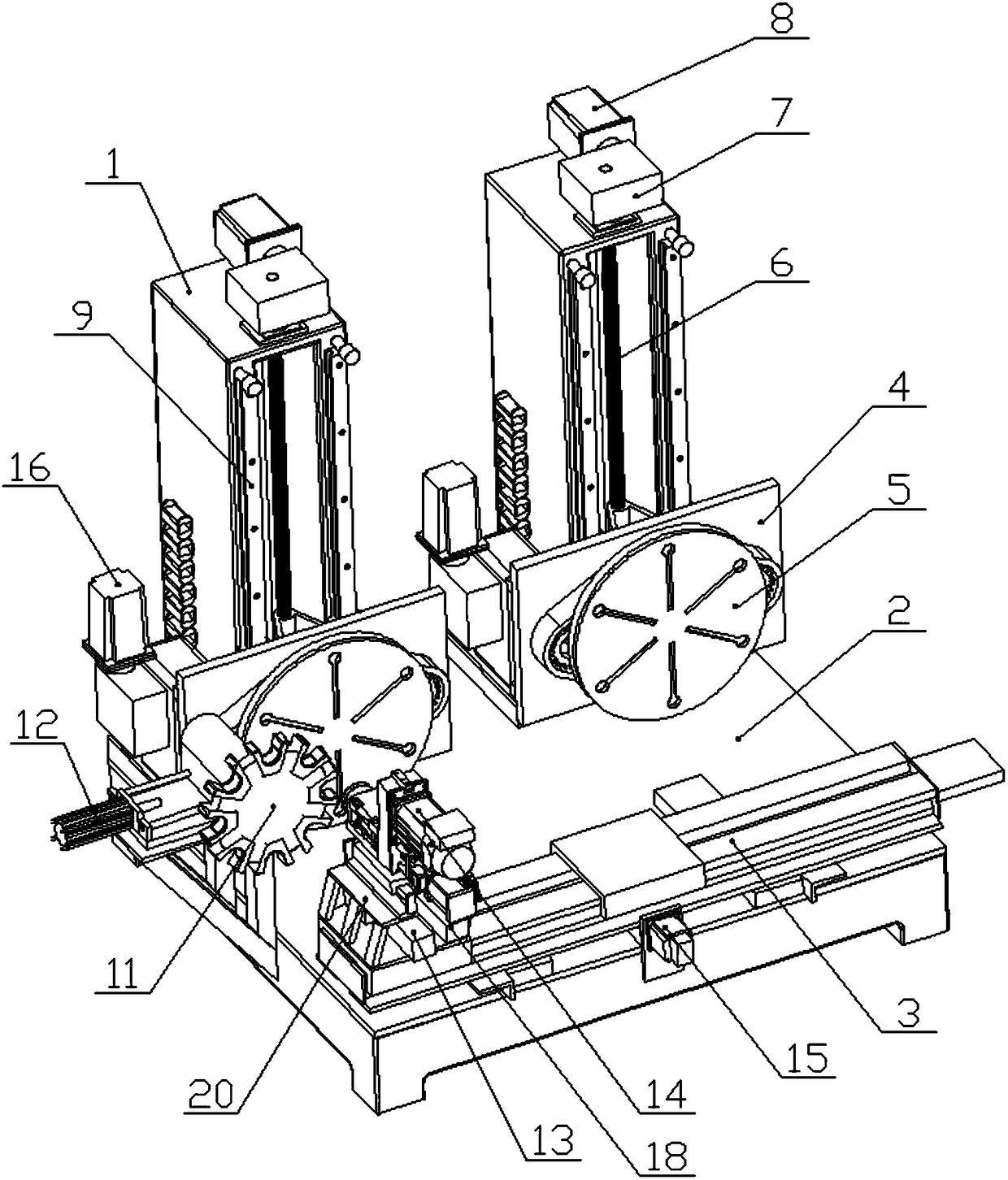

Special mechanical equipment for machining fan shaft sleeve

InactiveCN102363264ASolve processing efficiencySolve the machining accuracyPrecision positioning equipmentOther manufacturing equipments/toolsElectromagnetic clutchMechanical equipment

The invention discloses special mechanical equipment for machining a fan shaft sleeve. The mechanical equipment comprises a divider mechanism, a feeding mechanism, a drilling mechanism, a tapping mechanism, a plane milling mechanism, a chamfering and reaming mechanism, a discharge mechanism and a controller. The feeding mechanism, the drilling mechanism, the tapping mechanism, the plane milling mechanism, the chamfering and reaming mechanism and the discharge mechanism are uniformly distributed around the divider mechanism in included angles of 60 degrees; the divider mechanism consists of anindexing disc, a cam, a three-phase motor, an electromagnetic clutch, a reduction box and a high-speed precision intermittent divider; chamfering and reaming in the chamfering and reaming mechanism are implemented on the same station; and the controller is used for controlling the motion of each mechanism. By using the special mechanical equipment for machining the fan shaft sleeve, the production efficiency is greatly improved, the precision of a product is ensured, the defective rate is greatly reduced relative to other machining modes, and the requirement of industrial production is met.

Owner:SOUTH CHINA UNIV OF TECH +1

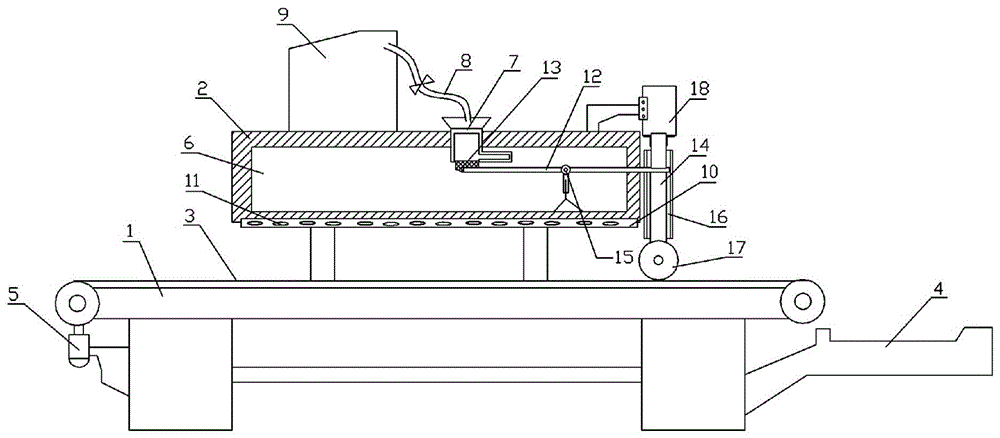

Turning integrated turning plate numerical control machining center

InactiveCN108857582ASolve the machining accuracySolve processing efficiencyFeeding apparatusDriving apparatusNumerical controlEngineering

The invention provides a turning integrated turning plate numerical control machining center composed of four-axis transmission mechanisms, a double-layer tool rest, a main shaft tool magazine and a lathe tool magazine. The four-axis transmission mechanisms include a Z axis responsible for lifting, an X axis, a Y axis, a rotation mechanism for rotating chucks and a rotating shaft of an automatic switching mechanism correspondingly, wherein the X axis and the Y axis are responsible for feeding and moving of the tool rest, and the rotating shaft is used when the turning integrated turning platenumerical control machining center is used for turning. The double-layer tool rest mechanism comprises a main shaft feeding mechanism on the upper layer and the tool automatic switching mechanism on the lower layer. The main shaft tool magazine mainly conducts automatic tool changing for the main shaft feeding mechanism on the upper layer. The lathe tool magazine mainly conducts automatic tool switching for the tool automatic switching mechanism on the lower layer during rotating turning. The chucks are fixedly connected with the rotation mechanism. The rotation mechanism is fixedly connectedwith a lifting mechanism. By means of rotating and lifting, the workpiece position of the turning integrated turning plate numerical control machining center is adjusted through numerical control, andthe cutting requirement of full-function numerical control machining is met through cooperation with an X-axis and Y-axis feeding mechanism, the tool automatic switching mechanism and the tool magazine mechanism; and the turning integrated turning plate numerical control machining center can be widely used for various types of machining occasions.

Owner:湖南鈊耐自动工装系统发展有限公司

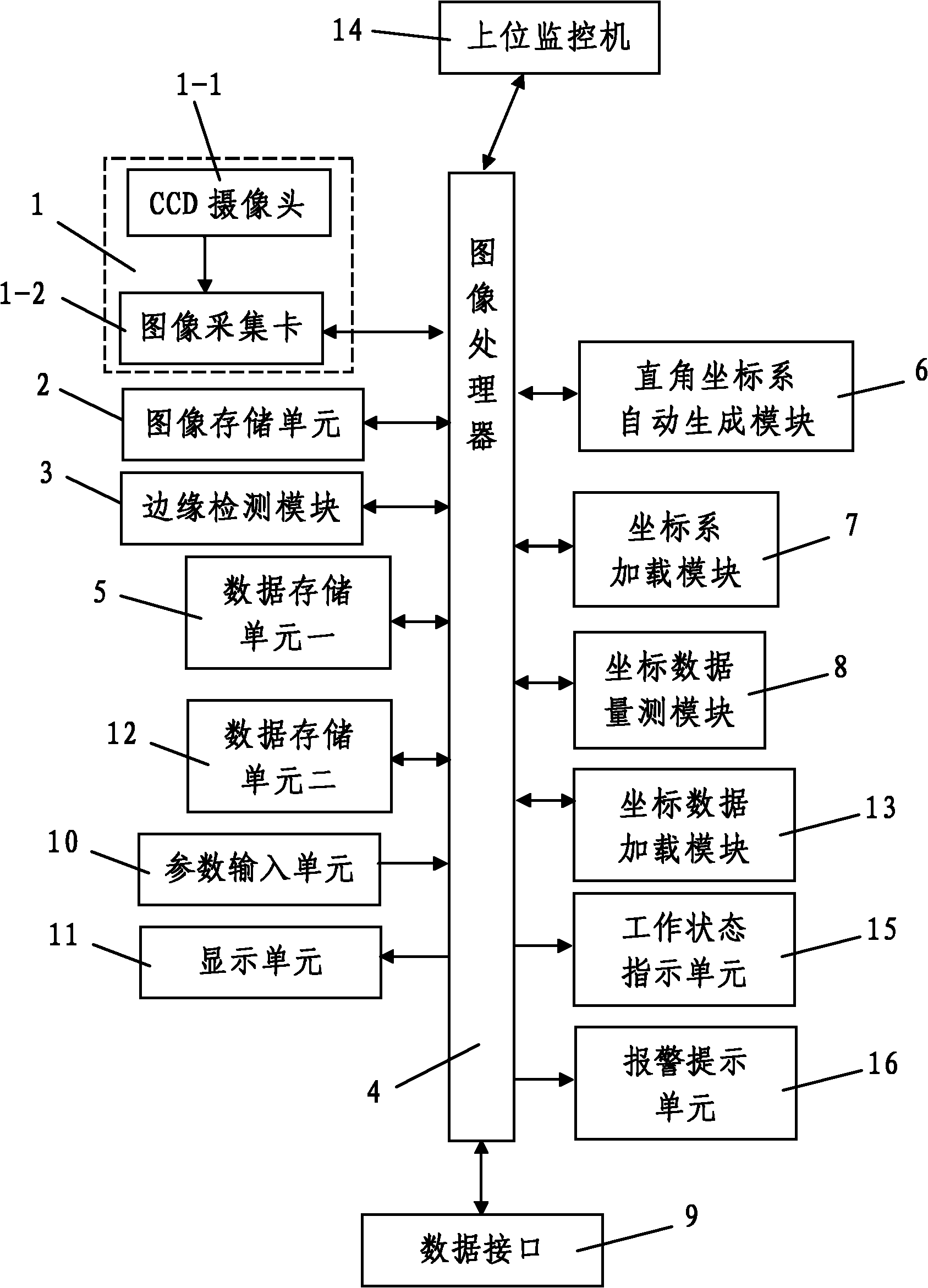

Automatic generation system of numerical control machine tool working diagram

InactiveCN103163835AReasonable designLow costProgramme controlComputer controlNumerical controlData synchronization

The invention discloses an automatic generation system of a numerical control machine tool working diagram. The automatic generation system of the numerical control machine tool working diagram comprises an image capture device, an image storage unit, an edge detection module, an image processor, a first data storage unit, a rectangular coordinate system automatic generation module, a coordinate system loading module, a coordinate data measurement module, a second data storage unit, a coordinate data loading module, a data interface, a parameter input unit and a display unit, wherein the image capture device is used for shooting molding product images, the edge detection module detects edges of the molding product images, the image processor extracts contour lines of molding products according to detection results of the edge detection module, the coordinate system loading module is used for loading measured coordinate data to the contour lines of the molding products synchronously, and the data interface, the parameter input unit and the display unit are respectively connected with the image processor. The automatic generation system of the numerical control machine tool working diagram is reasonable in design, simple and convenient to use and operate, good in using effects, high in intelligent degree and good in production processing images, can generate working diagrams for the numerical control machine tool automatically and quickly, and man-made design error does not exist.

Owner:XIAN KUOLI MACHANICAL & ELECTRICAL TECH

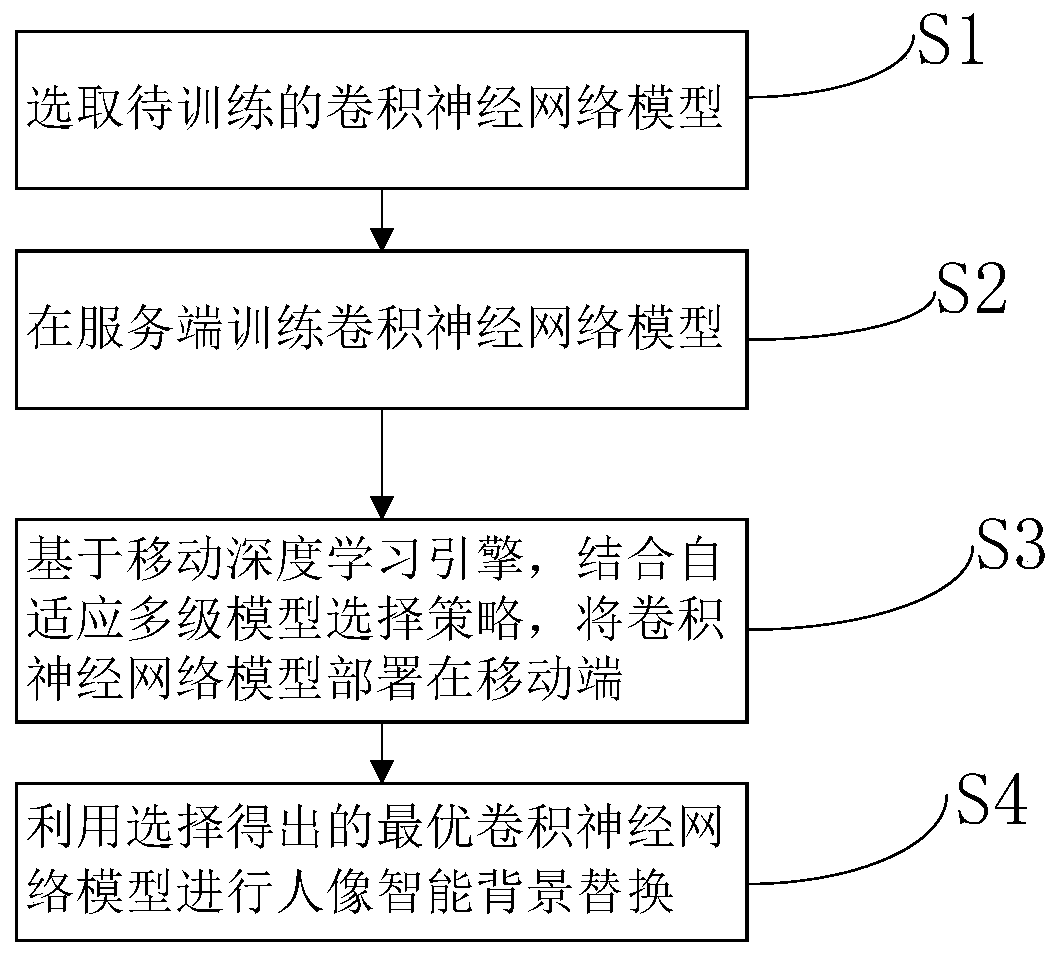

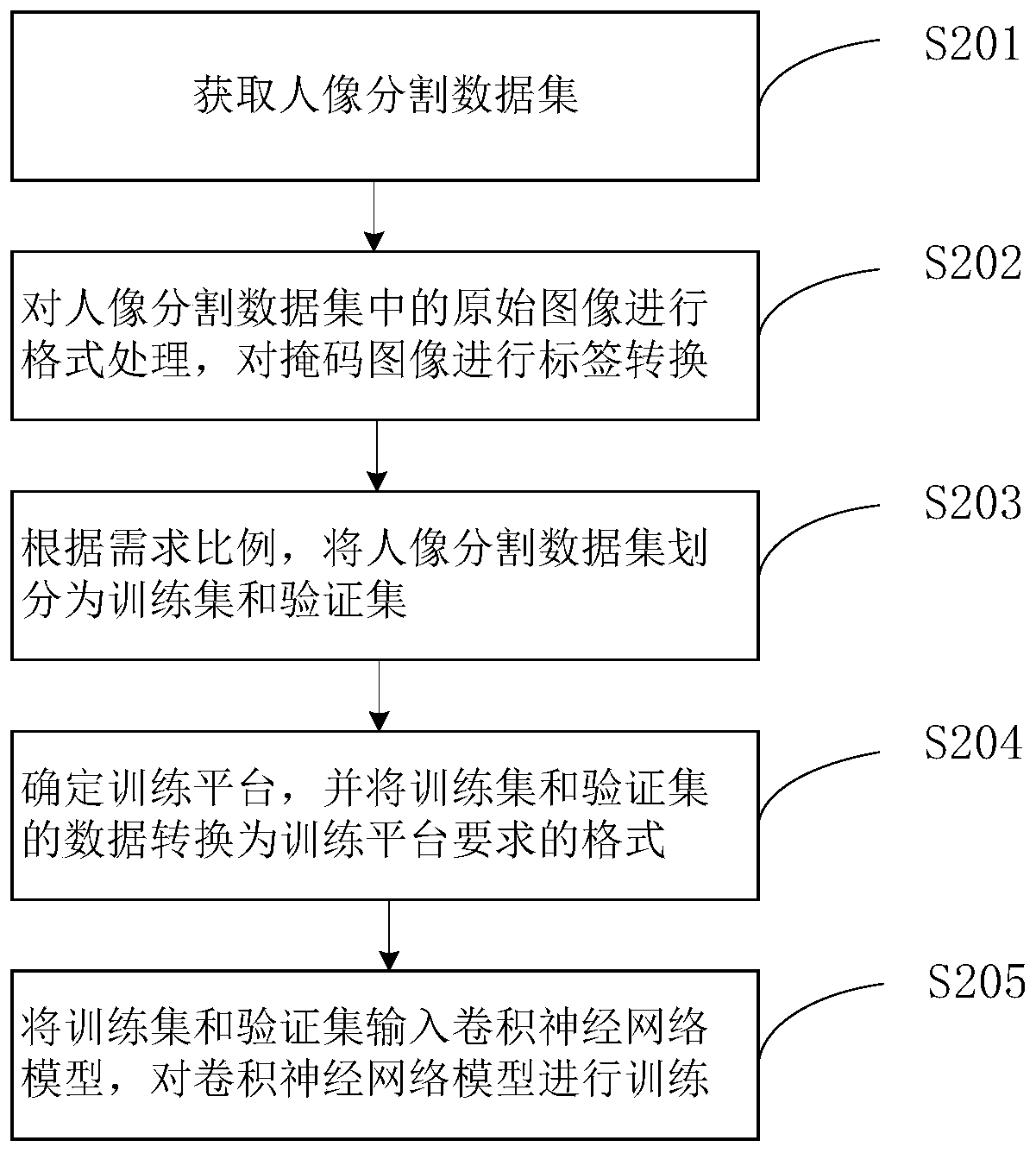

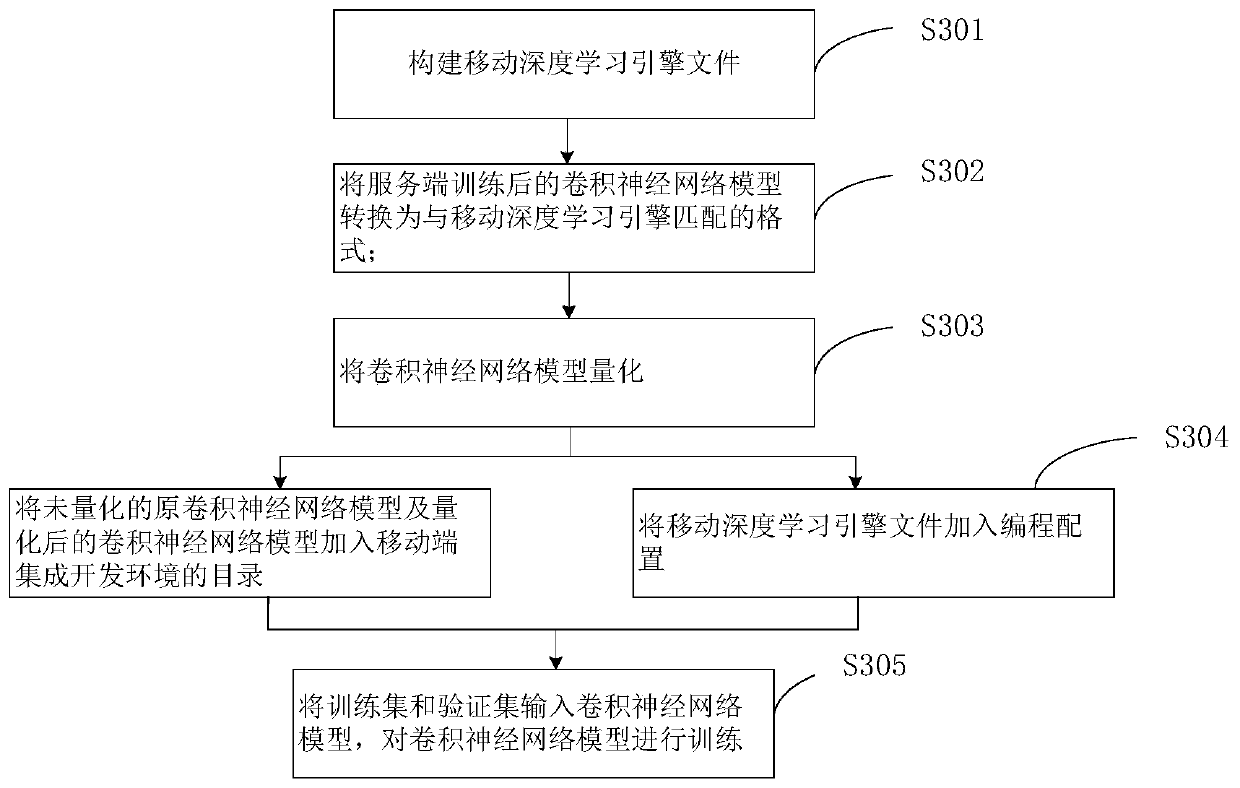

Mobile terminal portrait intelligent background replacement method based on mobile deep learning engine

PendingCN111369430ASolve the low processing efficiency and success rateImprove user experienceGeometric image transformationCharacter and pattern recognitionSelf adaptiveMobile end

The invention provides a mobile terminal portrait intelligent background replacement method based on a mobile deep learning engine. The method at least comprises the following steps: S1, selecting a convolutional neural network model to be trained; s2, training a convolutional neural network model at a server; s3, deploying the convolutional neural network model at a mobile terminal based on a mobile deep learning engine in combination with an adaptive multistage model selection strategy; and S4, carrying out portrait intelligent background replacement by utilizing the selected optimal convolutional neural network model. According to the invention, the background replacement function can be realized on the mobile device, and the problems of low processing efficiency and low success rate ofportrait background replacement caused by network factors are solved; besides, when the convolutional neural network model mobile terminal is deployed, a self-adaptive multistage model selection strategy is combined, the purpose of effectively selecting the optimal model according to the user equipment difference is achieved, and the user experience is improved.

Owner:SUN YAT SEN UNIV

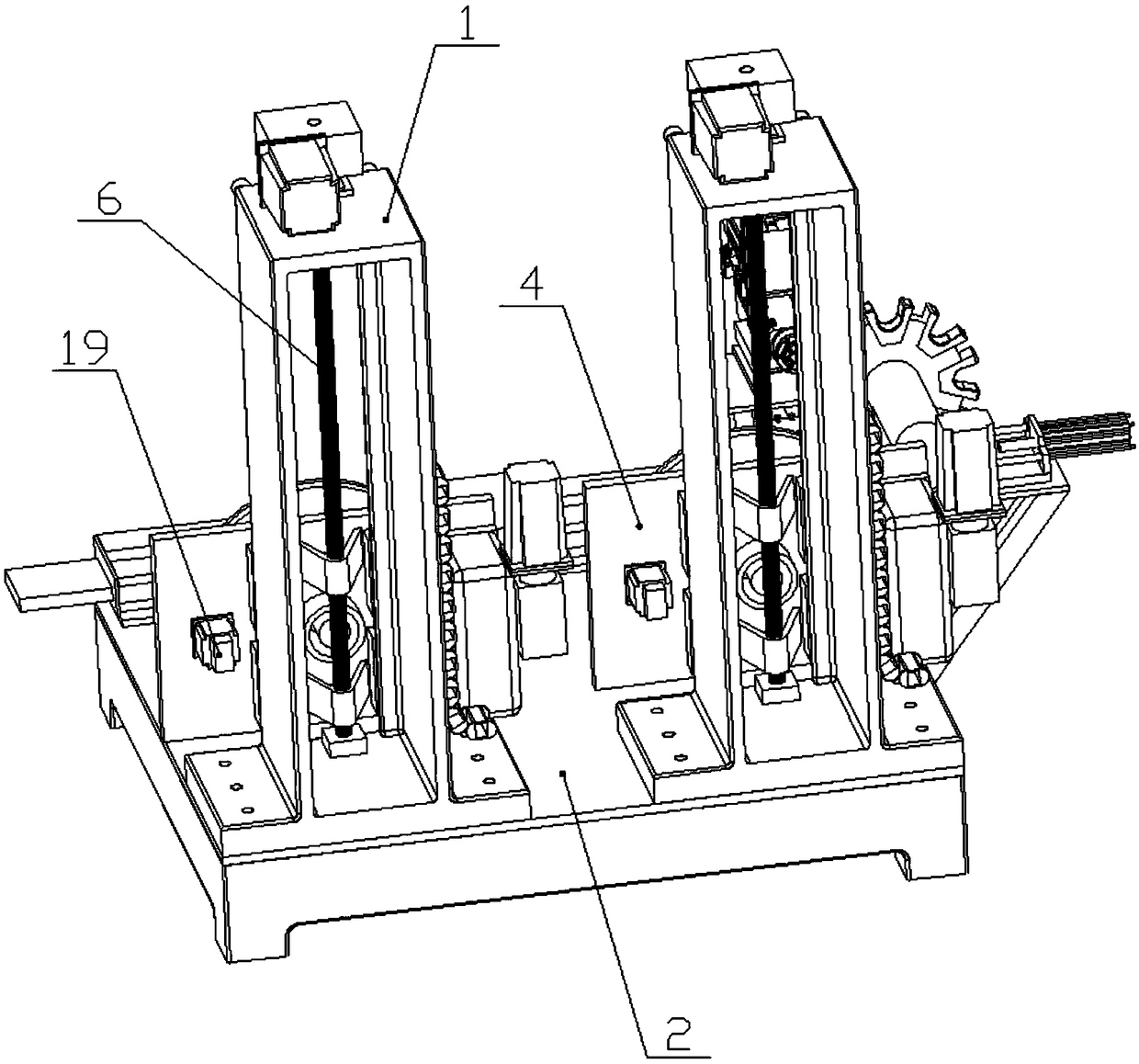

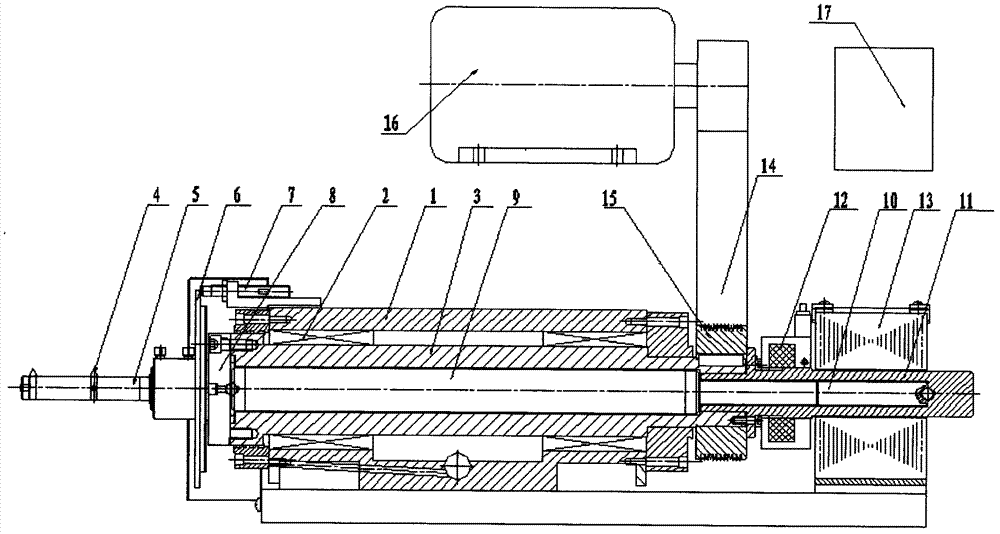

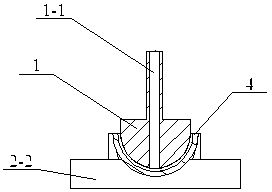

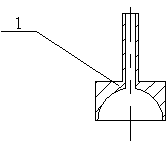

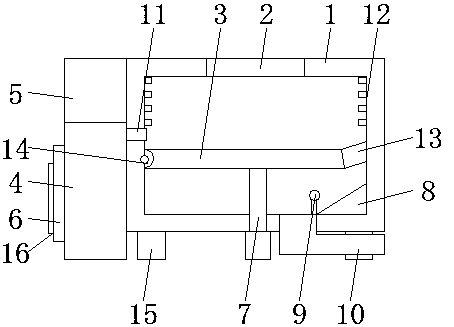

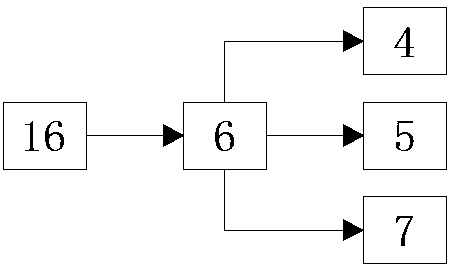

Boring head for boring non-circular holes

InactiveCN102814516ASolve the machining accuracySolve processing efficiencyBoring headsBoring/drilling machinesRotary encoderRadial position

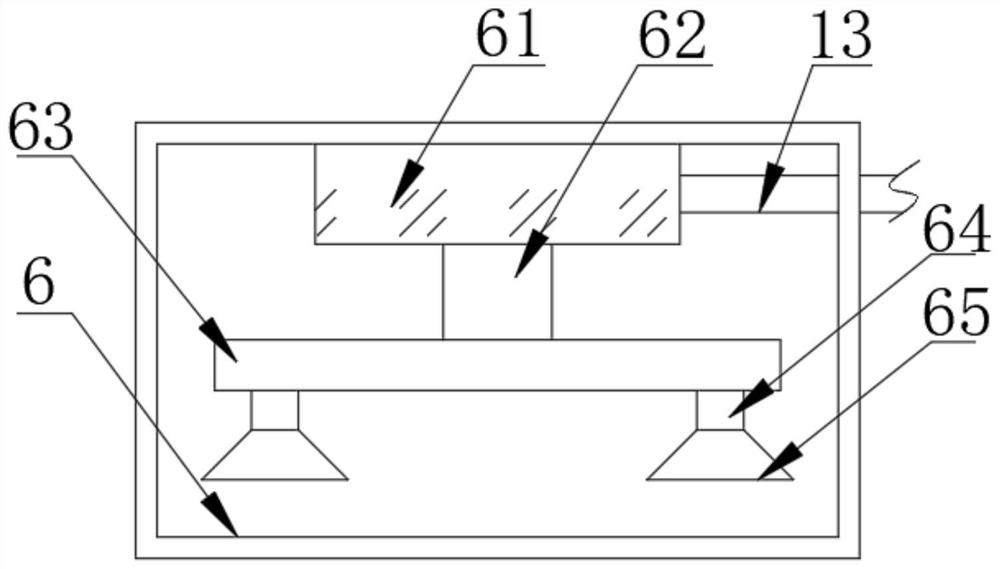

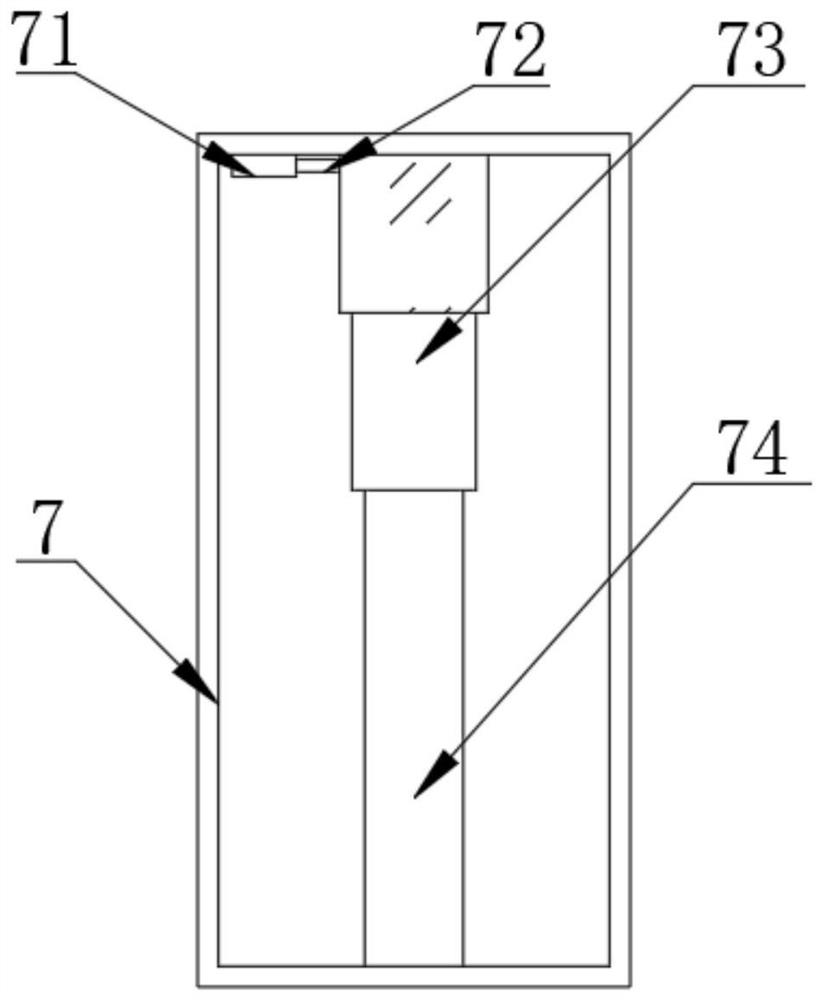

A boring head for boring non-circular holes mainly comprises a casing (1), a boring head bearing (2), a hollow shaft (3), a boring tool (4), a boring bar (5), a displacement measuring panel (6), a displacement sensor (7), a spring plate (8), a transitional bar (9), a magnetostrictive rod (10), a non-magnetic material tube (11), a rotary encoder (12), a coil (13), a belt (14), a belt pulley (15), a spindle motor (16), a driver (17) and the like. The driver (17) controls magnitude of field current in the coil (13) to drive the magnetostrictive rod (10) to constrict, and elastic deformation of the spring (8) is changed by the aid of the transitional bar (9), so that the radial position of the boring tool (4) is changed, and the non-circular holes can be bored accurately according to feedbacks of the displacement sensor (7) and the rotary encoder (12).

Owner:周众

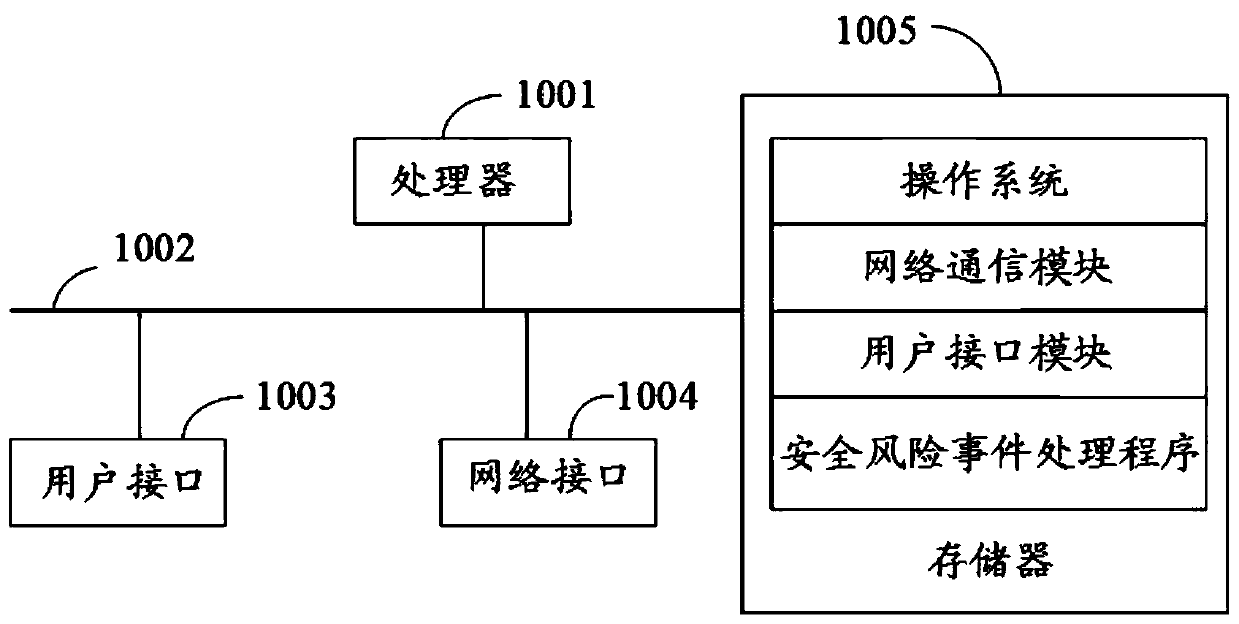

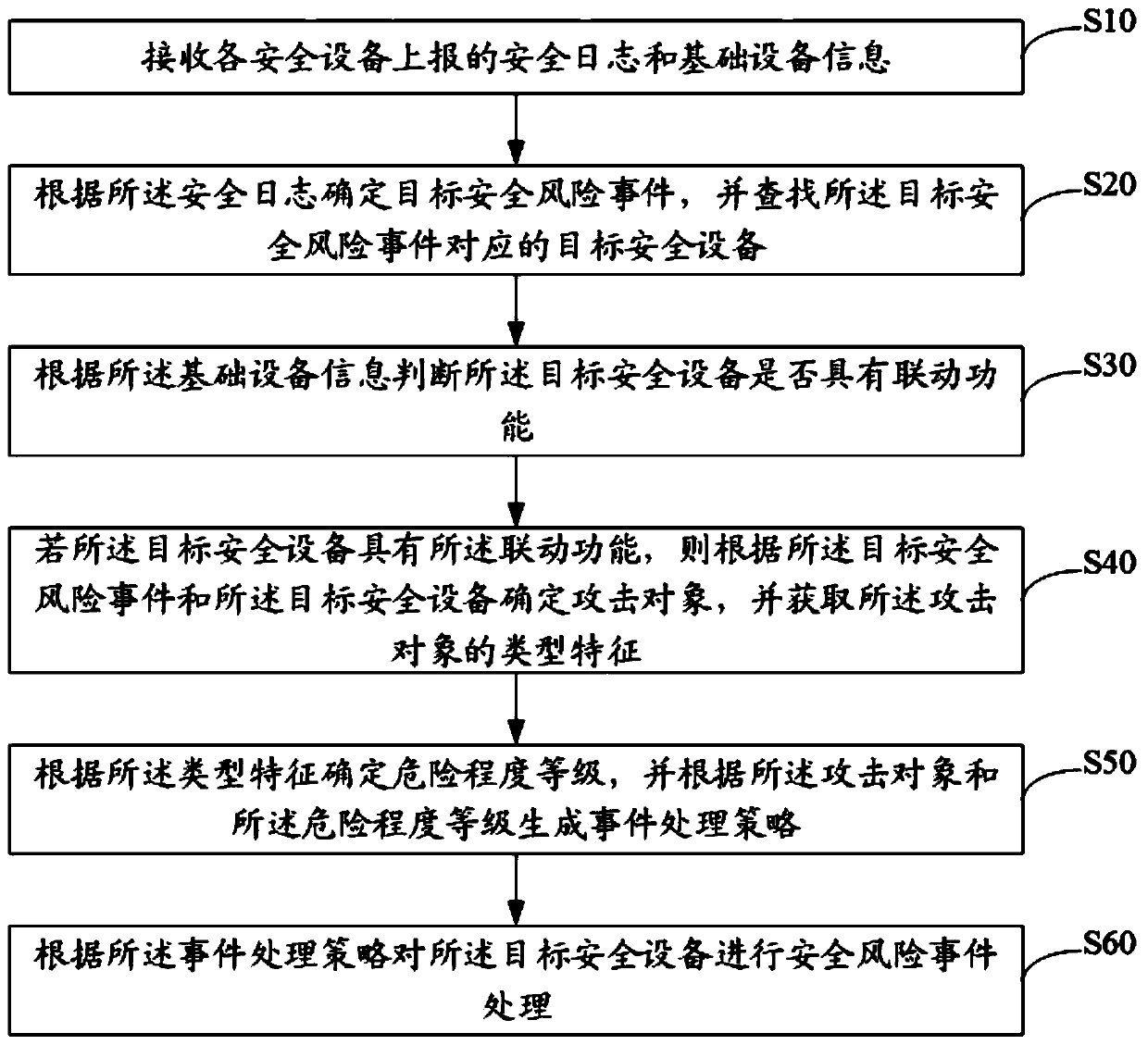

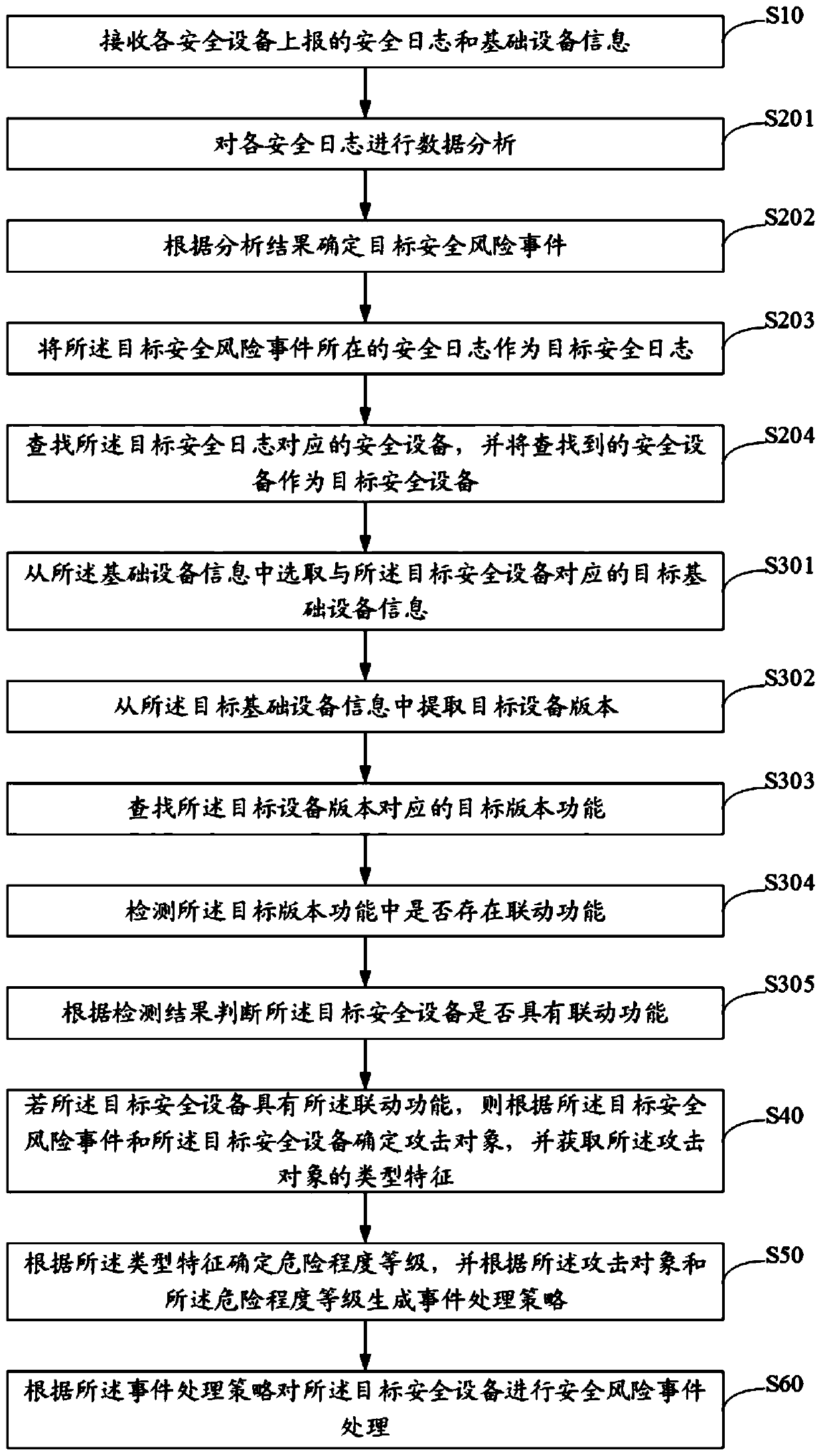

Security risk event processing method, apparatus and device, and storage medium

ActiveCN110881051AEasy to handleSolve processing efficiencyData switching networksAttackSecurity management

The invention relates to the technical field of safety management and discloses a security risk event processing method, apparatus and device, and a storage medium. The method comprises the followingsteps of: receiving a security log and basic device information reported by each piece of security device, determining a target security risk event and a target security device, if the target safety device has the linkage function, executing the next step; if so, determining an attack object according to the target security risk event and the target security device; acquiring type characteristicsof the attack object; determining a danger level according to the type characteristics; generating an event processing strategy to perform security risk event processing on the target security device.Therefore, the target security risk event is screened out from the security log reported by each security device. The target safety device is determined according to the target safety risk event, andthe event processing strategy is generated to process the safety risk event, so that the technical problems of how to process the safety risk event conveniently and how to improve the processing efficiency and safety are solved.

Owner:SANGFOR TECH INC

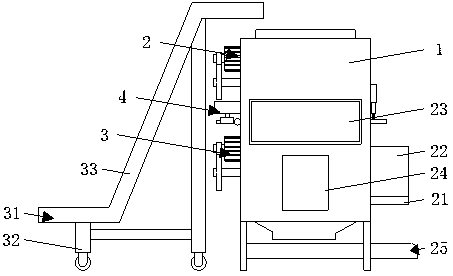

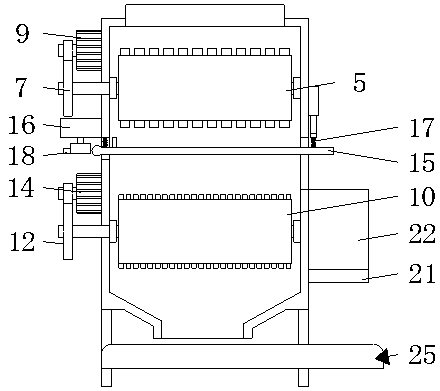

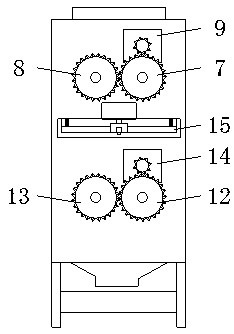

Automatic crusher for coal mine with de-doping function

InactiveCN109529998ASolve processing efficiencySolve problems affecting coal mine processing efficiencyGrain treatmentsEngineeringCrusher

The invention discloses an automatic crusher for a coal mine with a de-doping function. The crusher comprises a crusher body, a first crushing device is arranged inside the crusher body, a second crushing device is arranged inside the crusher body, and a de-doping device is disposed inside the crusher body and between the first crushing device and the second crushing device. The crusher can provide preliminary crushing for the coal mine by setting the first crushing device, the coal mine and impurities which are initially crushed are dropped onto the de-doping device, the unbreakable impurities are larger than the size of the crushed coal mine, the impurities are screened and removed by the de-doping device, the coal mine after the impurity removal is finely crushed by the second crushingdevice to obtain the qualified coal mine, and the cooperation of the first crushing device, the second crushing device and the de-doping device solves the problem in the prior art that the impuritiesin the coal mine are not automatically removed during crushing, which affects the processing efficiency of the coal mine.

Owner:丽水青蓝环保科技有限公司

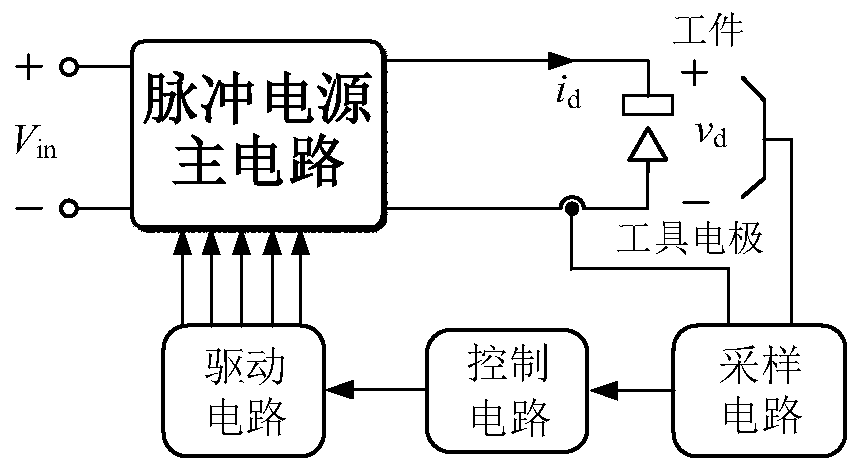

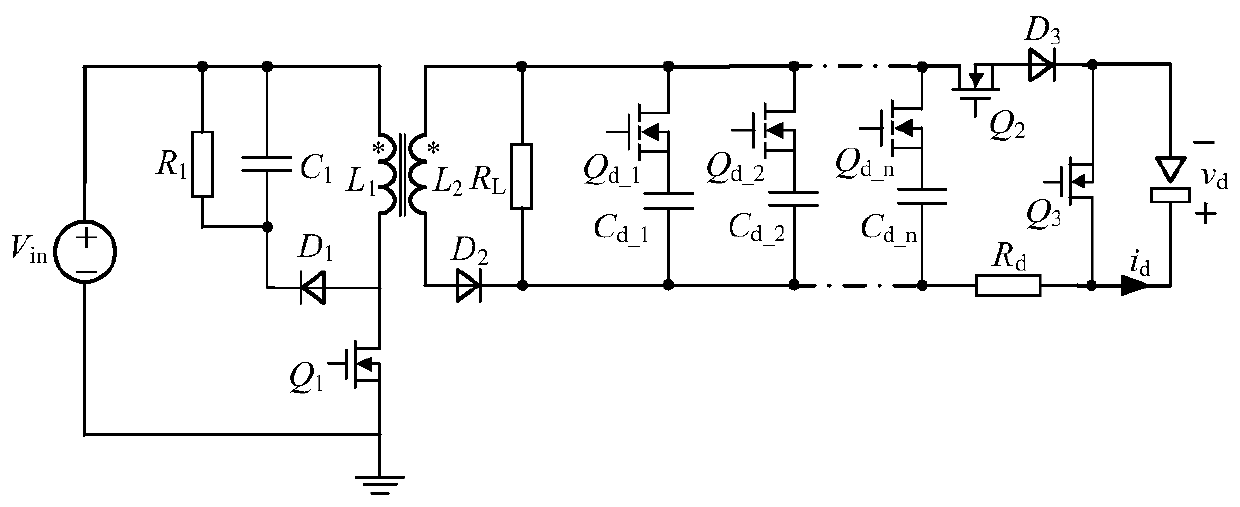

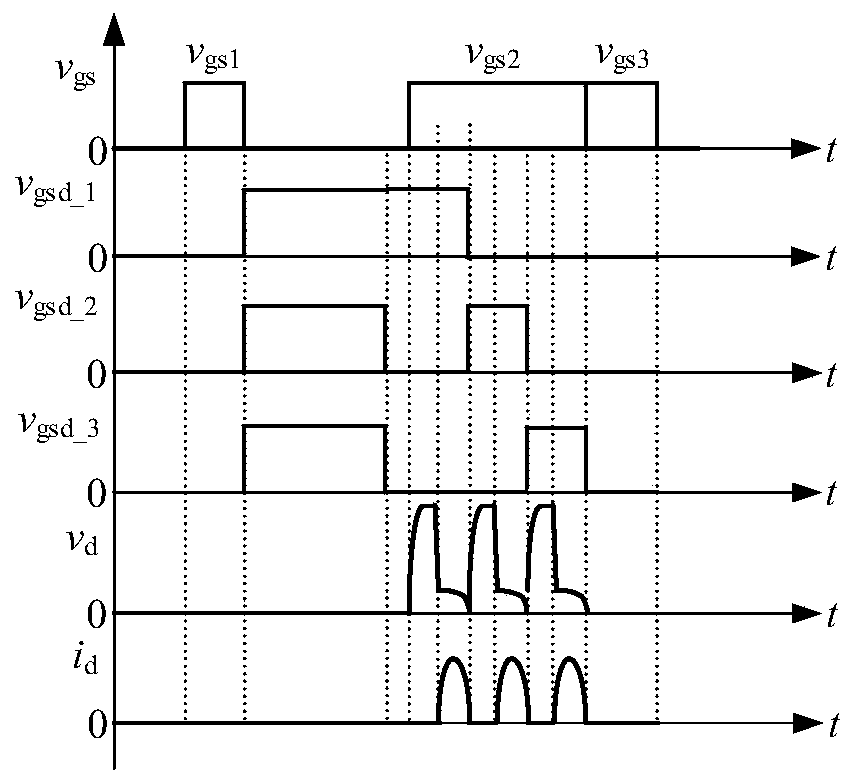

Micro and fine high-frequency grouped pulse power supply

ActiveCN111193428AIncrease the discharge frequencySolve processing efficiency and surface roughnessDc-dc conversionPulse generation by energy-accumulating elementPhysicsCapacitance

The invention discloses a micro and fine high-frequency grouped pulse power supply. The micro and fine high-frequency grouped pulse power supply comprises a direct-current power supply, a pulse powersupply main circuit, a gap voltage and current sampling circuit, an FPGA control circuit and a driving circuit, and the circuit pulse power supply main circuit comprises a flyback transformer, a primary side switch tube, a micro and fine discharge switch tube, an electricity elimination off-switch tube, first to nth switch tubes, a first resistor, a clamping capacitor, a first diode, a second resistor, a third resistor, a second diode, a third diode, and first to nth capacitors. The pulse power supply main circuit provides energy for the gap load, the gap voltage and current sampling circuit samples voltage and gap current at two ends of a gap, the FPGA control module generates PWM signals according to the sampled voltage and current, and the PWM signals are filtered and amplified by the driving circuit to drive the pulse power supply main circuit to be switched on and off. The flyback circuit is adopted to charge the discharge capacitor, input and output are isolated, discharge is notaffected by input voltage, and multi-level energy processing is achieved within a certain range.

Owner:NANJING UNIV OF SCI & TECH

Production process of inner ring of metal wound gasket

InactiveCN111347226AReduce manual laborQuality improvementWashersGrinding machinesManufacturing engineeringMetal

The invention discloses a production process of an inner ring of a metal wound gasket and belongs to the technical field of metal part processing. The production process comprises the following stepsof S1, loading steel strips automatically; S2, adjusting the size of a channel automatically; S3, polishing and derusting the steel strips automatically; S4, cleaning burrs on the surfaces of the steel strips; S5, carrying out bend forming; and S6, cutting and unloading the steel strips automatically. The production process is high in degree of automation, reduces the labor force, can transfer thesteel strips of different sizes and is relatively high in practicality, so that the production quality of the inner ring of the metal wound gasket is improved.

Owner:李林清

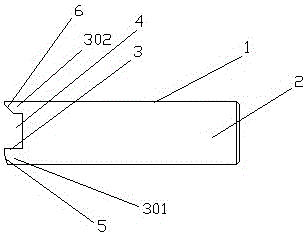

Chamfer tool

InactiveCN105081471AGood for vibration controlSolve processing efficiencyEngineeringProcess efficiency

The invention discloses a chamfer tool which comprises a tool body, wherein a holder is arranged at the rear end of the tool body, two oppositely arranged cutting blades, namely a first cutting blade and a second cutting blade, are arranged at the front end of the tool body, a chip space body is formed between the first cutting blade and the second cutting blade, chamber parts, namely a first chamber part and a second chamber part, are arranged on the first cutting blade and the second cutting blade respectively, a first chamber rear corner and a second chamber rear corner are arranged at the rear end of the first chamber part, and a third chamber rear corner, a fourth chamber rear corner and a fifth chamber rear corner are arranged at the rear end of the second chamber part. According to the way, the chamber tool provided by the invention can solve problems on aspects of processing efficiency and high-gloss surfaces, one blade is used for processing high-gloss surfaces, the other blade is used for chambering, one-step formation is achieved, the problems on the aspect of processing efficiency can be solved, and control to vibration of the tool is facilitated.

Owner:WUXI GUOHONG MEASURING & CUTTING TOOLS

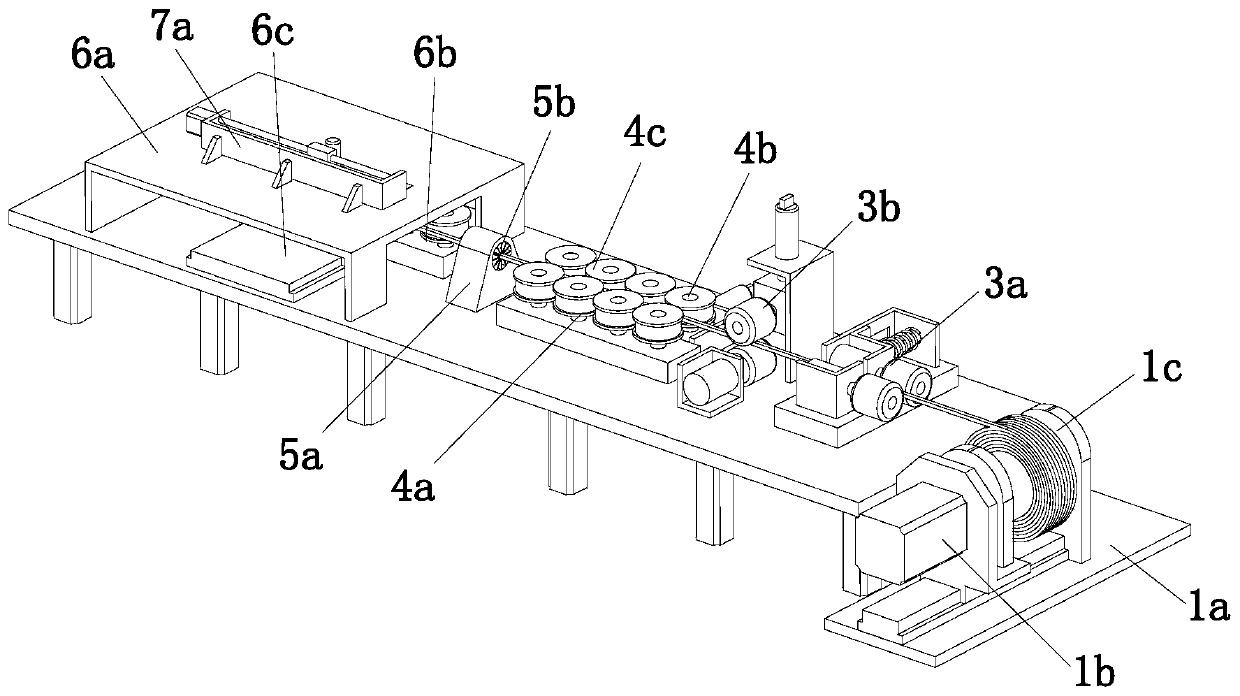

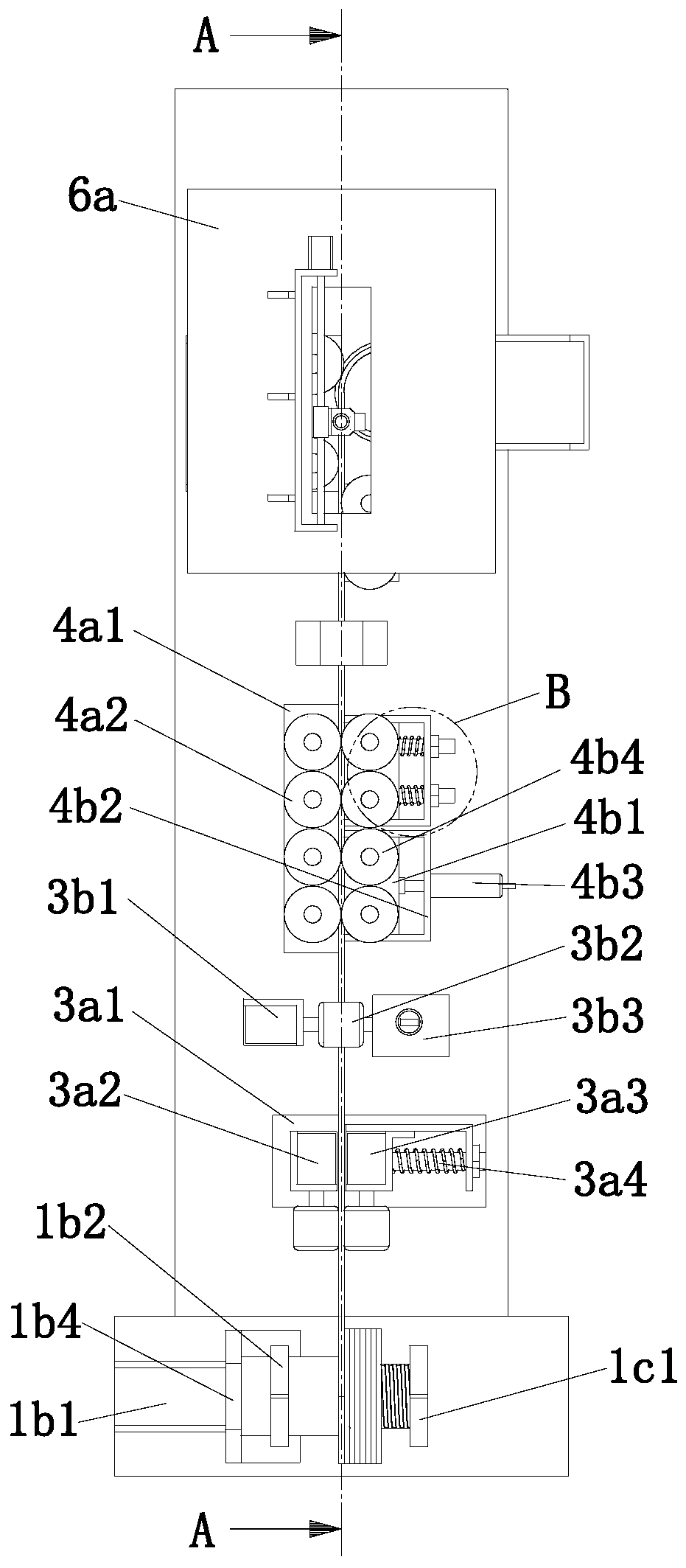

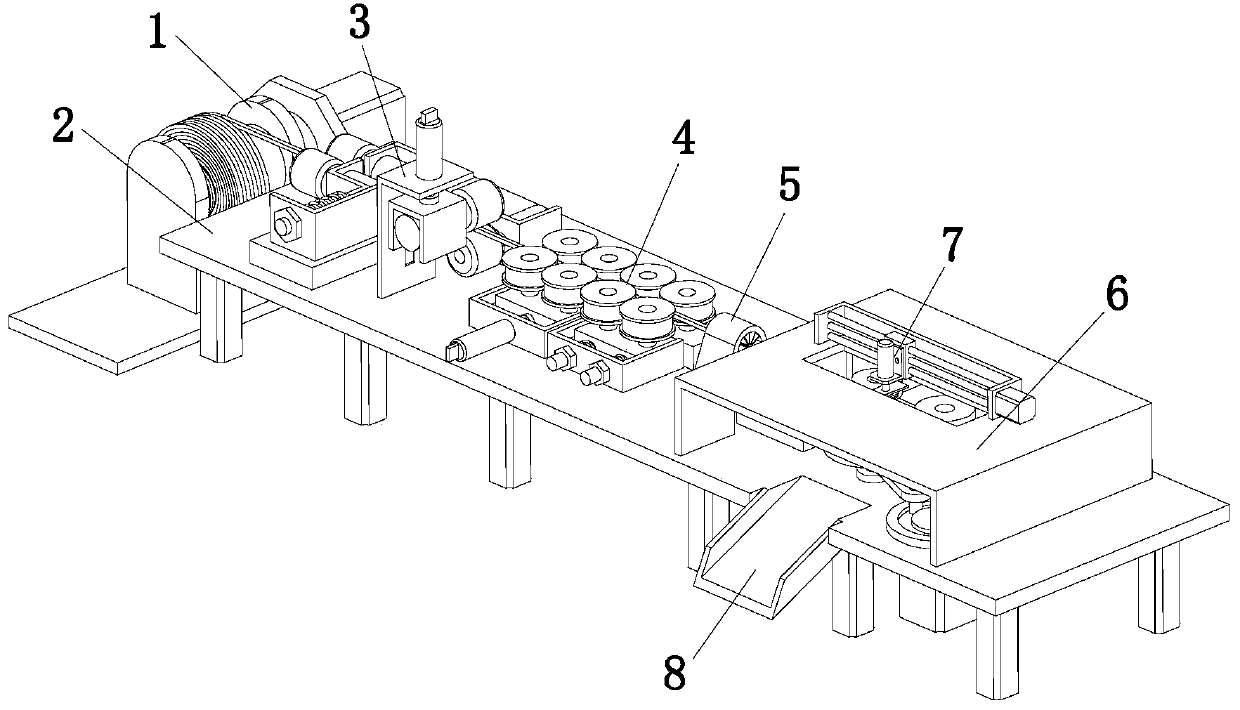

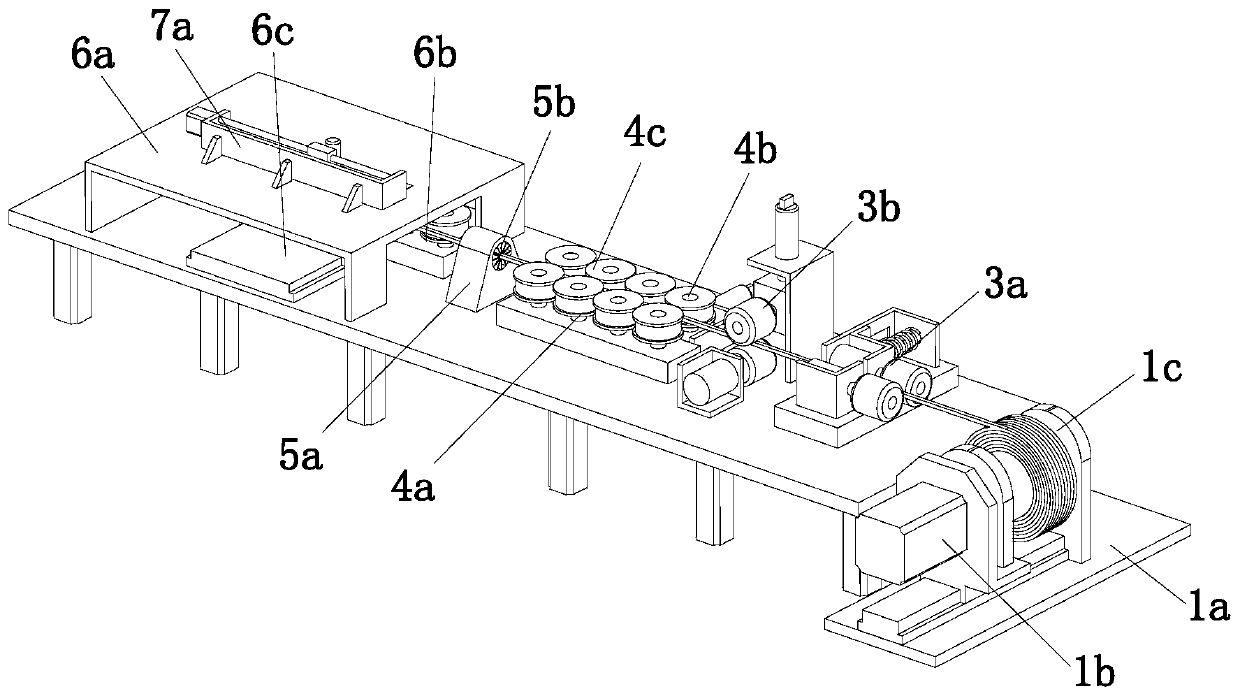

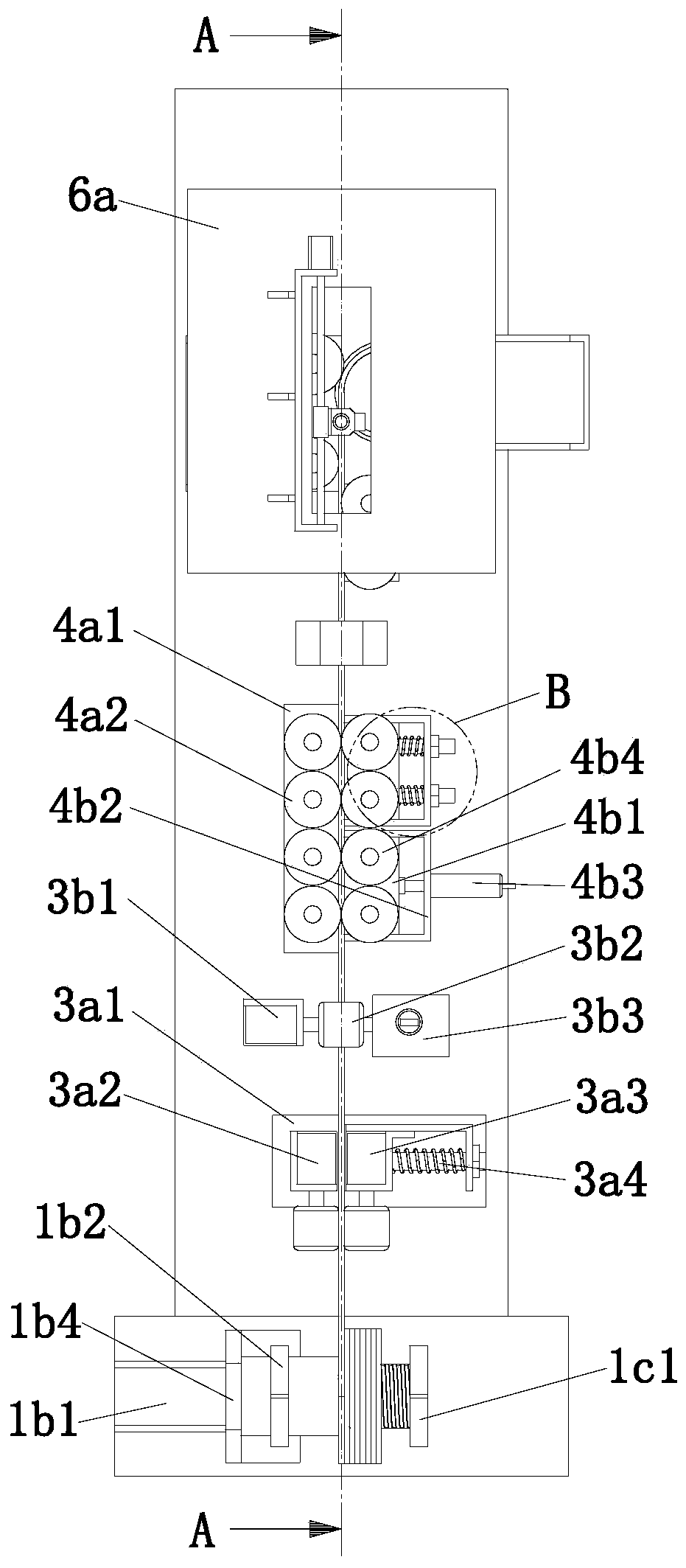

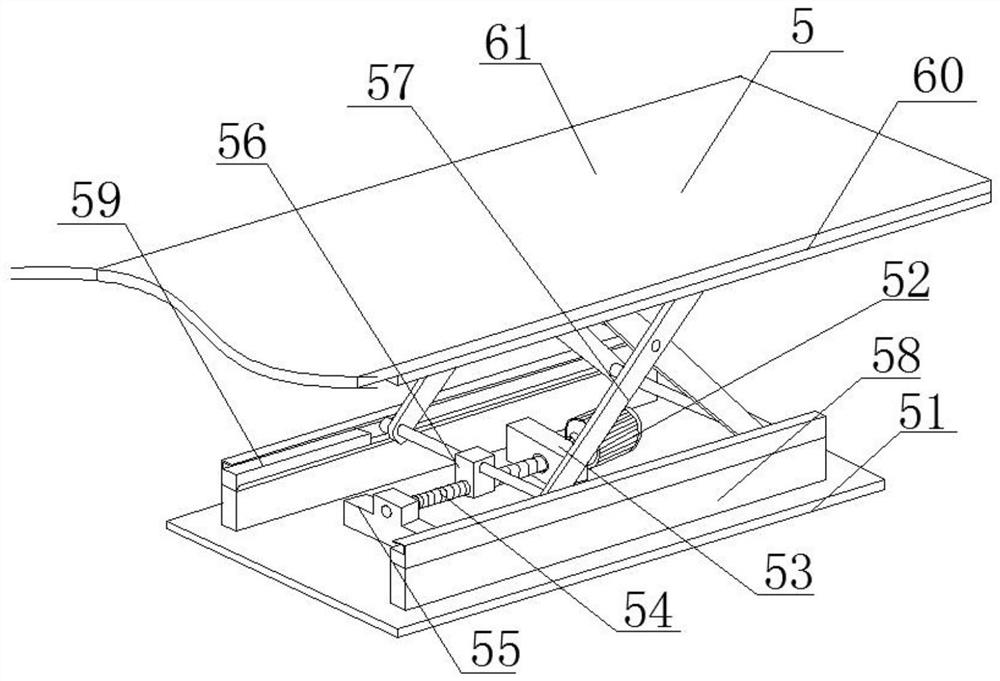

Metal wound gasket inner ring machining equipment

InactiveCN111451782AAuto resizeSolve processing efficiencyOther manufacturing equipments/toolsGrinding machinesMachiningWorkbench

The invention discloses metal wound gasket inner ring machining equipment, and belongs to the technical field of metal part machining. The metal wound gasket inner ring machining equipment comprises afeeding device and a workbench, a grinding and rust removing device, a guide traction device, a cleaning device and a bending forming device are sequentially arranged in the length direction of the workbench, a cutting device is arranged above the bending forming device, the feeding device comprises a bearing base plate, a driving assembly and a fixing assembly, the grinding and rust removing device comprises a first grinding assembly and a second grinding assembly, the guide traction device comprises a positioning guide assembly, a driving guide assembly and an adjusting traction assembly, and the bending forming device comprises a protective cover, a limiting assembly, a forming assembly and a driving adjusting assembly; and the protective cover is arranged on the top of the workbench in a covering mode and can form a containing space, and a guide slide way is arranged on the workbench. The metal wound gasket inner ring machining equipment has the advantages that the automation degree is high, the manual labor force is reduced, in addition, conveying of steel bars with different sizes can be realized, the practicability is higher, and the production quality of metal winding gasket inner rings is improved.

Owner:李林清

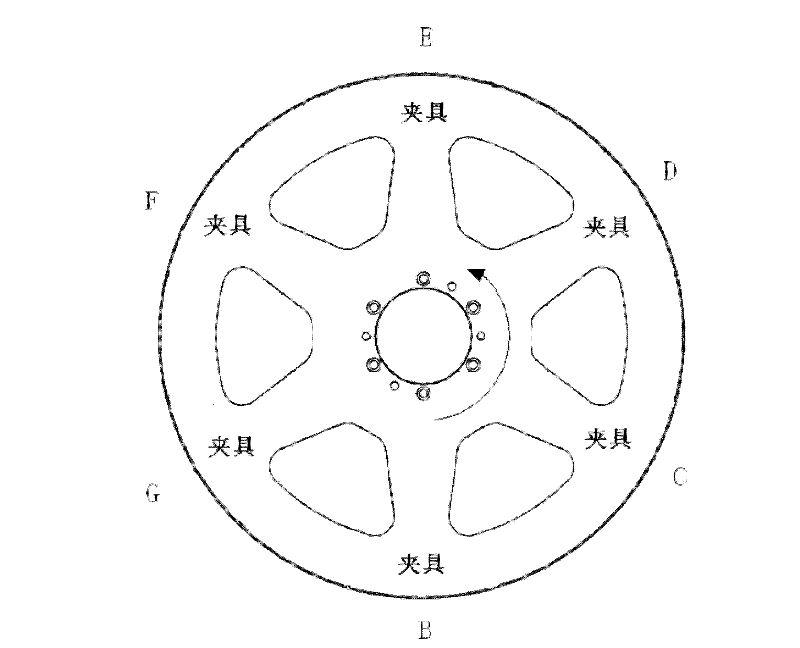

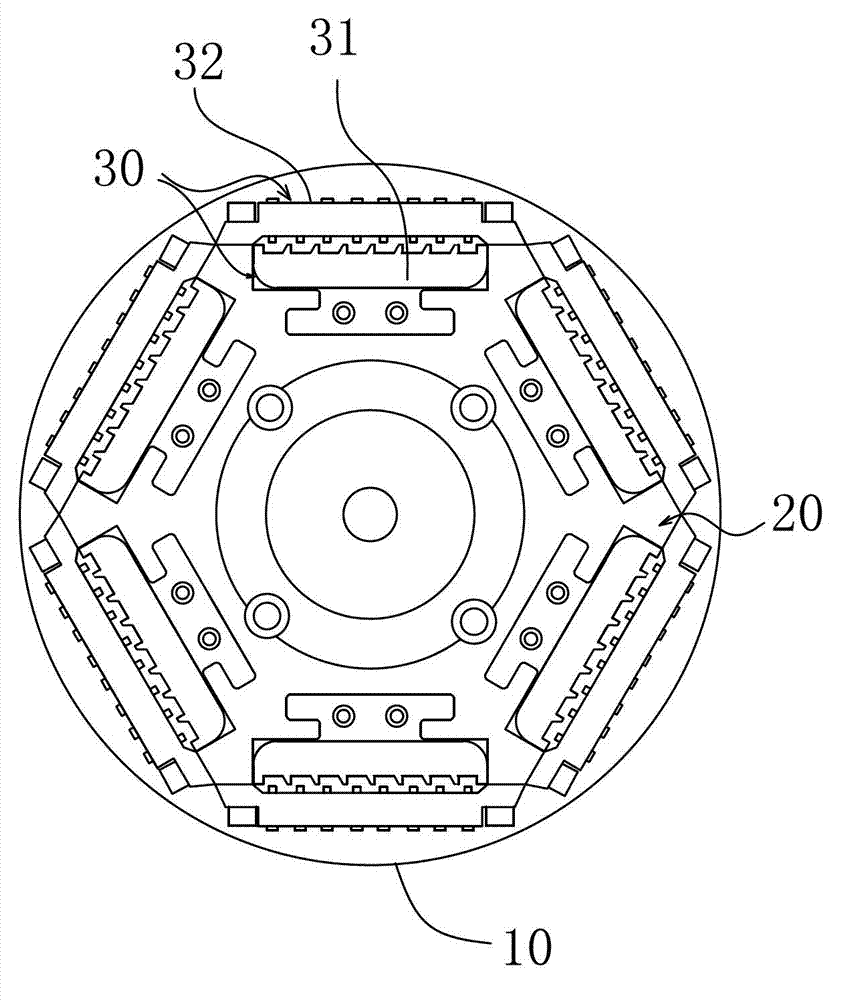

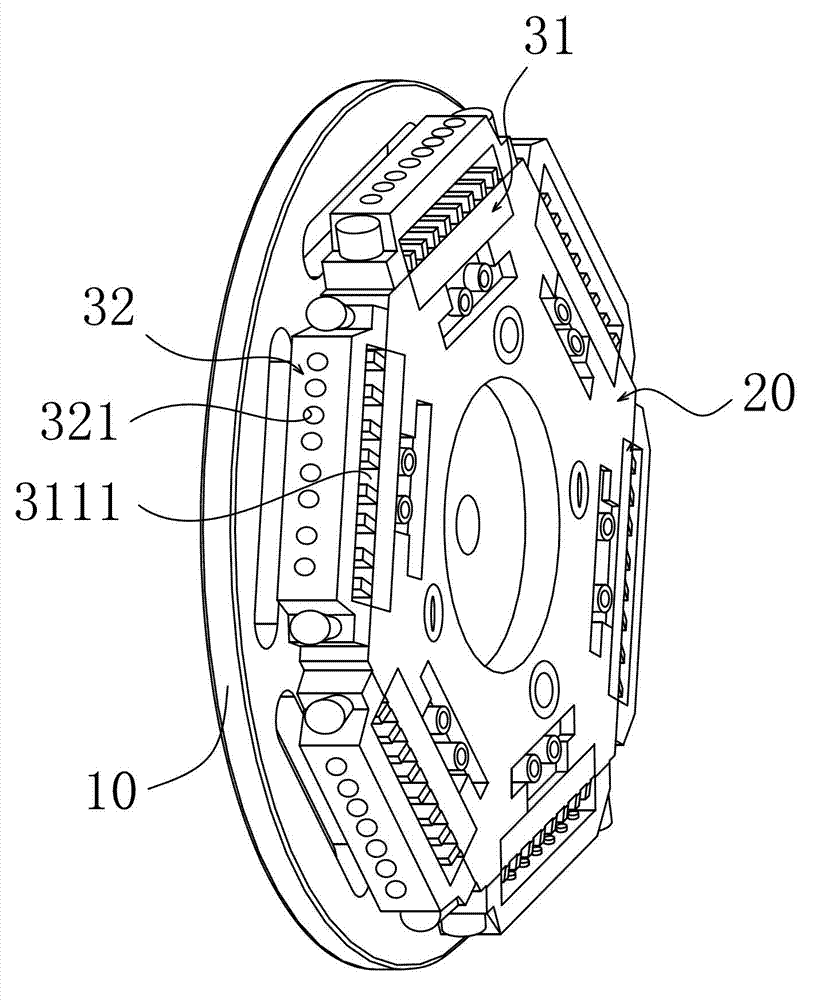

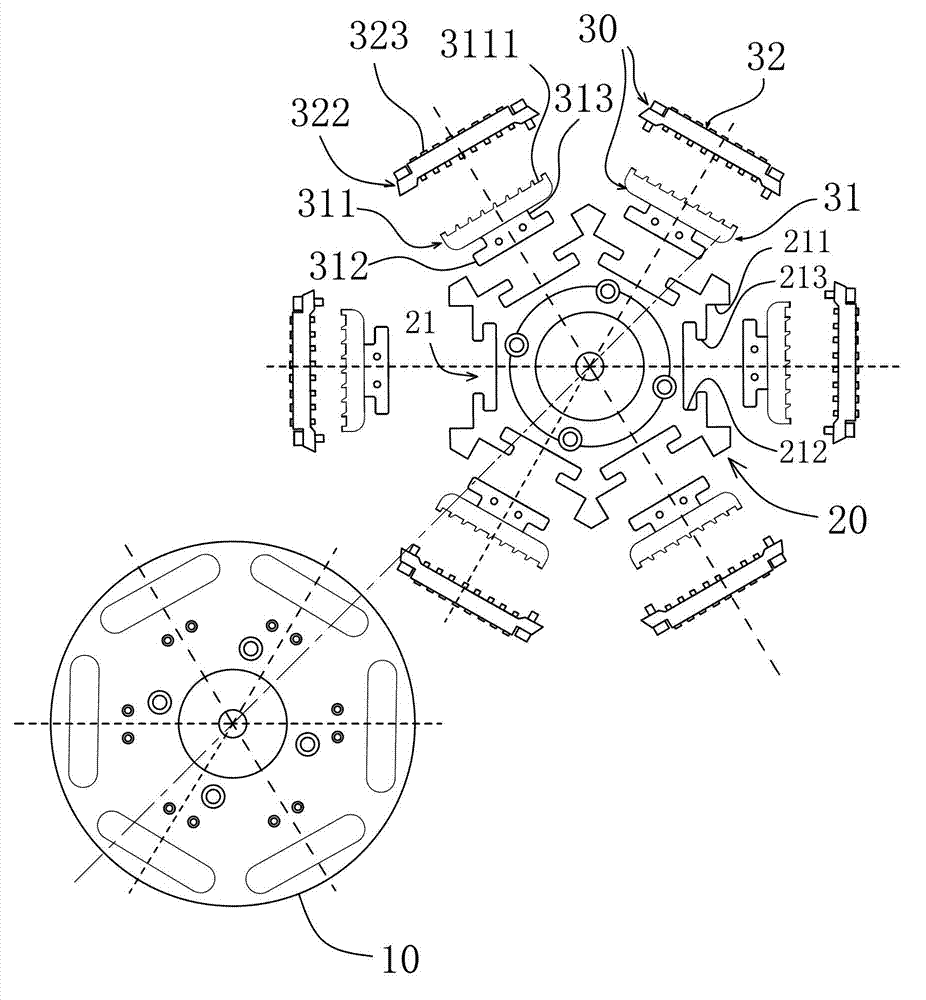

Wear-resistant clamp for grinding optical fiber connector blanks

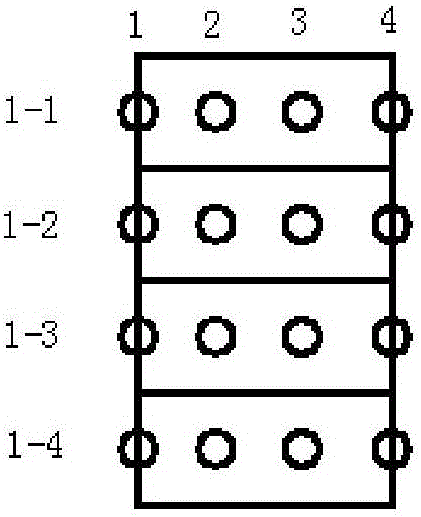

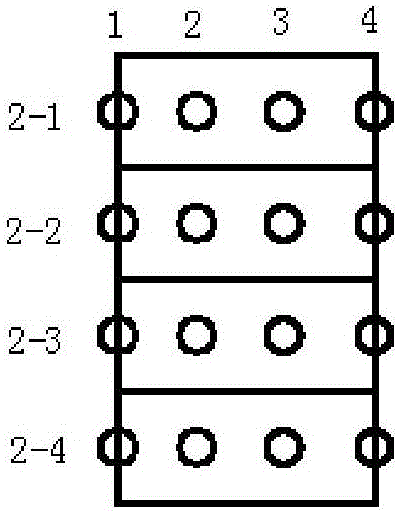

InactiveCN102896579AImprove work efficiencyNot easy to wear and deformWork carriersOptical fiber connectorTungsten

The invention discloses a wear-resistant clamp for grinding optical fiber connector blanks. The clamp is provided with a circular base (10), wherein the base (10) is provided with a polygonal clamp disk (20); each edge of the polygonal clamp disk (20) is provided with a clamp positioning gap (21) respectively; a group of unit clamps (30) is arranged in each clamp positioning gap respectively; each group of unit clamps (30) comprises a clamp body (31) made of tungsten steel and an adjustable pressure plate (32) which is detachably connected to the outer side of the clamp body (31); and each clamp body (31) is used for clamping a plurality of optical connector blanks to be ground through the adjustable pressure plates (32). Due to the adoption of the clamp, the wear resistance of the clamp is improved effectively, the service life of the clamp is prolonged, the quantity of single-batch grinding is large, the processing efficiency is high, and the product quality can be ensured fully.

Owner:SHENZHEN TYKOFIBER

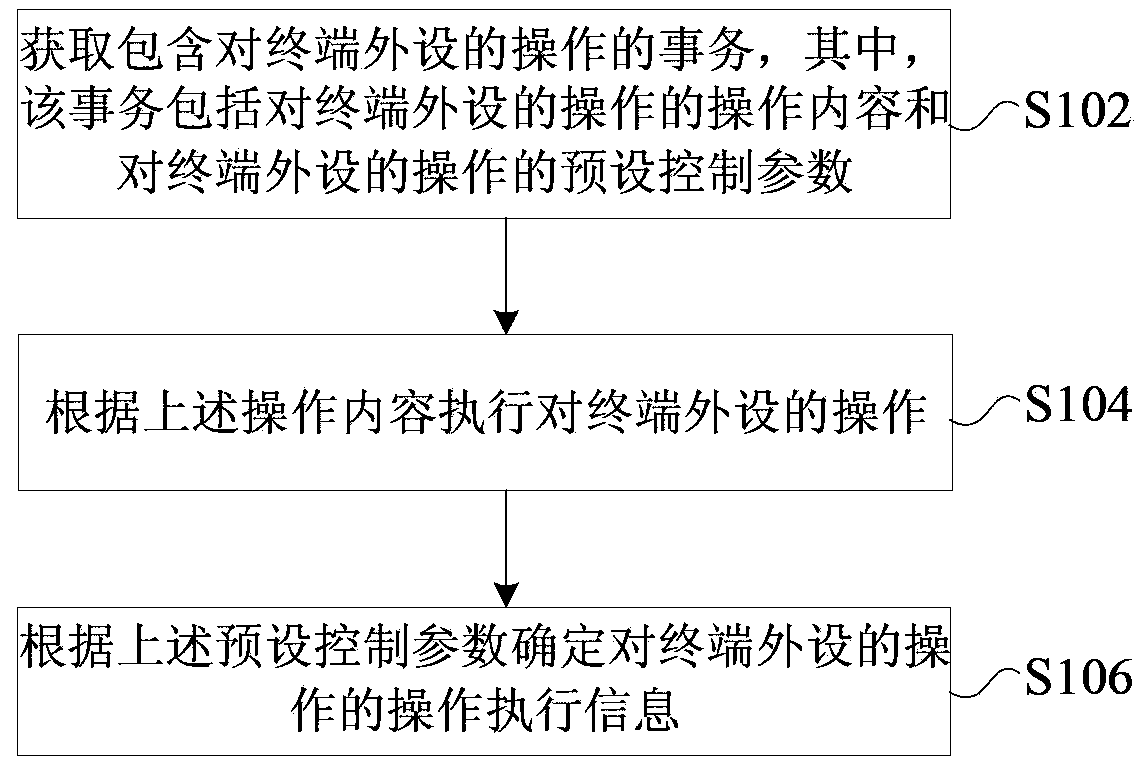

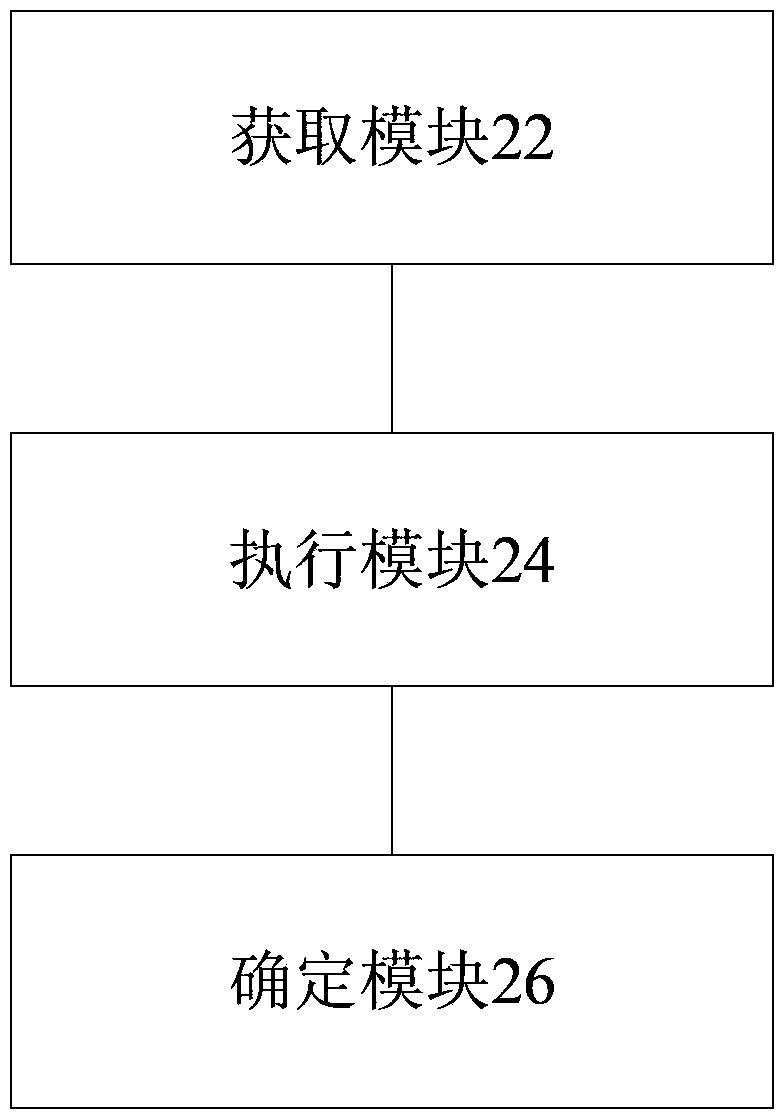

Method and device for processing operation on terminal peripheral

InactiveCN104113939ASolve processing efficiencyImprove execution efficiencyParticular environment based servicesNetwork topologiesComputer scienceControl parameters

The present invention provides a method and an apparatus for processing an operation on an endpoint peripheral. The method comprises: acquiring a task comprising the operation on the endpoint peripheral, the task comprising operation content of the operation on the endpoint peripheral and preset control parameters of the operation on the endpoint peripheral; executing the operation on the endpoint peripheral according to the operation content; determining operation execution information of the operation on the endpoint peripheral according to the preset control parameters. The present invention solves the problem in the prior art that the operation on the endpoint peripheral cannot be effectively controlled and processed, and greatly affects the processing efficiency of the system on the task, thereby processing the operation on the endpoint peripheral in time and effectively improving the task execution efficiency.

Owner:ZTE CORP

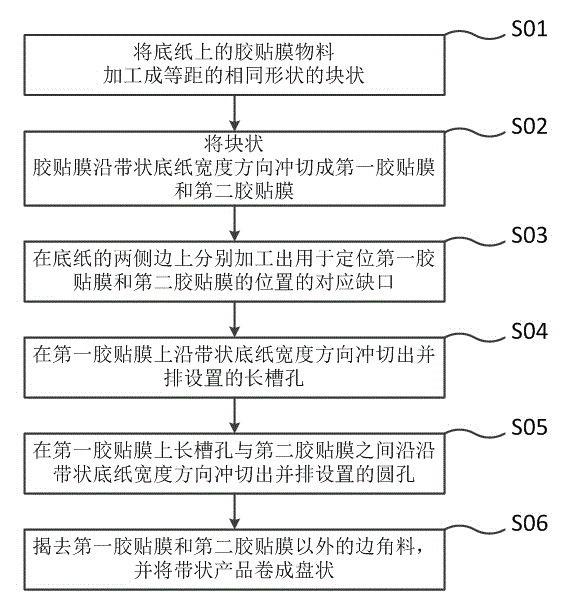

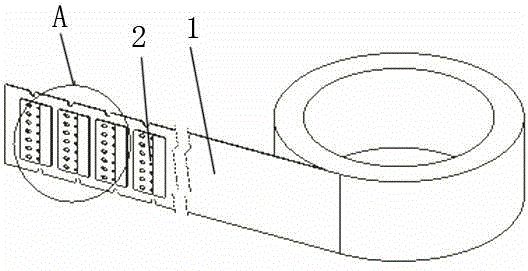

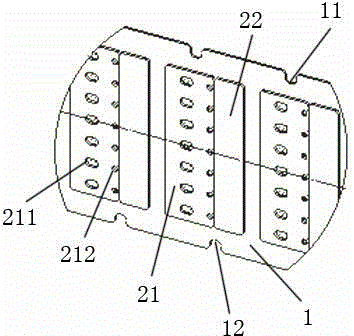

Gluing tape for SMT (surface mount technology) material strip connection and machining method thereof

ActiveCN104403595AThe connecting process is simpleImprove connection efficiencyFilm/foil adhesivesPaper sheetFilm material

The invention relates to the field of gluing equipment, particularly to a gluing tape for SMT (surface mount technology) material strip connection and a machining method thereof. The method comprises steps as follows: the gluing tape comprises a gluing film material and strip-shaped base paper, and the gluing film material on the base paper is machined into block-shaped gluing films in the same shape at equal intervals; each block-shaped gluing film is die-cut into a first gluing film and a second gluing film in the width direction of the strip-shaped base paper, and each first gluing film is larger than each second gluing film; corresponding gaps for positioning the first gluing films and the second gluing films are machined in two side edges of the base paper respectively; slotted holes arranged side by side are die-cut in the first gluing films in the width direction of the strip-shaped base paper. With the adoption of the gluing tape and the machining method, large and small gluing films can be accurately identified no matter whether manual material strip connection or mechanical material strip connection is adopted, the material strip connection is finished smoothly, the connection process is simple, the connection efficiency is high, the connection quality is high, and the problem that the machining efficiency of production lines is affected by existing connection methods can be solved.

Owner:SHENZHEN BORWIN PRECISION MACHINERY

Workbench with gluing device

ActiveCN105881974AThere is no problem of stacking and collapsingEvenly distributedEnvelopes/bags making machineryEngineeringCantilever

The invention discloses a workbench with a gluing device. The workbench comprises a base and a transverse box arranged on the base, the base is provided with a conveying platform which comprises a belt transmission mechanism and a motor connected with the belt transmission mechanism, the transverse box is internally provided with a glue containing cavity, the top of the transverse box is provided with a feed opening communicated with the glue containing cavity, the bottom of the glue containing cavity is provided with a glue feeding plate, multiple horizontally arranged drip holes are formed in the glue feeding plate, a cantilever lever is arranged in the transverse box, a sealing plug capable of sealing the feed opening is hinged to one end of the cantilever lever, a support rod is hinged to the other end of the cantilever lever, the support rod is connected in a sliding chute installed on the base in a sliding mode, a rolling roller is installed at the free end of the support rod and located over the conveying platform, a thrust cylinder is connected to the support rod, a controller is electrically connected to the thrust cylinder, and the controller is in signal connection with the motor. The workbench with the gluing device aims at solving the problems that due to the fact that existing glued profiles are pressed to be flat through weights, stacked materials collapse, and the processing progress and efficiency are affected.

Owner:HONG CONFUSED CHONGQING MACHINERY MFG CO LTD

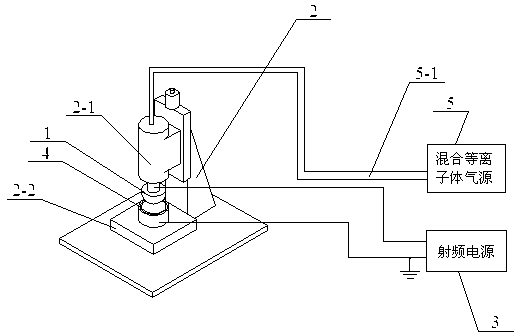

Device for processing rotary part by forming electrode air plasma

InactiveCN103236391ASolve processing efficiencySolve the processing qualityElectric discharge tubesPlasma welding apparatusMachined surfaceEngineering

The invention relates to a device for processing a rotary part by forming electrode air plasma, and belongs to the technical field of the processing of a silicon carbide or melted quartz type silicon-based material rotary part by plasma, which aims at solving the problems existing in the processing efficiency and quality of the high-precision rotary part. The upper end surface of a rotary forming electrode is connected with a rotary shaft in an insulating way, and the center of the rotary forming electrode is provided with an air outlet hole. When the inner surface is processed, the diameter of the working surface of the rotary forming electrode is 5 to 15mm smaller than the diameter of the inner surface of a to-be-processed part. When the outer surface is processed, the diameter of the working surface of the rotary forming electrode is 5 to 15mm larger than the diameter of the outer surface of the to-be-processed part. The rotary forming electrode is arranged near the to-be-processed surface of the to-be-processed part, and a certain discharging gap is maintained between the rotary forming electrode and the to-be-processed part. The device has the advantages that the simple and reasonable structure is adopted, and the air plasma processing method is utilized, so the removal of full-surface reflection is realized; and meanwhile, the problems existing in the processing efficiency and quality of the high-precision rotary part are solved.

Owner:HARBIN INST OF TECH

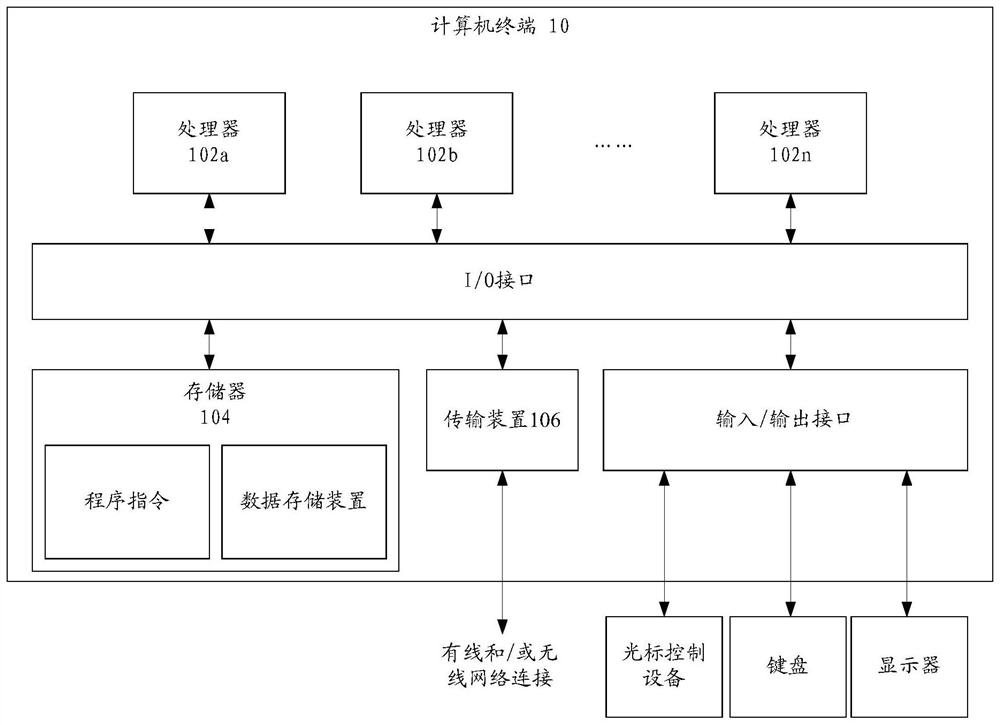

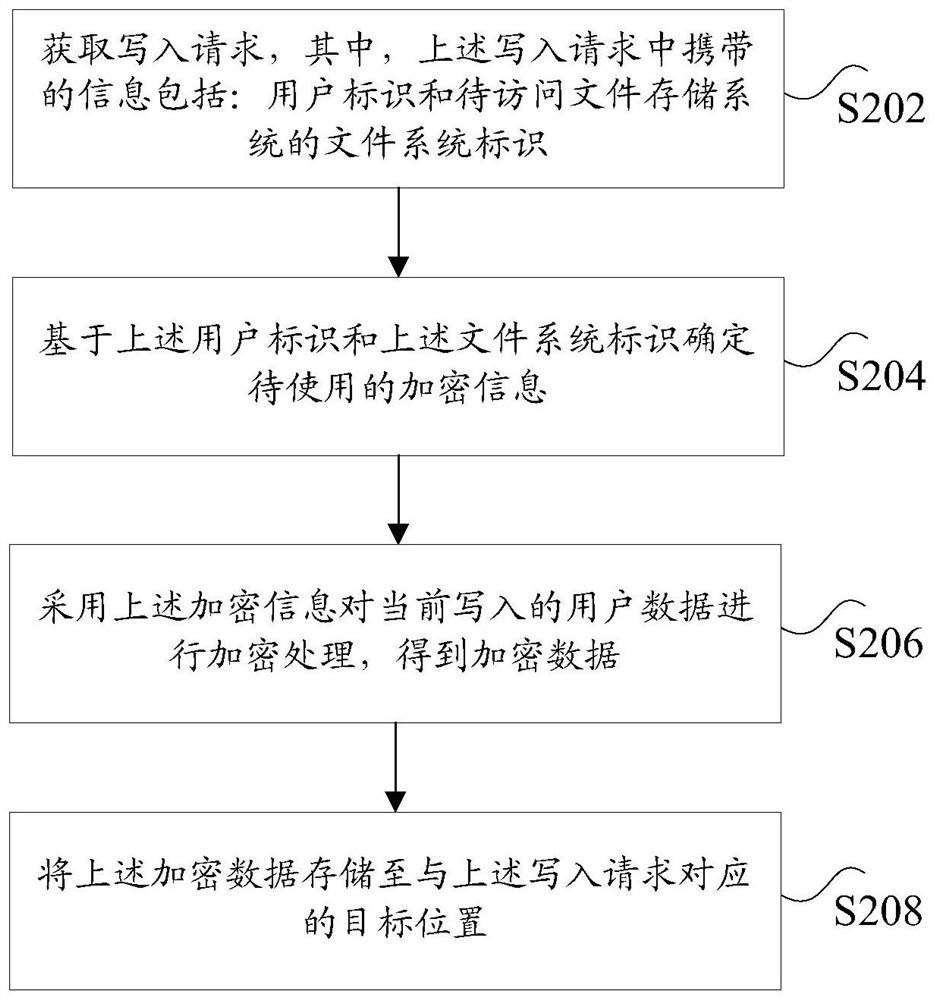

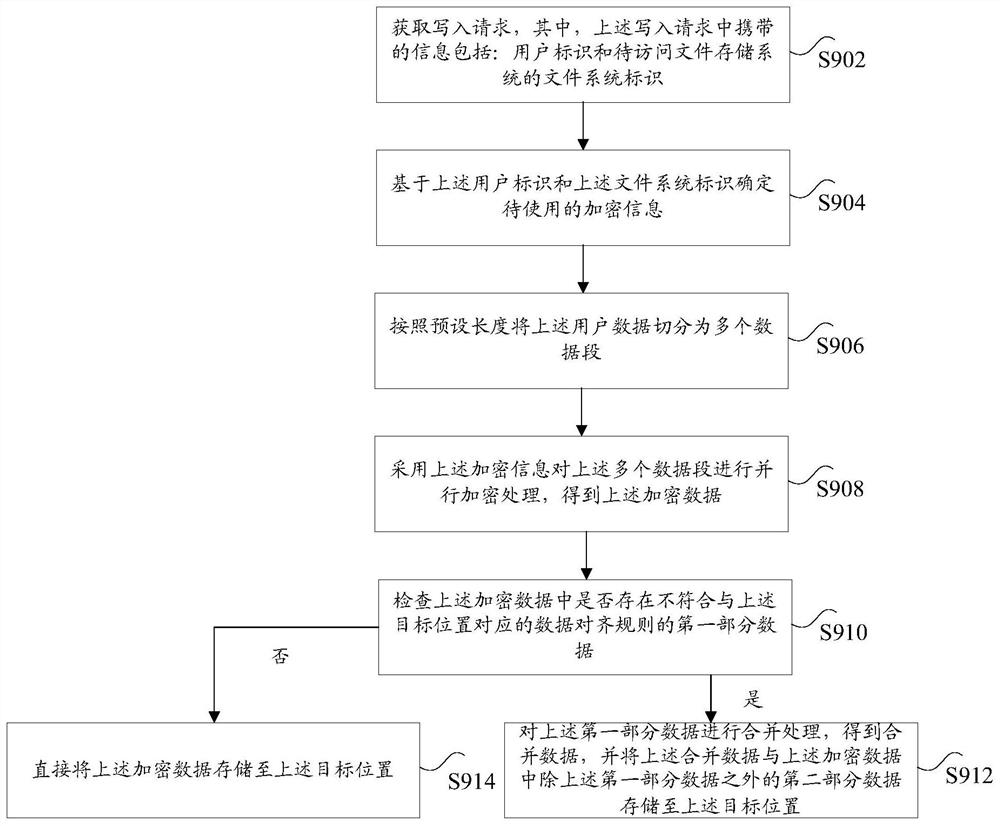

File data processing method and device

PendingCN113382029AImprove data securityImprove data processing efficiencyDigital data information retrievalDigital data protectionFile systemUser identifier

The invention discloses a file data processing method and device. The method is applied to a cloud file storage system, each file storage system adopts different encryption modes, and the method comprises the steps of acquiring a write-in request, wherein information carried in the write-in request comprises a user identifier and a file system identifier of a to-be-accessed file storage system; determining encrypted information to be used based on the user identifier and the file system identifier; encrypting the currently written user data by adopting the encrypted information to obtain encrypted data; and storing the encrypted data to a target position corresponding to the write-in request. According to the file data processing method and device, the technical problem that in an existing file data processing mode, the processing efficiency and safety are low when file data are encrypted is solved.

Owner:ALIBABA GRP HLDG LTD

Sander for wood board processing

InactiveCN112476101ASolve processing efficiencyGrinding feedersGrinding work supportsSanderDrive wheel

The invention discloses a sander for wood board processing. The sander comprises a placing frame and a frame plate, a lifting mechanism is arranged in the middle of the inner side of the placing frame, a screw rod is driven by a second motor to rotate, a threaded sleeve drives a cross-shaped rotating frame to slide in a sliding block, the cross-shaped rotating frame is folded, and therefore the position of a placing plate is changed; a second roller is arranged at the left side of the placing plate, so that a wood board can slide on the top of the second roller, and the problems that wood boards with different thicknesses are inconvenient to grind by a sander during wood board processing, and the processing efficiency of the wood boards is influenced are solved; and a leading-in mechanismis arranged at the top of the rear side of the placing frame, a driving wheel drives a driven wheel to rotate through a transmission belt through starting of a third motor, so that a rolling wheel rotates to roll the wood board into a cover body, the wood board is extruded and then moves to the bottom of a grinding roller through rotation of the rolling wheel and a first roller, and the problems that the wood board cannot be conveniently pushed to the position below the grinding roller for grinding, after the wood board is manually pushed in, the wood board is prone to vibration, and potentialsafety hazards exist for operators are solved.

Owner:宁夏泰昌木业有限公司

Efficient garbage combustion furnace enabling ash to be taken out conveniently

InactiveCN108019756ASolve processing efficiencyPrevent fallingIncinerator apparatusCombustion chamberEngineering

The invention discloses an efficient garbage combustion furnace enabling ash to be taken out conveniently. The efficient garbage combustion furnace comprises a combustion chamber. A feeding opening isformed in the top of the combustion chamber. The left side of the inner wall of the combustion chamber is movably connected with a tray. The left side of the combustion chamber is in bolted connection with an air blowing device. The position, located at the top of the air blowing device, of the left side of the combustion chamber is in bolted connection with a fire spray device. The left side ofthe air blowing device is in bolted connection with a control cabinet. The bottom of the combustion chamber is fixedly connected with an air cylinder. The top of the air cylinder penetrates the combustion chamber and is in contact with the tray. An ash discharging plate is fixedly connected to the bottom of the right side of the combustion chamber. A supporting rod is welded to the position, located on the left side of the ash discharging plate, of the bottom of the inner wall of the combustion chamber. According to the efficient garbage combustion furnace enabling the ash to be taken out conveniently, through cooperation of the tray, the air blowing device, the fire spray device, the control cabinet, the air cylinder, the ash discharging plate, the supporting rod, an ash discharging pipeand an air blowing pipe, the problems that in an existing garbage combustion furnace, ash cannot be conveniently taken out, and the garbage disposal efficiency is influenced are solved.

Owner:王腾蛟

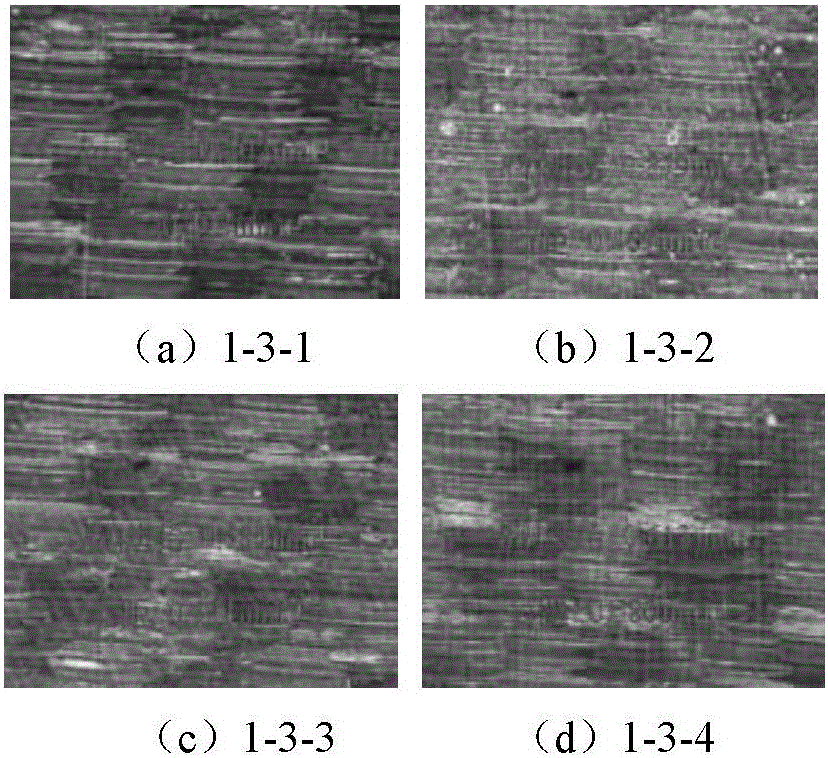

Technology design method for milling curve surface of cold-working-die steel spliced piece at high speed

ActiveCN105127495ASolve the conflict between processing efficiency and processing surface qualitySolve processing efficiencyMilling equipment detailsEngineeringHardness

A technology design method for milling a curve surface of a cold-working-die steel spliced piece at a high speed is disclosed, and relates to a high-speed milling method for a piece formed through splicing of two different kinds of materials. The method solves the problem that the high-speed milling processing efficiency of a different-material-spliced die curve surface conflicts with the processed surface quality. The method comprises: first step, establishing processed surface roughness experiment formulas of the two materials, so as to obtain a milling-cutter rotating speed design scheme of a high-speed milling experiment for the two-material-spliced piece; second step, determining the highest rotating speed of the high-speed milling experiment of the two-material-spliced curve-surface piece; third step, performing the high-speed milling experiment on the curve-surface spliced piece consisting of the two materials with different hardness; and forth step, providing a technological design scheme of the curve surface of the two-material-spliced piece subjected to high-speed milling. The method effectively solves the problem that the high-speed milling processing efficiency of a different-material-spliced die curve surface conflicts with the processed surface quality, and provides basis for making the high-speed milling technology enforcement scheme for the kind of die.

Owner:HARBIN UNIV OF SCI & TECH

Cold rolling mill with leveling mechanism

PendingCN113492152AAvoid unevennessAvoid processing cost lossShaping toolsMetal rolling arrangementsSteel platesStructural engineering

The invention discloses a cold rolling mill with a leveling mechanism, and particularly relates to the field of cold rolling mills. The cold rolling mill comprises a lower rack and rollers, roller columns are fixedly installed at the top of the lower rack, roller shafts are movably installed on the surfaces of the roller columns, an upper rack is fixedly installed at the top of the roller columns, an upper leveling box is fixedly installed on the side face of the upper rack, a first leveling column is fixedly mounted at the bottom of the upper leveling box, and an upper leveling plate is fixedly mounted at the bottom of the first leveling column. By arranging a leveling device, due to the fact that a steel plate is cylindrical during rolling, the steel plate is extruded unevenly during extrusion, the steel plate is produced and machined incompletely, and consequently the machining cost loss is caused, the leveling device can automatically level the steel plate after the steel plate is rolled, so that unevenness is prevented, the problem of the machining cost loss is avoided, the problem of low machining efficiency is solved, the machining efficiency is improved, and meanwhile, the evenness of the steel plate is improved.

Owner:无锡市冶龙机械有限公司

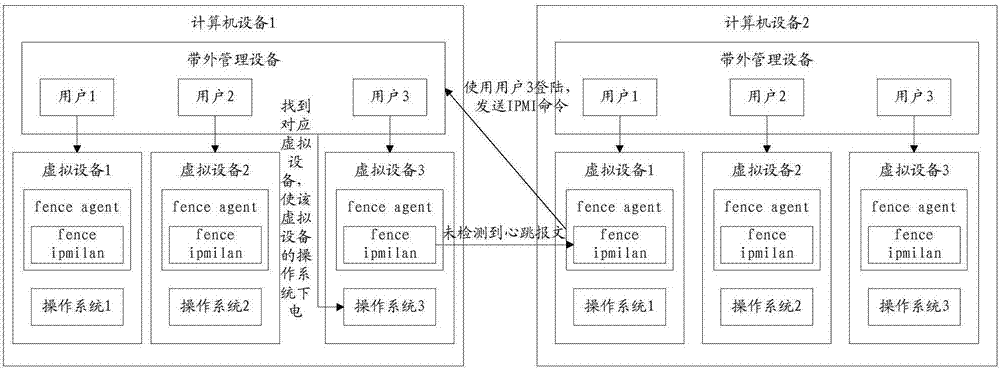

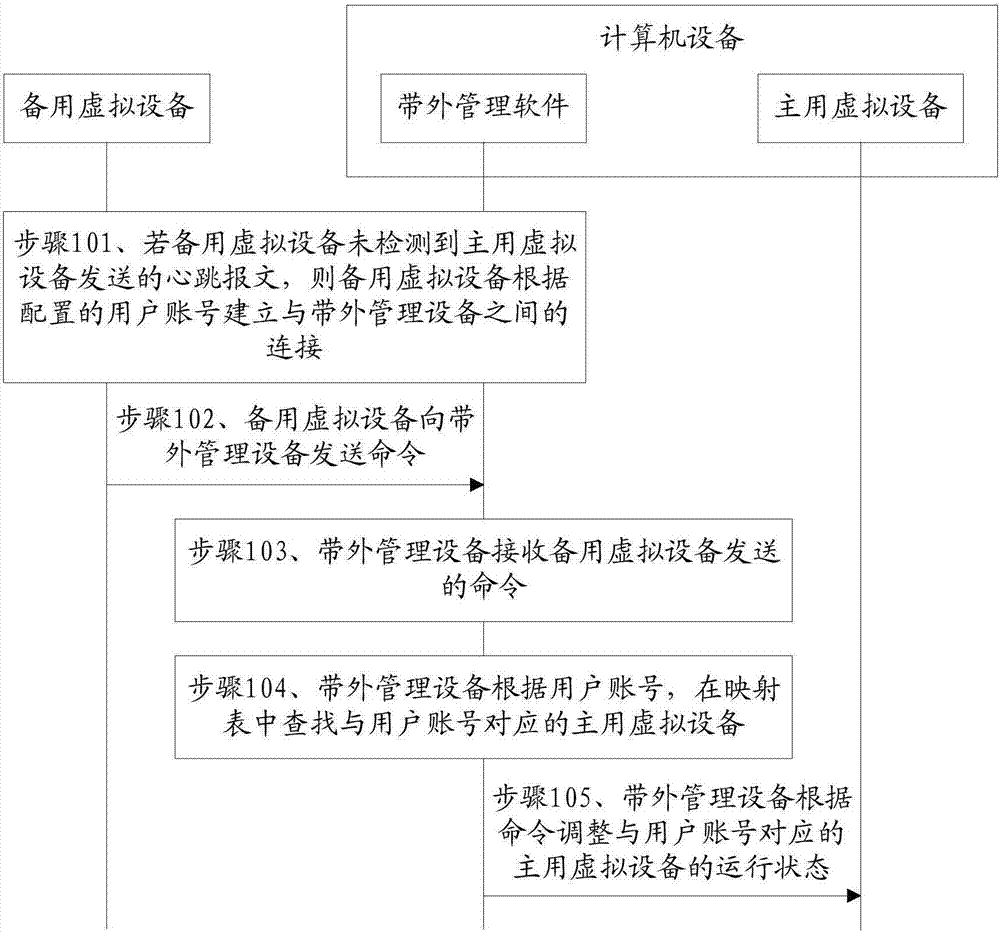

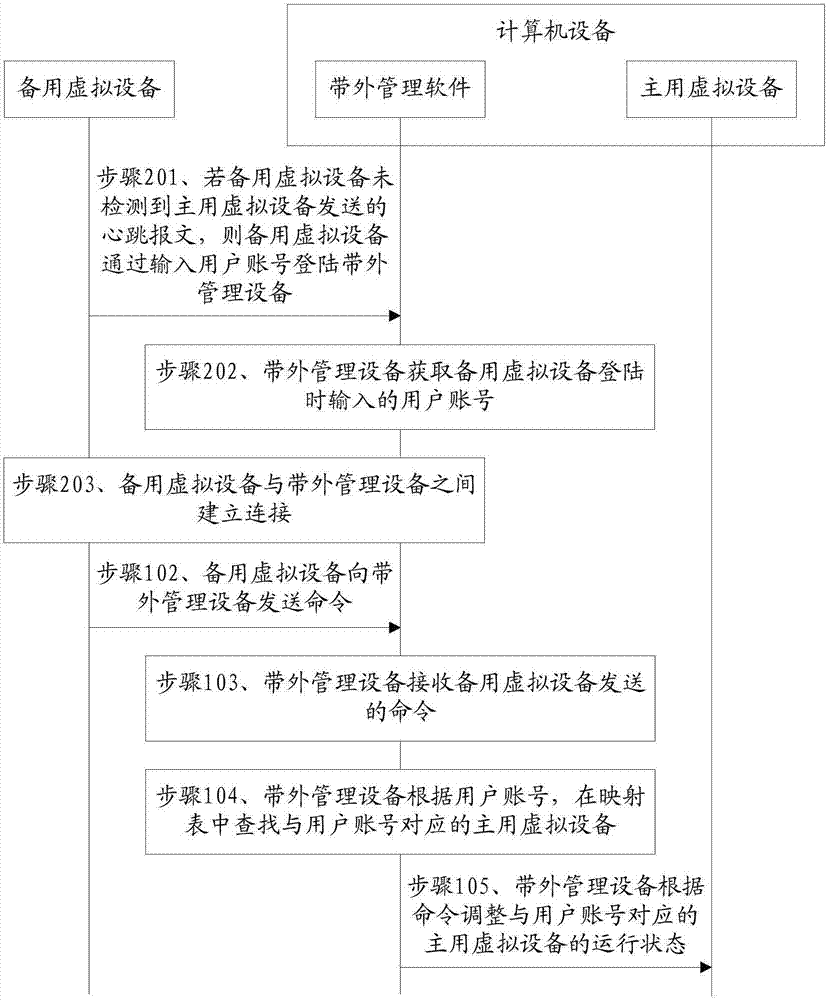

Virtual equipment management method, out-of-band management equipment and standby virtual equipment

ActiveCN107423113ASolve processing efficiencySoftware simulation/interpretation/emulationRedundant operation error correctionVirtual deviceComputer science

Embodiments of the invention disclose a virtual equipment management method, out-of-band management equipment and standby virtual equipment, relates to the technical field of computer equipment, and aims at solving the problems that the processing load of the out-of-band management equipment is increased and the processing efficiency of the out-of-band management equipment is reduced due to the deployment of self-defined software. The method comprises the following steps of: if the standby virtual equipment does not detects a heartbeat message sent by main virtual equipment, establishing connection with the out-of-band management equipment by the standby virtual equipment according to a configured user account number and sending a command to the out-of-band management equipment; and receiving the command sent by the standby virtual equipment by the out-of-band management equipment, searching main virtual equipment corresponding to the user account number in a mapping table according to the user account number and adjusting the operation state of the main virtual equipment corresponding to the user account number according to the command. The method is suitable for virtual equipment management.

Owner:XFUSION DIGITAL TECH CO LTD

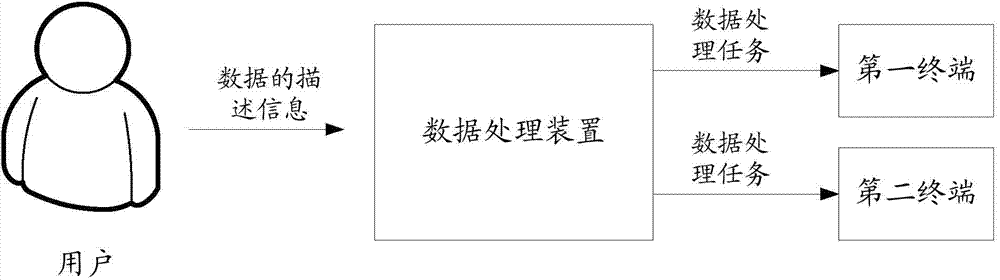

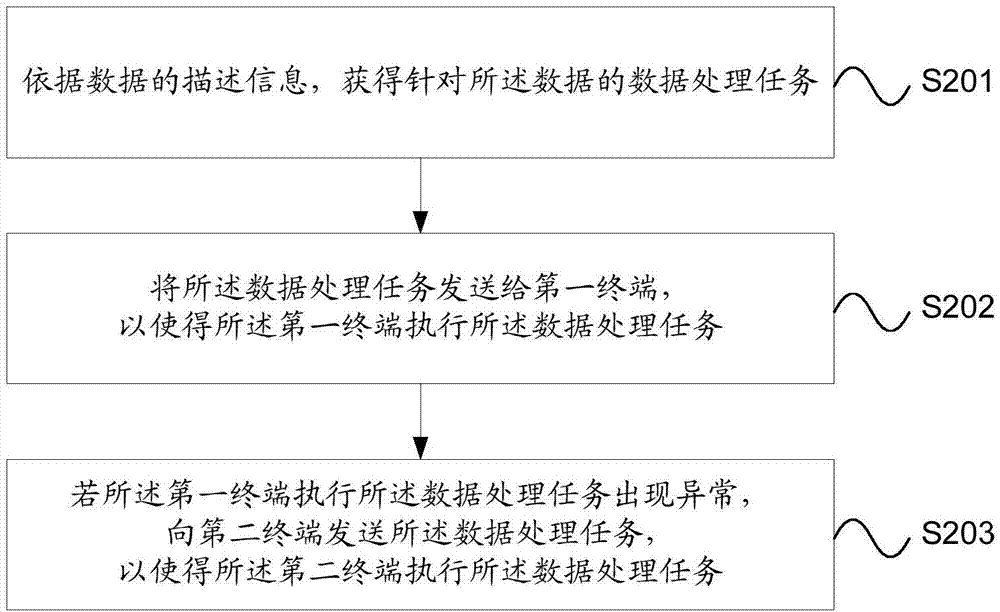

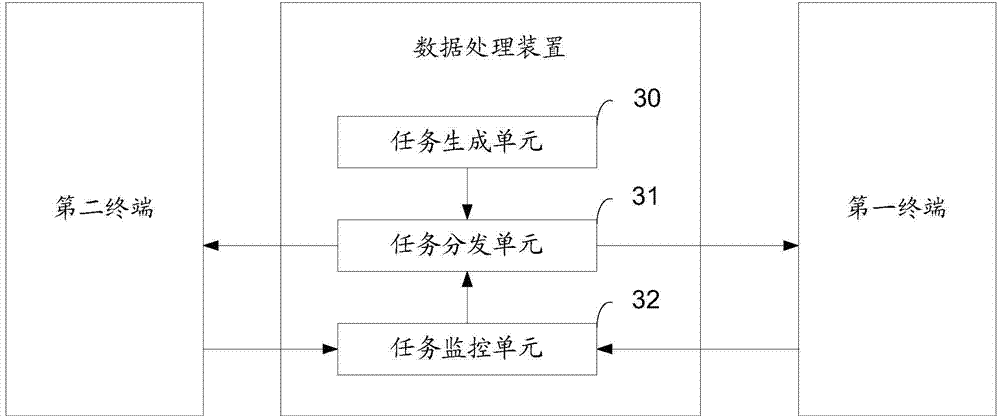

Data processing method and device

ActiveCN104281491AImprove processing efficiencyImprove reliabilityMultiprogramming arrangementsData processing systemData processing

An embodiment of the invention provides a data processing method and device. The data processing method includes that a data processing task aiming at data is acquired according to description information of the data; the data processing task is sent to a first terminal to enable the same to execute the data processing task; if an abnormality appears when the first terminal executes the data processing task, the data processing task is sent to a second terminal to enable the same to execute the data processing task. Consequently, by the technical scheme, data processing efficiency can be improved.

Owner:深圳太乐文化科技有限公司

Processing method of fire sprinkler cooling device

InactiveCN102294578ASolve processing efficiencySolve the processing qualityThread cutting toolsFire sprinklerEngineering

The invention proposes a processing method for a fire-fighting spray cooling device. Processing steps: 1. Weld flanges at both ends of the straight pipe; 2. Put the straight pipe after welding the flange on the pipe bender and bend it according to the design arc to make an arc bend; 3. On the arc bend Drill holes according to the angle, spacing and aperture required by the design; 4. Use the self-heating rotary extrusion die to perform rotary extrusion and stretching on the drilled holes to make the nozzle interface; 5. The nozzle after extrusion and stretching Sprinkler interface threads are processed in the interface to make nozzle interfaces with connection threads. In this method, the flange is welded on the straight pipe first, and then the pipe is bent, and the nozzle interface is formed by hot extrusion and stretching on the curved pipe. It has the advantages of less processing links, easy to grasp the processing position, reducing the consumption of working hours, reducing labor intensity, and ensuring the processing quality. It is suitable for production and processing of fire sprinkler cooling devices and other fire fighting equipment.

Owner:HULUDAO GUOLI IND FIRE ENVIRONMENTAL EQUIP MFG

Grinding machine tool for metal machining

PendingCN113199347AHigh selectivityIncrease efficiencyGrinding drivesGrinding machinesEngineeringMachine tool

The invention discloses a grinding machine tool for metal machining. The grinding machine tool comprises a machine tool machining table, wherein an electric cylinder is fixedly connected to the back face of the top end of the machine tool machining table; the top end of the electric cylinder is fixedly connected to the middle of the bottom end of a square connecting plate; an electric rotating machine is fixedly connected to one side of the top end of the square connecting plate; and one end of the output end of the electric rotating machine is fixedly connected to one end of a rotating shaft. The electric cylinder is started, so that a first grinding wheel and a second grinding wheel on an electric grinding machine are lifted, then the electric rotating machine is started, the first grinding wheel and the second grinding wheel on the electric grinding machine can rotate around the rotating shaft, finally, the electric grinding machine is started, and the first grinding wheel or the second grinding wheel can be used for comprehensively machining the surface of metal; and the problems that the grinding wheel of the grinding machine is fixed to the grinding machine tool, the grinding angle is difficult to adjust according to the structure of the metal surface, and the metal machining efficiency of machining personnel is affected are solved.

Owner:浏阳市银丰机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com