Processing method of fire sprinkler cooling device

A technology of spray cooling and processing method, which is applied in tangent devices, metal processing equipment, manufacturing tools, etc., to reduce labor intensity, ensure processing quality, and reduce processing links.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Shown according to accompanying drawing, processing method step of the present invention is as follows:

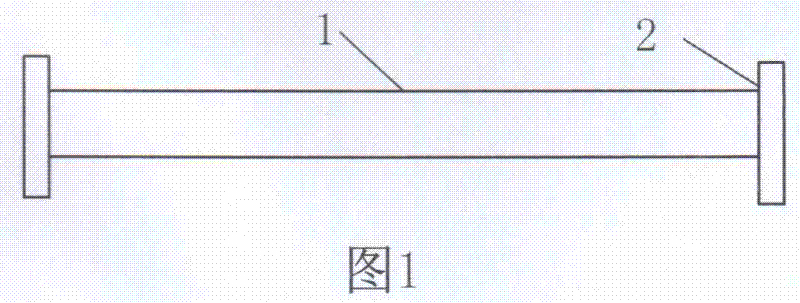

[0020] 1. Weld the flange 2 at both ends of the straight pipe 1;

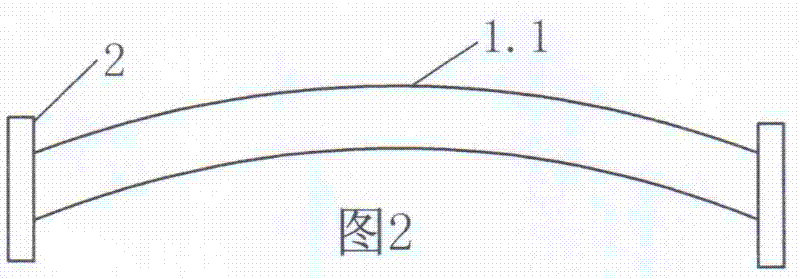

[0021] 2. Place the straight pipe after welding the flange on the pipe bender and bend it according to the design arc to make a curved pipe 1.1;

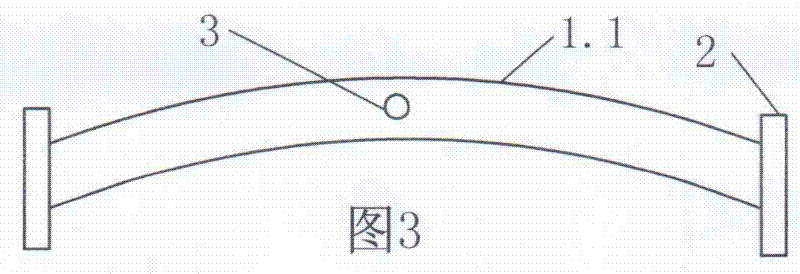

[0022] 3. Drill holes on the curved pipe according to the angle, spacing and aperture required by the design 3;

[0023] 4. Use the self-heating rotary extrusion die head 5 to carry out rotary extrusion and stretching on the drilled hole to make the nozzle interface 4;

[0024] 5. Process the nozzle interface thread 4.0 in the nozzle interface after extrusion and stretching to make the nozzle interface with connecting thread.

[0025] Self-heating rotary extrusion die head tool structure: the die head 5 is connected to the rotary power device 6 . Through the high-speed rotation of the die head, frictional heat is generated, and the pipe wall is rotated,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com