Automatic crusher for coal mine with de-doping function

A crusher and functional technology, which is applied in the field of automatic crushers for coal mines, can solve problems that affect the processing efficiency of coal mines and cannot automatically remove impurities in coal mines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

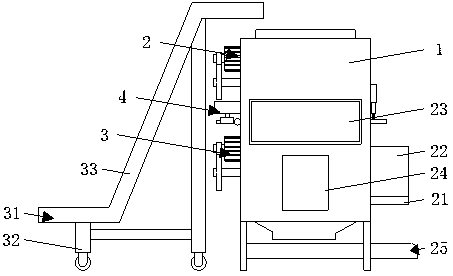

[0027] An automatic crusher for coal mines with the function of removing impurities, comprising a crusher body 1, a first crushing device 2 is arranged inside the crusher body 1, a second crushing device 3 is arranged inside the crusher body 1, and the crusher body 1 and between the first crushing device 2 and the second crushing device 3 is provided with an impurity removal device 4 .

[0028] In this technical solution, by setting the first crushing device 2, the coal mine can be initially crushed, and the coal mine and impurities after the preliminary crushing fall onto the impurity removal device 4. Since the uncrushable impurities are larger than the crushed coal mine, through The impurity removal device 4 screens and removes impurities, and the coal mine after the impurity removal is finely crushed by the second crushing device 3 to obtain qualified coal mines. The cooperation solves the problem that the existing technology cannot automatically remove the impurities in t...

Embodiment 2

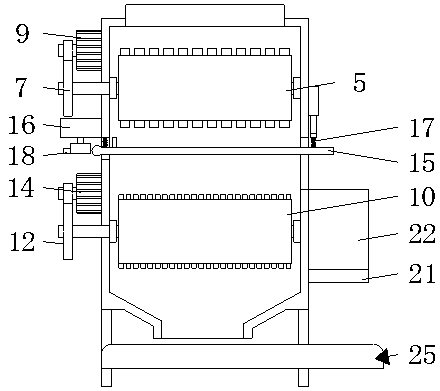

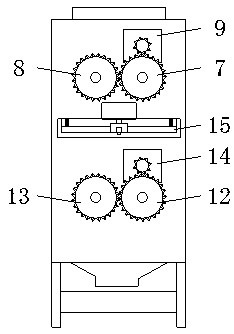

[0030] An automatic crusher for coal mines with the function of removing impurities, comprising a crusher body 1, a first crushing device 2 is arranged inside the crusher body 1, a second crushing device 3 is arranged inside the crusher body 1, and the crusher body 1 and between the first crushing device 2 and the second crushing device 3 is provided with an impurity removal device 4, the first crushing device 2 is composed of a first crushing roller 5, a second crushing roller 6, a first gear plate 7, a second The two gear discs 8 and the first motor 9 are composed, the first crushing roller 5 and the second crushing roller 6 are all rotatably connected to the inner wall of the crusher body 1, and the first crushing roller 5 and the second crushing roller 6 are located at the side of the feed inlet. At the bottom, the first motor 9 is installed on the side of the crusher body 1, the first crushing roller 5 is connected with the first gear plate 7 through the rotating shaft, th...

Embodiment 3

[0033]An automatic crusher for coal mines with the function of removing impurities, comprising a crusher body 1, a first crushing device 2 is arranged inside the crusher body 1, a second crushing device 3 is arranged inside the crusher body 1, and the crusher body 1 and between the first crushing device 2 and the second crushing device 3 is provided with an impurity removal device 4, the first crushing device 2 is composed of a first crushing roller 5, a second crushing roller 6, a first gear plate 7, a second The two gear discs 8 and the first motor 9 are composed, the first crushing roller 5 and the second crushing roller 6 are all rotatably connected to the inner wall of the crusher body 1, and the first crushing roller 5 and the second crushing roller 6 are located at the side of the feed inlet. At the bottom, the first motor 9 is installed on the side of the crusher body 1, the first crushing roller 5 is connected with the first gear plate 7 through the rotating shaft, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com