Auxiliary device for manufacturing main bearing oil feeding pipe of marine diesel machine and main bearing oil feeding pipe manufacturing method

A technology for marine diesel engines and auxiliary devices, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of increasing accidents, consuming more manpower and time, and increasing transportation costs, so as to avoid duplication of labor, The effect of reducing costs and reducing man-hour consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The auxiliary device for the prefabrication of the main bearing oil inlet pipe of a large marine diesel engine and the prefabrication method for the main bearing oil inlet pipe of a large marine diesel engine of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention cannot be limited by this scope of protection.

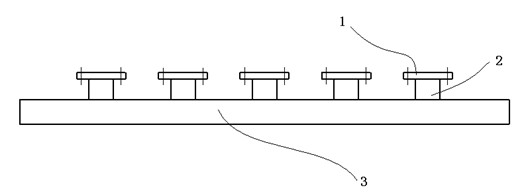

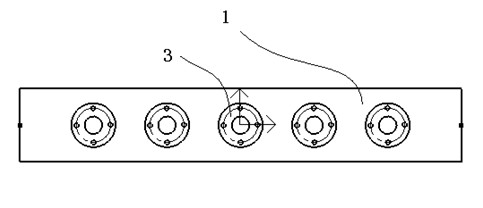

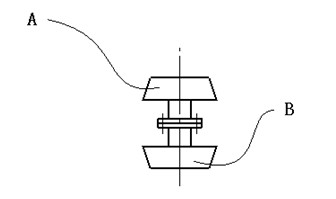

[0028] The structure of the marine large diesel engine main bearing oil inlet pipe prefabrication auxiliary device of the present invention can be obtained from figure 1 and figure 2 clearly see, figure 1 It is the front view structural diagram of the auxiliary device for the production of the main bearing oil inlet pipe on the marine diesel engine of the present invention, figure 2 It is a side structural view of the auxiliary device for making the oil inlet pipe of the main bearing on the marine diesel engine of the present invention. As can be seen from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com