Patents

Literature

60results about How to "Reduce man-hour consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for filling and mining after ore caving

ActiveCN102587916AReduce impact damageImprove work efficiencyUnderground miningSurface miningSpelunkingMineral Sources

The invention discloses a method for filling and mining after ore caving, which includes the following steps: exploiting; mining quasi work; cutting work: including excavation of mine collection trench and patio cutting, cutting a patio at one end portion of a rock drilling chamber, cutting the patio by using a vertical deep hole ore falling stage chamber method, and enabling patio cutting to provide sufficient compensation space for actual mining; chamber extraction work: constructing a downward blasthole in the rock drilling chamber, filling and blasting, one-time blasting charging at the entire middle section height of the blasthole, and enabling blasting to adopt one-time lateral blasting and ore removal; filling and maintaining: closing all outlets communicated with a lower mine of the empty area, burying strainer pipes, leading in filling pipelines from the upper portion of the chamber, and filling and maintaining the chamber; and pillar recovery: recovering pillars after filling and maintaining the chamber, and the pillar recovery is the same as the chamber extraction work. The method for filling and mining after ore caving is high in recovery rate of mineral resources, small in blasting impact effect, low in cost and high in production efficiency.

Owner:金建工程设计有限公司

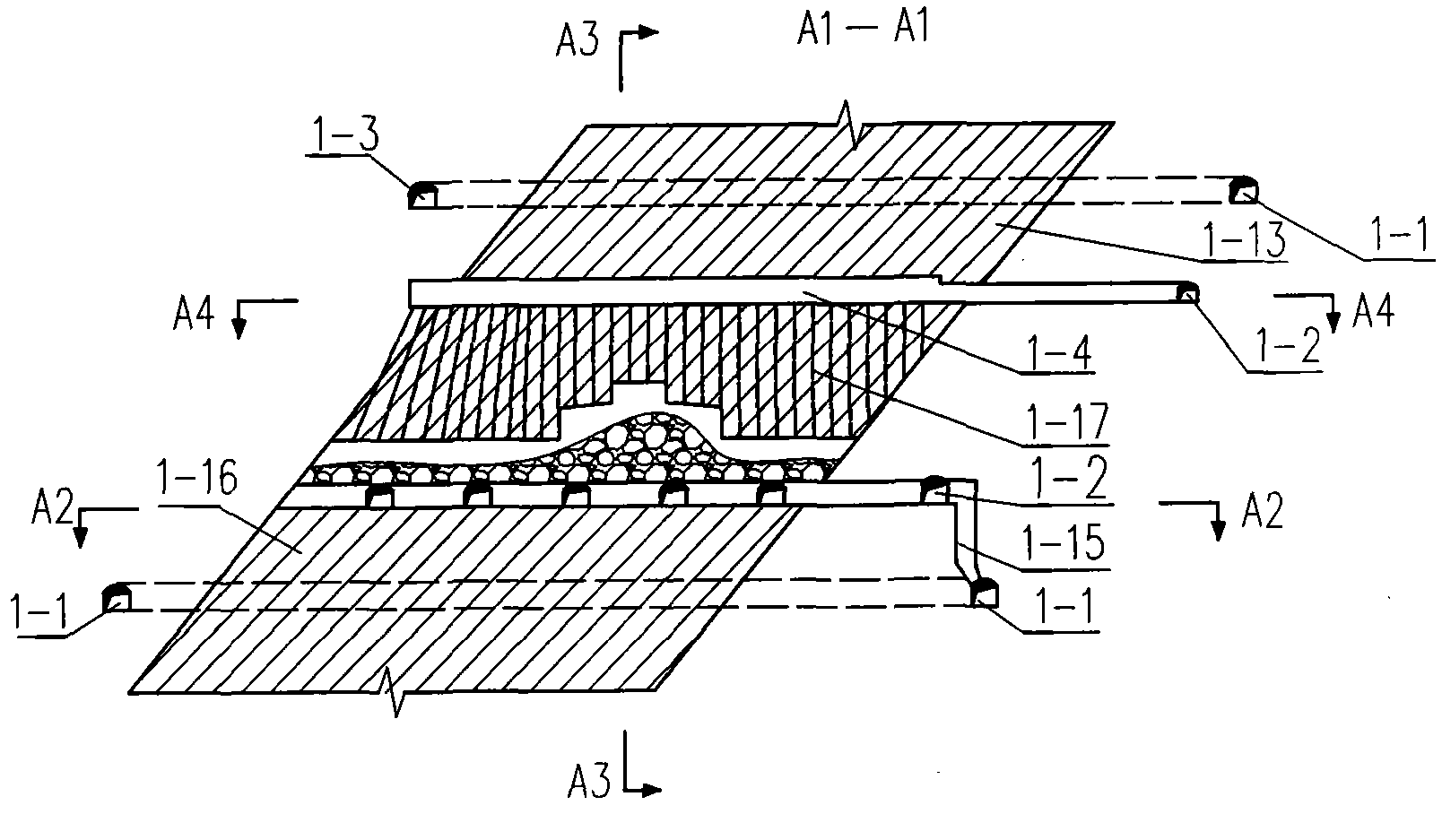

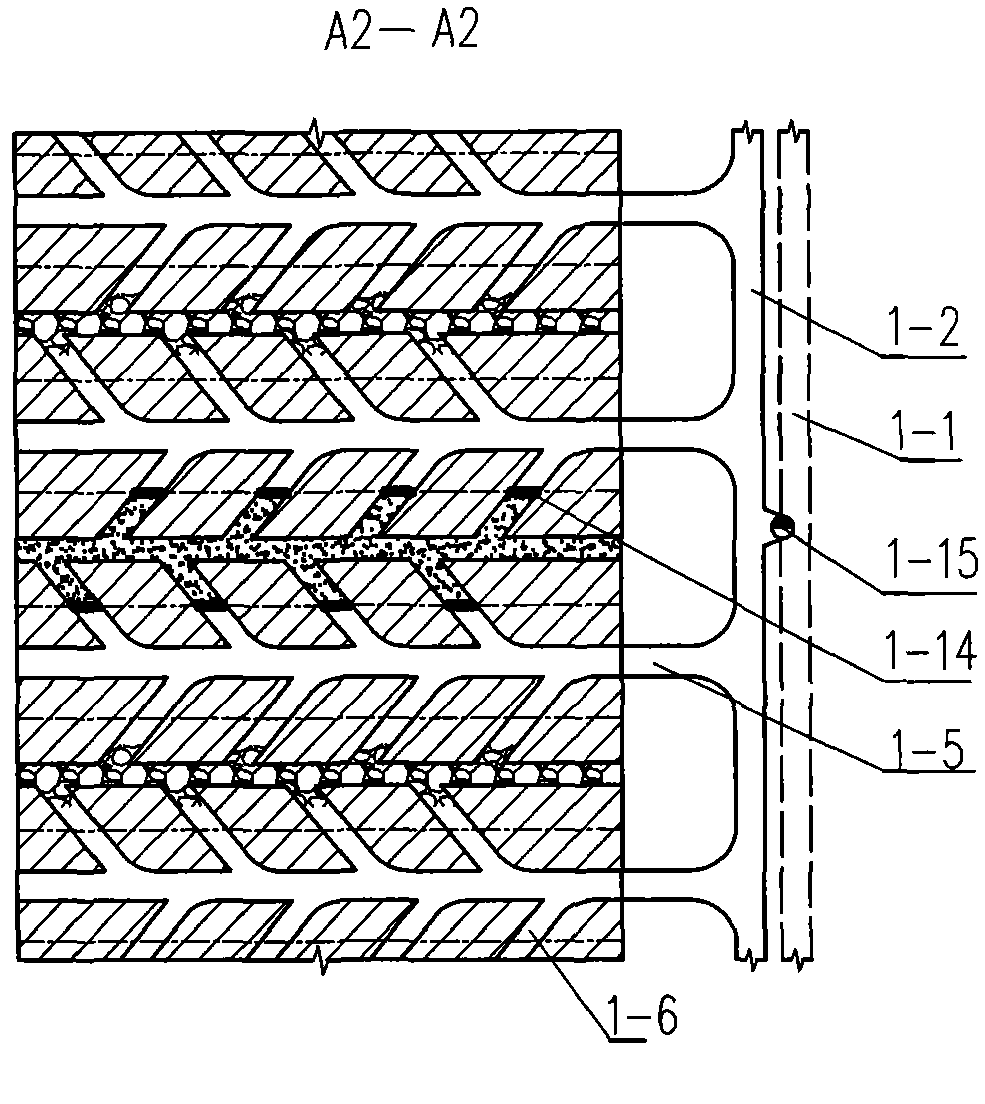

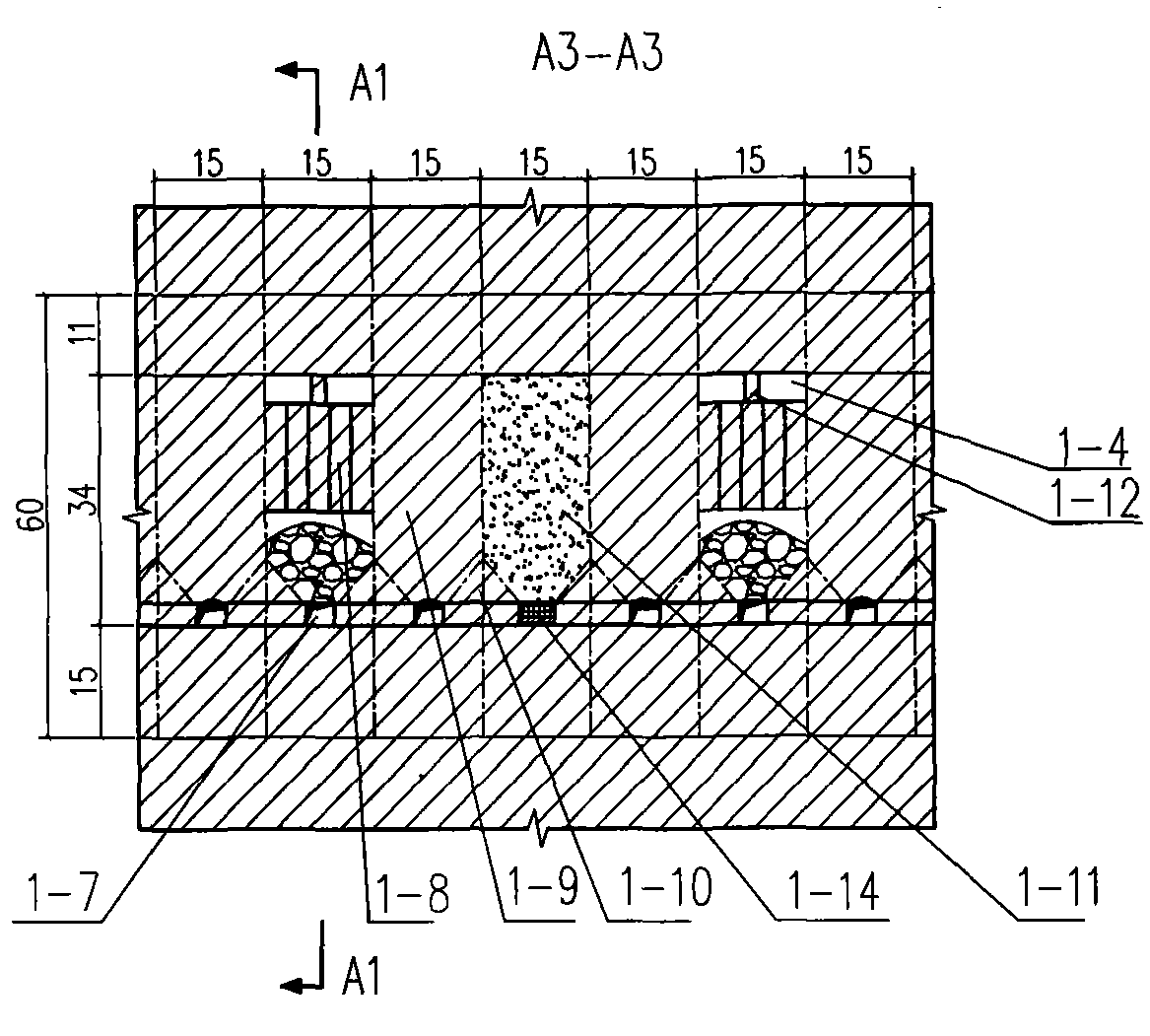

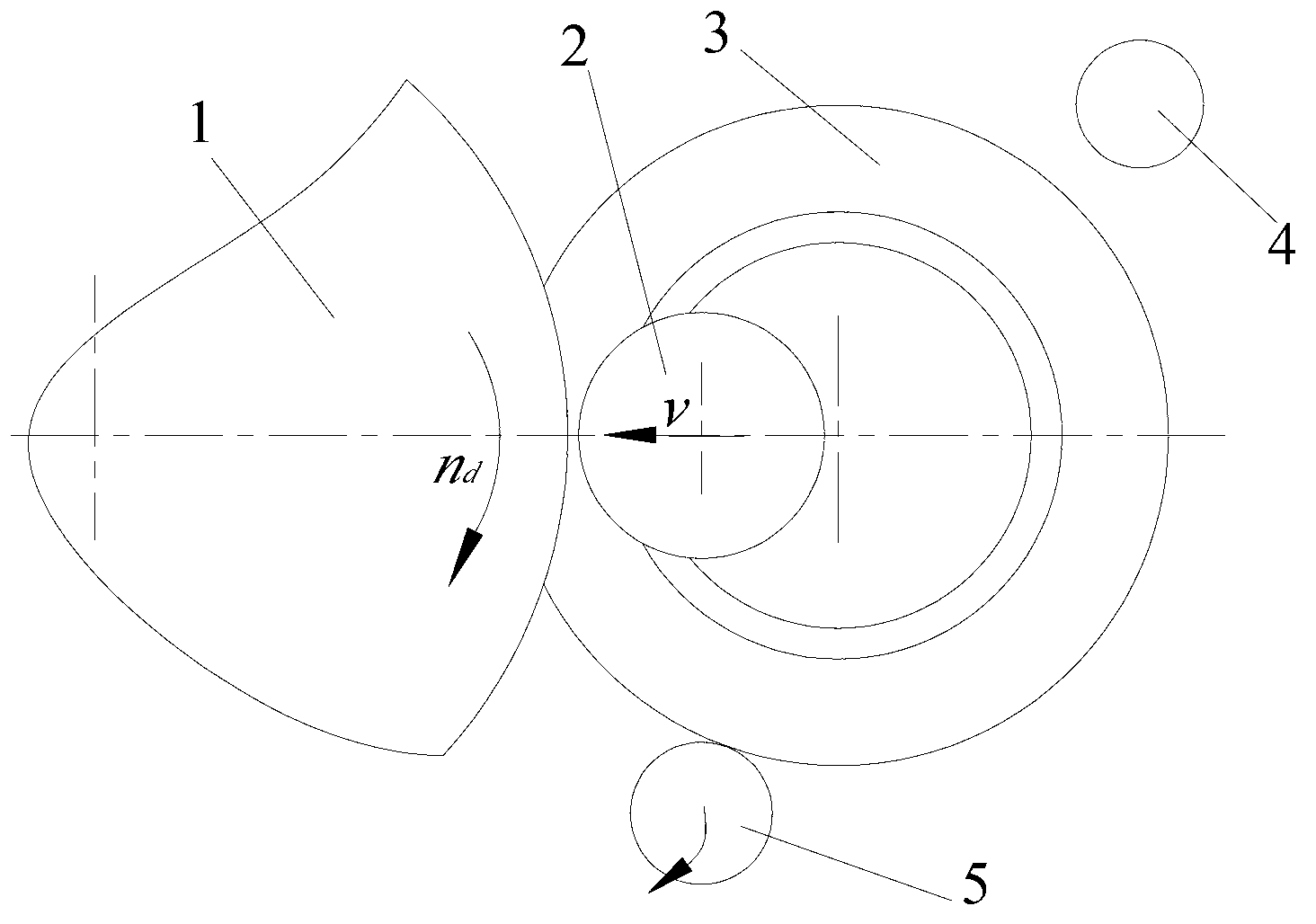

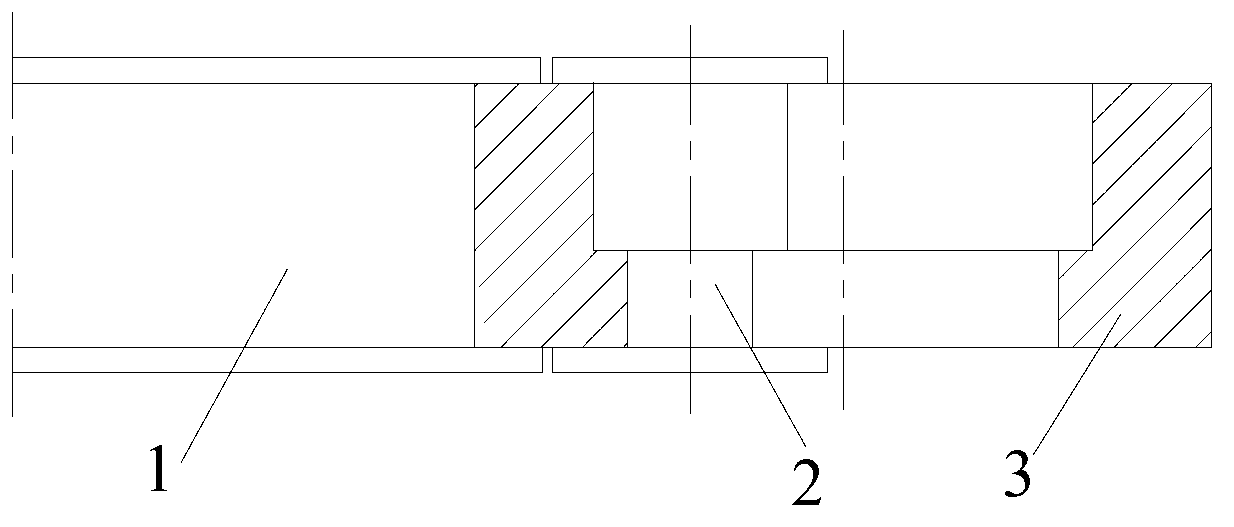

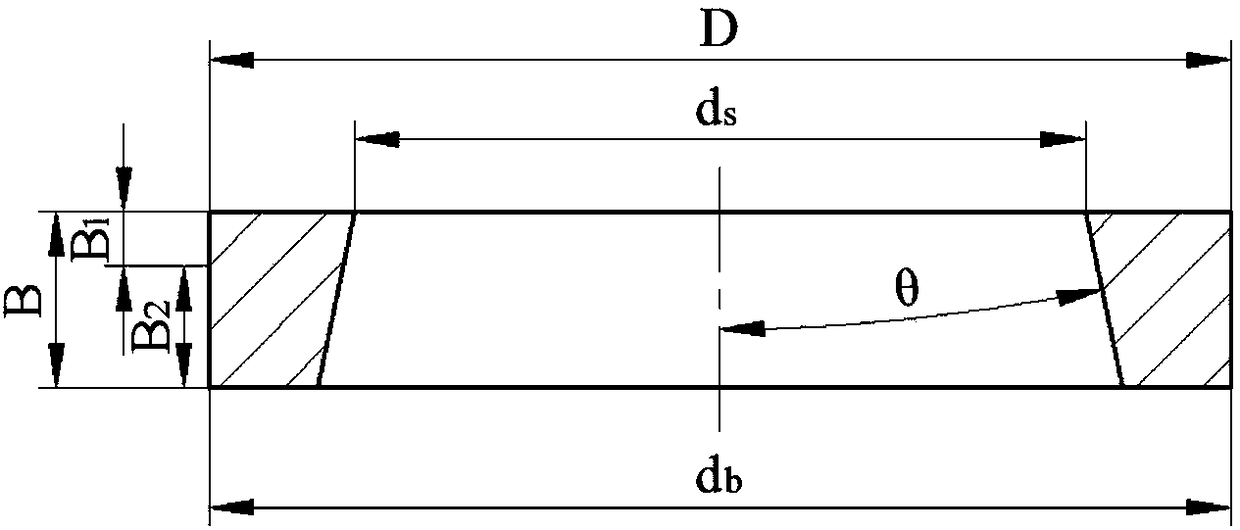

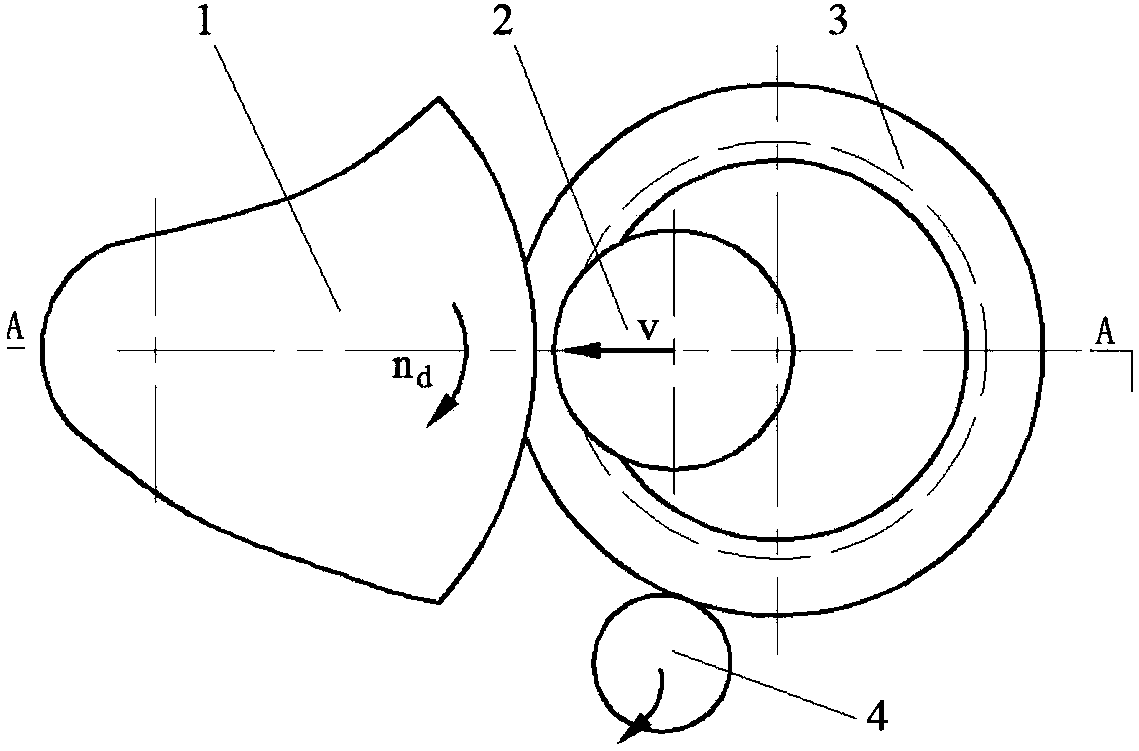

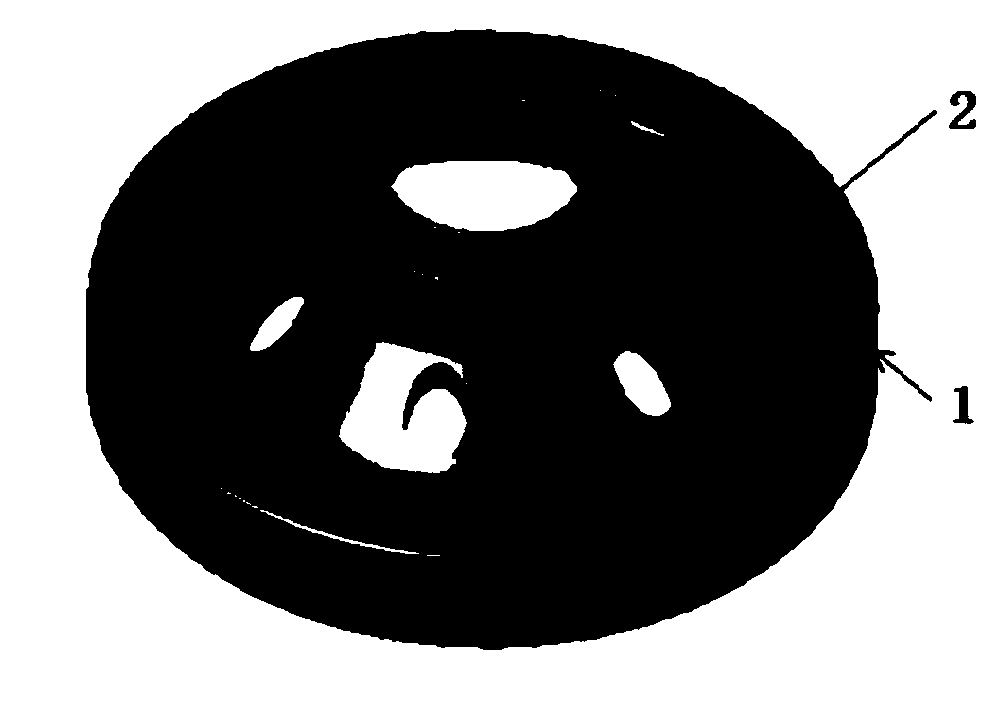

Cold rolling forming method for automotive hub bearing ring part with L-shaped cross section

ActiveCN103316926AImprove streamline distributionImprove distributionRoll mill control devicesMetal rolling arrangementsThree stageEngineering

The invention relates to a cold rolling forming method for an automotive hub bearing ring part with an L-shaped cross section. The cold rolling forming method for the automotive hub bearing ring part with the L-shaped cross section is characterized by comprising the following steps of (1) designing and producing a ring blank, namely confirming the ring blank shape and size according to a ring part size and a rolling rate, performing blanking, heating, upsetting, punching and punching the wed through bar materials and forming into a cold rolling ring blank; (2) designing hole types, namely confirming sizes of a driving roller and a spindle-shaped chamber according to the shape and the size of the ring part and designing working surface radial sizes of the driving roller and a spindle according to the ring blank size, cold rolling deformation conditions and device parameters; (3) performing cold rolling forming, namely arranging a machined driving roller and a machined spindle into a cold rolling ring machine, putting a machined ring blank into the cold rolling ring machine, reasonably distributing the spindle feed speed and the feed amount according to three stages such as high-speed rolling, medium speed rolling and low speed rolling to perform control and enabling the cold rolling process to be ended when the external diameter of the measured ring part achieves a preset value. The cold rolling forming method for the automotive hub bearing ring part with the L-shaped cross section has the advantages of being capable of enabling reasonable design and effective control of cold rolling forming technologies of the hub bearing ring part with the L-shaped cross section to be achieved, guaranteeing stable cold rolling forming, reducing rejection rates during cold rolling and being high in production efficiency, low in production cost and good in production quality.

Owner:WUHAN UNIV OF TECH

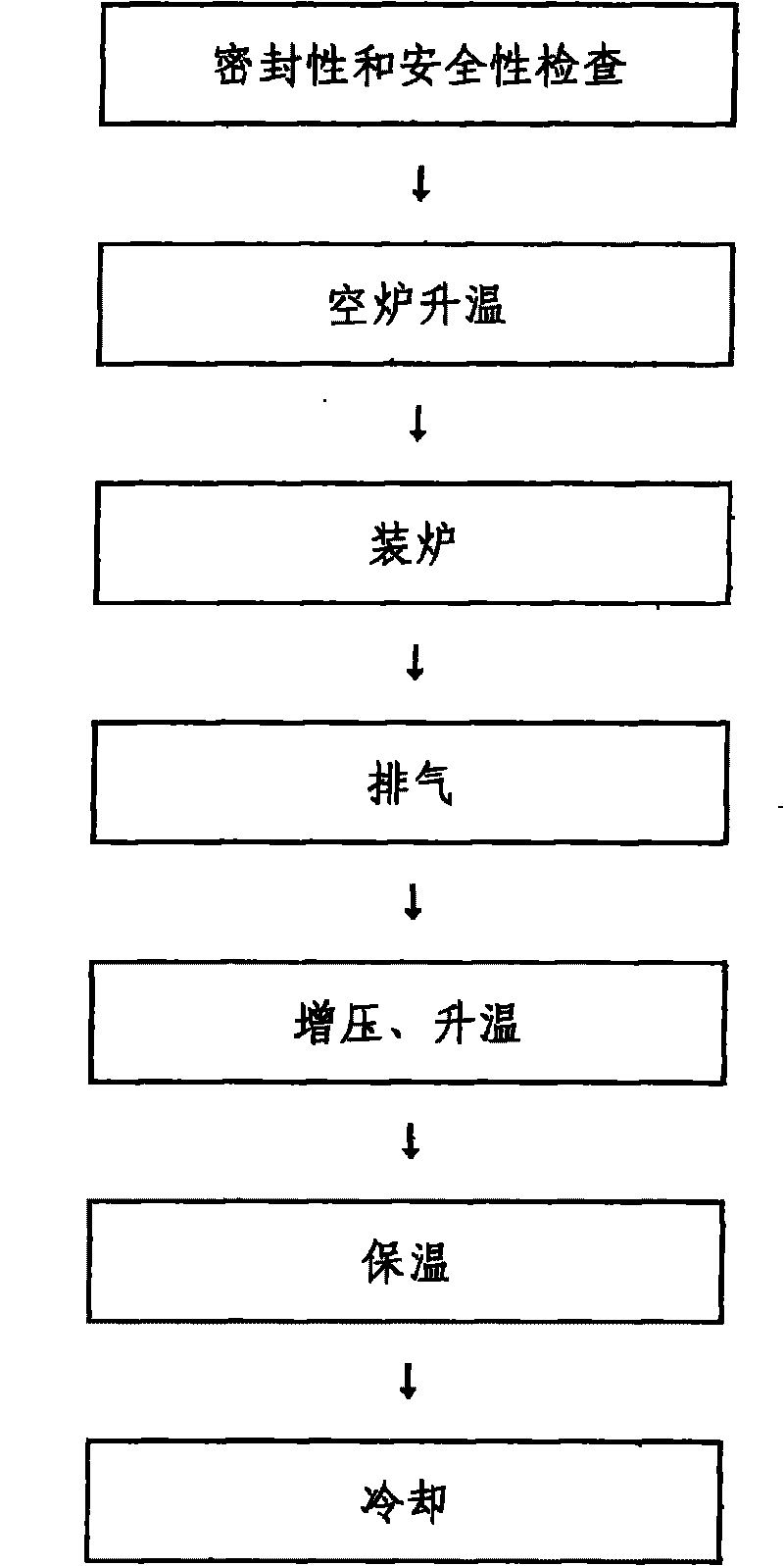

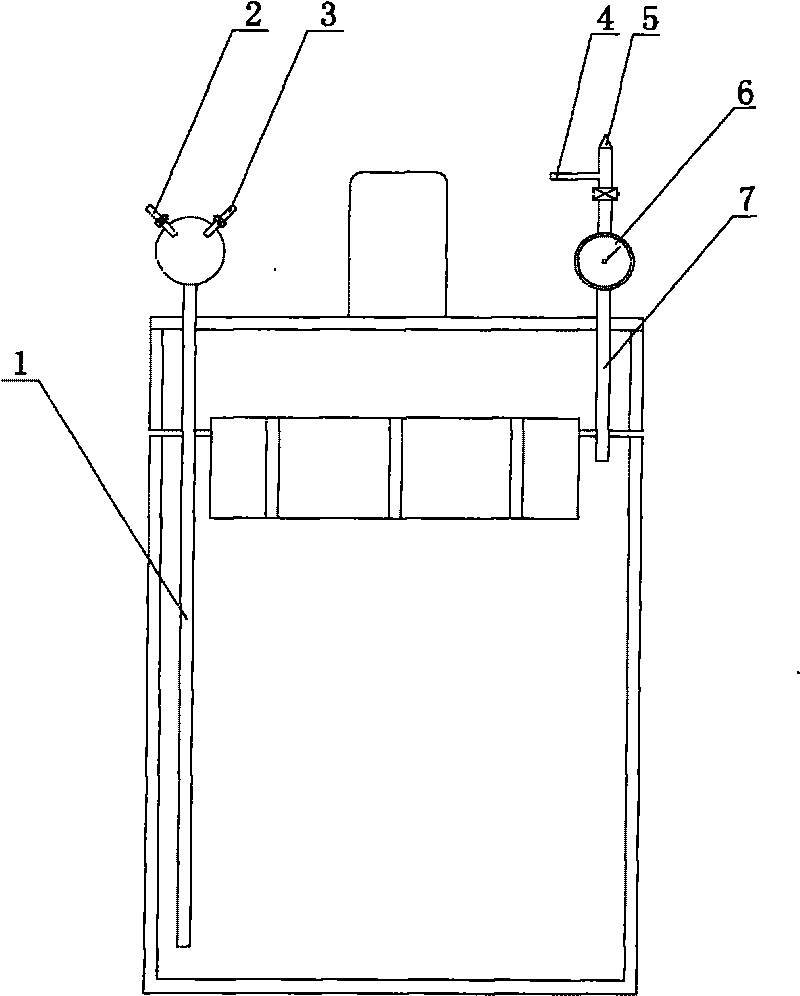

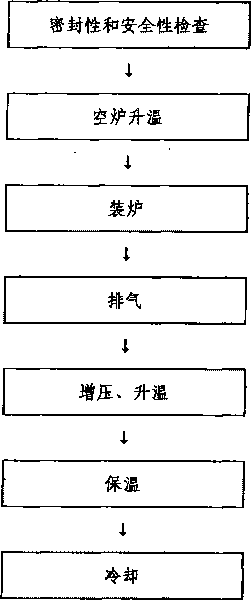

Pressurized gas nitrocarburizing method

InactiveCN101698929AAccelerate the speed of co-infiltrationImprove surface wear resistance (corrosion)Solid state diffusion coatingMetallurgyInlet valve

The invention relates to a pressurized gas nitrocarburizing method, belonging to the technical field of heat treatment of materials. The method is suitable for quickly nitrocarburizing on surface layers of steel workpieces, the main technical characteristic is that the method contain a procedure and the procedure comprises the following steps sequentially: sealing, checking safety, heating an empty furnace, charging, exhausting gas, pressurizing and heating, keeping heat and cooling. In the step of heating the empty furnace, the temperature in the furnace is controlled within 400 DEG C-500 DEG C, and the temperature of the empty furnace is kept for 0.5-1 hour; in the exhausting step, gas carbon dioxide and ammonia gas are respectively introduced in a gas inlet valve (2) and a gas inlet valve (3) to the inner bottom of a nitrocarburizing furnace through a gas inlet pipeline 1, and the air in the furnace is exhausted by a gas exhaust pipeline 7; in the pressurizing and heating step, the pressure is 5000Pa-60000Pa, the temperature is 500 DEG C-600 DEG C; and in the heat insulating step, and the heat insulation time is 1.5-3 hours. The invention has the advantages of simple technology, high nitrocarburizing speed and the like, can be used to obviously shorten the heat insulation time, effectively save the energy and the working hours, and reduce the production cost.

Owner:江南工业集团有限公司

Ship manufacturing method for pre-mounting steering engine base in segmentation step

The invention discloses a ship manufacturing method for pre-mounting a steering engine base in a segmentation step. The ship manufacturing method comprises the following steps of: carrying out segmentation on a deck of a steering engine room; drawing a gantry arrangement and reinforcement picture of an upper gantry of the deck of the steering engine room at a positive segmentation state; incorporating the gantry arrangement and reinforcement picture with a segmental fitting-out tray management list so as to ensure that the pre-mounting of the steering engine base is completed in a segmental manufacturing step, and the requirement on installation precision can be met; and conveying the deck of the steering engine room in a segmental manner to a next process in a positive state of the upper gantry. The steering engine base is welded before being coated in a segmental manner, so that the segmental fitting-out integrality can be improved. Therefore, the damage area of a coating layer of a ship stern ballast cabin is reduced, the risk of sand wash on the entire ship stern ballast cabin can be effectively reduced, a coating construction period is shortened, and a PSPC (Performance Standard for Protective Coatings) can be met.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

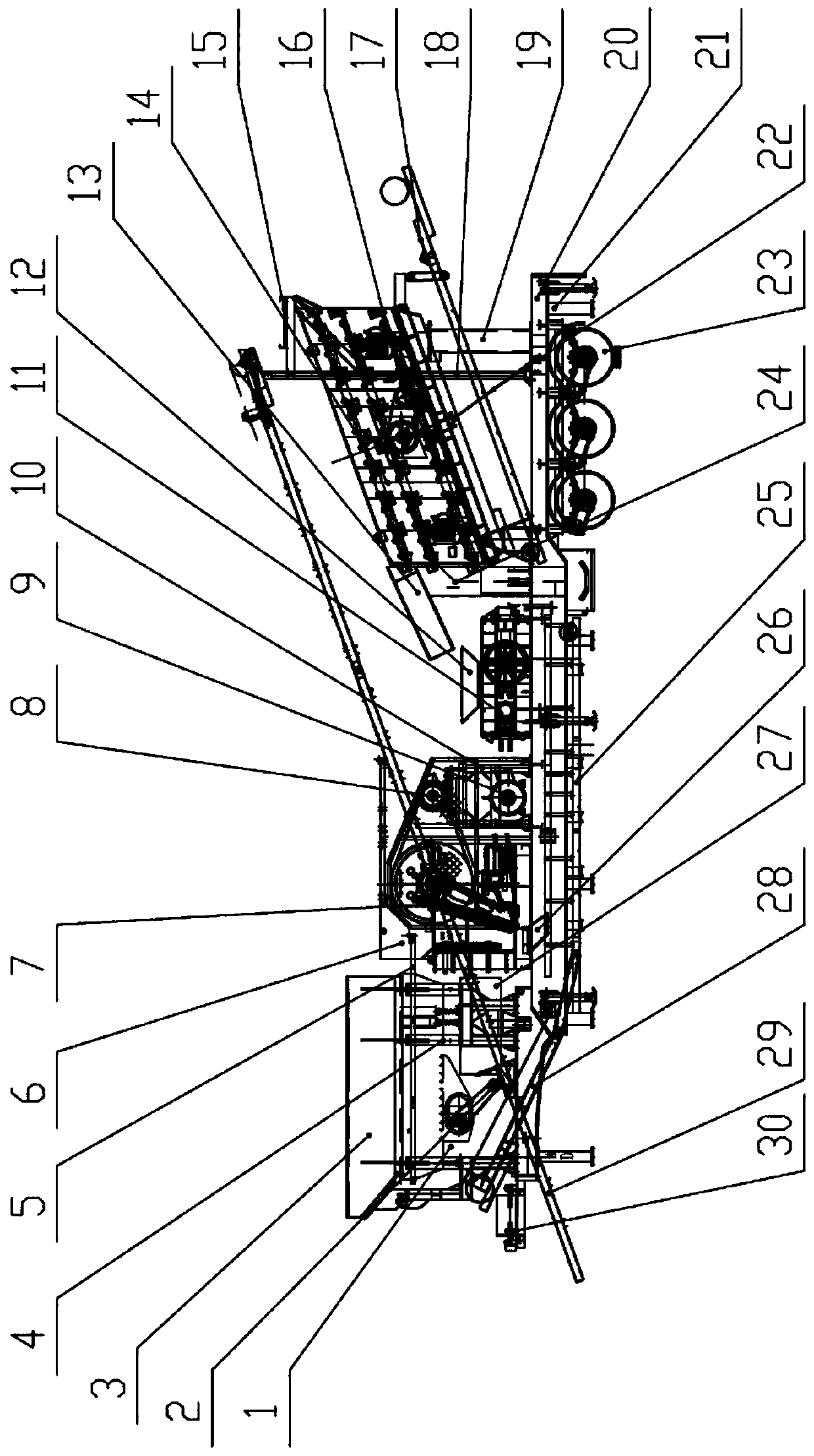

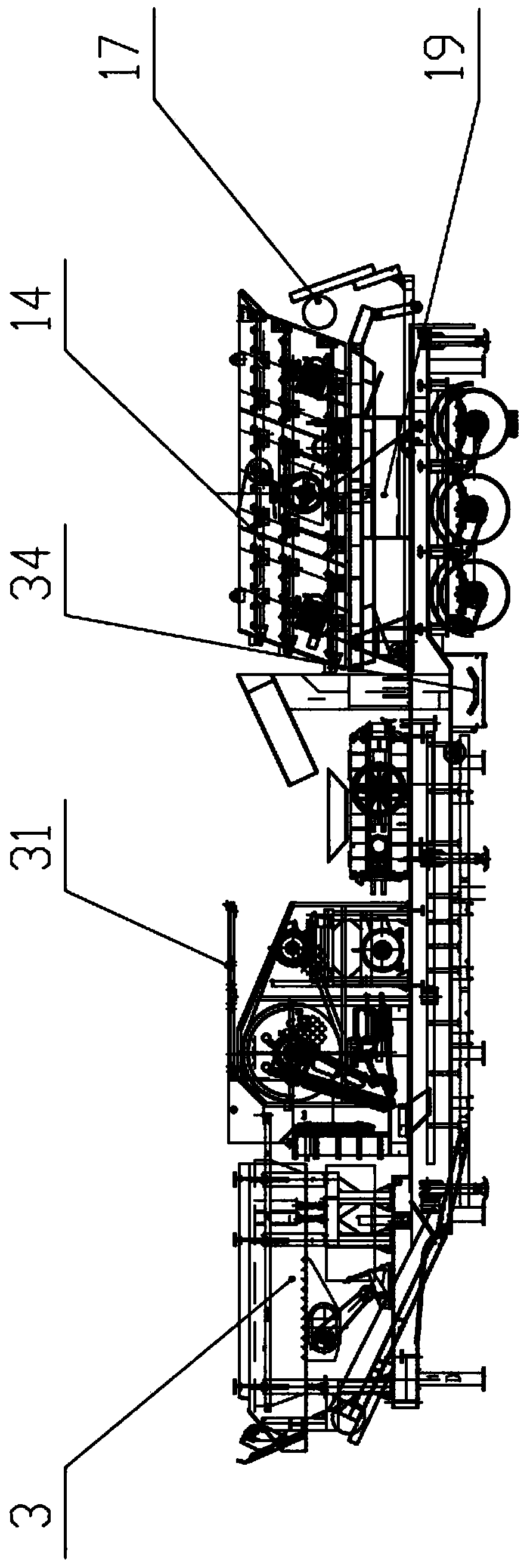

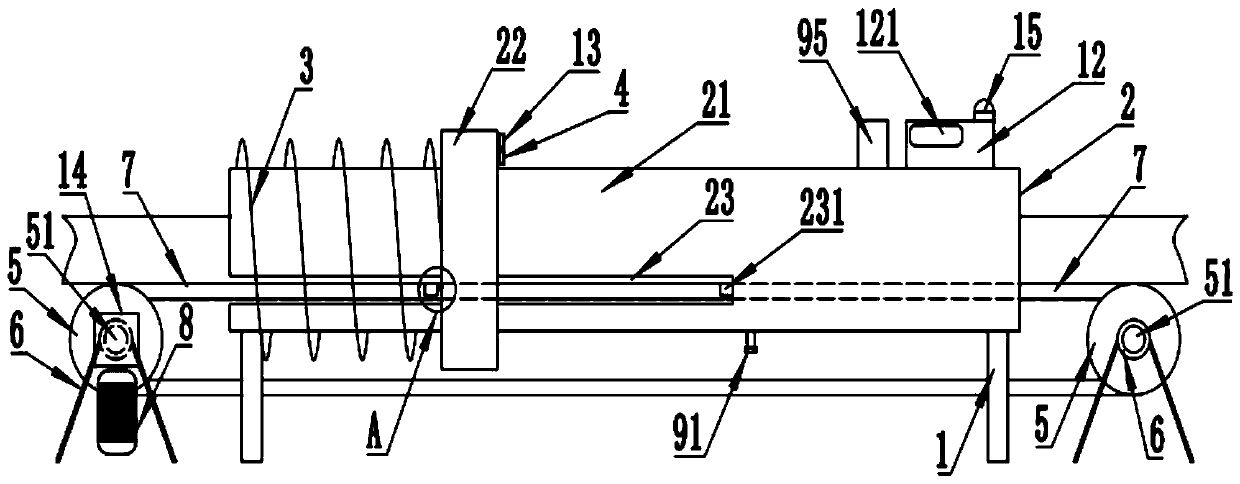

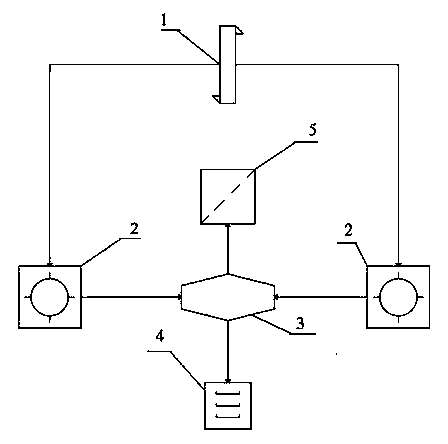

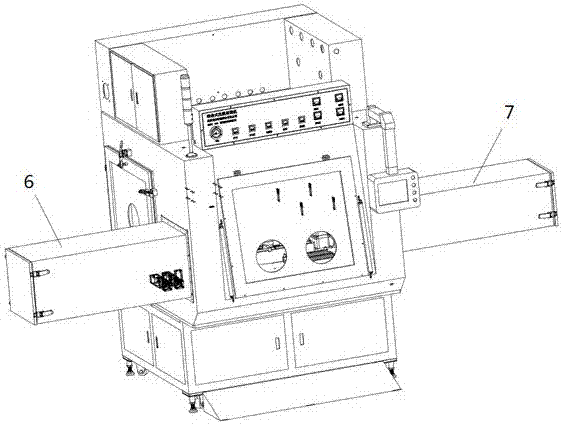

Environment-friendly aggregate series mobile crushing station

InactiveCN103752394AReduce man-hour consumptionCompact and reasonable space layoutGrain treatmentsLand resourcesBelt conveyor

The invention relates to an environment-friendly aggregate series mobile crushing station which is applicable to materials in various rigidities, as well as coarse crushing, intermediate crushing and fine crushing tasks in different fields. The station comprises vibratory feeding equipment, primary crushing equipment, secondary crushing equipment and vibratory screening equipment which are arranged from the front to the back, wherein a discharge port of the vibratory feeding equipment corresponds to a feed hopper of the primary crushing equipment; an unfinished product discharge hopper of the vibratory screening equipment corresponds to a feed hopper of the secondary crushing equipment; a first belt conveyor is arranged at discharge ports of the primary crushing equipment and the secondary crushing equipment in a penetrating manner; the first belt conveyor and a subsequent belt conveyor connected with the first belt conveyor are further connected to a feed port of the vibratory screening equipment; and a finished product discharge port of the vibratory screening equipment corresponds to a finished product belt. The station adopts an integrated complete unit, is reasonable and compact in spatial arrangement, optimizes a working site to the greatest extent, saves the land resources, can be combined flexibly according to different crushing technological requirements, is high in adaptability, reduces space occupation, saves cost, and is reliable and safe in performance and convenient to service.

Owner:上海建冶路桥机器设备有限公司

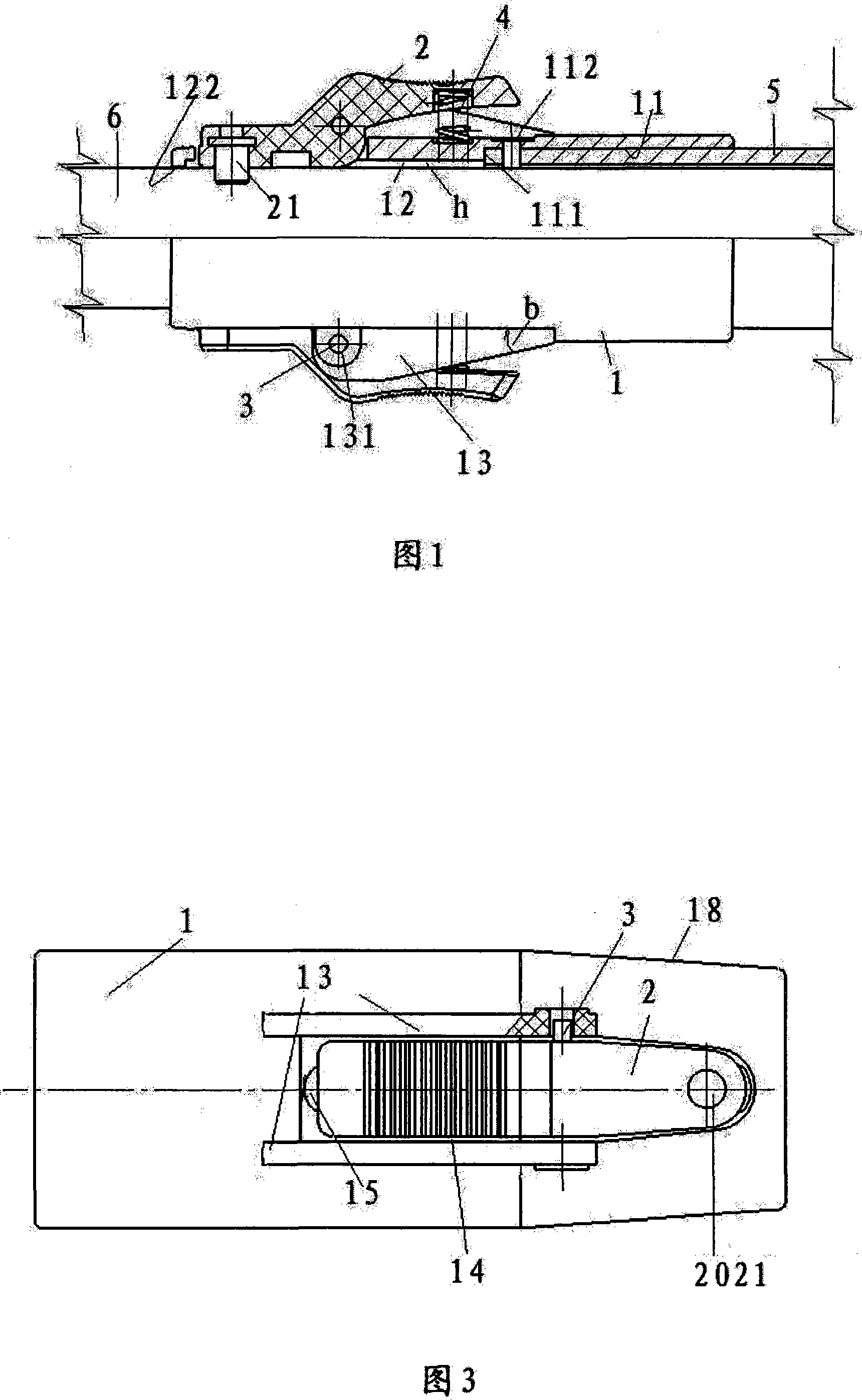

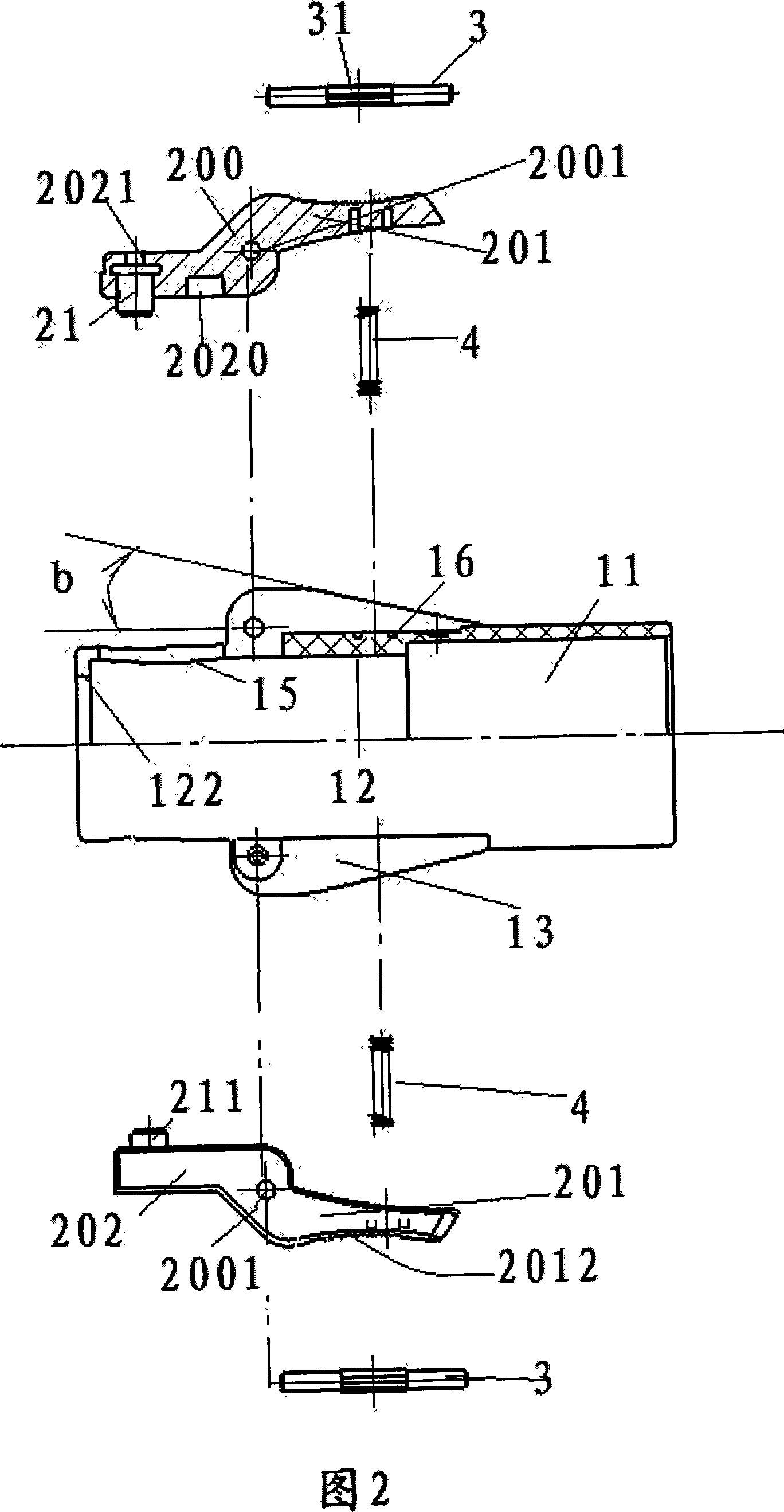

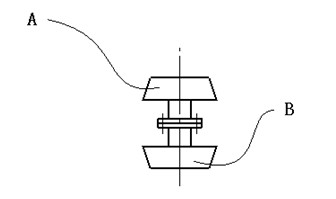

Device for locking telescoping rod

InactiveCN101092984AEasy to assembleSimplified assembly stepsRod connectionsEngineeringMechanical engineering

This invention relates to a locking device of an extension rod including a base jacket fixedly holding an expansion outer pipe and locking pressed piece pivoted by the jacket, in which the base jacket includes an internal stop assemble part fixing the outer pipe and an inner tube expansion part making the inner pipe to expand freely, the outer side of the jacket is set with side ears for locking the press piece, slot channels allowing the locked press piece to press on the outer wall of the inner pipe are set at the side wall of the base jacket, the locked press piece is composed of a press body molded at one run and a locking post pressing on the front, the press body includes a locking front arm and a dynamic arm, a press piece pivot hole combined with the pivot hole of the side ears is set on the press body, a spring location device is set at a slightly back position of the dynamic arm and a locking post is pressed on the front of the arm and a location convex part extends into the step hole of the expansion inner pipe.

Owner:TIANJIN JINMAO GROUP

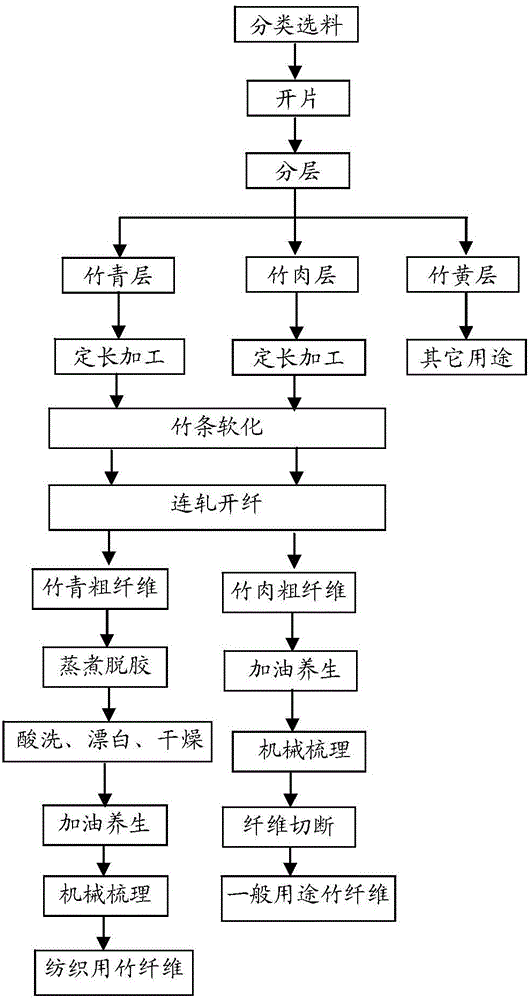

Method for extracting bamboo fibers from bamboo in layering mode

ActiveCN105113023AExcellent fiber finenessImprove qualityVegetable materialMechanical fibre separationGeneral purposeCarding

The invention provides a method for extracting bamboo fibers from bamboo in a layering mode. The method comprises the steps that bamboo materials are classified, selected, sliced and layered into bamboo outside layer bamboo canes, bamboo middle layer bamboo canes and bamboo inner skin layer bamboo canes, and then fixed-length bamboo cane softening and continuous rolling splitting are carried out in sequence to obtain crude bamboo fibers of the bamboo outside layer and crude bamboo fibers of the bamboo inside layer; the procedures of stewing and degumming, bleaching, acid pickling, drying, emulsified oil adding for maintenance and mechanical carding are carried out on the crude bamboo fibers of the bamboo outside layer in sequence, and the bamboo fibers for spinning are obtained; the procedures of emulsified oil adding for maintenance, mechanical carding and fiber cutting off are carried out on the crude bamboo fibers of the bamboo inside layer in sequence, and the bamboo fibers for a general purpose are obtained. The bamboo fibers for spinning and the bamboo fibers for the general purpose can be obtained at the same time, and the utilization rate of the bamboo materials is effectively increased.

Owner:ZHEJIANG FORESTRY UNIVERSITY

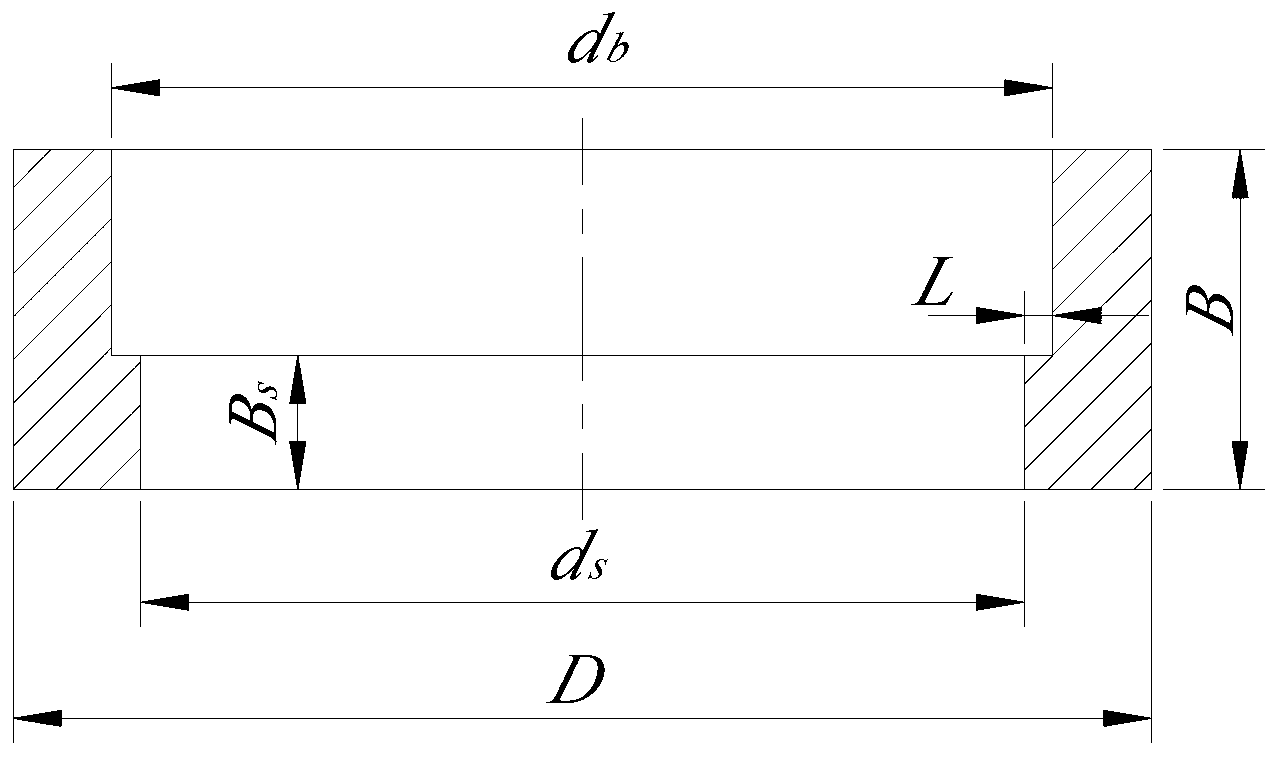

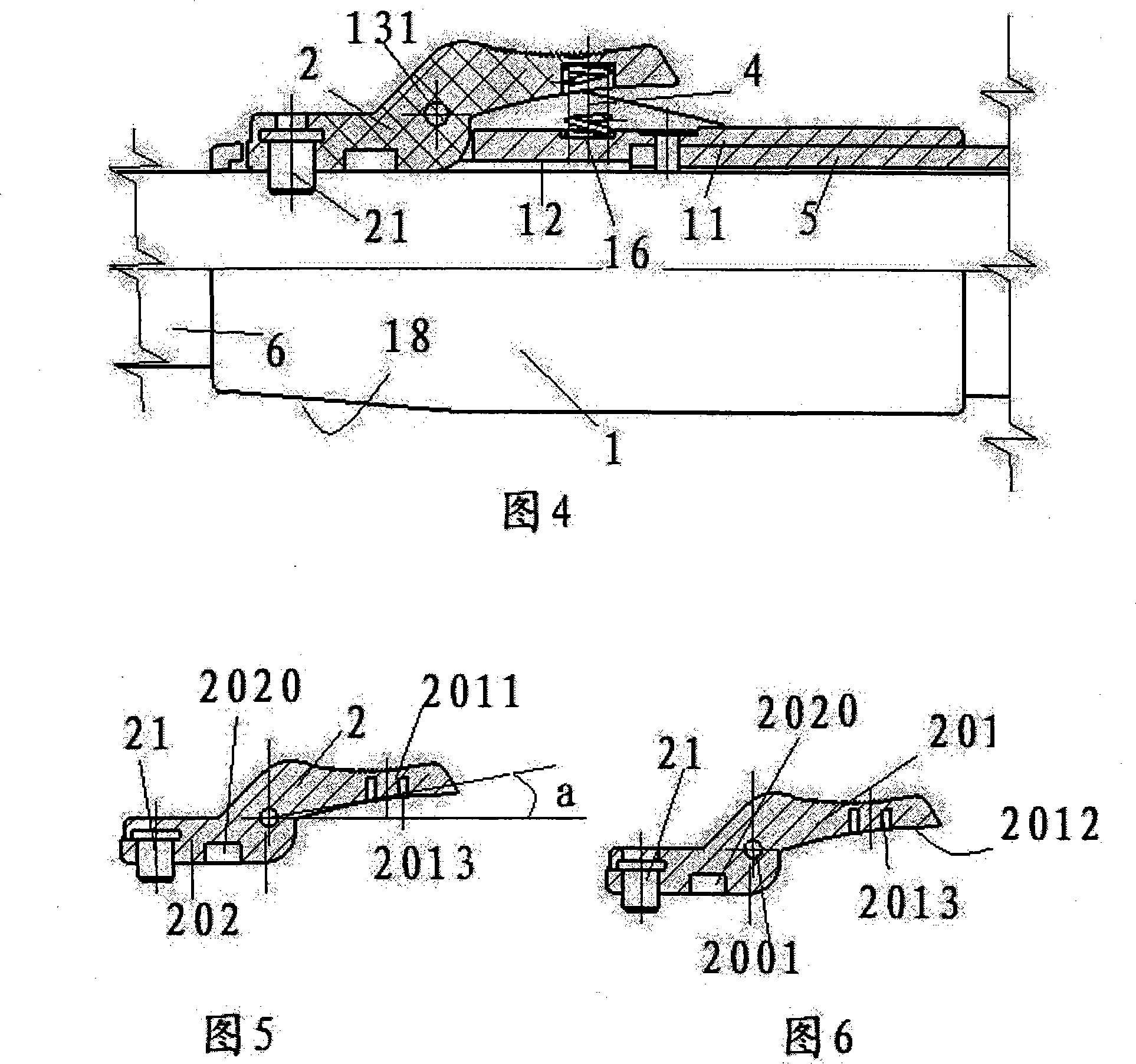

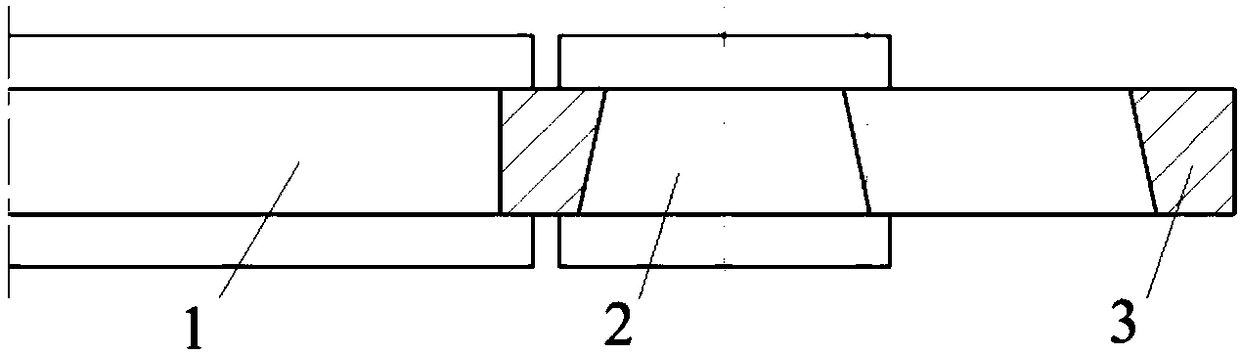

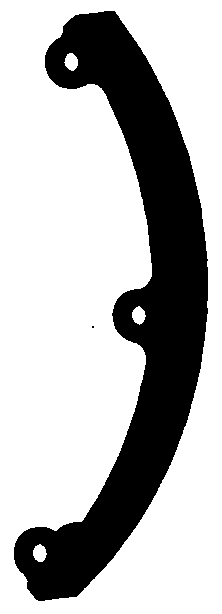

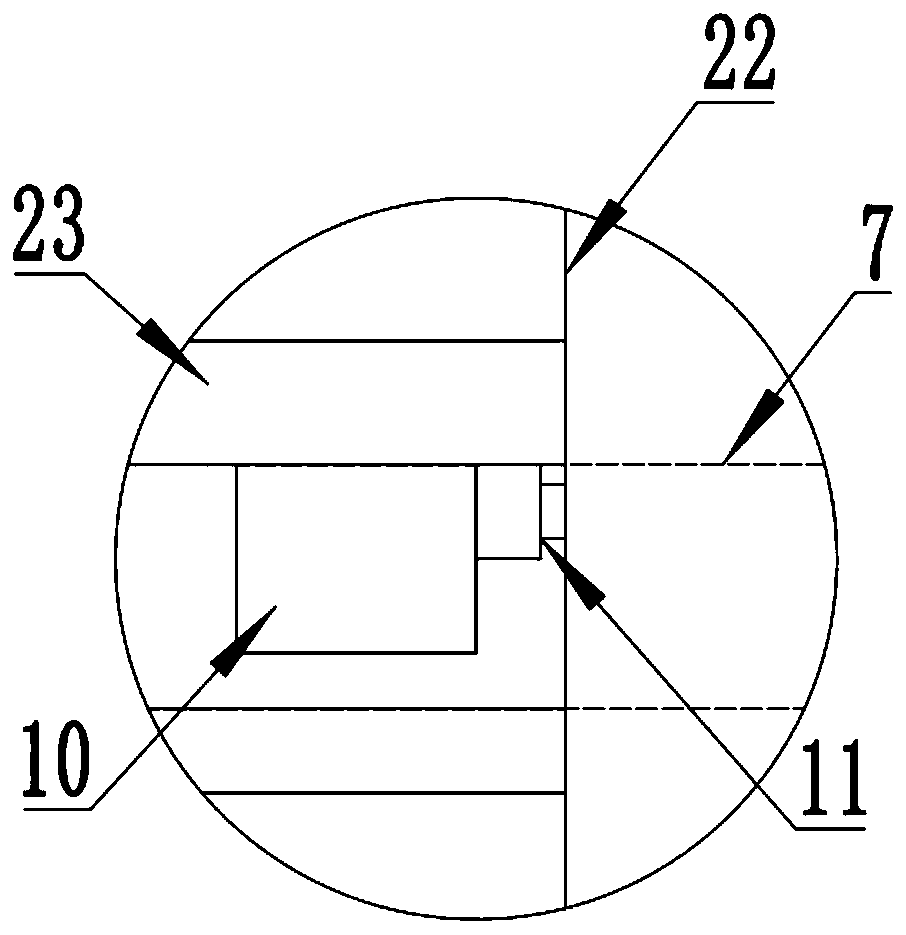

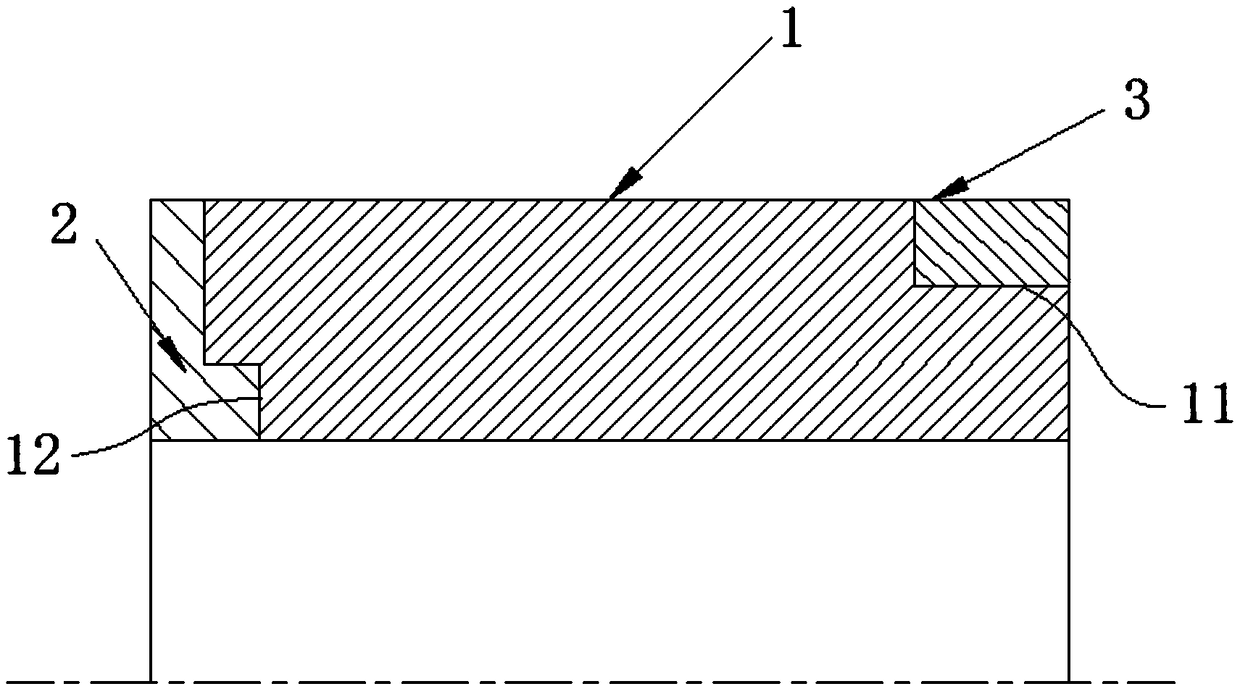

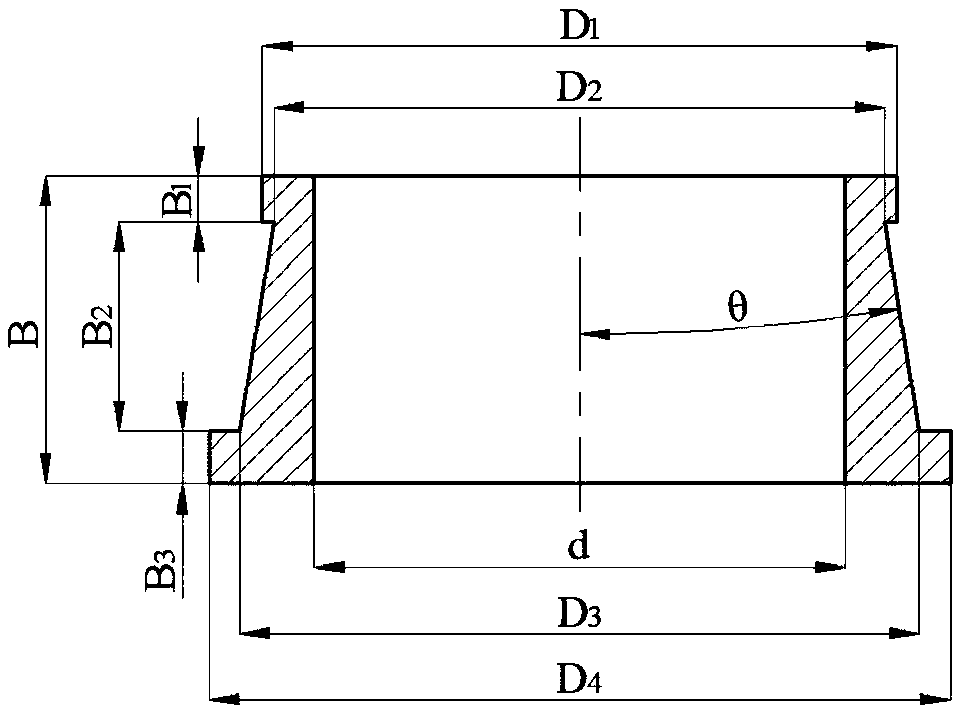

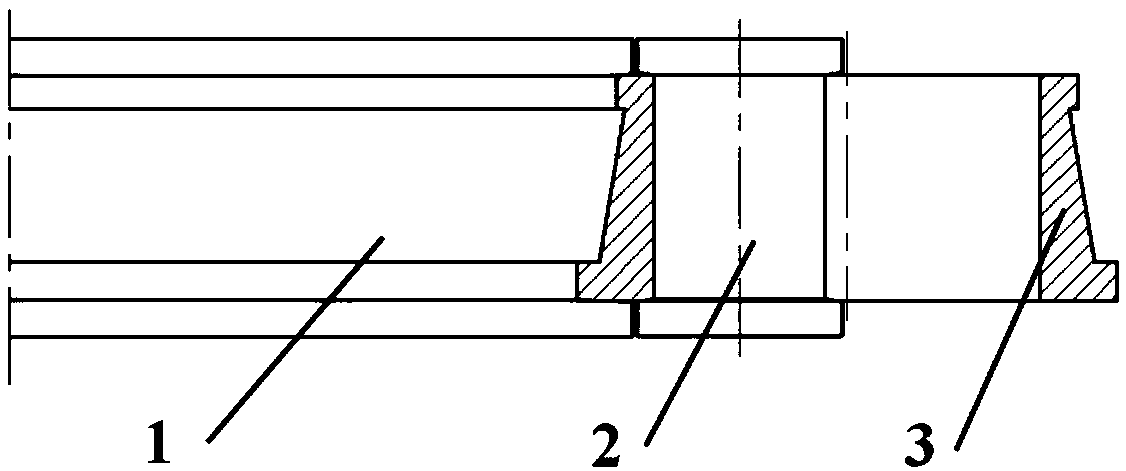

Method for precisely cold-rolling and forming outer ring of tapered roller bearing

InactiveCN108568489AAvoid damageReduce man-hour consumptionMetal rollingEngineeringMechanical engineering

The invention discloses a method for precisely cold-rolling and forming an outer ring of a tapered roller bearing. The method comprises the following steps: S1, designing a ring blank: a ring blank tapered hole and a ring blank cylindrical hole are coaxially arranged in the ring blank, the small-diameter ends of the ring blank tapered hole and the ring blank cylindrical hole are connected, the diameter of the ring blank cylindrical hole is less than the diameter of the small-diameter end of the ring blank tapered hole; S2, cold-rolling and forming: a cold-rolling hole pattern comprises workingsurfaces of a driving roll and core roll, the shape of the working surface of the driving roll and the shape of the outer surface of an outer ring piece are consistent, the shape of the working surface of the core roll and the shape of the inner surface of the outer ring piece are consistent, the driving roll and the core roll are both designed to I-shapes, the ring blank is put between the driving roll and the core roll, the upper end and the lower end of the driving roll and the core roll axially constraint the ring blank, the driving roll does rotating motion, meanwhile, the core roll doesradial feeding motion, and then the ring blank is cold-rolled and formed. The method has the advantages that the forming precision is high and the product quality, the material efficiency and the processing efficiency are improved.

Owner:WUHAN UNIV OF TECH

Processing technology of gear lever bushing

The invention relates to a processing technology of a gear lever bushing. The processing technology comprises following steps: (1), discharging; (2), primary turning; (3), secondary turning; (4), tertiary turning; (5), inner hole processing; (6), inner hole diameter precision detection; (7), inner hole diameter roundness detection; (8), inner hole surface finish detection; (9), washing. According to the processing technology of the gear lever bushing, raw material consumption, labor-hour consumption and rejection rate can be reduced, and processing precision and production efficiency are improved.

Owner:天津市利成工贸有限公司

Titanium piston

A titanium piston comprises a piston top provided with an arc-shaped concave pit, a piston pin hole tube seat, a cylindrical piston skirt and piston pin hole tubes. A pair of piston pin holes are symmetrically formed in the piston skirt. The titanium piston is characterized in that the titanium piston is formed by the piston top, the piston pin hole tube seat, the piston skirt and reinforcing ribs through welding; the piston top is welded to one end of the piston skirt; the pair of piston pin hole tubes are oppositely welded in the piston skirt; and the piston pin hole tubes are welded to the inner sides of the piston pin holes through piston pin hole tube supports. By the adoption of the titanium piston, the defects that an existing manufacturing technique is tedious, low in efficiency and high in manufacturing cost are fundamentally overcome, the efficiency of an internal combustion engine can be effectively improved, and the service life is prolonged.

Owner:沈阳中钛装备制造有限公司

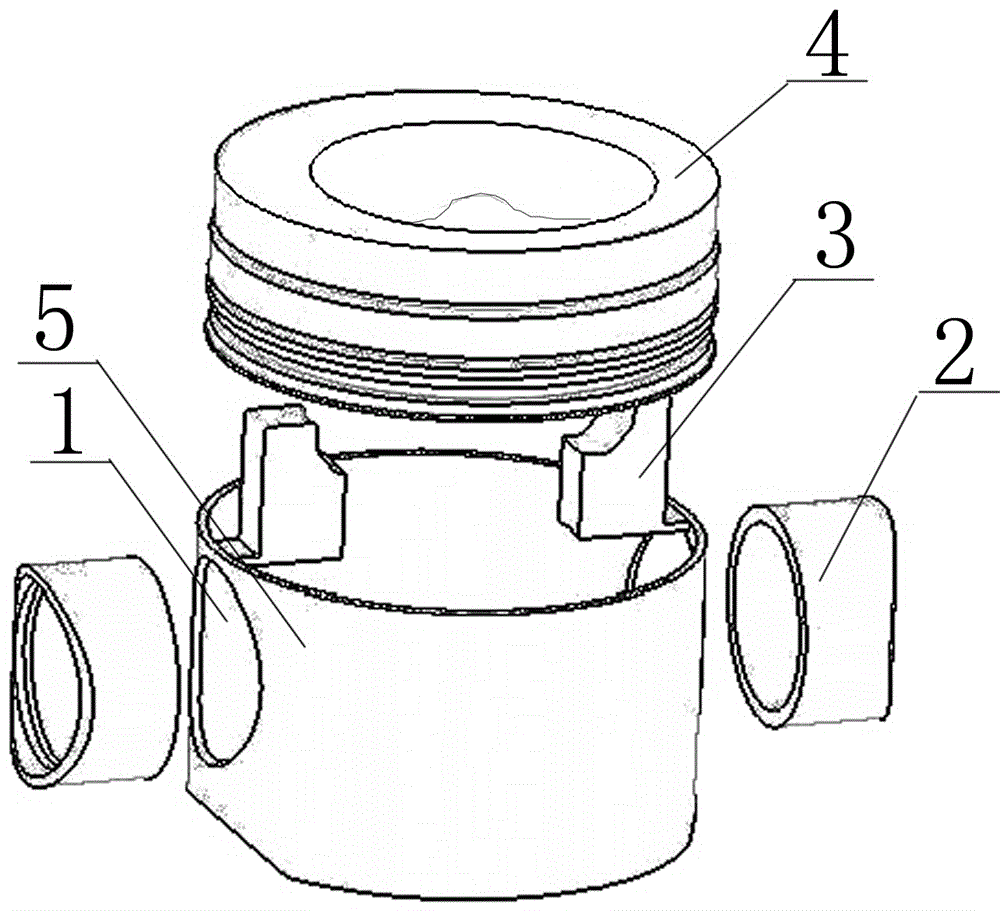

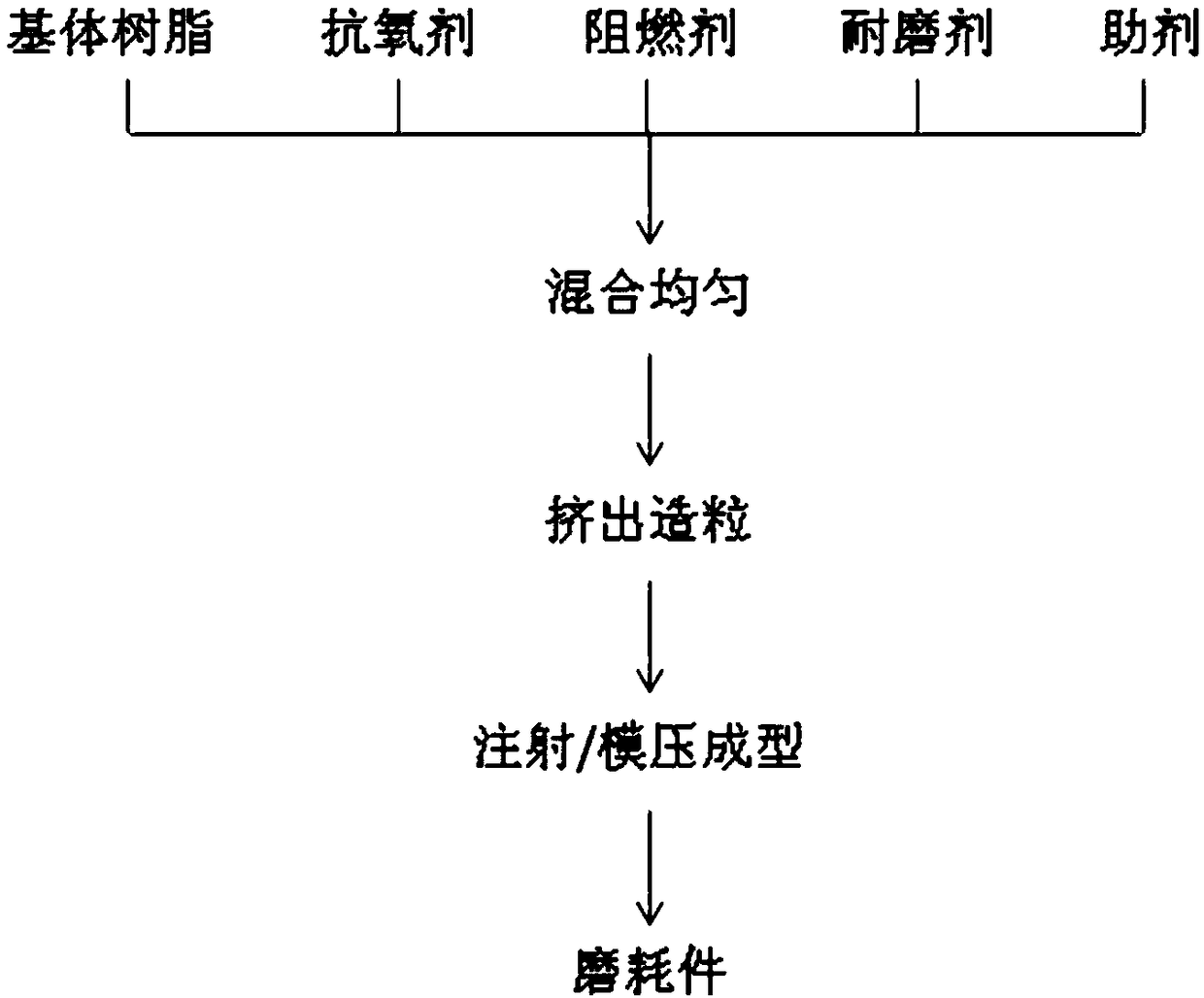

Auxiliary guide wheel abrasion part and preparation method

The invention discloses an auxiliary guide wheel abrasion part which is prepared from modified thermoplastic materials by injection molding or compression molding. The modified thermoplastic materialscomprise, by weight, 100 parts of matrix resin, 0.1-0.5 part of antioxidants, 0.1-20 parts of fire retardants, 0.1-10 parts of abrasion-resistant agents and 0.1-3.5 pasts of additives. The auxiliaryguide wheel abrasion part is directly injected and molded without extruding and granulating, and modified additives are added by a master batch mode. The thermoplastic materials have a low friction coefficient and a flame-retardant function and are excellent in abrasion resistance and simple in manufacturing process. The prepared abrasion part wraps an outer ring of an aluminum alloy support, abrasion of the support and a cement track beam caused by direct contact between the support and the cement track beam can be avoided, and the running noise of a vehicle is low. The abrasion part is convenient to replace and low in cost, labor-hour consumption is reduced by 60%, the cost is reduced by 90%, and repair and maintenance cost can be effectively reduced.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Out-of-bottle bag rooting method for tissue culture seedlings of Europe and America hybrid aspens

InactiveCN102919128AReduce manufacturing costReduce overall man-hoursPlant tissue cultureHorticulture methodsGreenhousePeat

The invention relates to an out-of-bottle bag rooting method for tissue culture seedlings of Europe and America hybrid aspens. The method is to the problem that the cultivation cost is high, the production phase is long and the survival rate of transplanting of tissue culture seedlings is low in a tissue culture process of the Europe and America hybrid aspens. The method comprises the following steps: 1, plastically packaging the bottom of polypropylene plastic bags with a sealing machine to manufacture rooting culture bags; 2, mixing peat soils with sands, sterilizing at high speed to obtain composts and packing the composts into the rooting culture bags; 3, burrowing in the composts in the culture bags and wetting each hole with rooting culture solution; and 4, taking out the tissue culture seedlings of the Europe and America hybrid aspens from culture mediums, planting the tissue culture seedlings into the holes of the culture bags, sealing the top of the culture bags with the sealing machine, placing in greenhouses to culture for 5-7 days, gashing the top of the culture bags and then culturing for 8-10 days to obtain the rooting seedlings of the Europe and America hybrid aspens. The method is used in the field of asexual propagation of the Europe and America hybrid aspens.

Owner:NORTHEAST FORESTRY UNIVERSITY

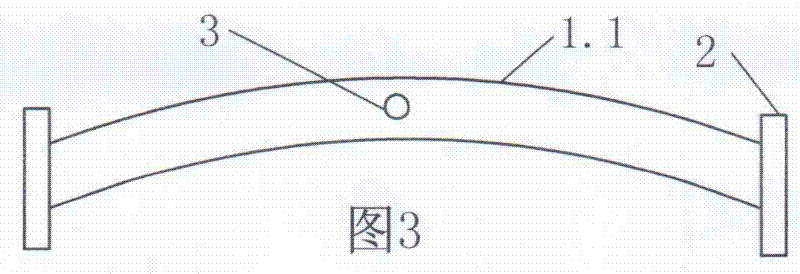

Cable eccentricity detection device

ActiveCN111076657AReduce frictional resistanceHigh precisionUsing electrical meansElectric machineryControl theory

The invention discloses a cable eccentricity detection device comprising a screw rod and a nut. Two ends of the screw rod are fixedly erected on a bracket; an eddy current sensor is fixed on the nut;belt wheels are arranged below the two ends of the screw rod; and a conveying belt is wound on the belt wheels in a tensioning manner. A motor can drive the conveyor belt to convey the cable in the screw rod; a spring ejector rod rotates along with the conveying belt and can pass through a through hole formed in one end of the screw rod and push the nut to slide simultaneously; a touch switch is trigger simultaneously to trigger an eddy current sensor; the eccentricity degree of the cable core can be reflected through a range value, measured by the eddy current sensor, of the displacement signal of the cable core. The spring ejector rod is pushed by a flange to retract into the screw rod, so that the nut slides and resets under the effect of the spring. A processor is arranged and is usedfor receiving a displacement signal measured by the eddy current sensor and calculating the range value of the displacement signal; and the processor is further provided with a display screen for displaying the range value so as to achieve the function of non-destructive on-line real-time automatic detection of the eccentricity of the cable.

Owner:ANHUI FUXING CABLE GRP

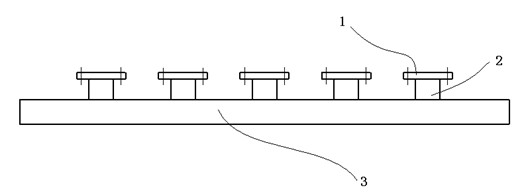

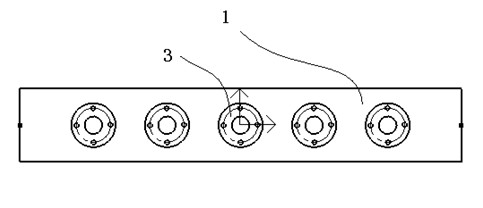

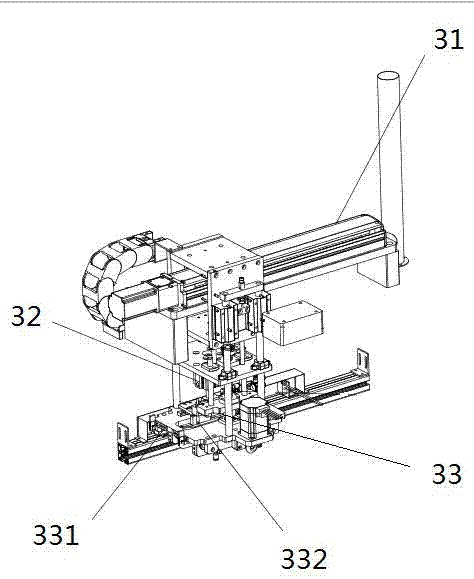

Auxiliary device for manufacturing main bearing oil feeding pipe of marine diesel machine and main bearing oil feeding pipe manufacturing method

ActiveCN102152046AReduce man-hour consumptionAvoid duplication of effortWelding/cutting auxillary devicesAuxillary welding devicesGeneral assemblyDiesel engine

The invention relates to an auxiliary device for manufacturing a main bearing oil feeding pipe of a marine diesel engine and a method for manufacturing the main bearing oil feeding pipe. The auxiliary device comprises a bottom plate, supporting pipes fixed on the bottom plate and supporting pipe flanges fixed on the supporting pipes, wherein the bottom plate is a rectangular straight and rigid plate, and the length of the bottom plate is equal to that of the bearing oil feeding pipe; the supporting pipes are cylindrical steel pipes; the plurality of supporting pipes are vertically fixed on the bottom plate; the distance between every two supporting pipes corresponds to that between every two supporting pipes on the main bearing oil feeding pipe; supporting pipe flanges which is of the same type with flanges on the main bearing oil feeding pipe are arranged at the tops of the supporting pipes; and in the manufacturing method, a first tool in the auxiliary device adopts a rack manufacturing unit to weld the main bearing flanges, a second tool adopts a pipe piece manufacturing unit to manufacture a main bearing oil feeding principal pipe, and finally general assembly is carried out. By the auxiliary device and the manufacturing method, the production accuracy and the production efficiency of the bearing oil feeding pipe of the marine diesel engine are improved.

Owner:HUDONG HEAVY MACHINERY

Compound shaft sleeve structure of magnetic suspension motor rotor

PendingCN108757735AMeet performance needsLow costShaftsBearing componentsInterference fitAustenitic stainless steel

The invention discloses a compound shaft sleeve structure of a magnetic suspension motor rotor. The compound shaft sleeve structure comprises a transition sleeve body, a magnetism isolating ring and adetection ring. The magnetism isolating ring and the detection ring are separately arranged on two sides of the transition sleeve body and are in interference fit to the transition sleeve body; the detection ring is arranged on the transition sleeve body in a sleeving mode, and the outer wall surface of the detection ring is aligned to the outer wall surface of the transition sleeve body; one endof the magnetism isolating ring penetrates the transition sleeve body and the outer wall surface of the magnetism isolating ring is aligned to the outer wall surface of the transition sleeve body; the transition sleeve body is made from high alloy steel, the magnetism isolating ring is made from austenitic stainless steel, and the detection ring is made from a nickel-based alloy. By utilizing thecharacteristics of different materials reasonably, the materials draw on each other's strength through a structural design, so that the integral optimum performance is achieved. The compound shaft sleeve structure is low in cost of parts and easy to produce, and the output is improved.

Owner:NANJING CIGU TECH CORP LTD

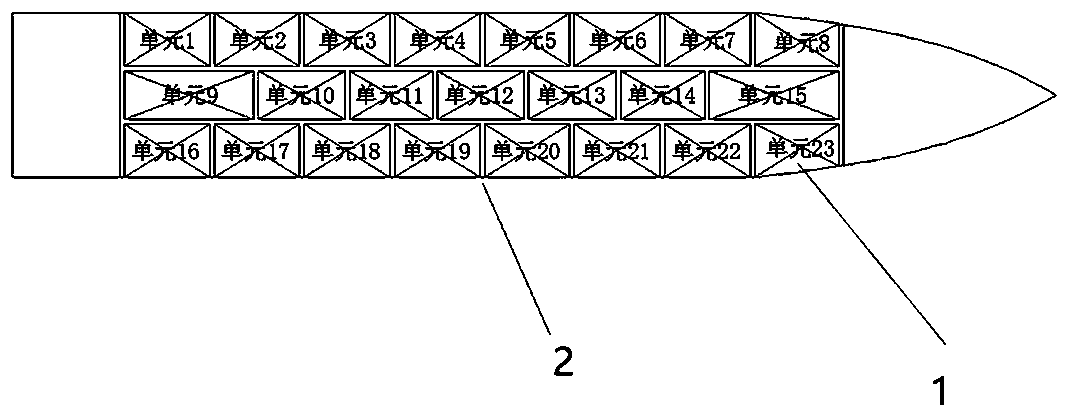

Method of installing heating coil used for liquid cargo tank of chemical cargo ship

The invention relates to a method of installing a heating coil used for a liquid cargo tank of a chemical cargo ship. The liquid cargo tank is divided first, corresponding heating coil unit modules ofeach liquid cargo tank unit are prepared separately and then are hoisted and installed according to an installation progress to achieve one cabin and one module in each liquid cargo tank. Heating coil pipe docking work of an original slipway is completed in advance on a platform, the mode that hoisting is conducted once in each cabin is achieved, the labor intensity is reduced, the working environment of construction personnel is improved, the working efficiency is improved, the slipway cycle is greatly shortened, and the construction cost of the chemical cargo ship is reduced.

Owner:上海船舶工艺研究所(中国船舶集团有限公司第十一研究所)

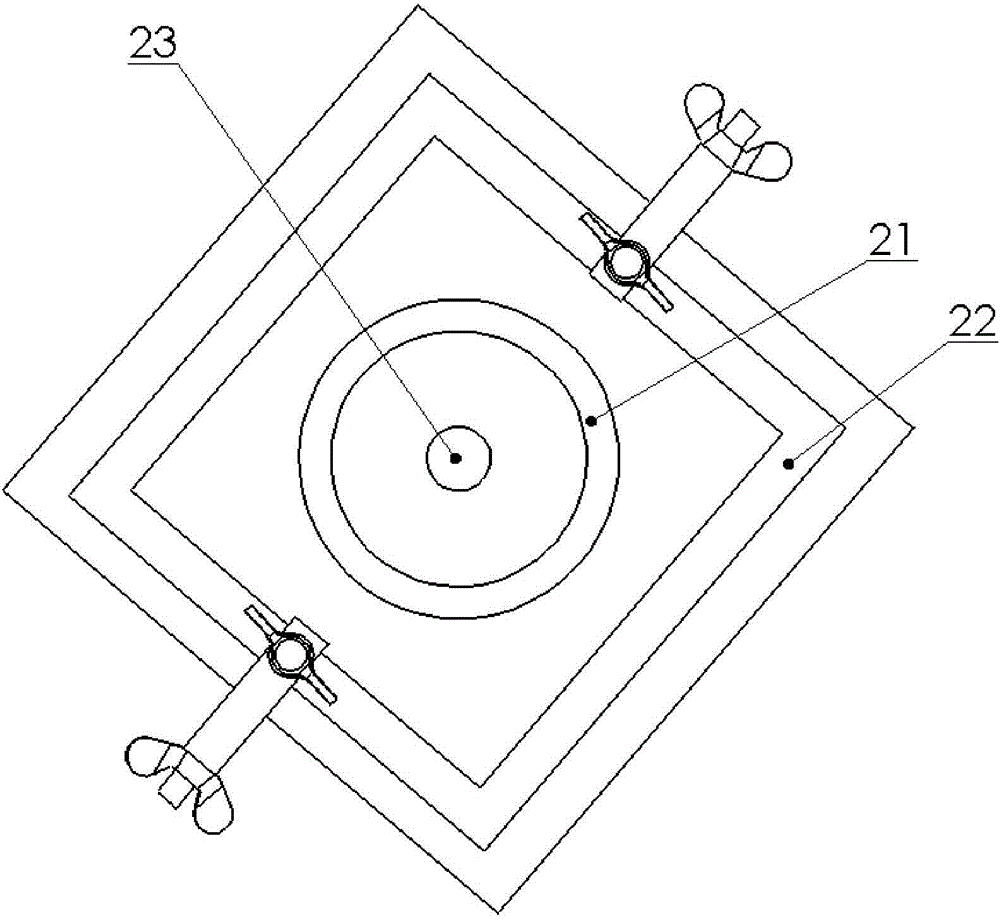

Symmetric integrated crushing system

The invention discloses a symmetric integrated crushing system, mainly comprising a vertical hoister, a horizontal crusher, a center body, a negative pressure powder removing device and a grading and vibrating screen, wherein the vertical hoister, the horizontal crusher, the center body, the negative pressure powder removing device and the grading and vibrating screen are arranged on a same frame and form a stereoscopic structure. Two lateral discharge holes are respectively connected with a left feed inlet and a right feed inlet of the center body, so material crashing and crushing zones are further formed in the center body, and the area of a bottom outlet of the center body matches with the area of a screen surface of the grading and vibrating screen. The crushing system is of a totally-enclosed structure. The symmetric integrated crushing system provided by the invention has the advantages of a compact designed structure, easy and convenient installation, good adaptability, good sealing performance, uniform granularity of a discharged material, great production capacity, a high crushing ratio, environment friendliness, conservation of energy and capacity of saving more than 30% of energy.

Owner:TAI ZHOU TENG DA CONSTR ENG MACHINERY

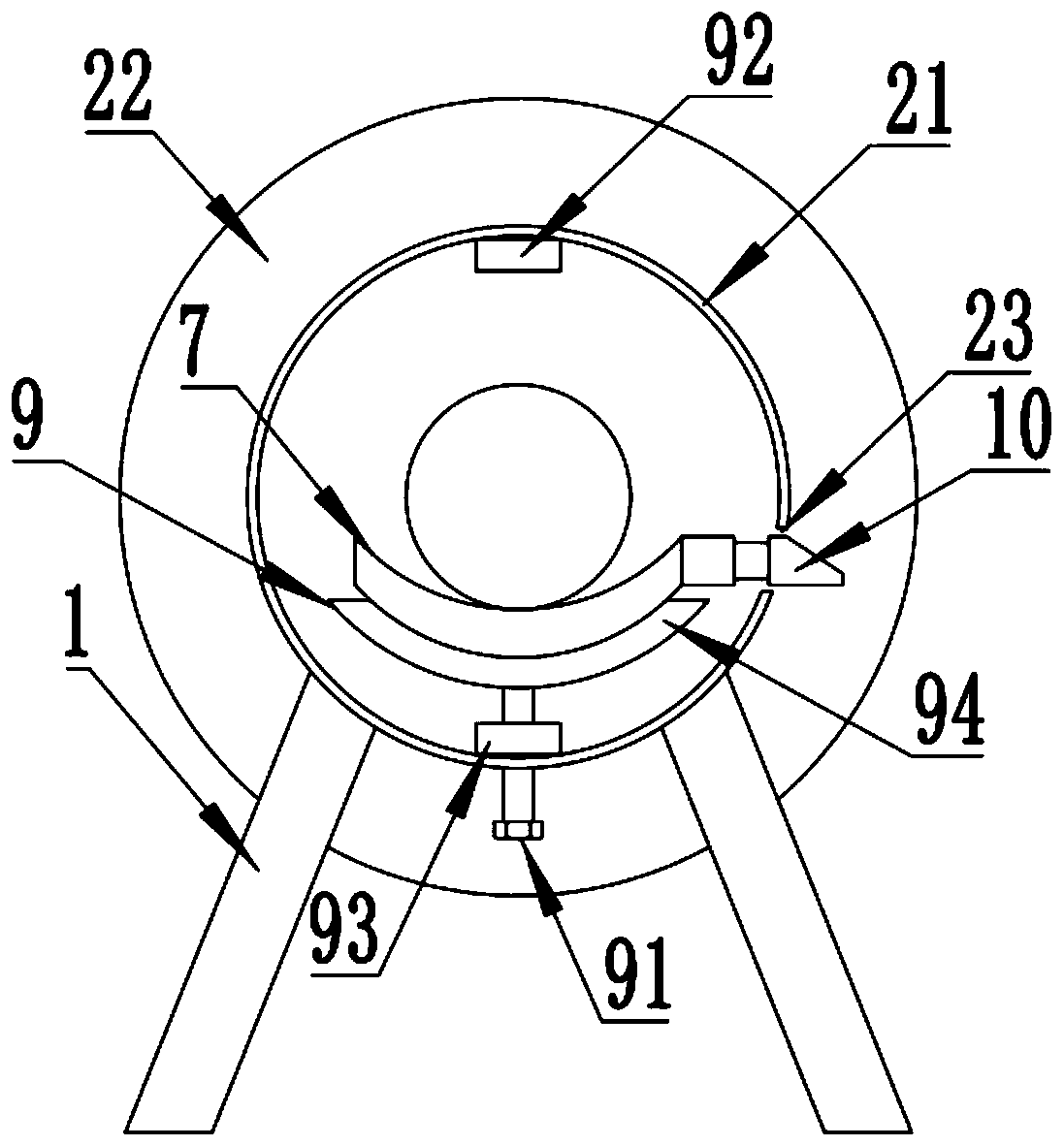

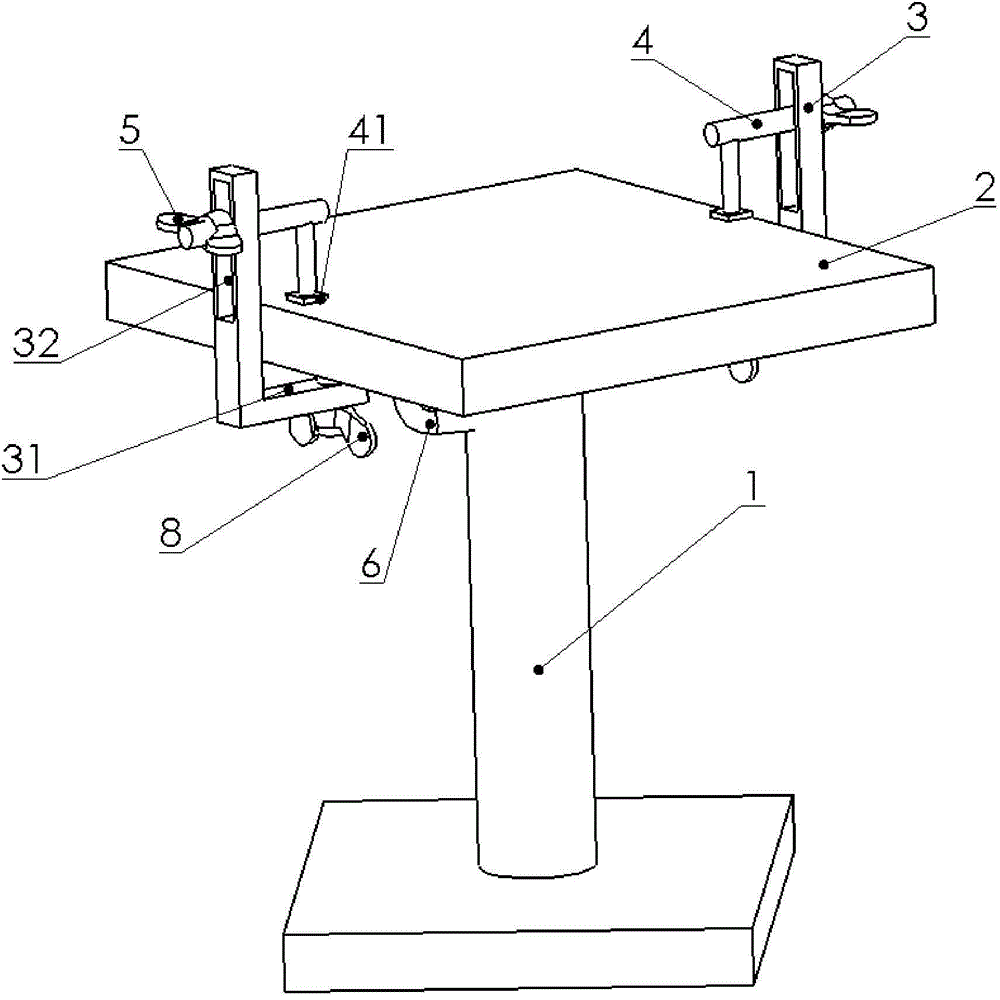

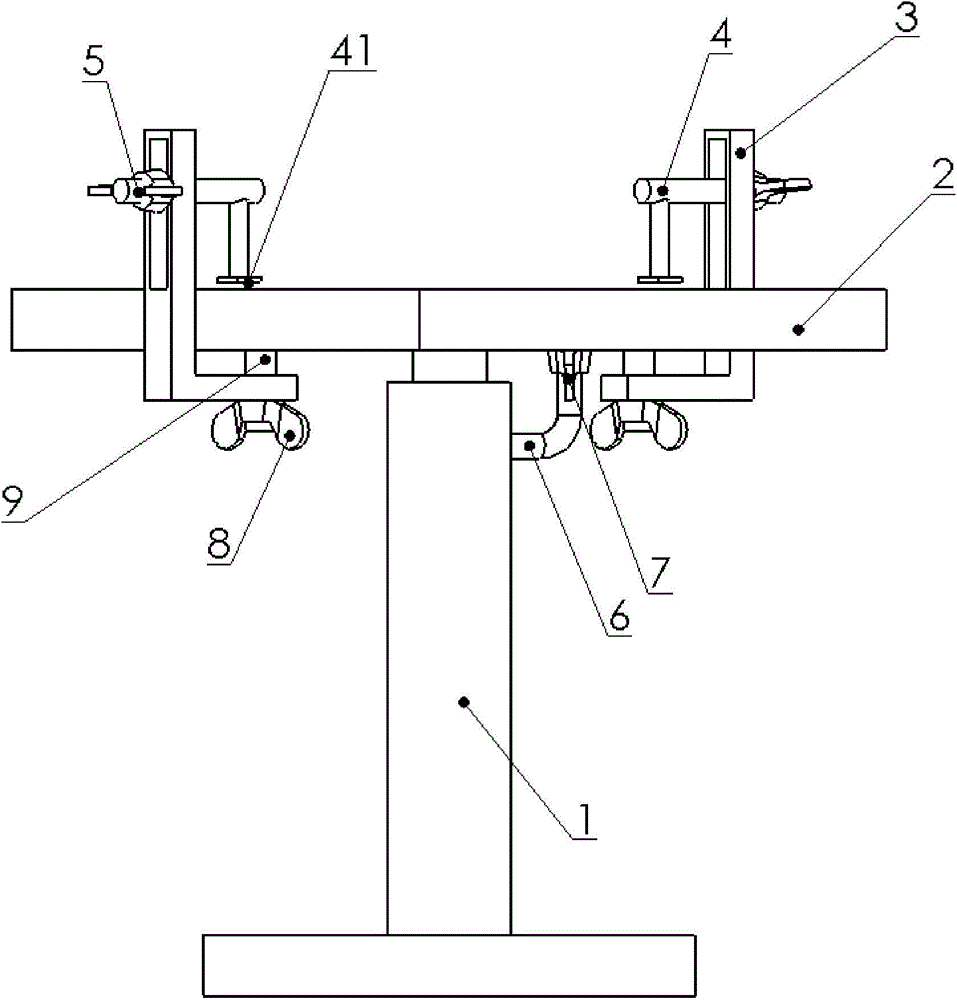

Rotary tool for welding

InactiveCN105750787AReduce labor intensityReduce man-hour consumptionWelding/cutting auxillary devicesAuxillary welding devicesSoldering processIndustrial engineering

The invention provides a rotary tool for welding. The rotary tool for welding comprises a support, an operation table and a plurality of compressing units, wherein a positioning groove is formed in the middle part of the bottom of the operation table; the positioning groove is hinged to the upper part of the support; a positioning unit is arranged at a hinge position between the operation table and the support; the plurality of compressing units are connected to the operation table in a sliding way respectively. By adopting the rotary tool for welding, the labor intensity and labor force during welding of large-sized welded parts can be lowered greatly, and the welding efficiency is increased.

Owner:天津右岸牵伊网络科技有限公司

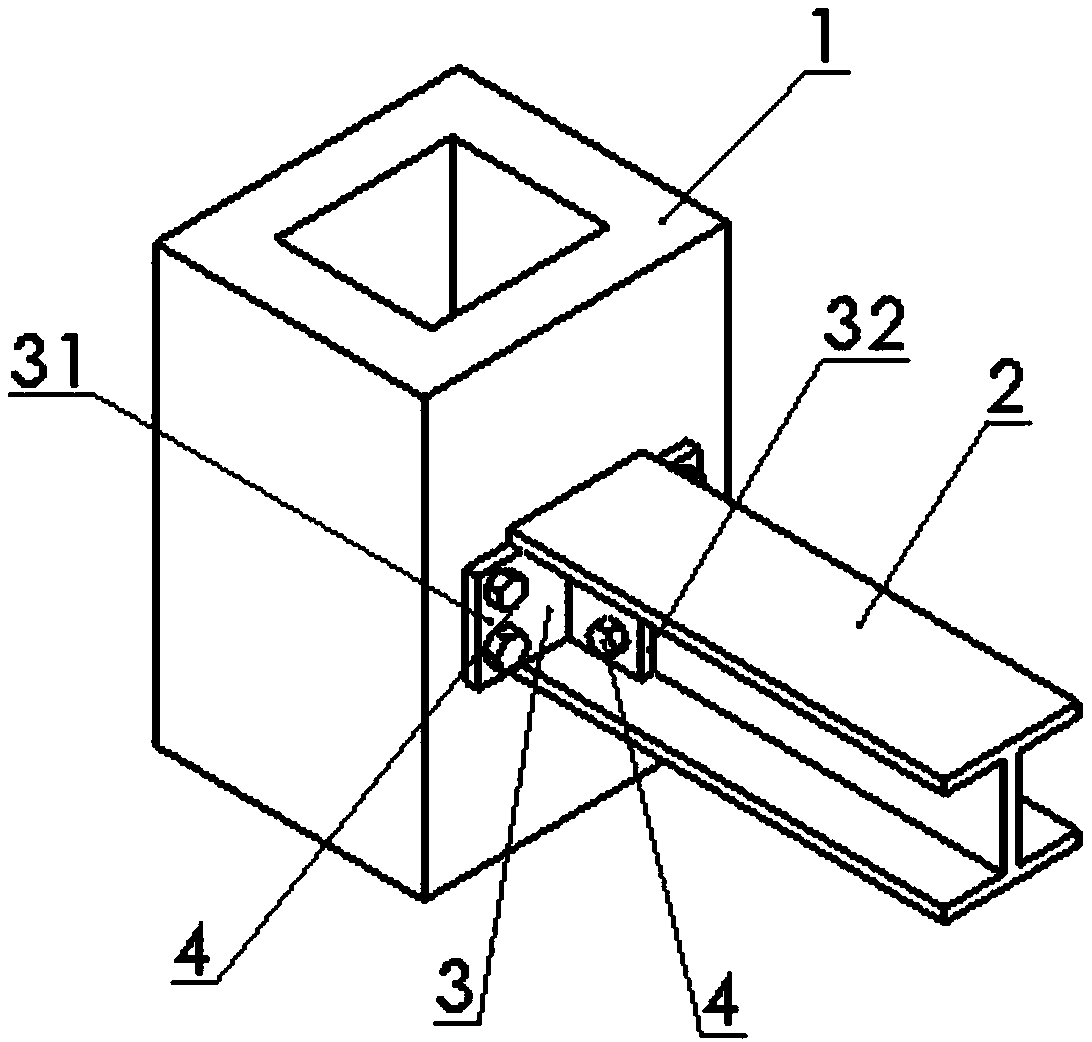

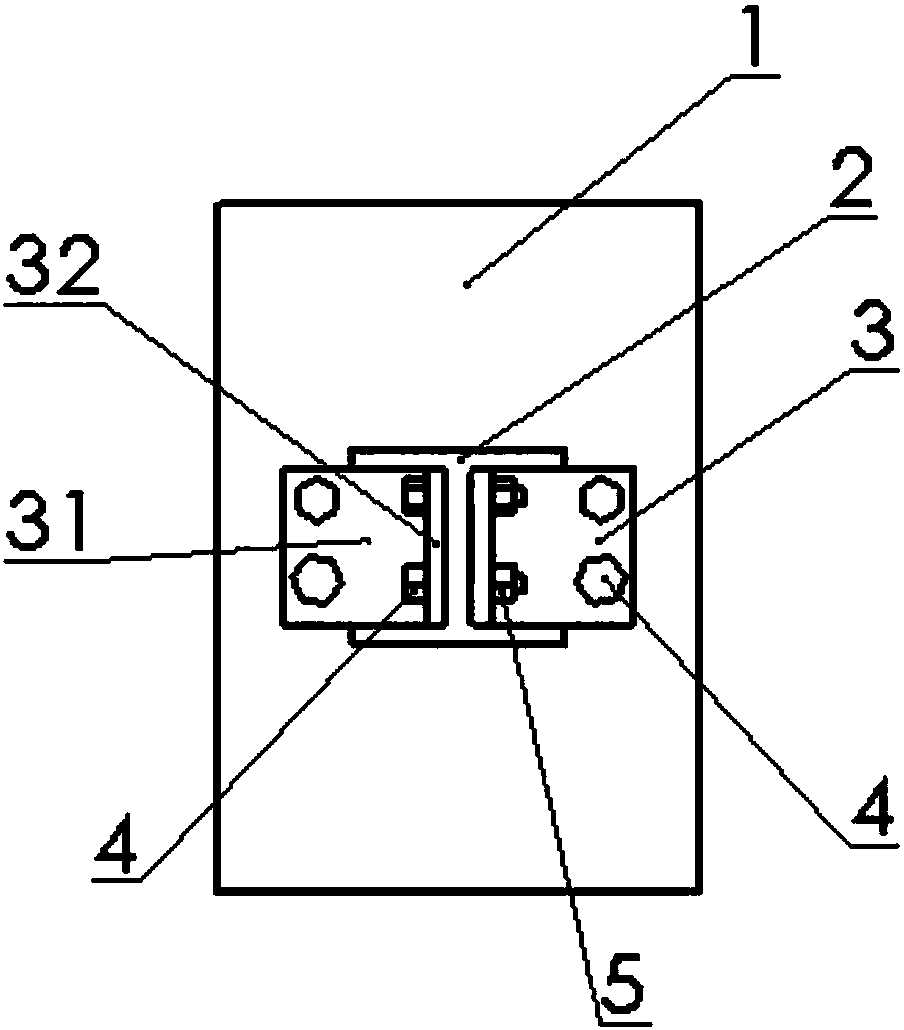

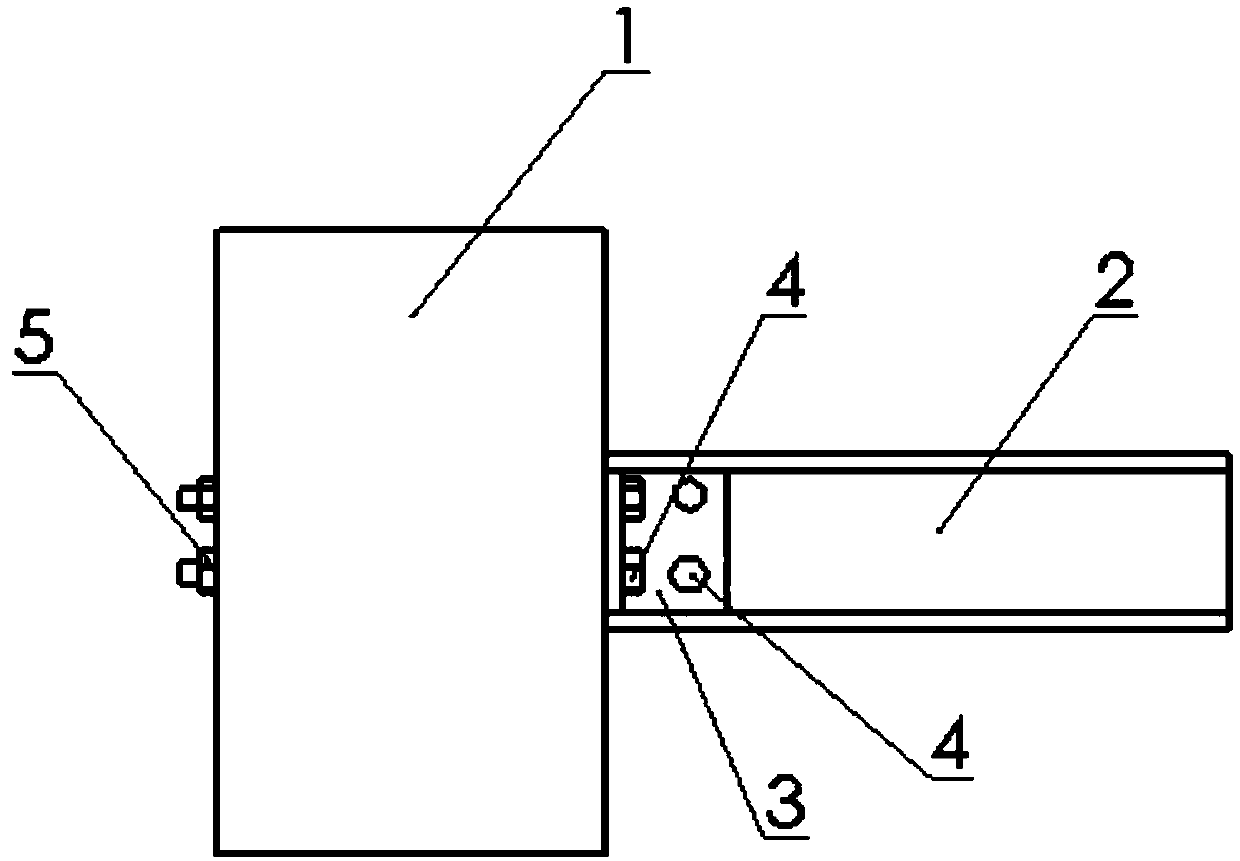

Connection structure of H-shaped steel and concrete rectangular steel column

InactiveCN109797847AHigh strengthAvoid pouring discontinuitiesBuilding constructionsSteel columnsUltimate tensile strength

The invention provides a connection structure of H-shaped steel and a concrete rectangular steel column. The connection structure comprises the rectangular steel column, the H-shaped steel and a connection unit; the H-shaped steel is fixedly installed on a side of the rectangular steel column through the connection unit; the connection unit comprises a connection plate and a fixed element, and theconnection plate is respectively in close contact with the H-shaped steel and the rectangular steel column. The connection structure described in the invention adopts a thread-fastened connection mode, the problem that the joint strength of the rectangular steel column and the H-shaped steel is lowered due to the existence of welding thermal stress after welding connection is avoided, the problemthat the whole strength of a concrete structure is reduced as the local deformation of the rectangular steel column caused by welding gives rise to concrete pouring discontinuity is avoided, and theexpenditure of time for carrying out the welding connection at a construction site is simultaneously reduced.

Owner:新昌县瑞博装饰材料有限公司

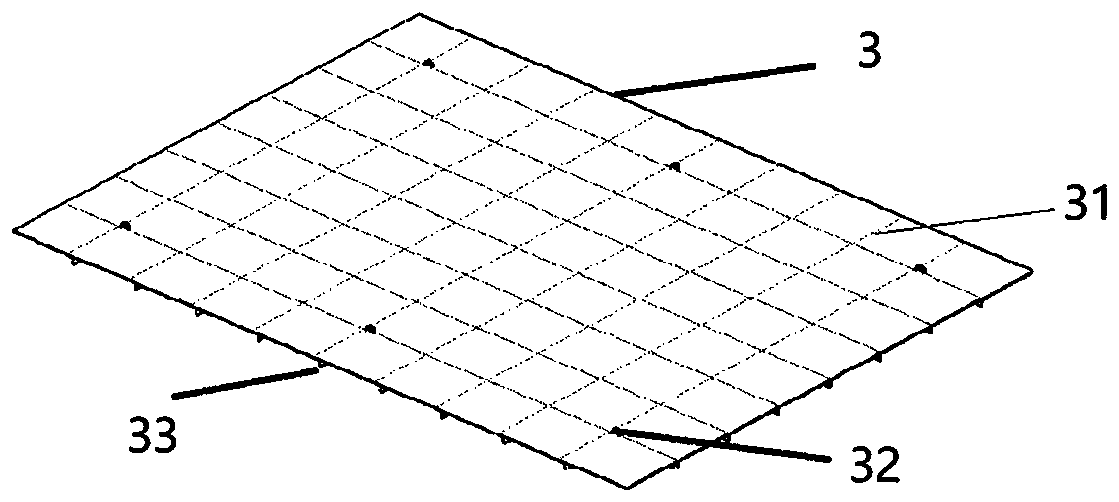

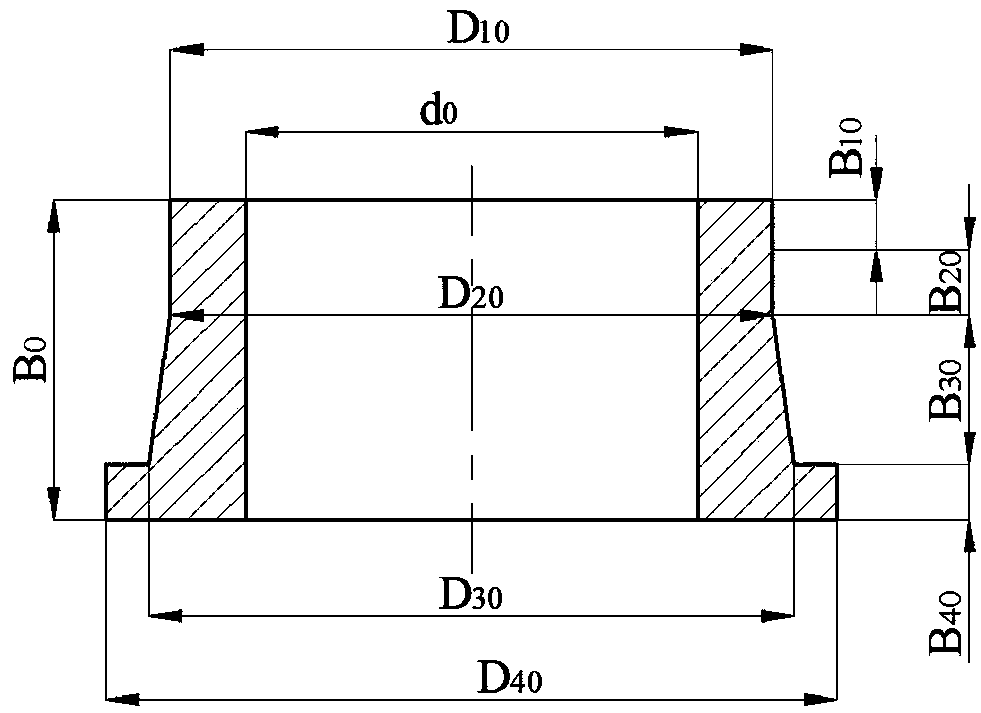

Old rolling forming method for tapered roller bearing inner ring

The present invention discloses cold rolling forming method for tapered roller bearing inner ring, comprising the following steps of: S1, dividing the ring blank into a smoothly connected ring blank small cylinder, a ring blank small round table body, a ring blank large round table body and a ring blank large cylinder in the height direction sequentially; S2, forming a rolling groove by the working surfaces of a drive roller, a core roller and a guide roller. The drive roller, the core roller and the guide roller are both designed as an I-shaped structure, the working surface shape of the drive roller and the guide roller is consistent with the shape of the outer surface of the inner ring member, the working surface shape of the core roller is consistent with the shape of the inner surfaceof the inner ring member. The flanges at the upper and lower ends of the drive roller and the core roller and the guide roller are axially constrained to the both faces of the ring blank, respectively, driving roller to rotate. At the same time, the core roller performs the radial feed motion to perform cold rolling forming on ring blank. The cold rolling forming method for tapered roller bearinginner ring has the advantages that forming precision is high, and product quality, material utilization rate and processing efficiency can be improved.

Owner:WUHAN UNIV OF TECH

Method for treating oxide layers of multilayer heat treatment surface of explosive composite plate

InactiveCN102581735AReduce manufacturing costSimple processPolishing machinesComposite plateUltimate tensile strength

The invention provides a method for treating oxide layers of a multilayer heat treatment surface of an explosive composite plate. The method includes: polishing the metal multilayer surface by the aid of a polishing tool before heat treatment of the explosive composite plate; and then carrying out heat treatment. The explosive composite plate is obtained by the aid of the technological method after heat treatment, the multilayer surface is transparent or semi-transparent and lightly brown and white, and an oxide cover is thin, appears similar to a 'floating rust' layer on the metal multiplayer surface, does not need to be treated or can be slightly treated by a mechanical method or a chemical method. The method is simple in process and convenient in operation, materials and working hours are remarkably saved, and loss of the thickness of the multilayer surface is greatly reduced. In addition, the oxide cover of the explosive composite plate can be effectively prevented during heat treatment, consumption of materials and consumption of working hours are reduced, labor intensity is reduced, and production cost is saved.

Owner:LUZHOU NORTH CHEM IND

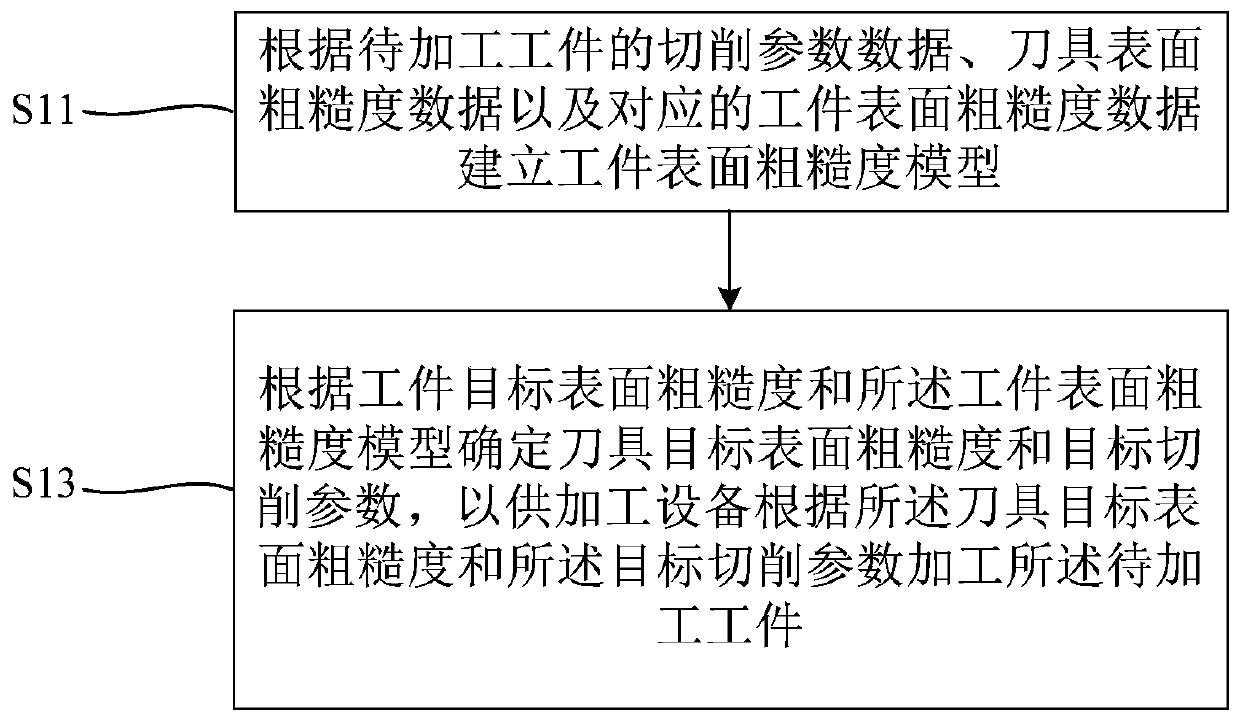

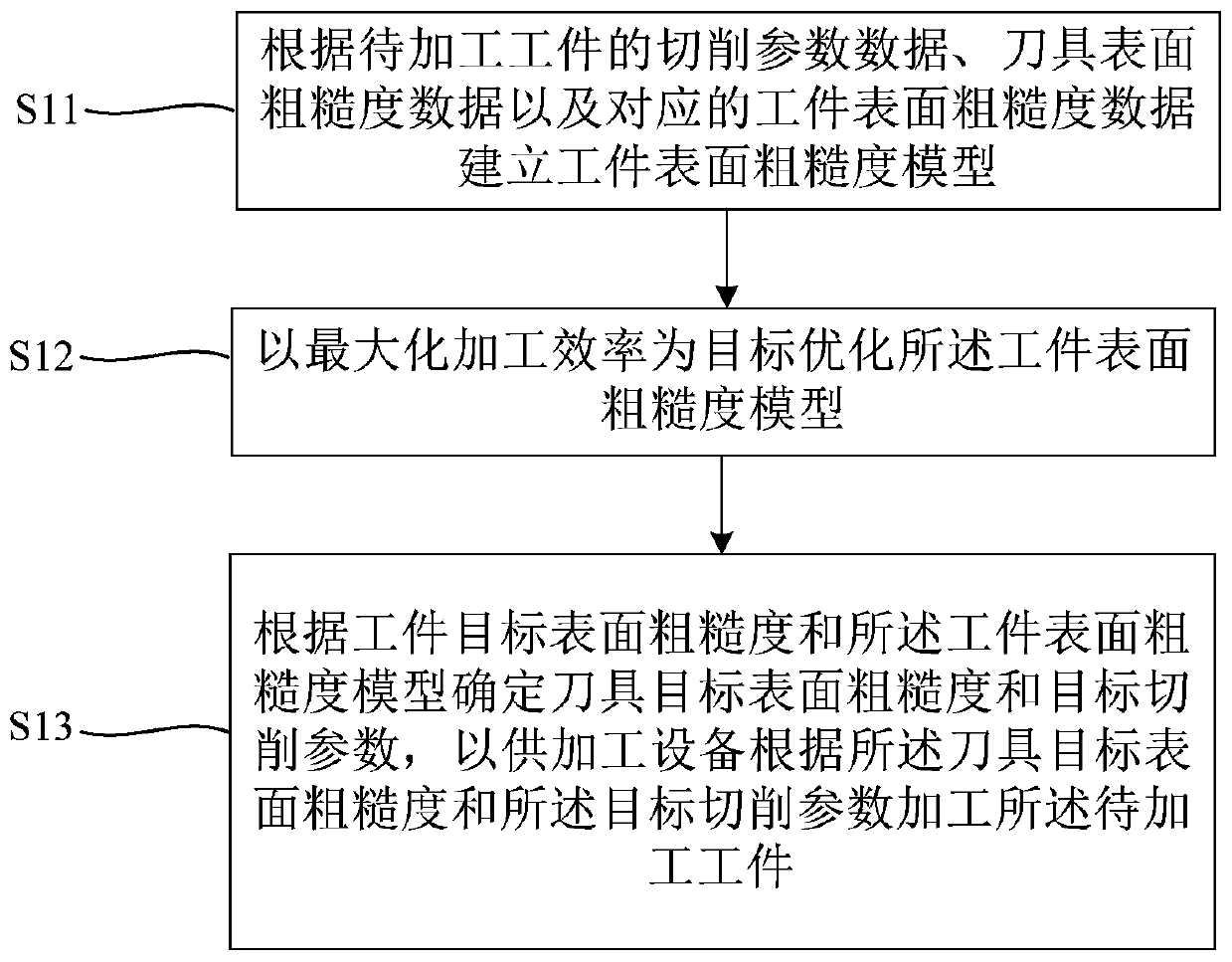

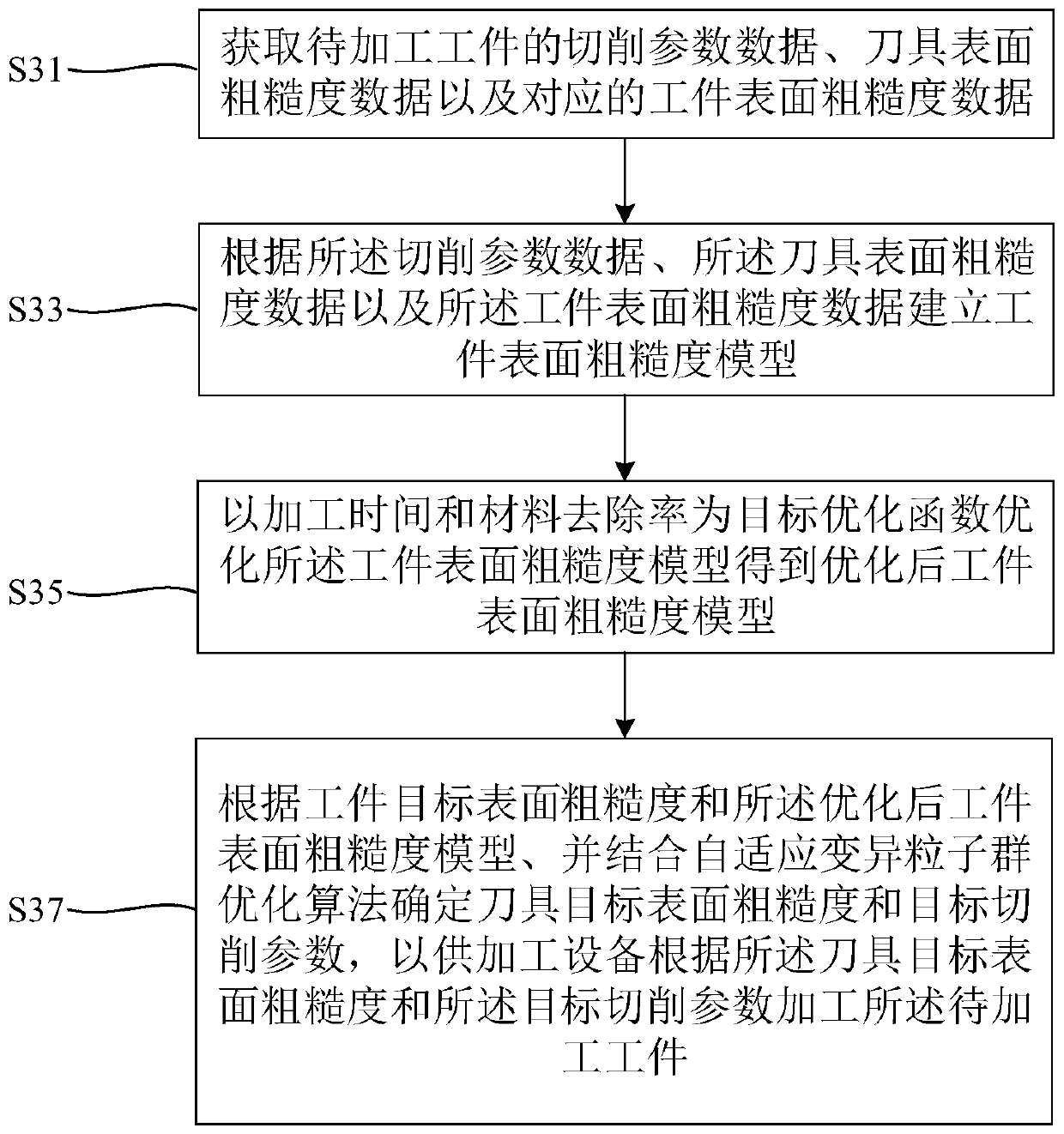

Workpiece surface roughness control method and device and numerical control machining equipment

InactiveCN110509096AReduce man-hour consumptionReduce processing costsMetal working apparatusAdaptive controlSelf adaptiveParticle swarm optimization

The embodiment of the invention discloses a workpiece surface roughness control method and device and numerical control machining equipment. The workpiece surface roughness control method comprises the steps: cutting parameter data of a workpiece to be machined, cutter surface roughness data and corresponding workpiece surface roughness data are acquired; a workpiece surface roughness model is established according to the cutting parameter data, the cutter surface roughness data and the workpiece surface roughness data; the workpiece surface roughness model is optimized with machining time andmaterial removal rate as a target function to obtain the optimized workpiece surface roughness model; and according to workpiece target surface roughness and the optimized workpiece surface roughnessmodel, self-adaptive variable particle swarm optimization algorithm is combined, and cutter target surface roughness and target cutting parameters are determined, so that the machining equipment canmachine the workpiece to be machined according to the cutter target surface roughness and the target cutting parameters. According to the workpiece surface roughness control method, workpiece surfaceroughness can be accurately controlled.

Owner:XIANGTAN UNIV

Processing method of fire sprinkler cooling device

InactiveCN102294578ASolve processing efficiencySolve the processing qualityThread cutting toolsFire sprinklerEngineering

The invention proposes a processing method for a fire-fighting spray cooling device. Processing steps: 1. Weld flanges at both ends of the straight pipe; 2. Put the straight pipe after welding the flange on the pipe bender and bend it according to the design arc to make an arc bend; 3. On the arc bend Drill holes according to the angle, spacing and aperture required by the design; 4. Use the self-heating rotary extrusion die to perform rotary extrusion and stretching on the drilled holes to make the nozzle interface; 5. The nozzle after extrusion and stretching Sprinkler interface threads are processed in the interface to make nozzle interfaces with connection threads. In this method, the flange is welded on the straight pipe first, and then the pipe is bent, and the nozzle interface is formed by hot extrusion and stretching on the curved pipe. It has the advantages of less processing links, easy to grasp the processing position, reducing the consumption of working hours, reducing labor intensity, and ensuring the processing quality. It is suitable for production and processing of fire sprinkler cooling devices and other fire fighting equipment.

Owner:HULUDAO GUOLI IND FIRE ENVIRONMENTAL EQUIP MFG

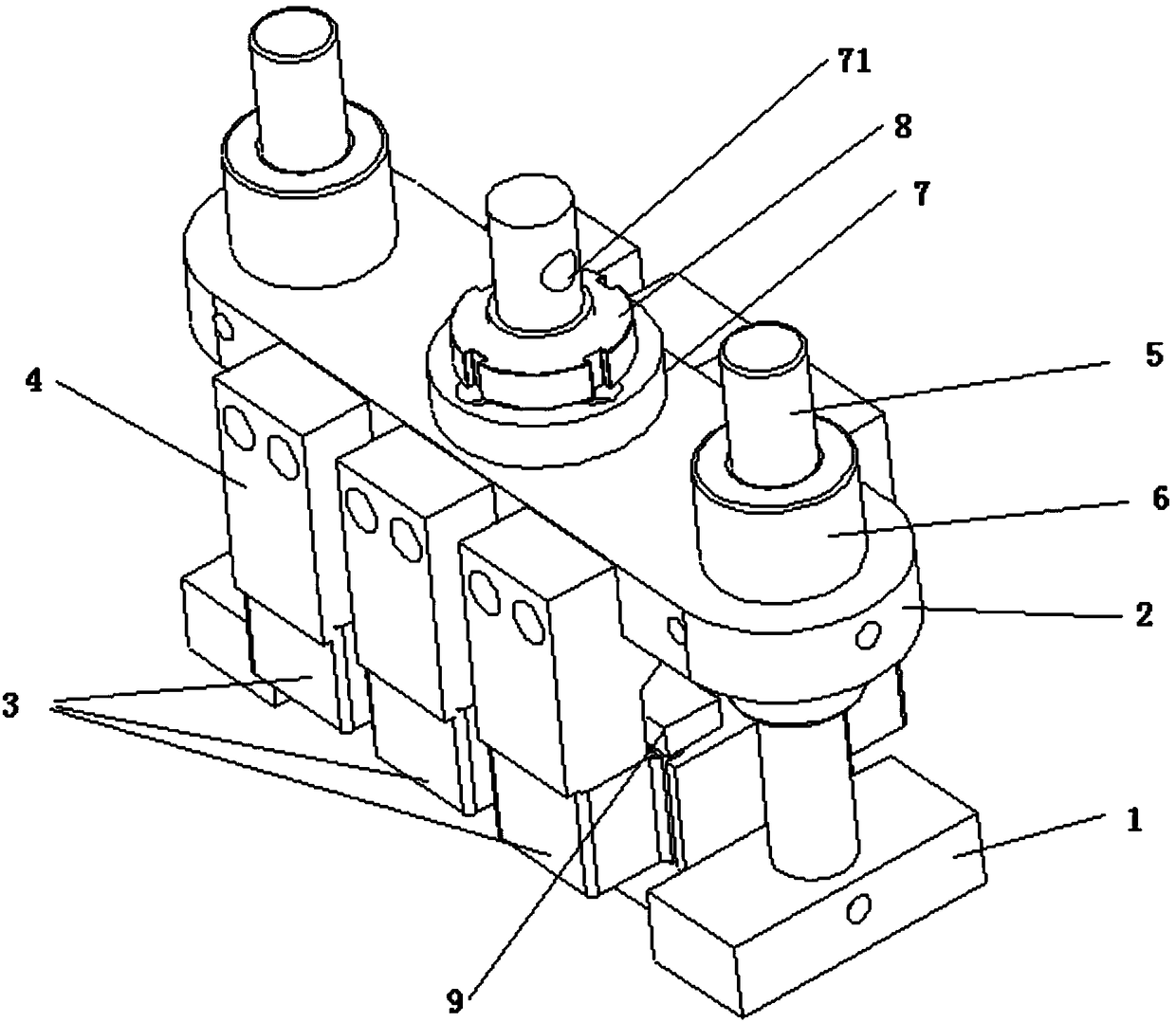

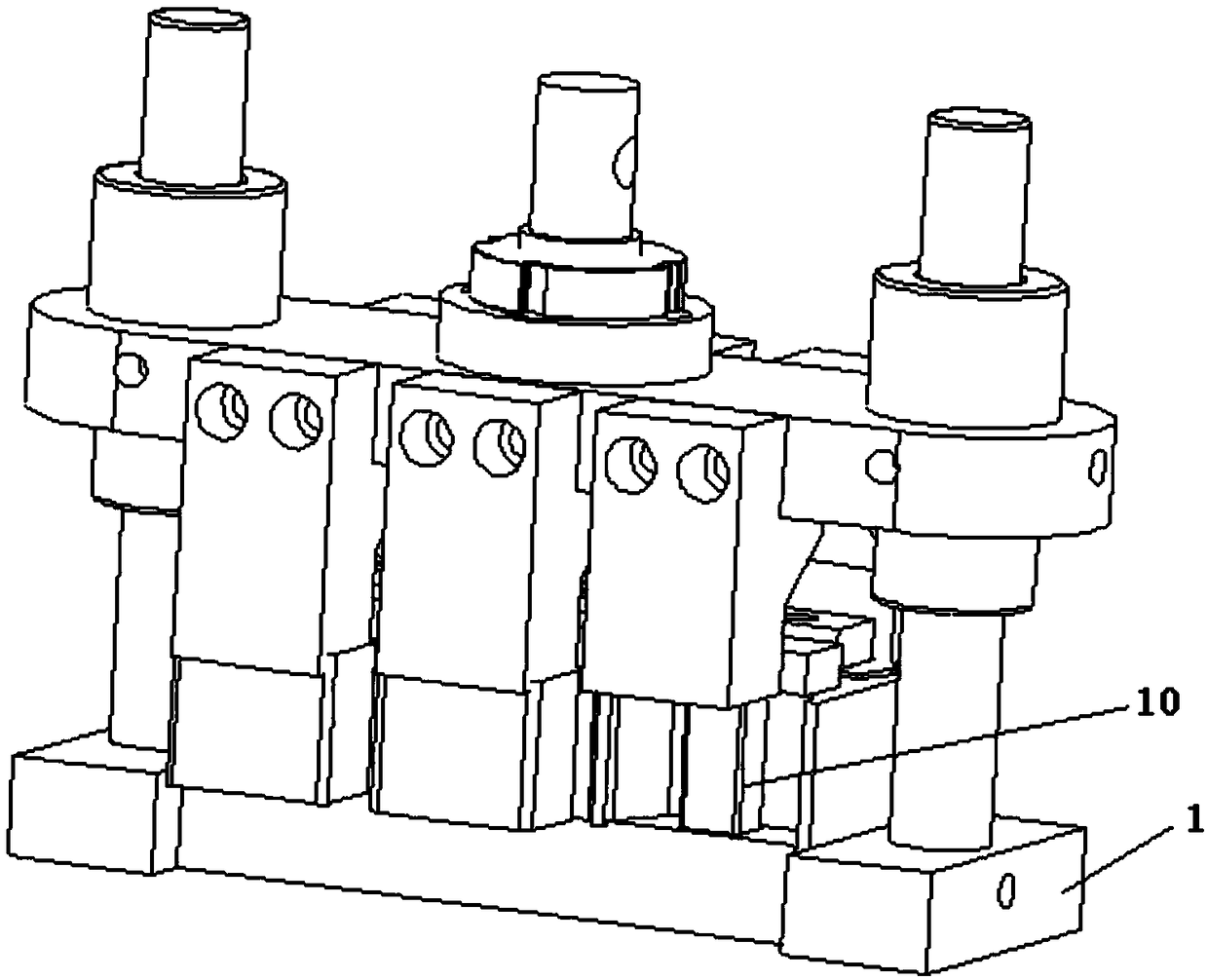

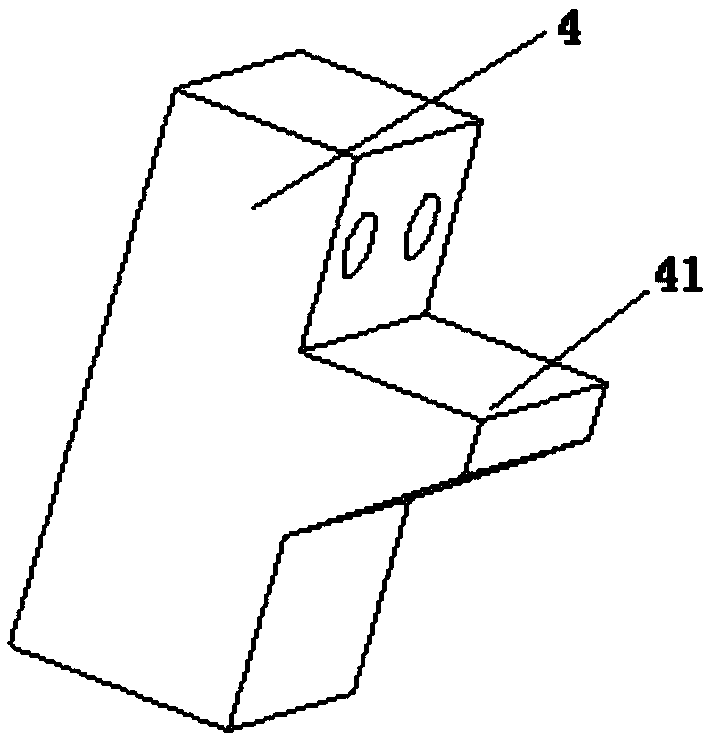

Bonding material shearing strength testing tool and bonding material shearing strength tester

PendingCN108732040AShort test intervalsTest numerical scienceMaterial strength using steady shearing forcesMaterials scienceStrength testing

The invention provides a bonding material shearing strength testing tool and a bonding material shearing strength tester. The bonding material shearing strength testing tool comprises: a base, a plurality of detection blocks and a plurality of pressing blocks, wherein the detection blocks are arranged in parallel and are arranged in the base; each detection block comprises a first structure body and a second structure body, which are adhered, and a bonding surface is arranged between the first structure body and the second structure body; the distribution of the pressing blocks is consistent to the distribution of the detection blocks; the pressing blocks are used for acting on the second structure bodies; the plurality of pressing blocks are distributed in a ladder shape and each pressingblock is cut in sequence; therefore, the pressing block with the greatest height is used for applying a shearing force on the corresponding detection block at first, and the second structure body iscut off from the corresponding first structure body; then other pressing blocks are cut in sequence according to the height sequence of the pressing blocks; the plurality of detection blocks can be detected in one step and the efficiency is relatively high.

Owner:VANGUARD BEIJING TECH DEV

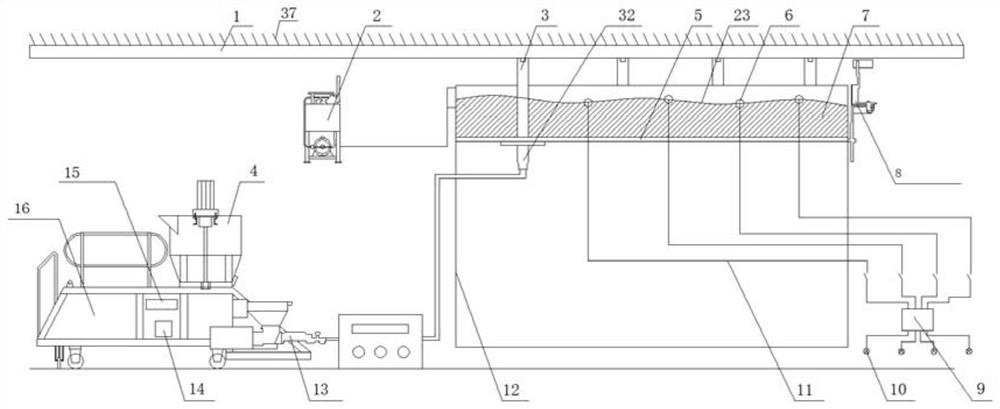

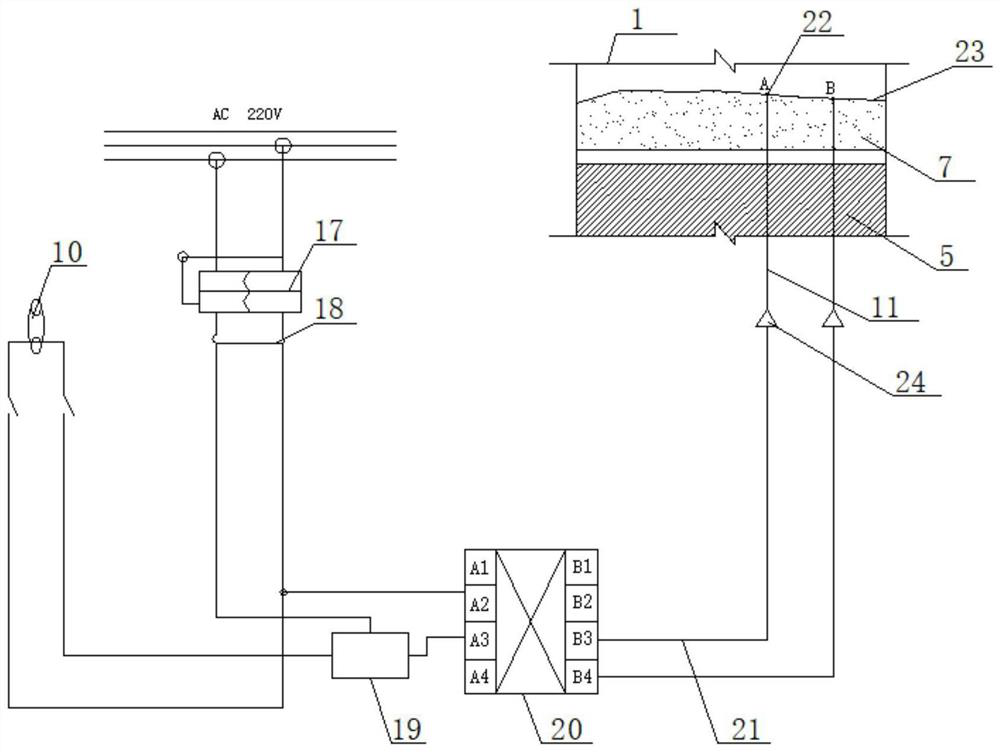

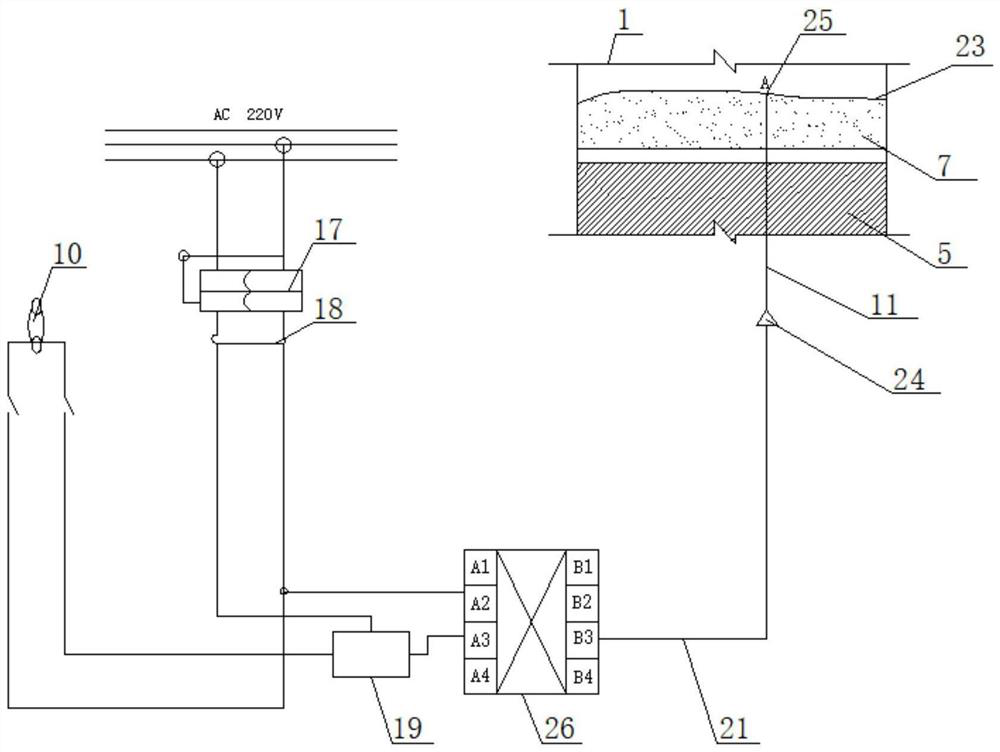

Tunnel vault anti-void early warning device and concrete real-time monitoring method thereof

PendingCN114658444AThere is no blocking problemNo quality defectsMining devicesUnderground chambersArchitectural engineeringEngineering

The invention discloses a tunnel vault anti-void early warning device which comprises a grouting vehicle and a primary building trolley end mold, and the grouting vehicle is provided with a sewage treatment system, a monitor and an effect evaluation system. According to the tunnel vault anti-void early warning device and the concrete real-time monitoring method and the real-time observation process thereof, the tunnel lining arch self-alarm anti-void construction technology based on the cloud video technology is adopted, in the construction process, the secondary lining procedure and the grouting procedure basically belong to parallel procedures, grouting can be completed immediately while secondary lining is completed, and the construction efficiency is improved. The problem of grouting pipe blocking does not exist, meanwhile, the secondary lining pouring and filling grouting conditions are observed in real time through the cloud video technology, the tunnel vault disengaging prevention early warning is utilized, the tunnel vault concrete pouring compactness condition is checked, an alarm is given in time, vault disengaging is effectively prevented, the tunnel lining construction quality is improved, the lining construction defects are overcome at a time, and the construction efficiency is improved. The method has obvious comprehensive economic benefits, and can greatly save later-stage cost.

Owner:赵立财

Rhinestone distribution method for clothes

The invention relates to a rhinestone distribution method for clothes. The rhinestone distribution method is characterized by comprising the following steps of: 1, selecting a positioning template, and making marking points on the positioning template; 2, placing rhinestones on the corresponding marking points one by one, and making the backs of the rhinestones be in contact with the positioning template; 3, covering the positioning template by adhesive paper, and transferring all the rhinestones distributed on the positioning template to the adhesive paper; 4, moving the adhesive paper to the clothes, and making the rhinestones correspond to set positions one to one; 5, ironing the clothes, and fixedly sticking the rhinestones to the clothes; and 6, dismounting the adhesive paper, and finishing distributing the rhinestones on the whole clothes. With the rhinestone distribution technology, a plurality of rhinestones can be arranged, heated, stuck and fixed. Compared with the existing rhinestone distribution method, the rhinestone distribution method has the advantages that the working time is only 1 / 10 of the original working time or even shorter, so that the working time is saved, and the working efficiency is greatly improved; the working time is saved, so that the manufacturing cost of the clothes is reduced; and the accuracy of the rhinestone distribution positions is improved.

Owner:TIANJIN YINGDAK

Method applied to structural design of power transformer and material utilization amount statistics

InactiveCN104239651AShorten the timeSolve problems that cannot be auditedInductances/transformers/magnets manufactureSpecial data processing applicationsTransformerMicrosoft Office

The invention relates to a method applied to a structural design of a power transformer and material utilization amount statistics. According to the method applied to the structural design of the power transformer and the material utilization amount statistics, the CAD software is not adopted, a procedure is designed in the Microsoft Office Excel, meanwhile, the electromagnetic design and the structural design of the power transformer and statistical calculation of material utilization amount are carried out, the problems that errors are often made on the aspect of drawing size in the structural design of the power transformer and the errors can not be thoroughly checked are solved, consumption of labor time is reduced, and work efficiency and drawing quality are improved. The statistical calculation time of the material utilization amount is shortened after the structural design of the power transformer is completed. The method applied to the structural design of the power transformer and the material utilization amount statistics has the advantages of being safe, feasible and convenient to implement.

Owner:福建省闽西天龙变压器有限公司

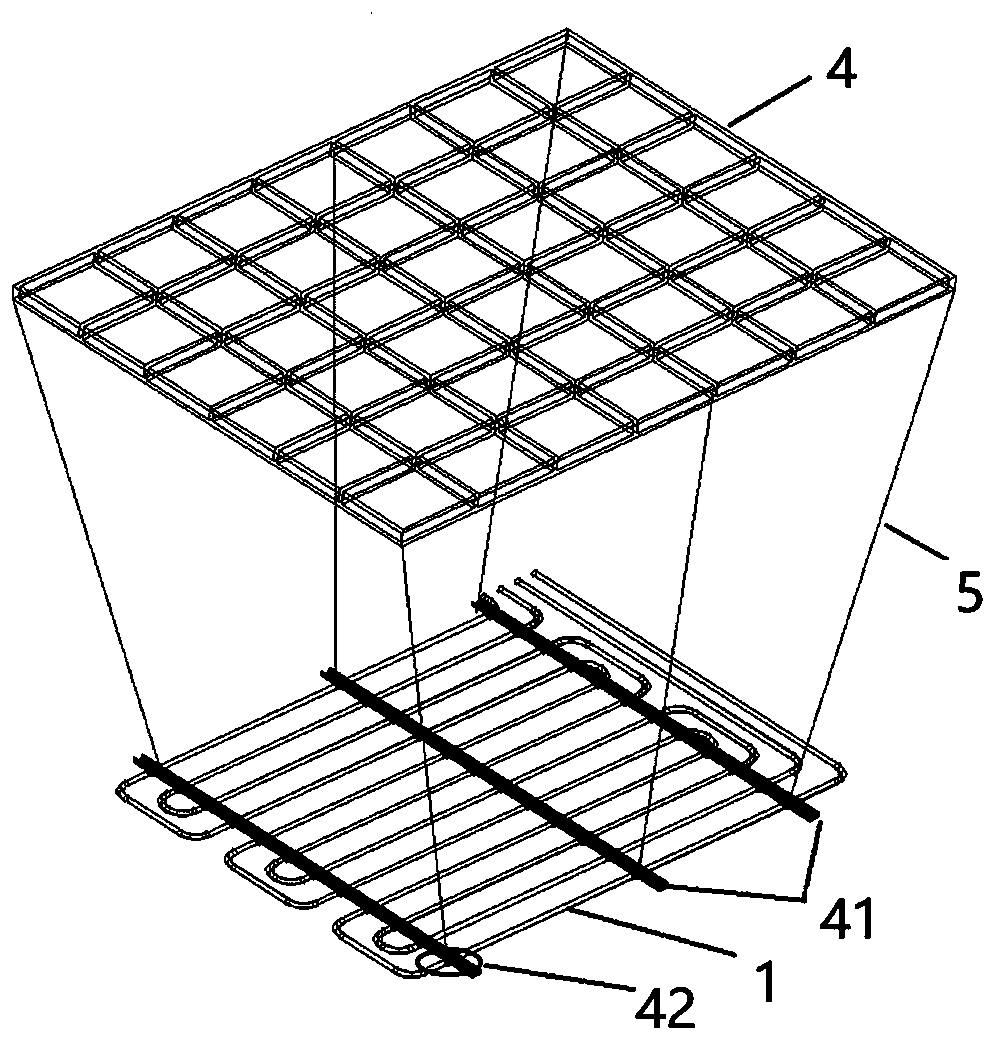

Steel reinforcement cage for construction

The invention relates to a steel reinforcement cage for construction. The steel reinforcement cage comprises a plurality of circular steel bars and a plurality of first steel bars, which are arrangedin a ring shape. The first steel bars are fixedly welded to the circular steel bars. The circular steel bars are sequentially and uniformly arranged along the length direction of the first steel bars.The provided steel reinforcement cage is prefabricated in a factory, automatic bending and welding facilities are used to produce the steel reinforcement cage, the efficiency is largely improved, andthe consumption of onsite labor and time is reduced.

Owner:SUZHOU SHIHAO BUILDING MATERIAL NEW TECH ENG

Ship manufacturing method for pre-mounting steering engine base in segmentation step

The invention discloses a ship manufacturing method for pre-mounting a steering engine base in a segmentation step. The ship manufacturing method comprises the following steps of: carrying out segmentation on a deck of a steering engine room; drawing a gantry arrangement and reinforcement picture of an upper gantry of the deck of the steering engine room at a positive segmentation state; incorporating the gantry arrangement and reinforcement picture with a segmental fitting-out tray management list so as to ensure that the pre-mounting of the steering engine base is completed in a segmental manufacturing step, and the requirement on installation precision can be met; and conveying the deck of the steering engine room in a segmental manner to a next process in a positive state of the upper gantry. The steering engine base is welded before being coated in a segmental manner, so that the segmental fitting-out integrality can be improved. Therefore, the damage area of a coating layer of a ship stern ballast cabin is reduced, the risk of sand wash on the entire ship stern ballast cabin can be effectively reduced, a coating construction period is shortened, and a PSPC (Performance Standard for Protective Coatings) can be met.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

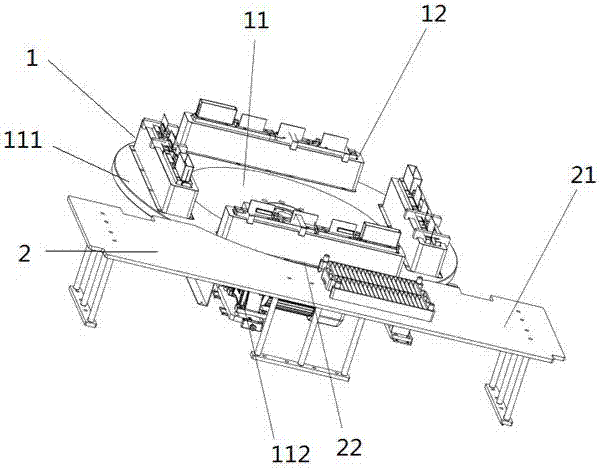

Liquid injection device and operating method thereof

InactiveCN108011070AOptimizing the liquid injection processIncrease productivityAssembling battery machinesFinal product manufactureVacuum pumpingEngineering

The invention relates to a liquid injection device. The liquid injection device is characterized by comprising a rotation transmission mechanism, wherein the rotation transmission mechanism comprisesa turntable, a plurality of jigs are uniformly arranged on a surface of the turntable, a loading and unloading mechanism, an expansion liquid injection mechanism, a vacuum-pumping liquid injection mechanism and a vacuum-pumping sealing mechanism are arranged on the turntable according to a process, and the jig positions are in one-to-one correspondence to the mechanisms. A machine originally requiring large occupancy area is highly integrated with a system, the limited space is utilized to the maximum extent by application of the turntable and a scale division assembly, meanwhile, the liquid injection process flow is optimized, the original multi-step complicated process is further simplified and integrated, the production efficiency is improved, and the time consumption is reduced.

Owner:惠州市至元智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com