Patents

Literature

46results about How to "Avoid tinkering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

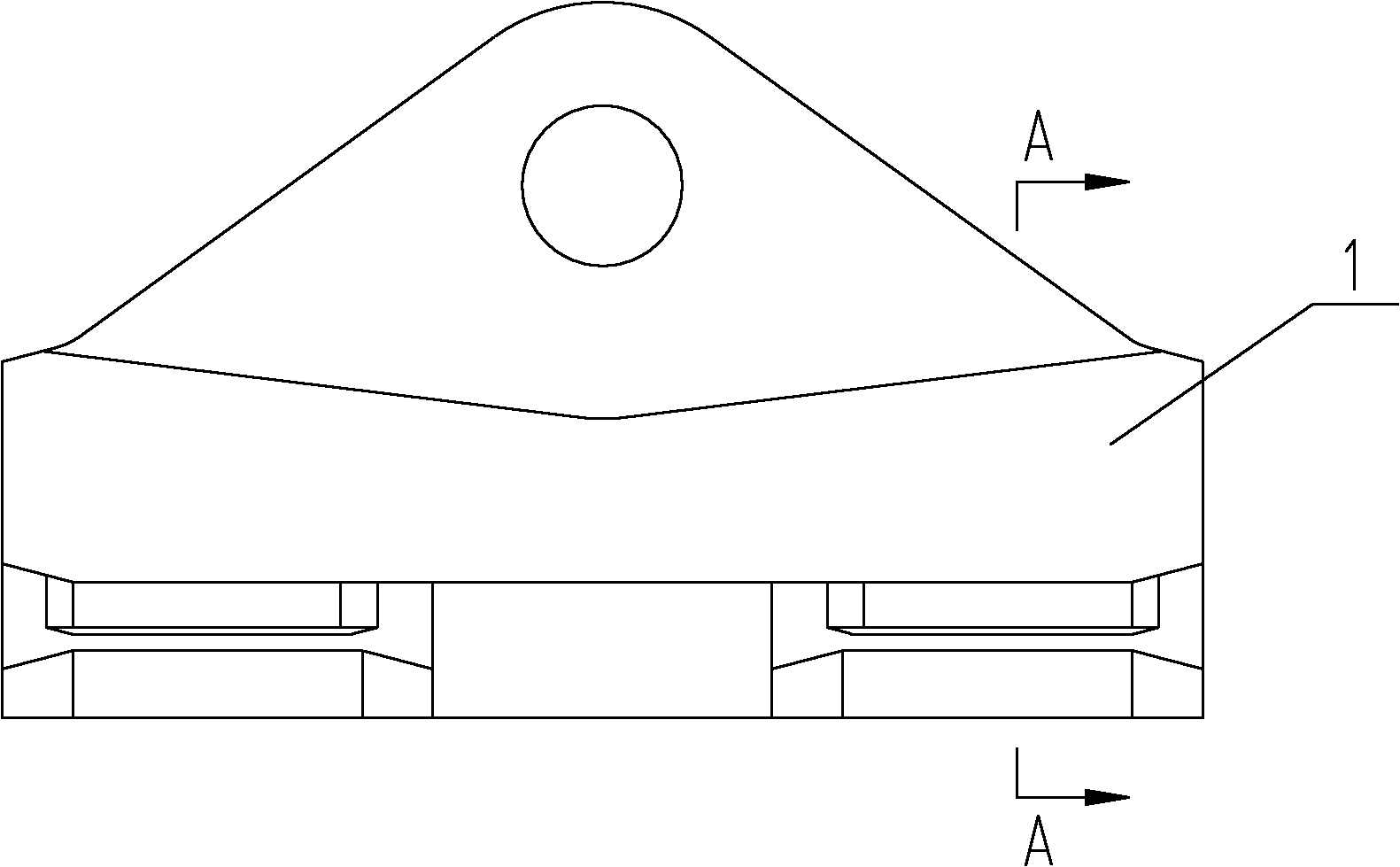

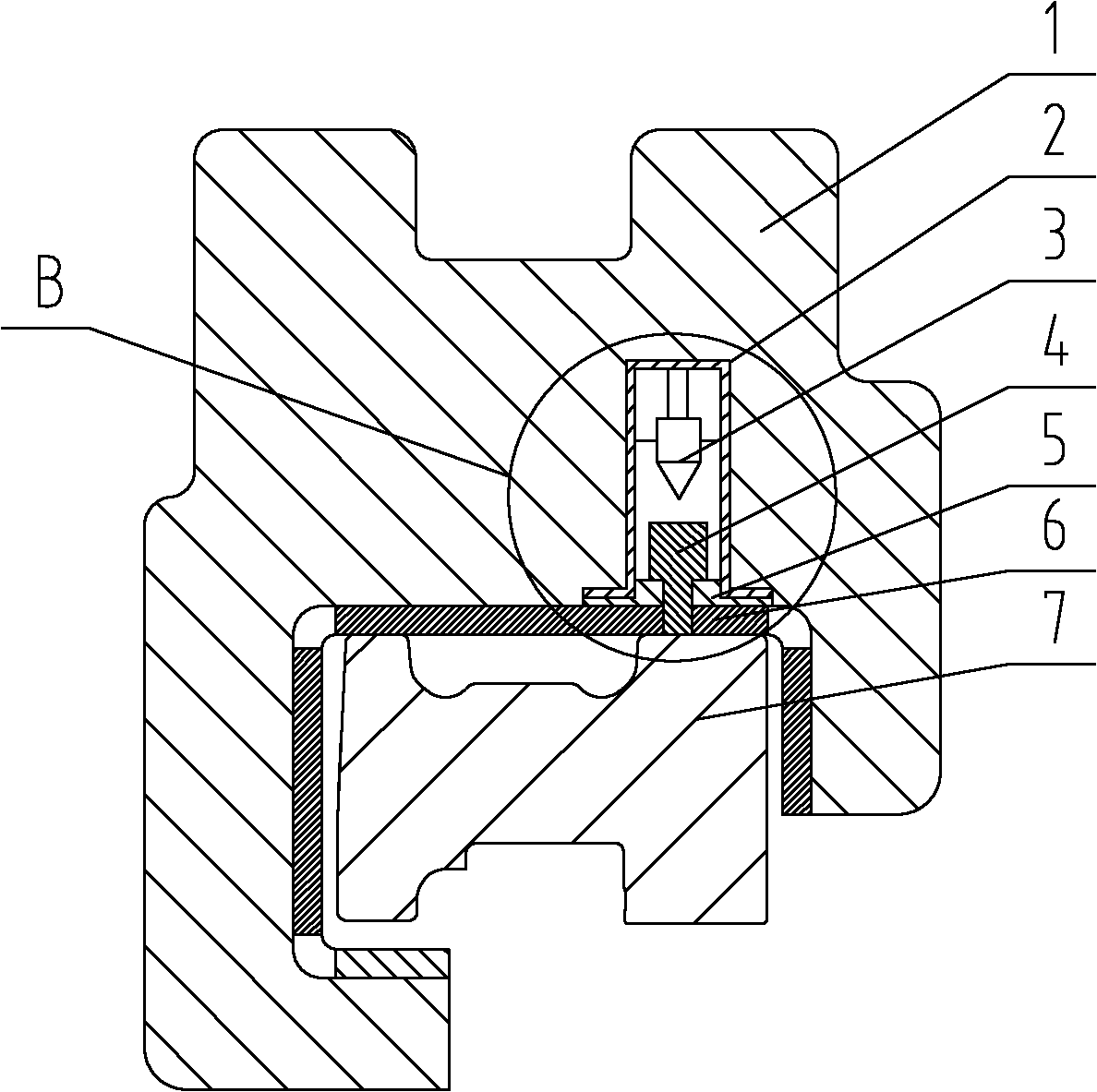

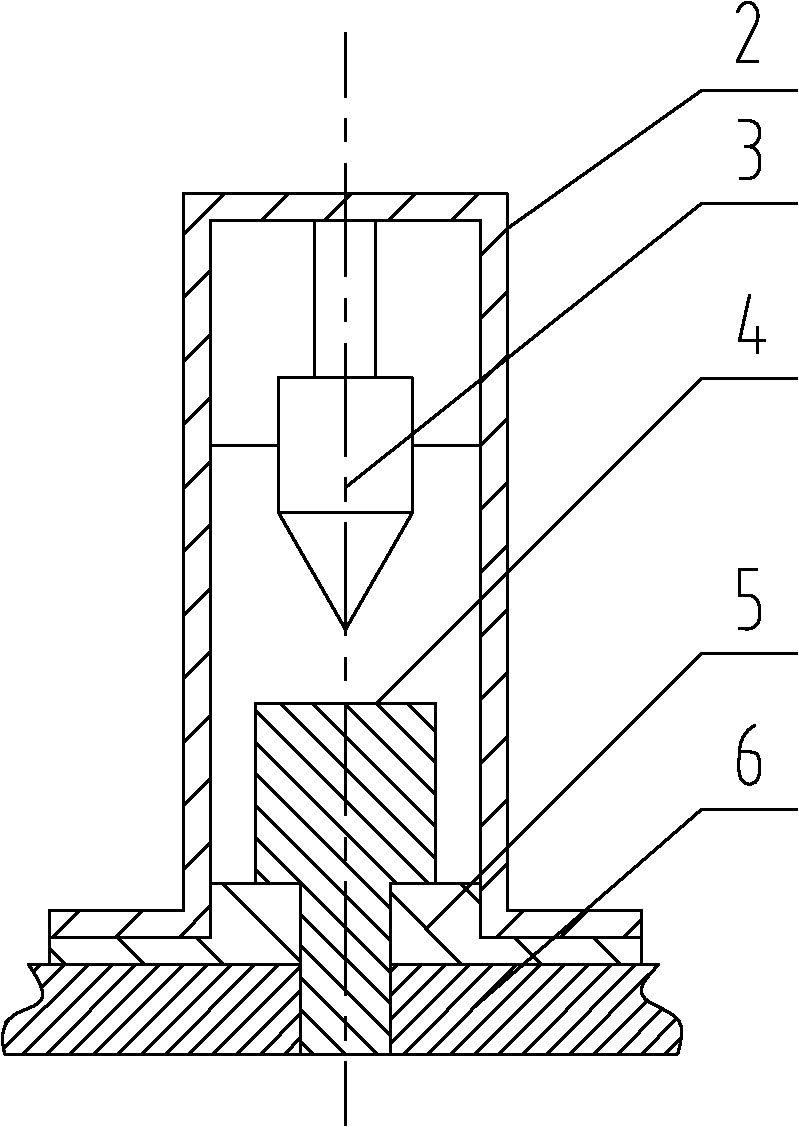

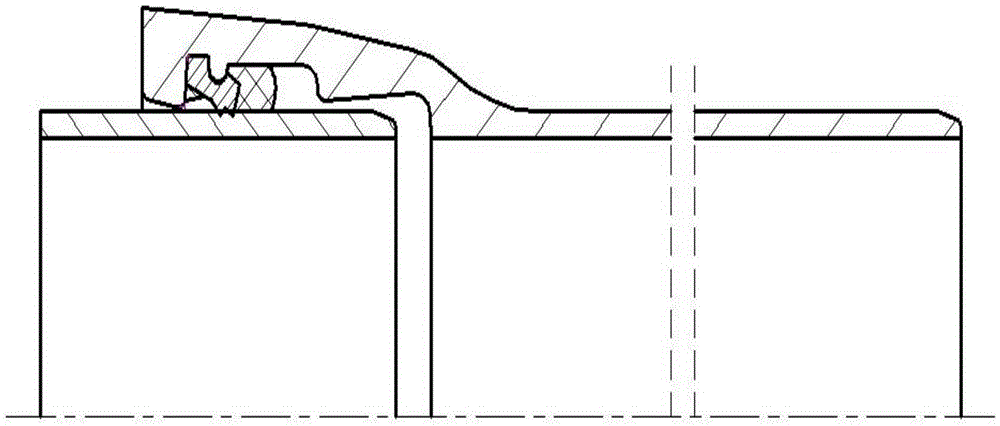

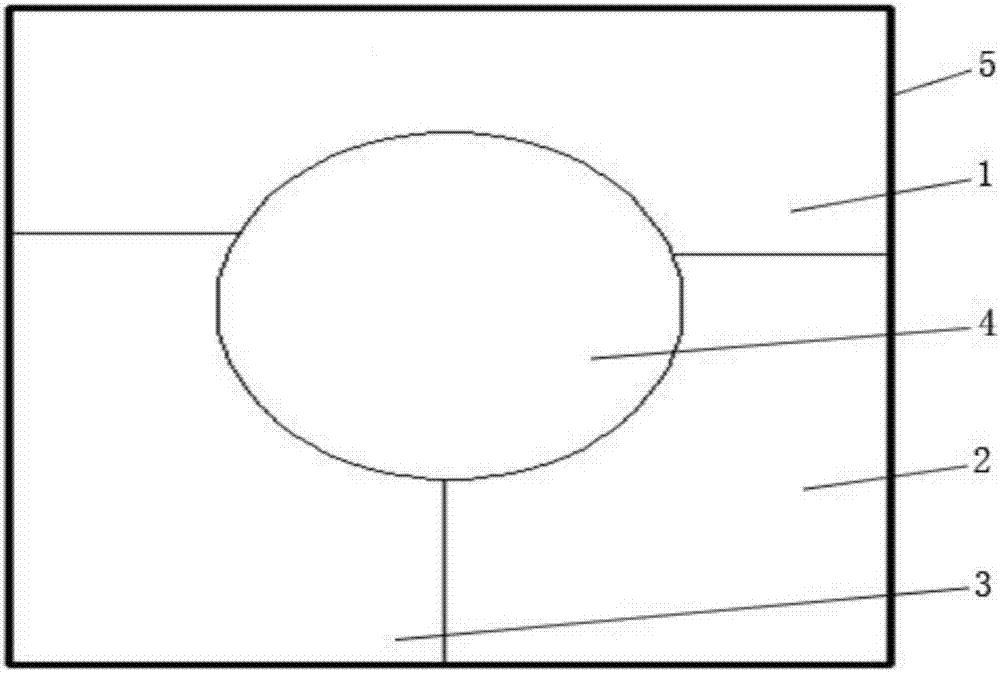

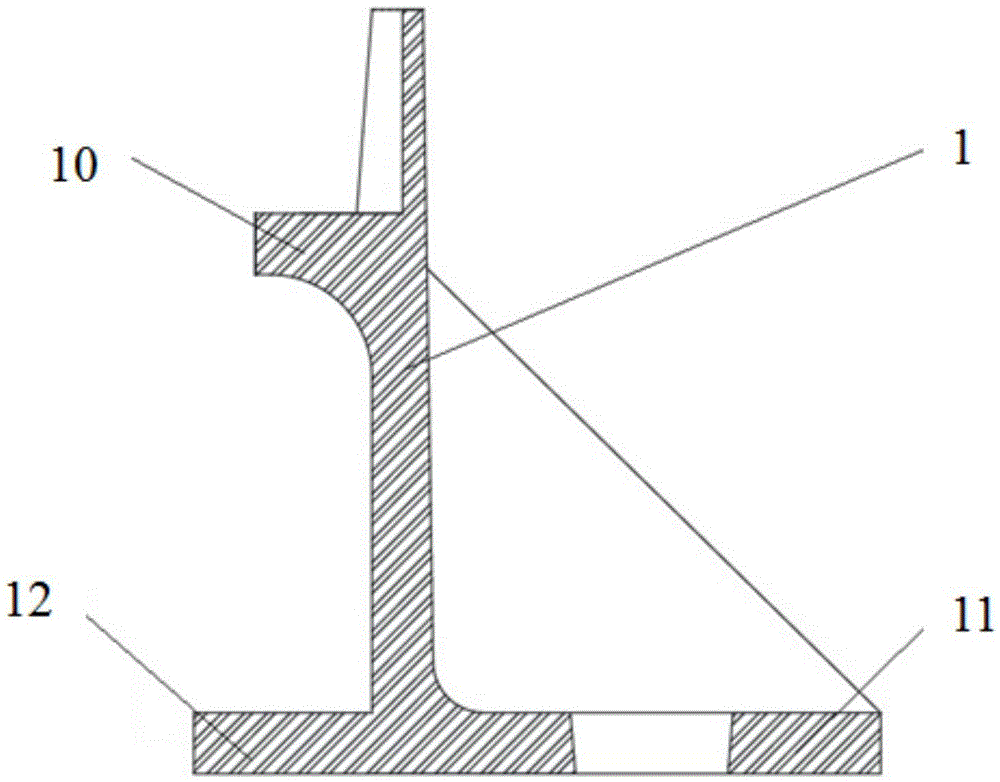

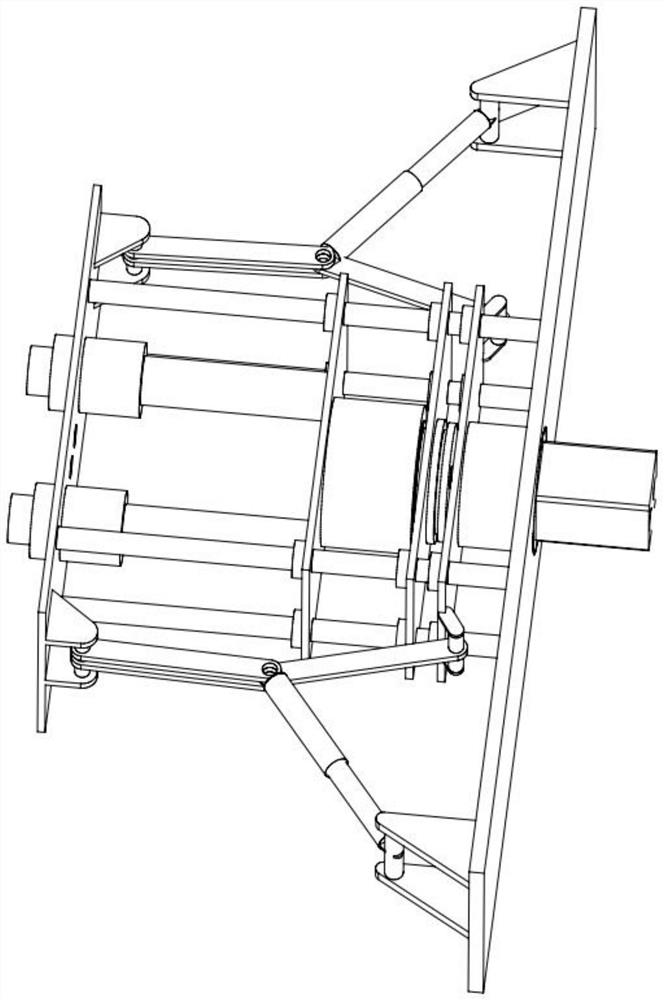

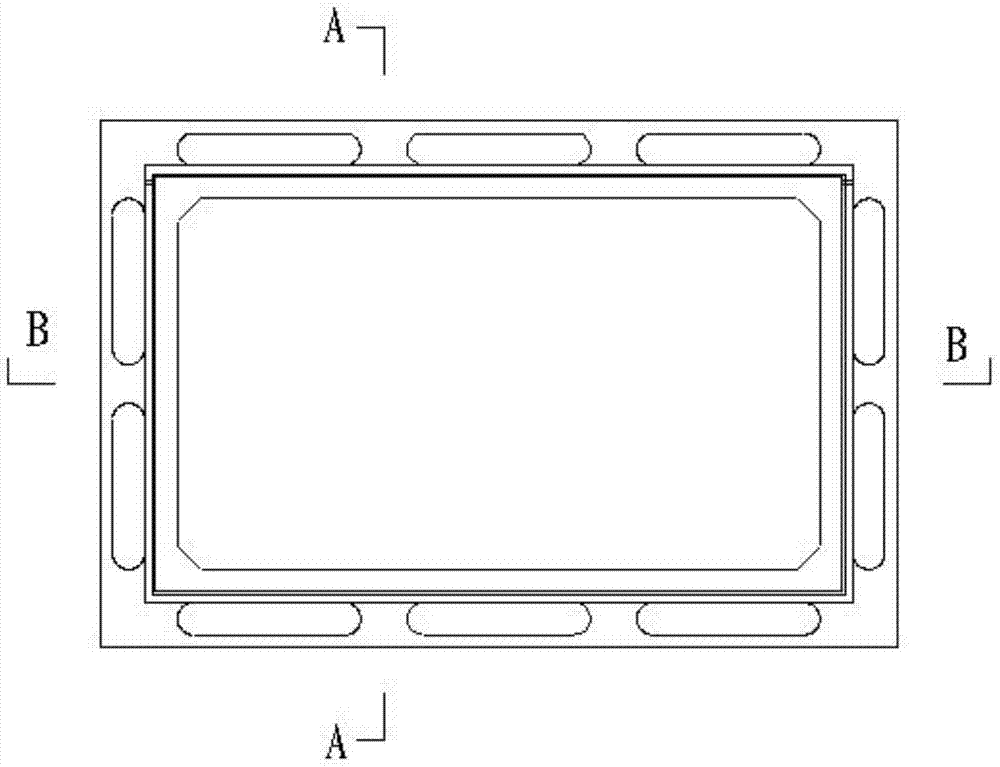

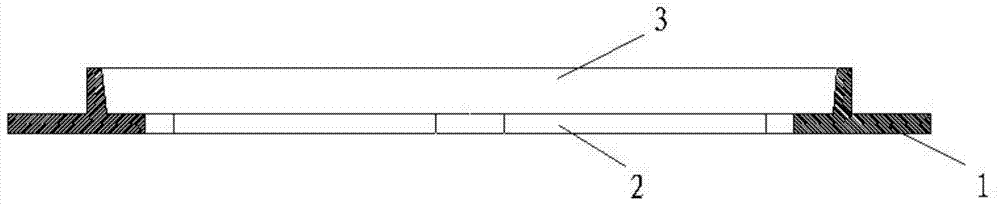

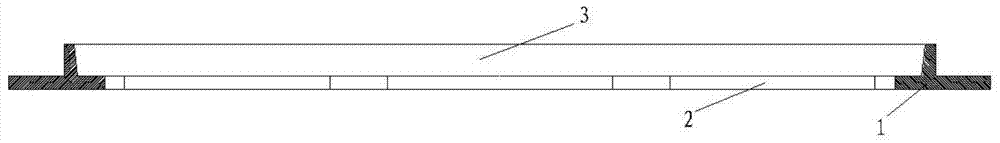

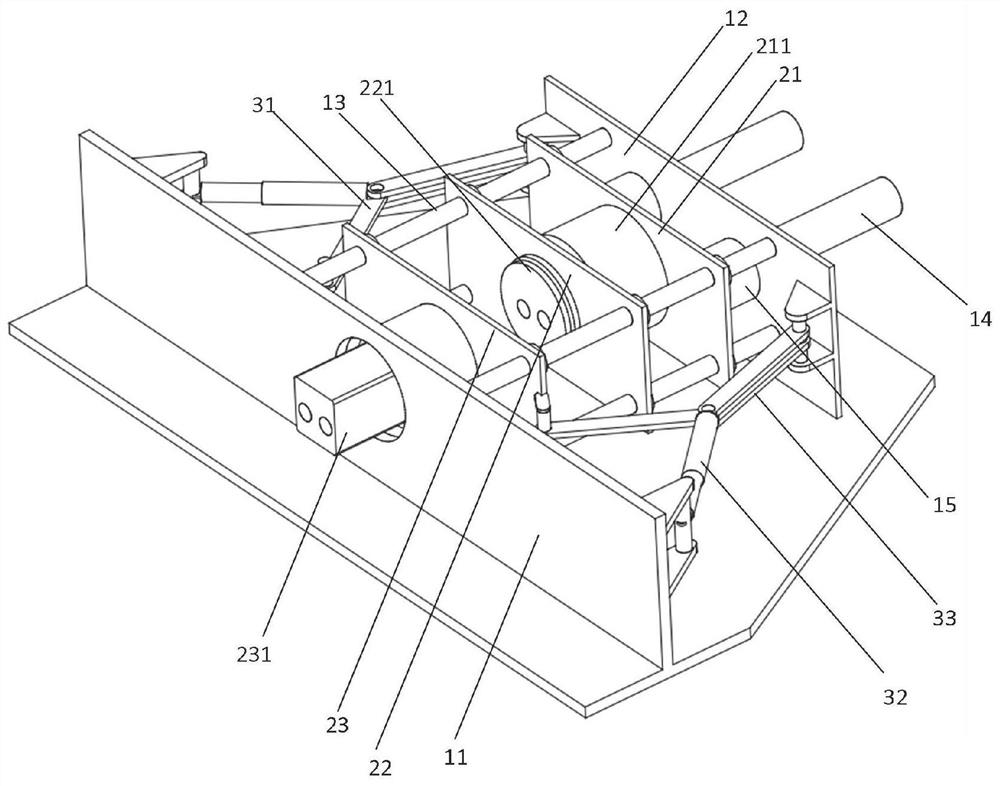

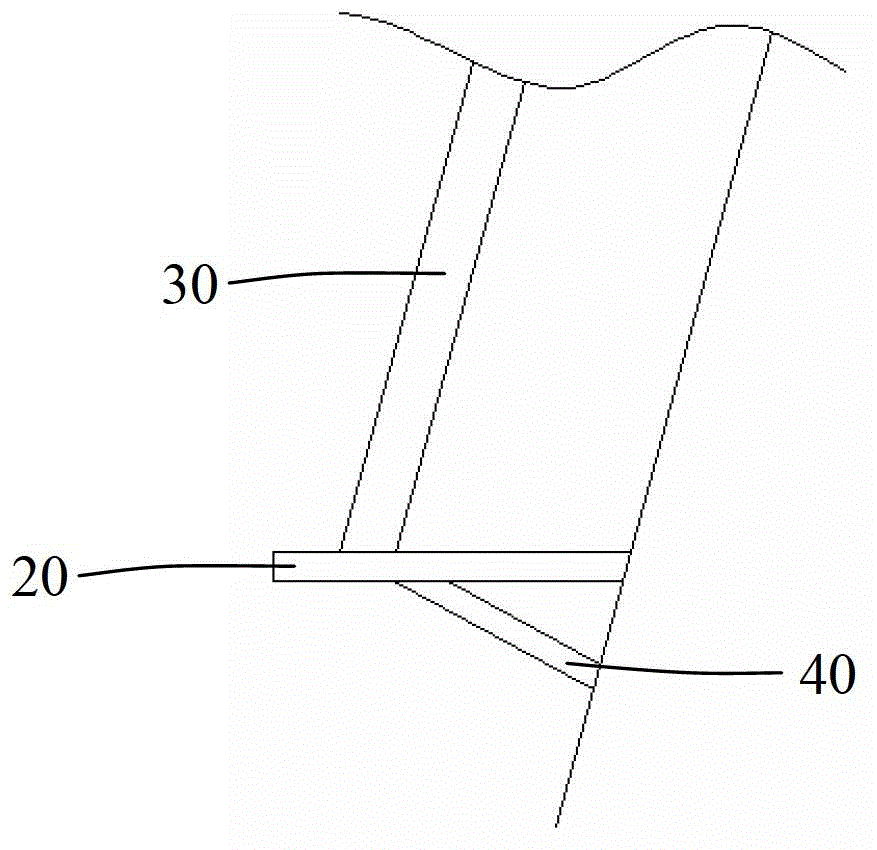

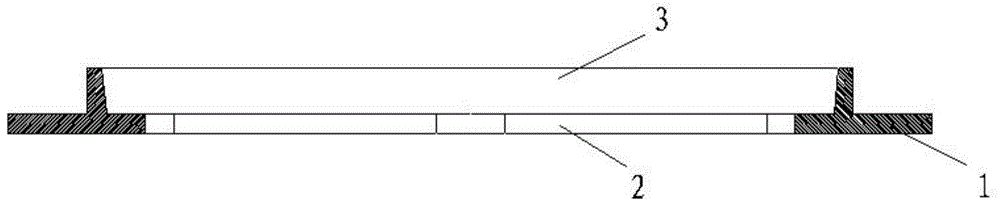

Coal mining machine and guiding skid shoe component

The invention relates to the mechanic field, in particular to a guiding skid shoe component, comprising a guiding skid shoe having a guide groove, a wear layer fixed on an upper surface of the guide groove, a movable measuring rod and a sensor; the guiding skid shoe comprises a mounting hole over the guide groove; the wear layer is provided with a measuring hole passing through the guide groove and the mounting hole, the movable measuring rod is located in the mounting hole, and a lower end of the movable measuring rod is in sliding fit with the measuring hole along the axial direction of the measuring hole; and the sensor is located in the mounting hole and used for measuring displacement of the movable measuring rod. With reduction of the thickness of the wear layer, the movable measuring rod gradually moves upwards, and the sensor can measure the displacement of the movable measuring rod and measure the wearing capacity of the wear layer. The sensor can conveniently and accurately measure the wearing capacity of the wear layer to perform real-time measurement on the wearing capacity of the wear layer, so that the wear layer can be repaired and the guiding skid shoe can be changed in time, and derailment of the guiding skid shoe and damage on other elements caused by excessive wearing of the wear layer are avoided.

Owner:益阳市科技成果转化服务中心 +1

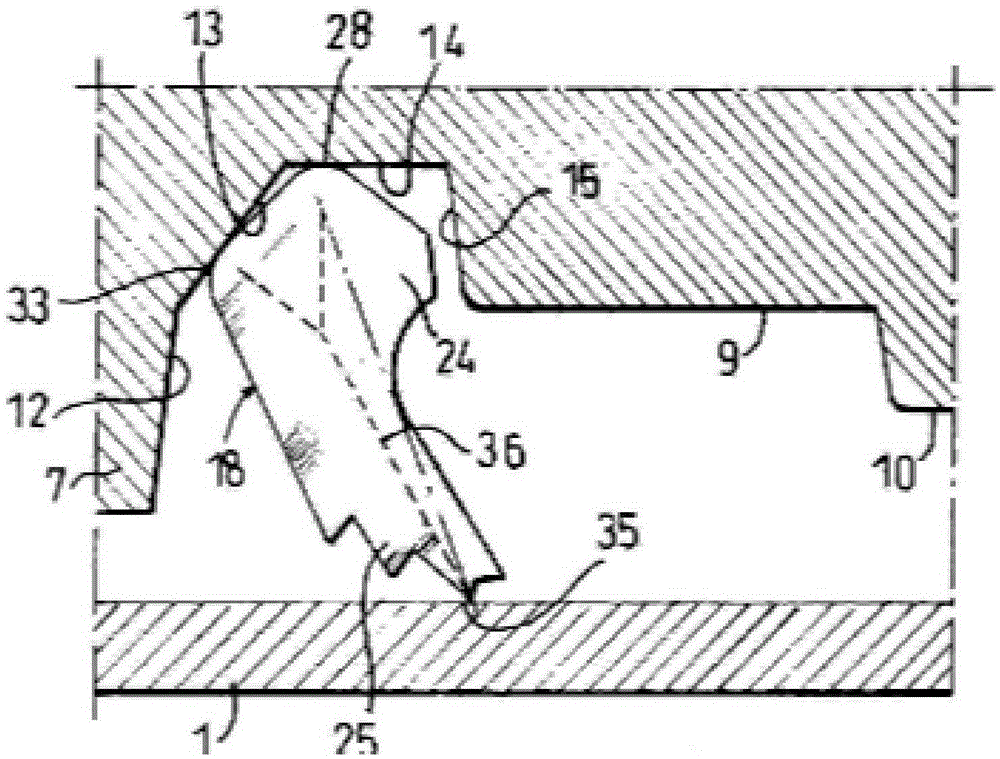

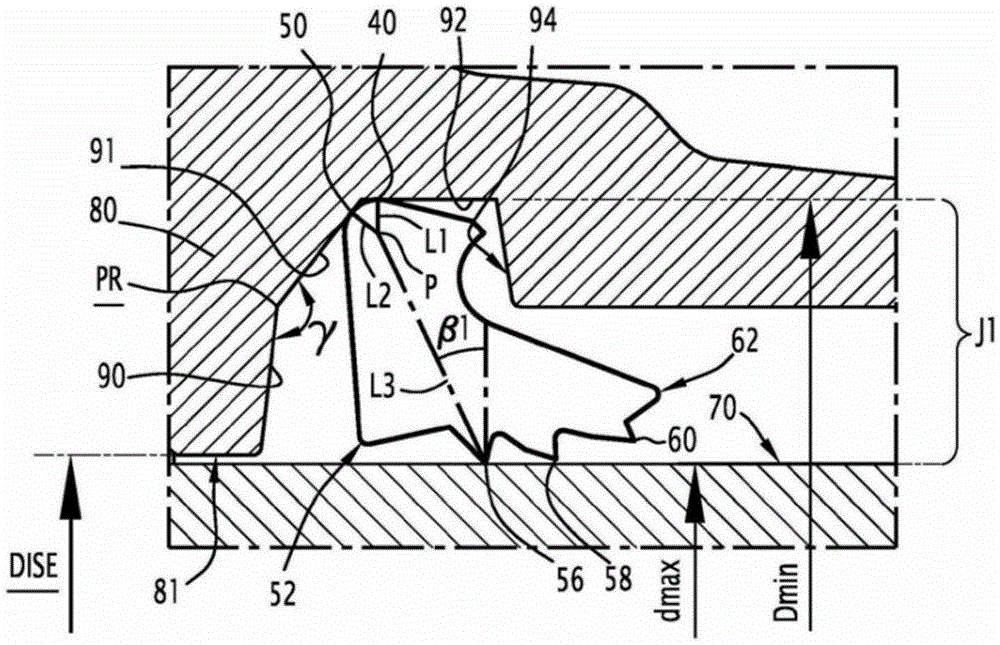

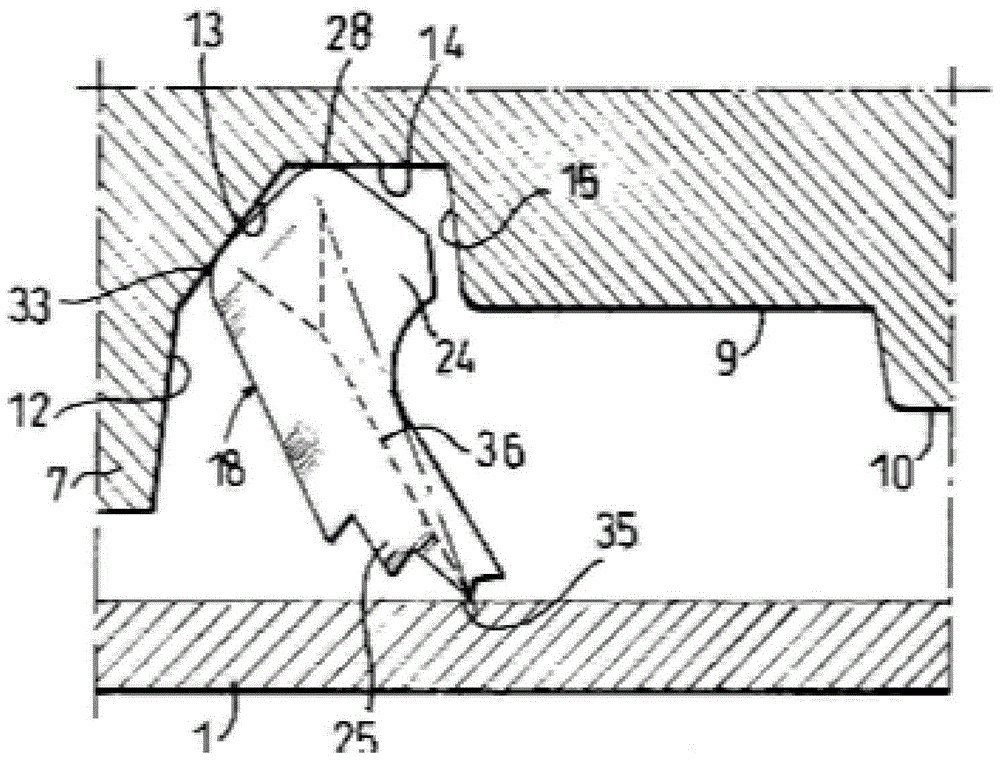

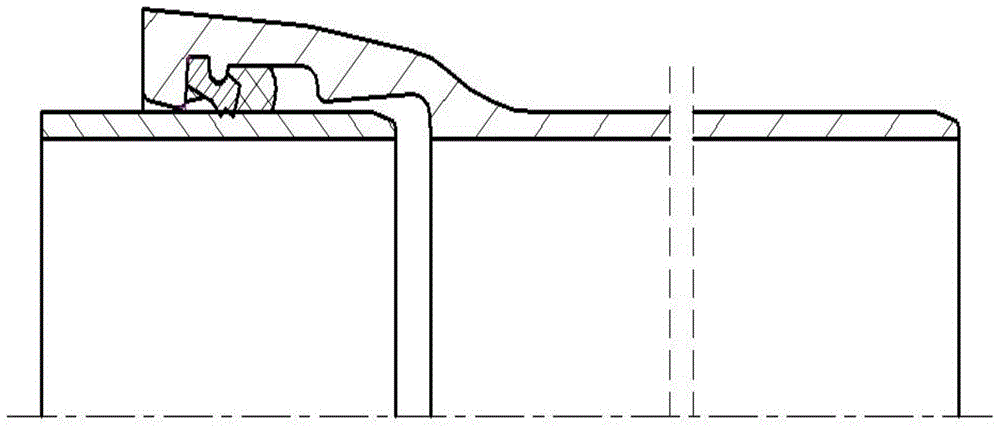

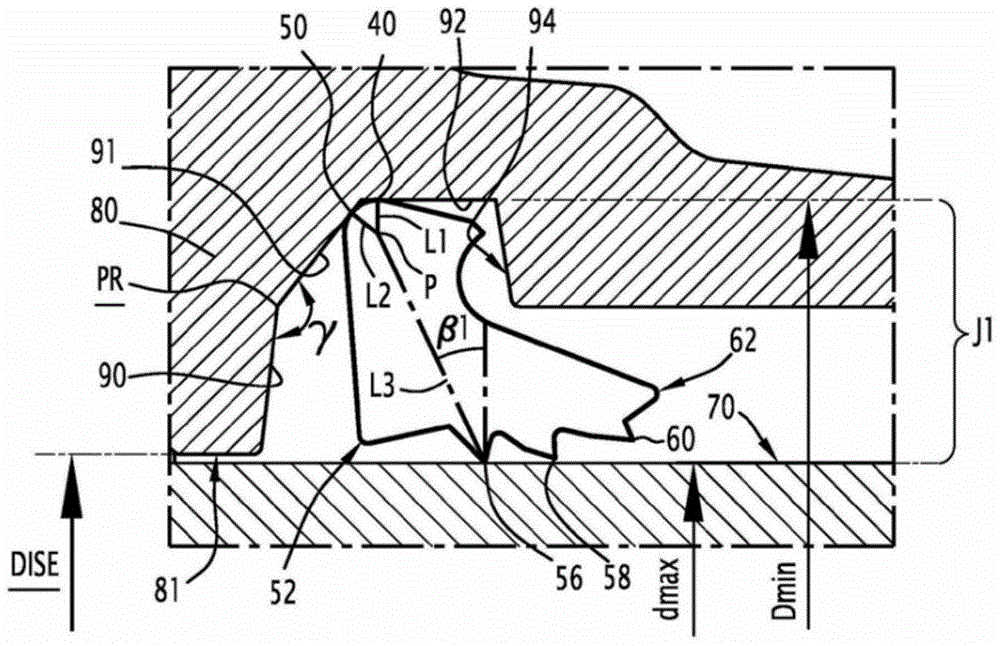

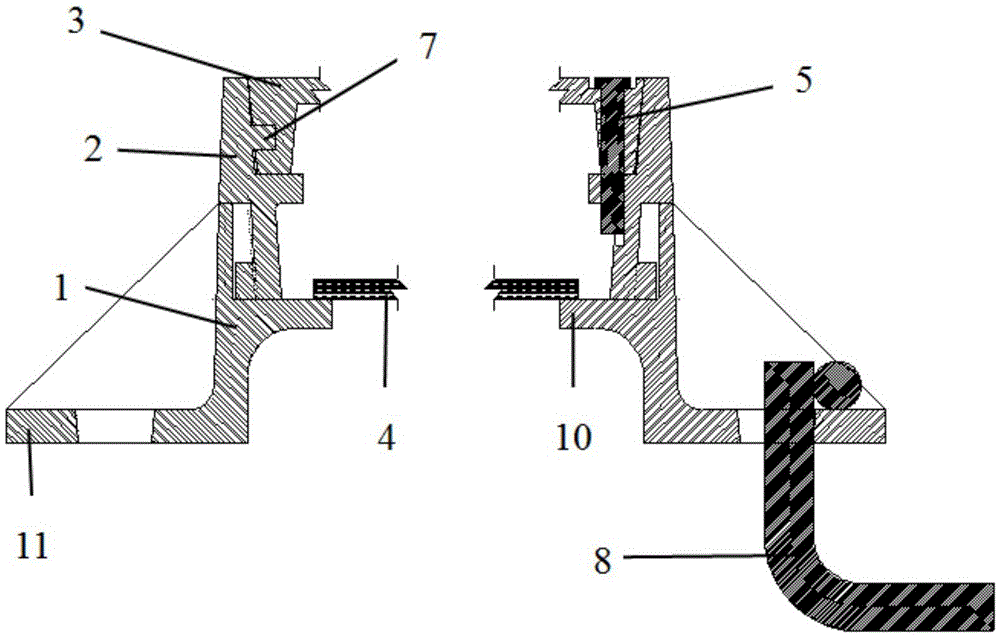

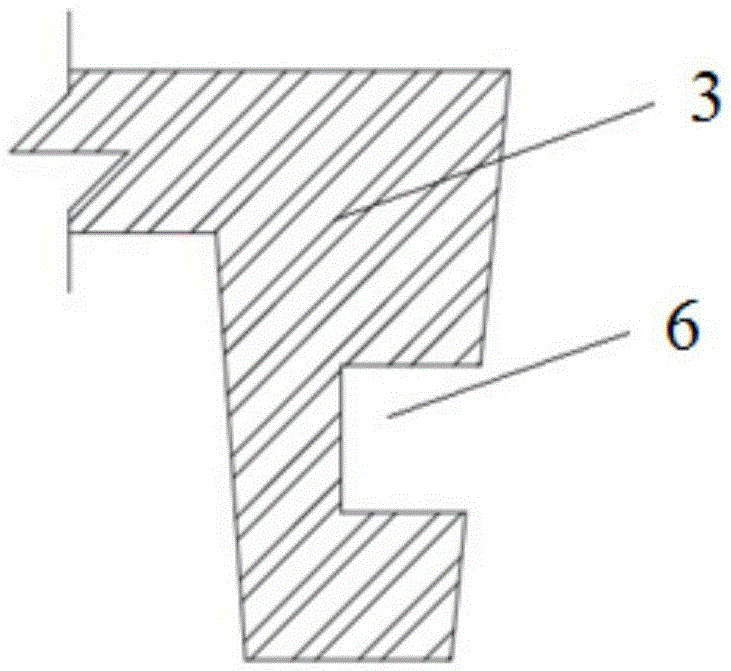

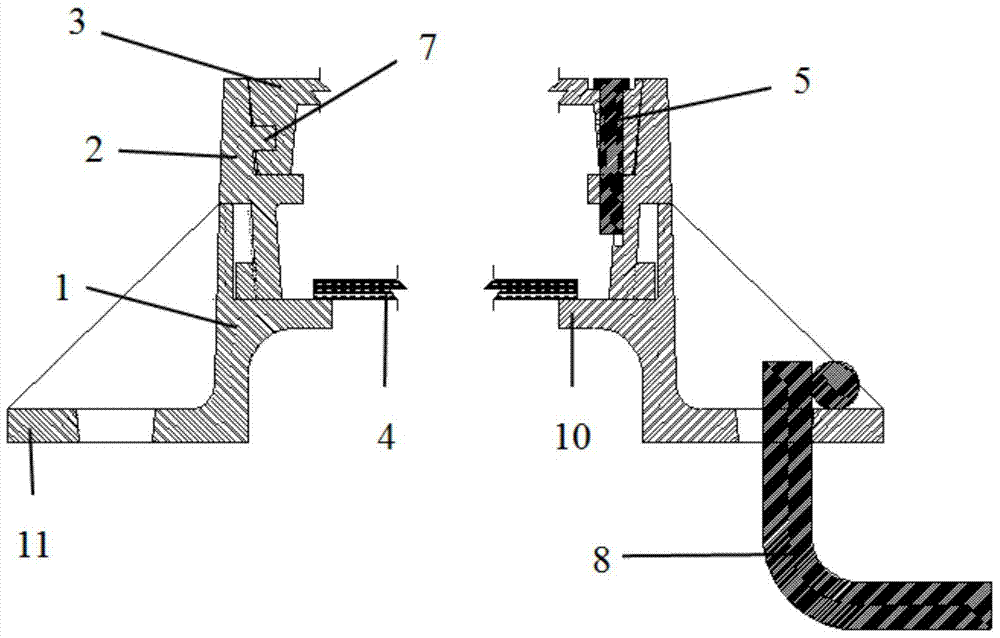

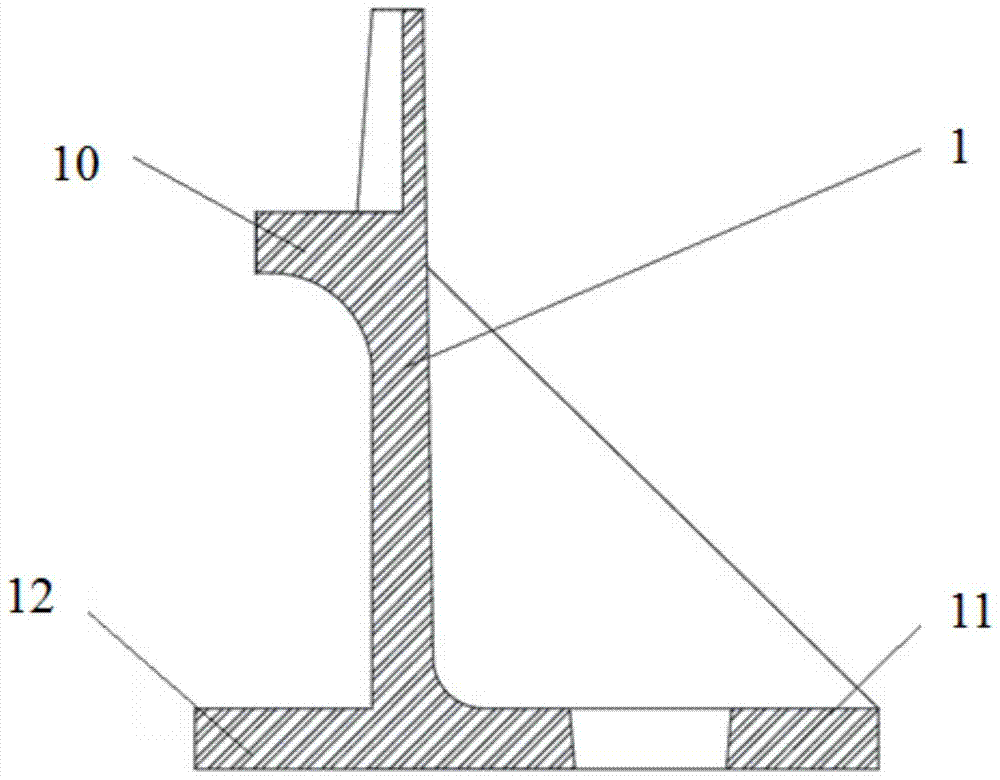

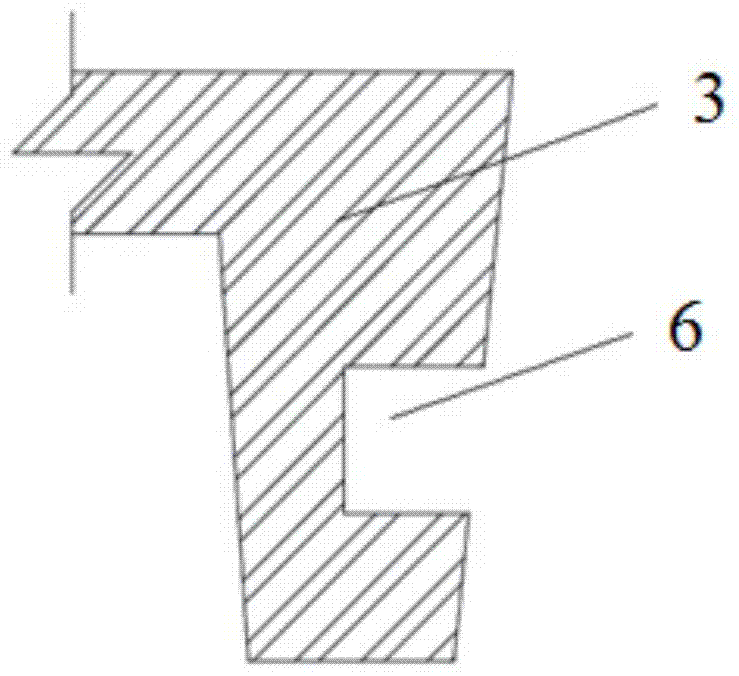

Socket and spigot type pipeline connector with anchoring structure

The invention relates to a socket and spigot type pipeline connector with an anchoring structure. The socket and spigot type pipeline connector with the anchoring structure is used for continuous nodular cast iron pipes. By means of the socket and spigot type pipeline connector, anchoring reliability can be improved, structural service life can be prolonged, pipeline maintaining cost can be reduced, optimization and simulation of the connector structure can be performed easily, and pipeline transporting capacity is improved. The socket and spigot type pipeline connector comprises a socket, a spigot and a sealing piece which is arranged between the socket and the spigot and used for sealing and locking the pipeline connector. The socket comprises an annular groove which is formed by sequentially connecting a first annular vertical wall, a conical wall, a cylindrical inner wall and a second annular vertical wall in a defined manner. The sealing piece comprises an elastic material ring and a plurality of anchoring pieces embedded in the elastic material ring. Each anchoring piece comprises a head and a plurality of meshing teeth. Each anchoring piece is provided with a rotating circle center. The portion, connected with the annular groove in an abutting manner, of each head is an arc supporting face. The abutting joint area of each arc supporting face and the annular groove is located on the joint of the first annular vertical wall and the conical wall.

Owner:XINXING DUCTILE IRON PIPES CO LTD

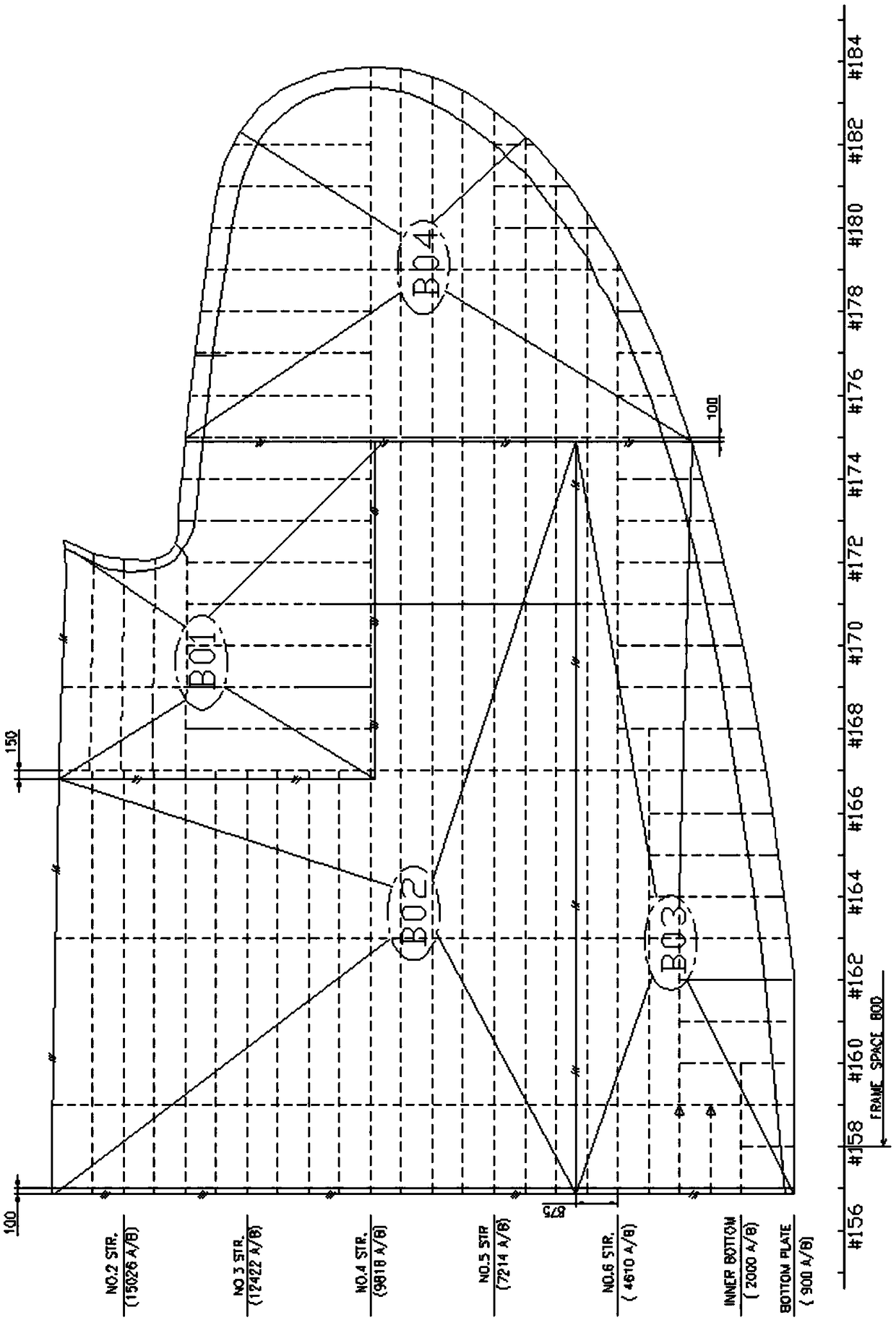

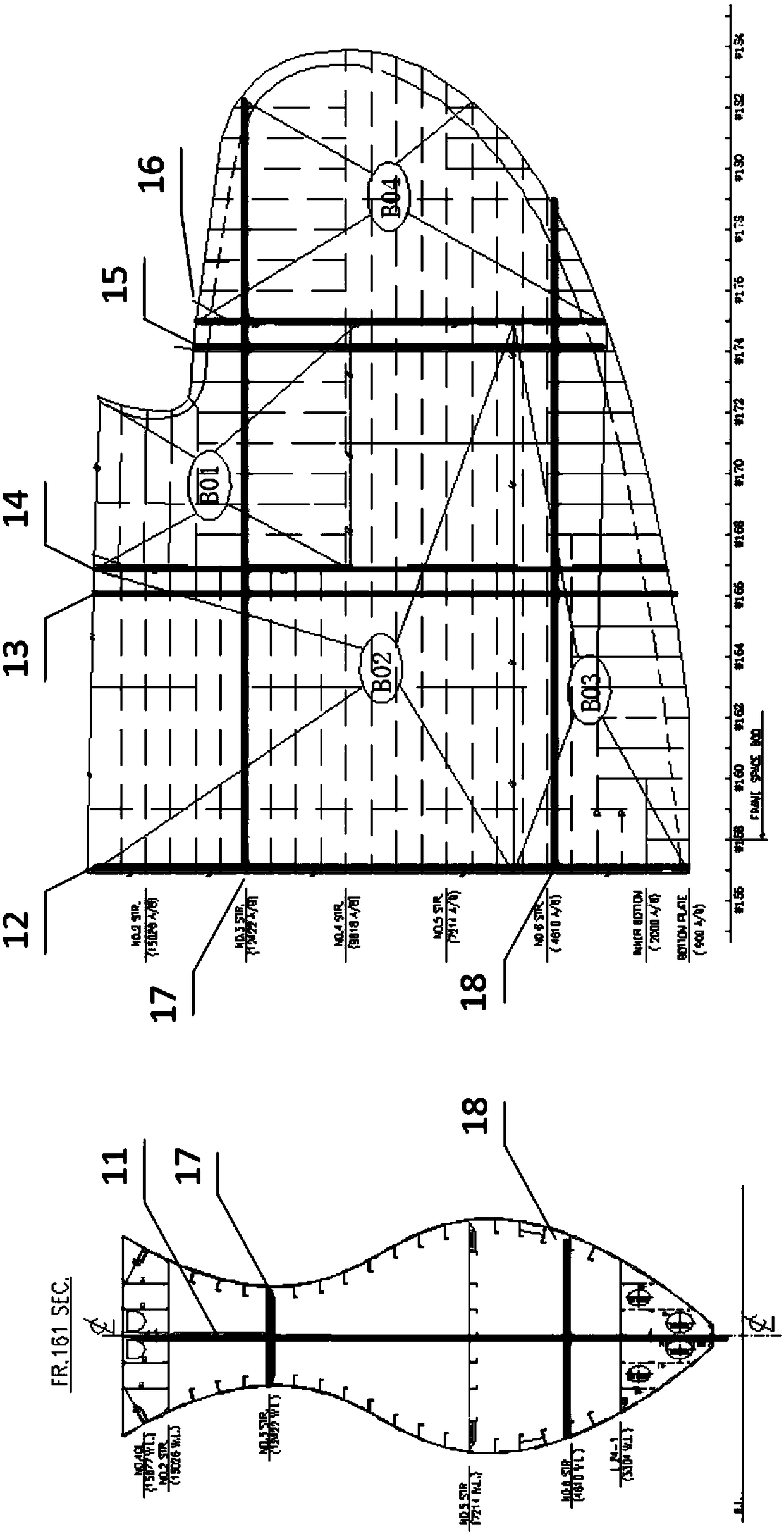

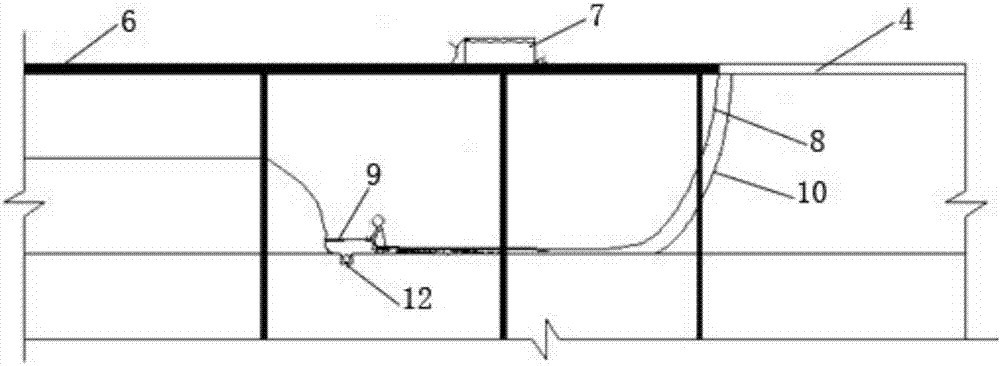

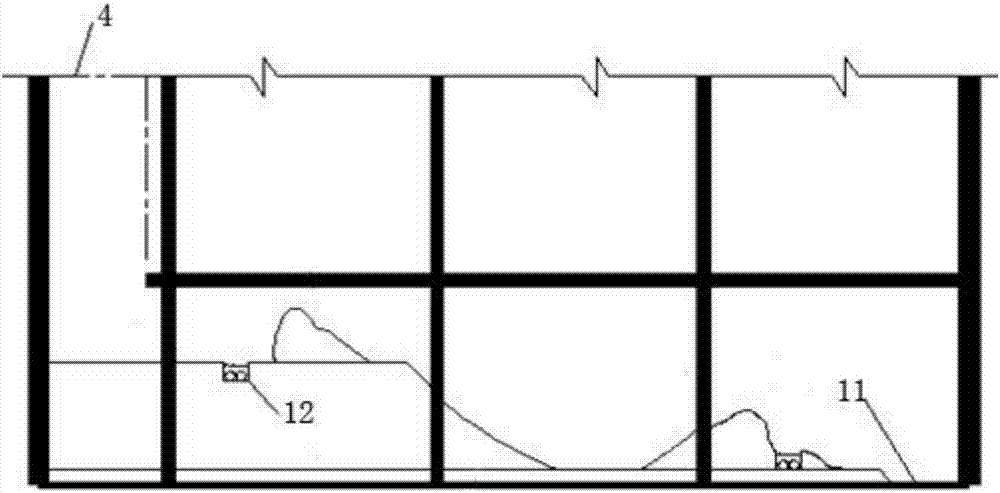

Ship manufacturing method for pre-mounting steering engine base in segmentation step

The invention discloses a ship manufacturing method for pre-mounting a steering engine base in a segmentation step. The ship manufacturing method comprises the following steps of: carrying out segmentation on a deck of a steering engine room; drawing a gantry arrangement and reinforcement picture of an upper gantry of the deck of the steering engine room at a positive segmentation state; incorporating the gantry arrangement and reinforcement picture with a segmental fitting-out tray management list so as to ensure that the pre-mounting of the steering engine base is completed in a segmental manufacturing step, and the requirement on installation precision can be met; and conveying the deck of the steering engine room in a segmental manner to a next process in a positive state of the upper gantry. The steering engine base is welded before being coated in a segmental manner, so that the segmental fitting-out integrality can be improved. Therefore, the damage area of a coating layer of a ship stern ballast cabin is reduced, the risk of sand wash on the entire ship stern ballast cabin can be effectively reduced, a coating construction period is shortened, and a PSPC (Performance Standard for Protective Coatings) can be met.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

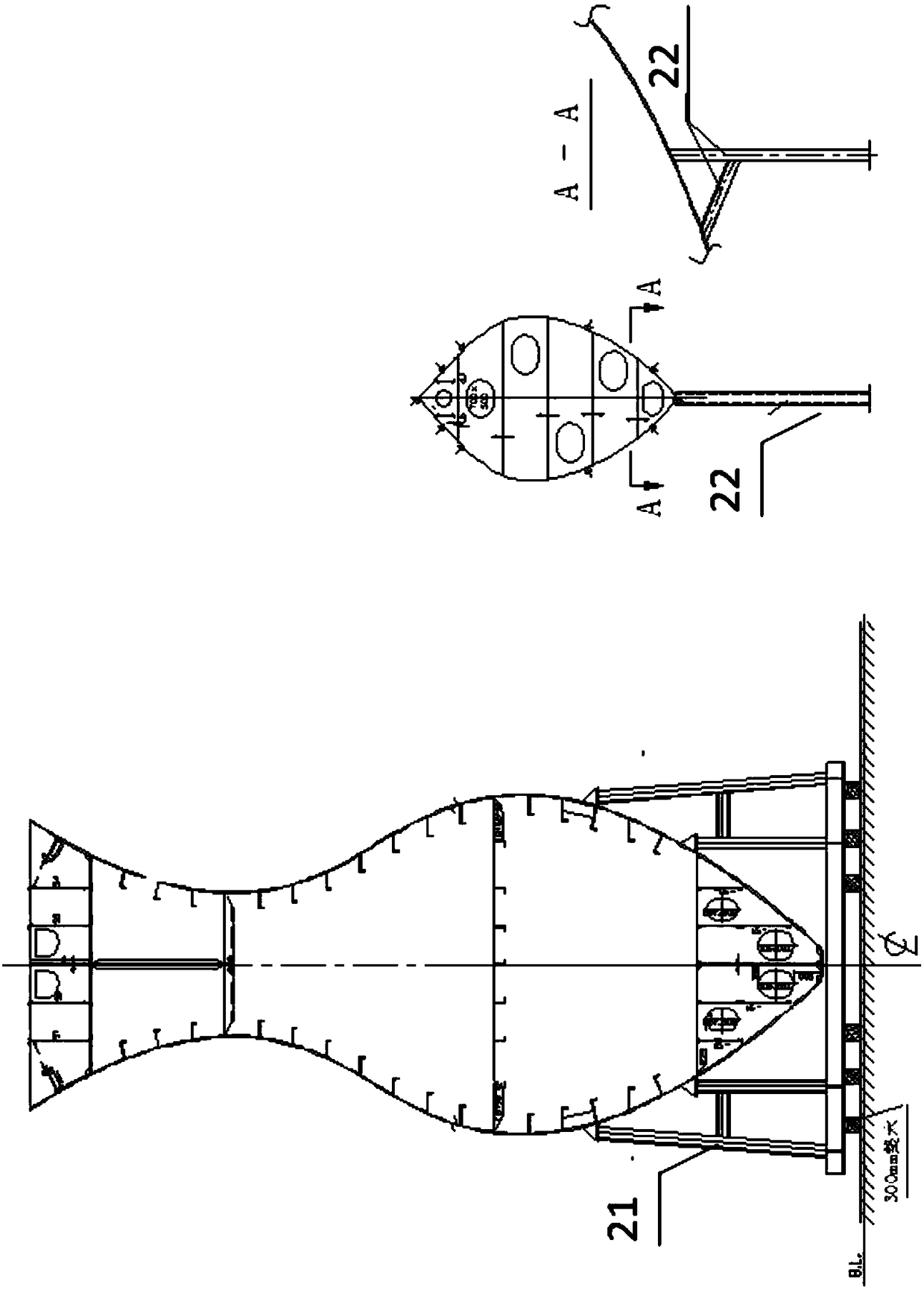

Bulbous bow refit technology

ActiveCN108773455AShorten docking periodReduce workloadWatercraft hull designVessel partsMarine engineeringProjection line

The invention provides a bulbous bow refit technology. The bulbous bow refit technology comprises the three main processes of manufacturing of a new bulbous bow, removing of an old bulbous bow, and hoisting of the new bulbous bow. During hoisting of the new bulbous bow, an original ship center line, a rib position line and a horizontal detecting line are drawn on an original ship outer plate, projection lines of the original ship center line and the rib position line are drawn on the dock floor, and by combining a floating crane, a large segmented positioning tool and a segmented positioning trolley and taking the center line, the rib position line, the horizontal detecting line and the projection lines of the center line and the rib position line as the standard, precise positioning of the new bulbous bow in transverse, longitudinal and height directions is achieved. The bulbous bow refit technology can fully utilize existing equipment to shorten the docking period, and operation is accurate and quick.

Owner:广州文冲船舶修造有限公司

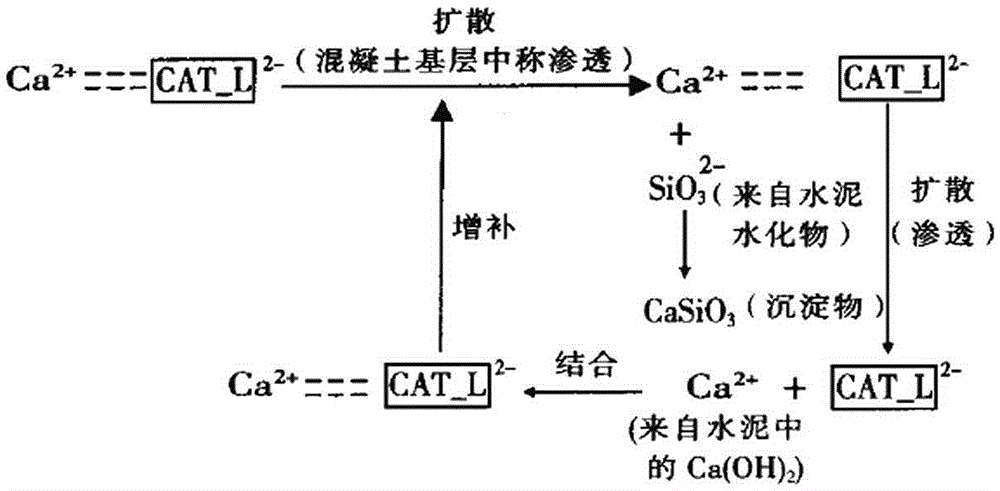

Quick-setting type waterproof mortar having self-repairing function and secondary permeability resistance as well as preparation method thereof

InactiveCN105347767AAvoid tinkeringReach the effect of secondary impermeabilitySilica fumeAntifoam agent

The invention discloses a quick-setting type waterproof mortar having self-repairing function and secondary permeability resistance as well as a preparation method thereof. The quick-setting type waterproof mortar having self-repairing function and secondary permeability resistance is prepared by using the following raw materials and water: a mixed cement, quartz sand, silica fume, heavy calcium, a capillary crystalline active master, a water reducer, an antifoaming agent, a coagulation accelerator and cellulose ether; and the mixed cement is composed of an ordinary portland cement and a quick-setting type sulphoaluminate cement. The quick-setting type waterproof mortar is used for repairing construction, if secondary leakage is happened, the capillary crystalline active master, the a repairing mortar and cement hydration product portlandite in concrete are continuously reacted for realizing self restoration, so that secondary anti-permeability effect can be reached, and secondary or multi-time restoration for regenerated cracks can be avoided.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

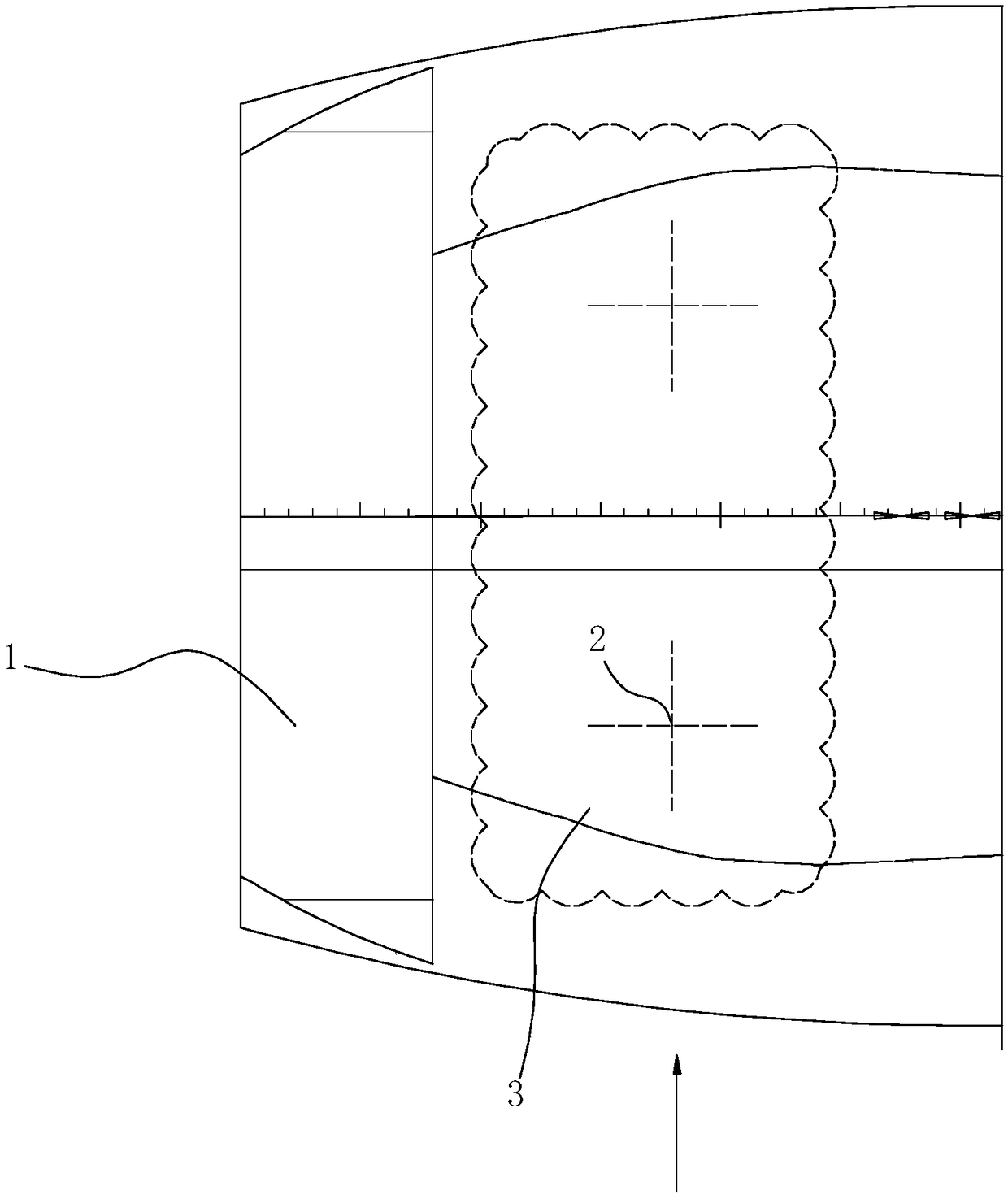

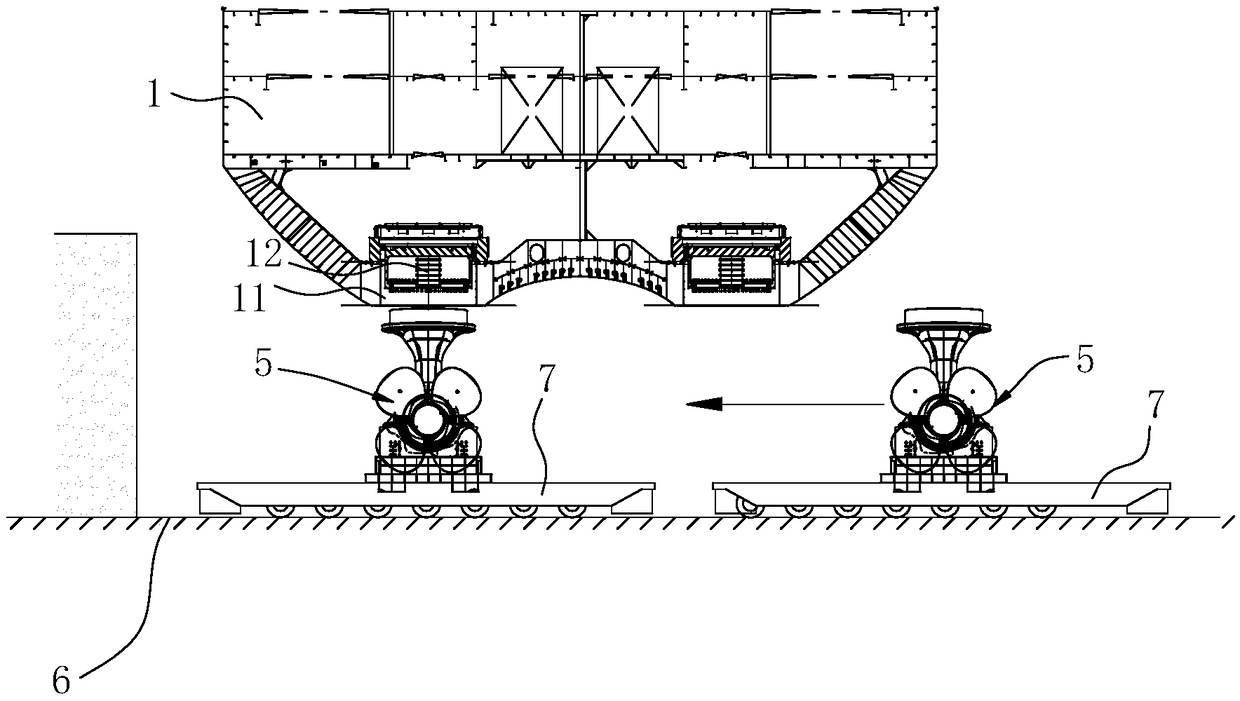

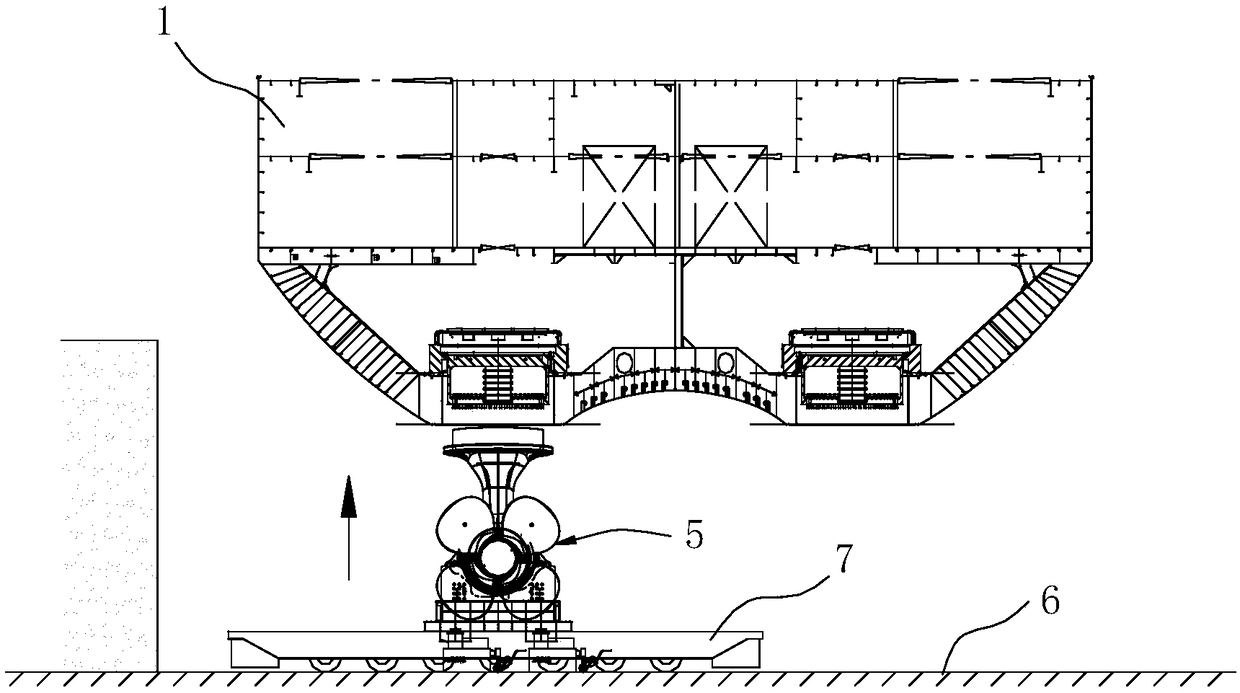

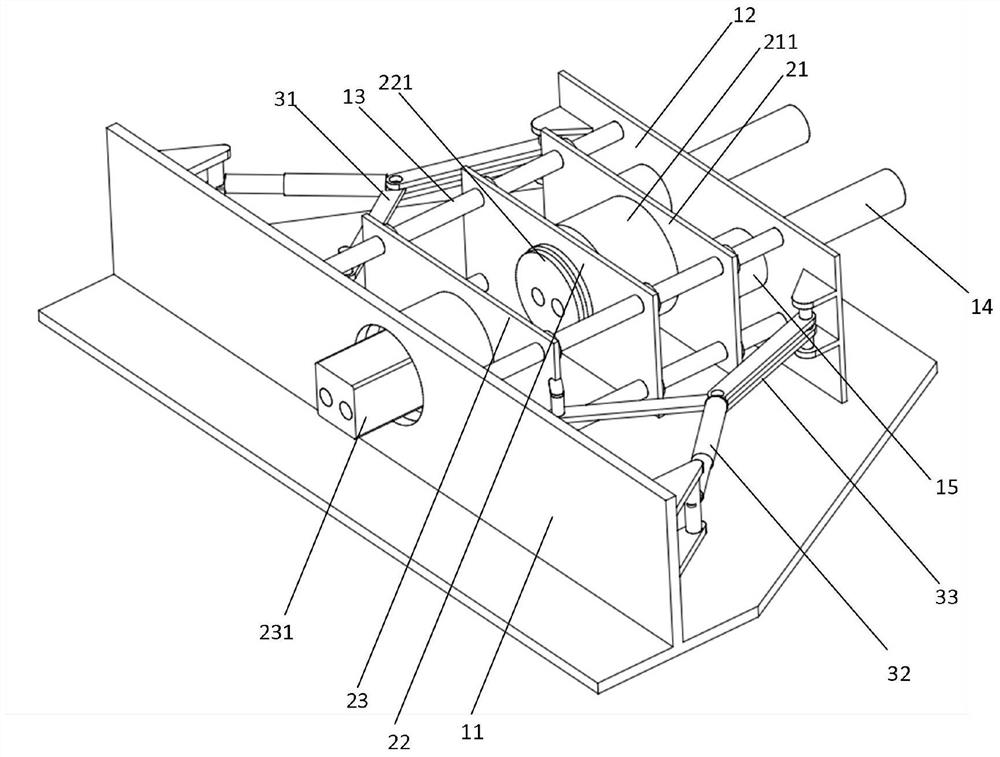

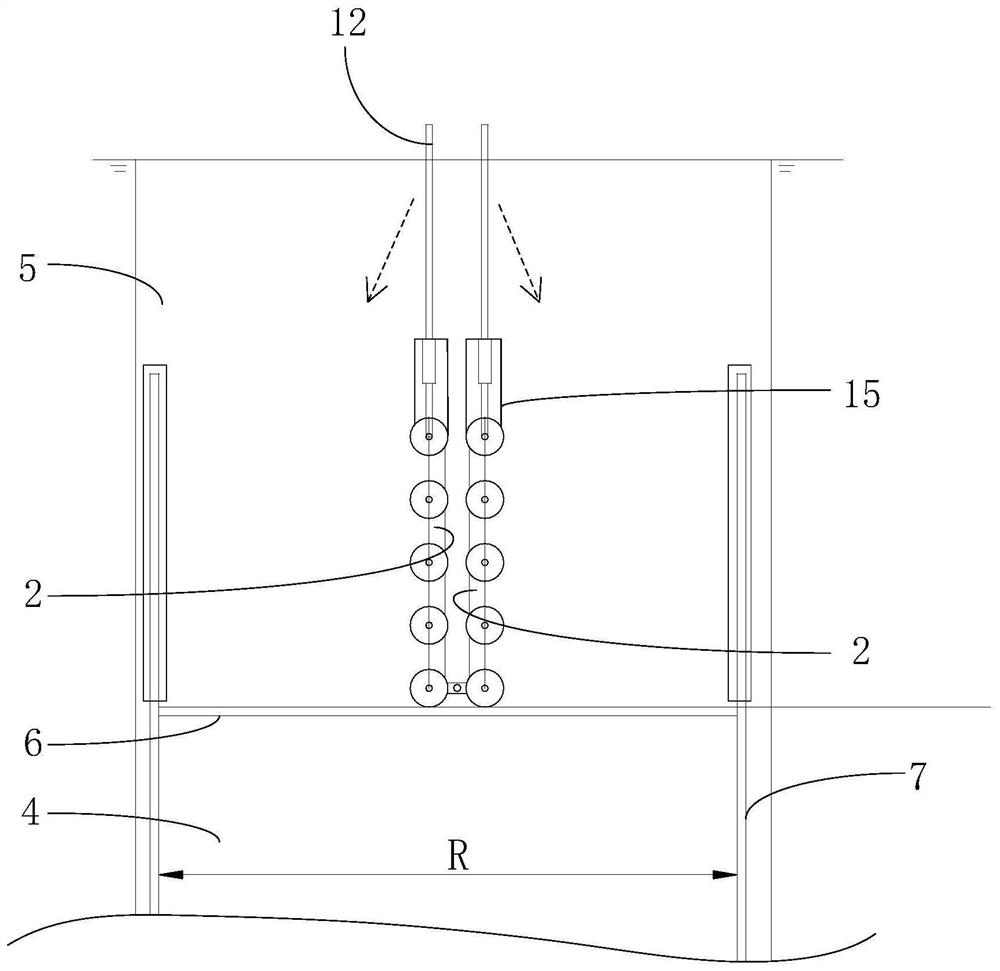

Mounting method of propulsion device

ActiveCN109178202AAvoid weldingAvoid tinkeringVessel designingBuilding constructionAerospace engineering

The invention discloses a mounting method of a propulsion device, comprising the following steps: S10, providing an elevator, a propulsion device, a three-dimensional jacking machine and a hull section of the propulsion device to be installed, fixing the hull section on a construction plane, so that the hull section is located above the construction plane; S20, hoisting the propulsion device on the lifting vehicle, and lifting the propulsion device to the first height position by the lifting vehicle; S30, displacing the propulsion device from the first height position to the mounting positionof the propulsion device by the three-dimensional jacking machine; and S40, connecting the propulsion device with the steering device arranged at the mounting position. It can be used for mounting heavy propulsion units.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

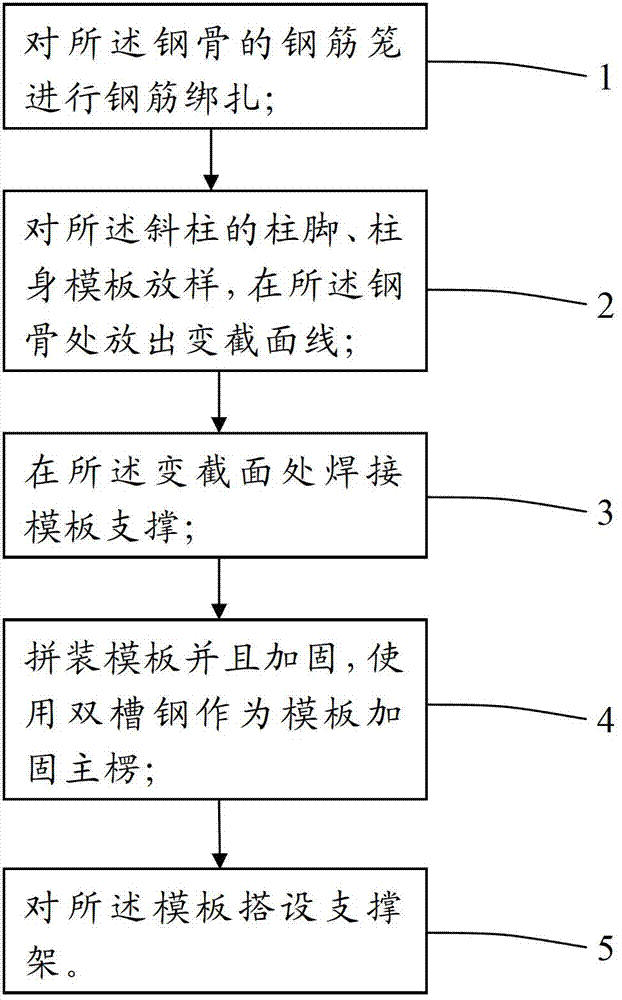

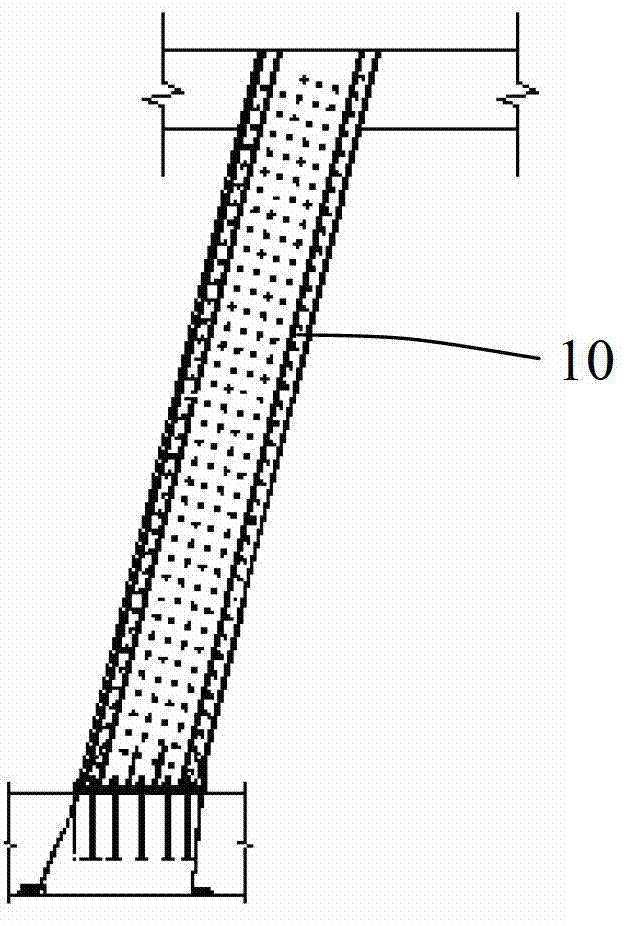

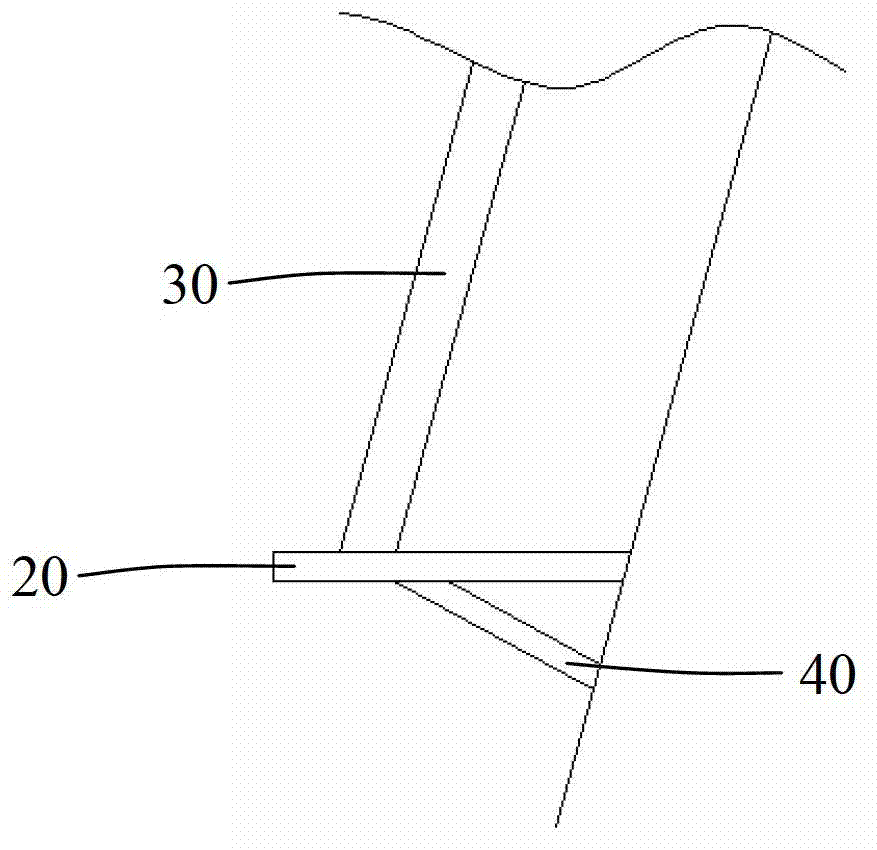

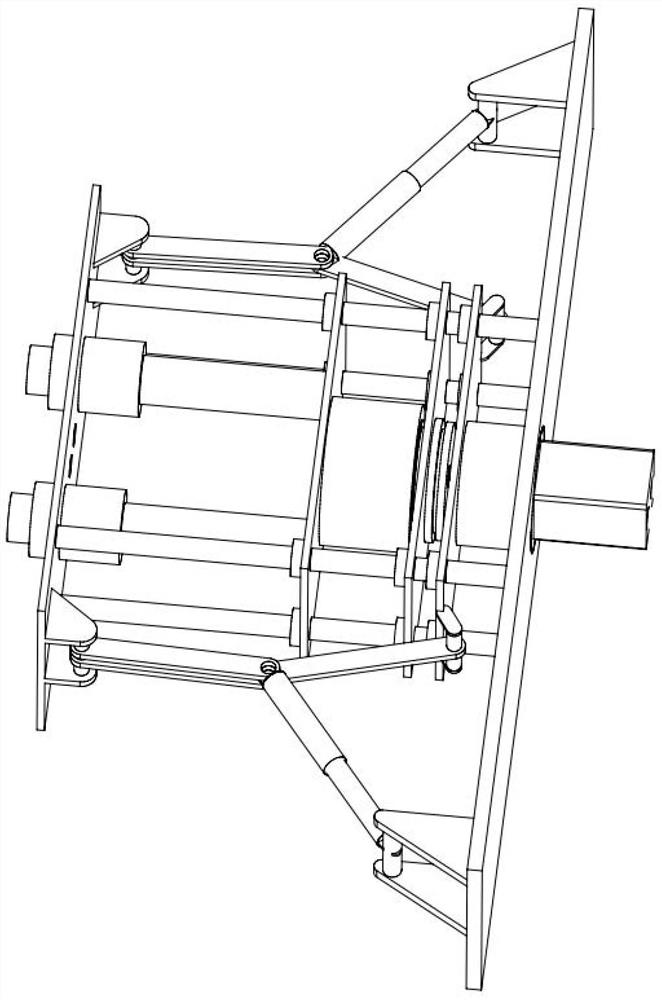

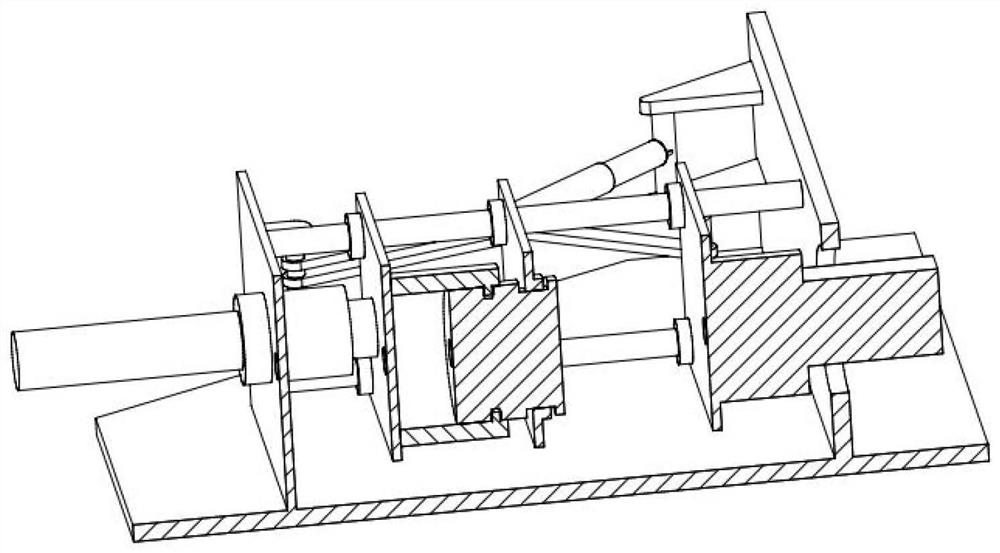

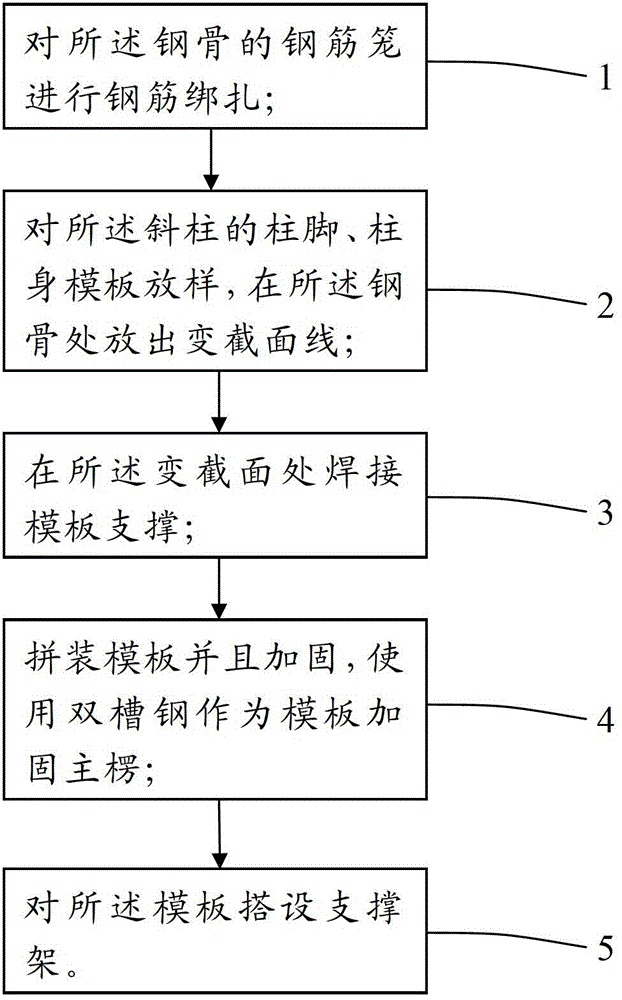

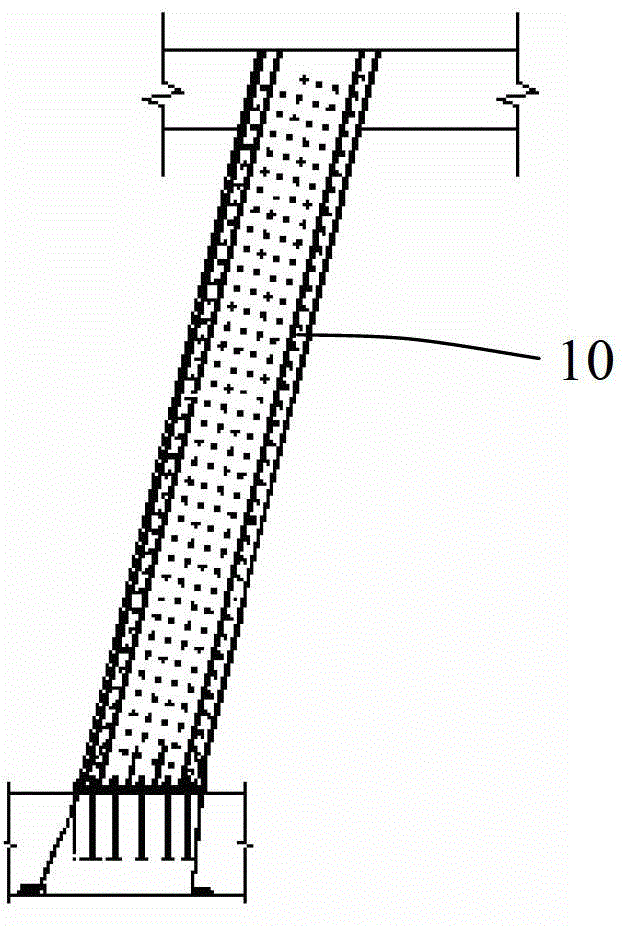

Mounting method for templates of box-type steel skeleton inclined column

ActiveCN102926532AReduce the possibility of pressure instabilityReduce spatial distortionForms/shuttering/falseworksInstabilityRebar

The invention discloses a mounting method for templates of a box-type steel skeleton inclined column, which comprises the following steps that 1) a steel reinforcement cage of a steel skeleton is bound by steel reinforcements; 2) a column foot template and a column body template of the inclined column are subjected to lofting; a variable cross-section wire is put at the steel skeleton; 3) a template support is welded at a variable cross section; 4) templates are assembled and reinforced; double-groove steel is adopted as template reinforcing main ribs; and 5) a supporting frame is erected by the templates. The mounting method for the templates of the box-type steel skeleton inclined column has the benefits that 1) as the double-groove steel is adopted as the template reinforcing main ribs, welding of an anchor bolt on an inclined column body, subsequent cutoff and surface repair of concrete are avoided effectively; and 2) the steel reinforcement support is welded at the variable cross section of the column for bearing the pressure of the column body template, the probability of instability of the column foot template due to the pressure is reduced, and the probability of repeated position adjusting processes of the column foot template and the column body template is avoided.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

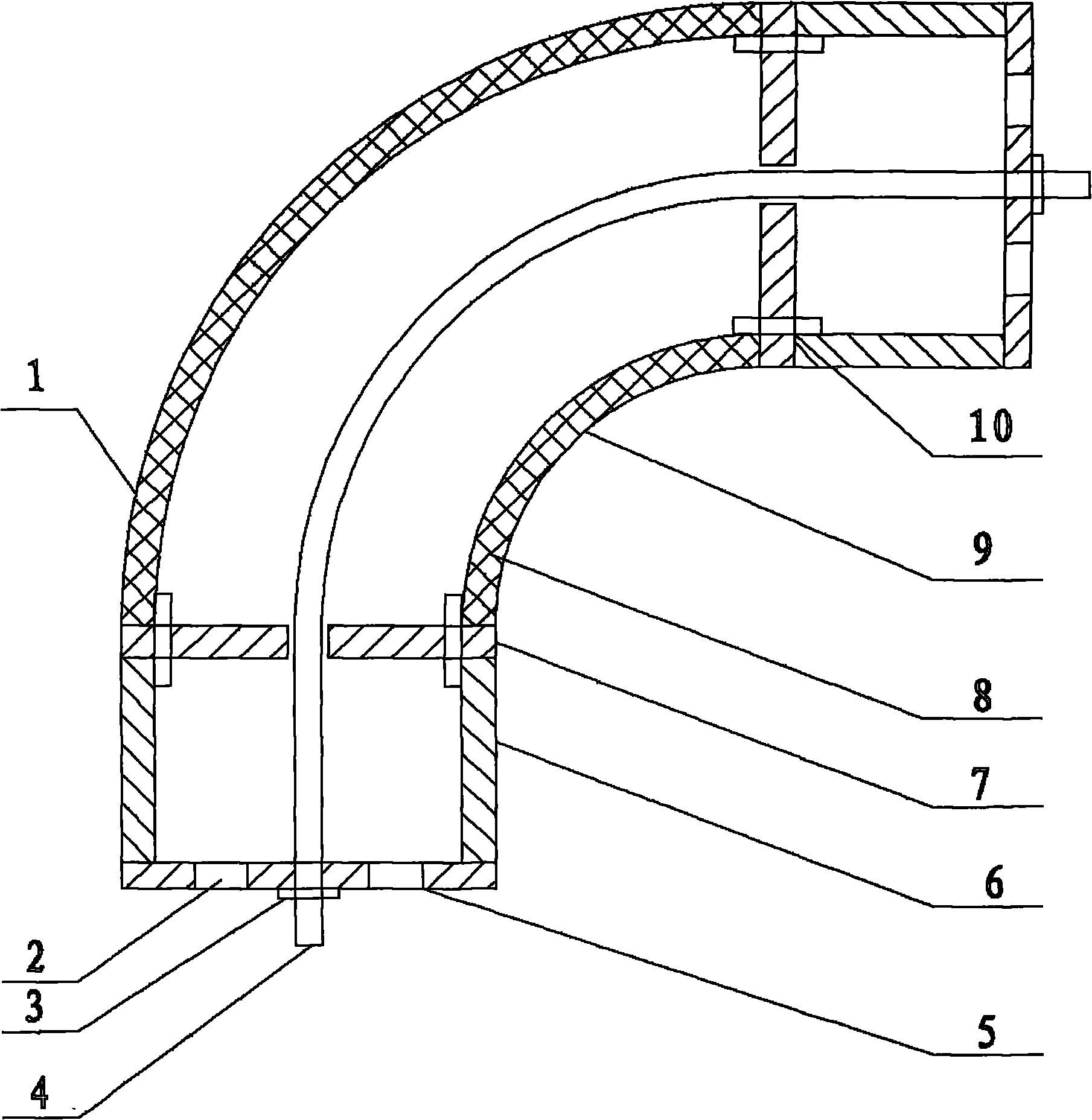

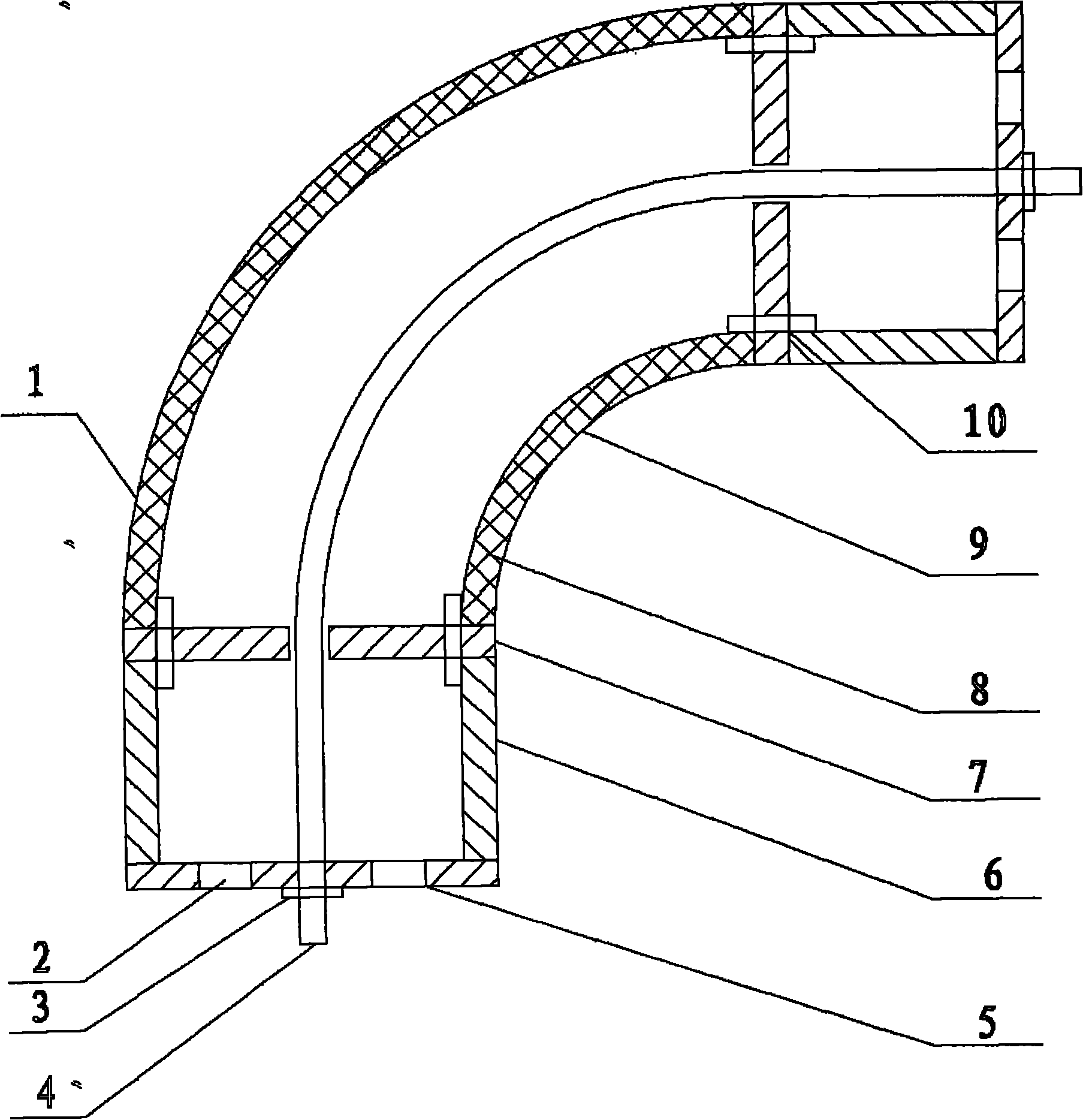

Glass reinforced plastic elbow die and manufacturing method thereof

InactiveCN102145519ASave materialMeet the requirements of hand lay-up processDomestic articlesProduction ratePlastic materials

The invention relates to a glass reinforced plastic elbow die and a manufacturing method thereof. The die comprises an end cover, a connection section die, an elbow die body, an intermediate plate and a pull rod. The elbow die body consists of an elbow inner template and an elbow outer template which are made of glass reinforced plastic material. The lengths of arc seams at both sides, which are butted in a matching mode, are at least 10mm. The connection section die is one of a straight tube connection section die, a butting connection section die, a socket connection section die and a lap joint flange connection section die. The manufacturing method of the elbow die body comprises the following steps of: 1, making a scraper; 2, making a cement die; 3, duplicating a glass reinforced plastic die; 4, carrying out machining; and 5, carrying out surface polishing treatment. The glass reinforced plastic elbow die and the manufacturing method solve the problem that the steel is easy to rust, are easy to repair, have the advantages of simple structure, high precision, high quality, high productivity and low manufacturing cost and are easy to demould. A product produced by the elbow die has a smooth inner wall, good seepage prevention performance and attractive appearance. The materials are saved. Due to the adoption of the elbow die, not only can the requirement of a hand lay-up process be met, but also the requirements of a mechanical winding process can be met.

Owner:奉玉贞

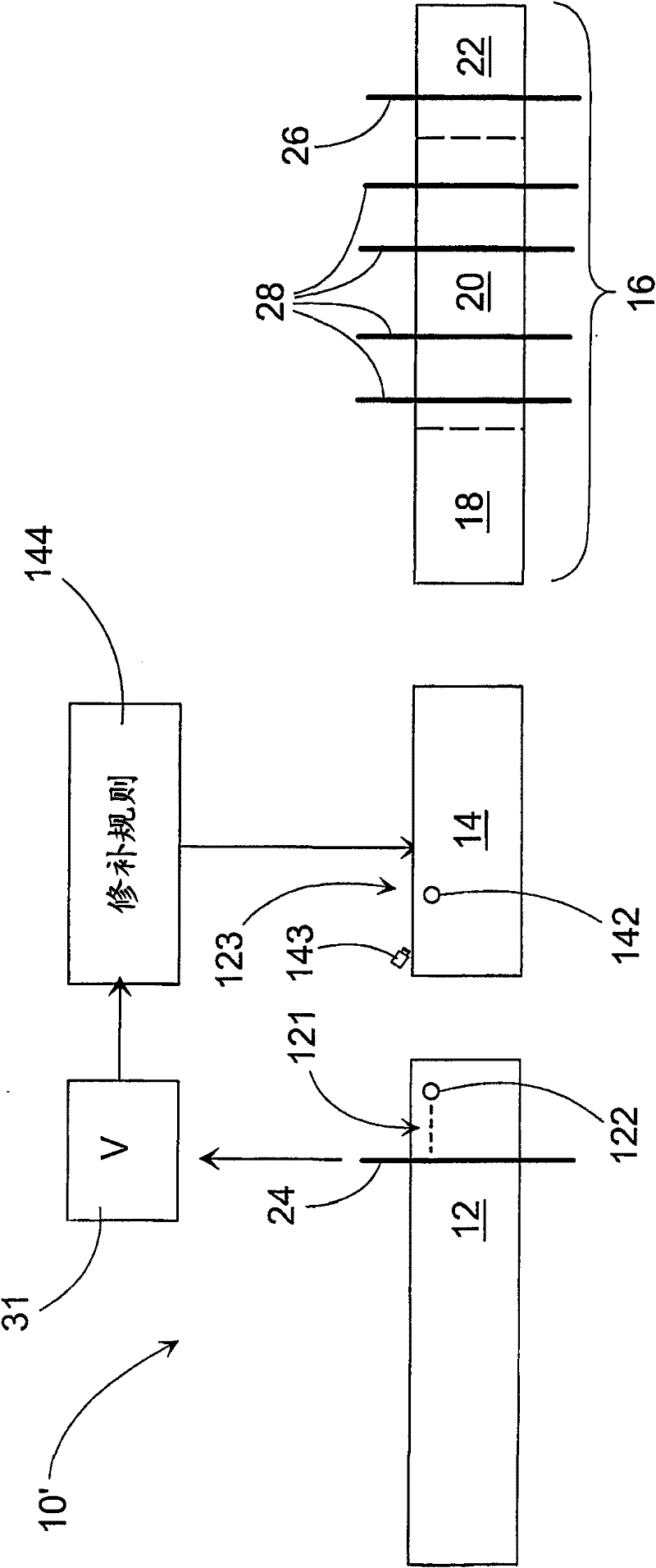

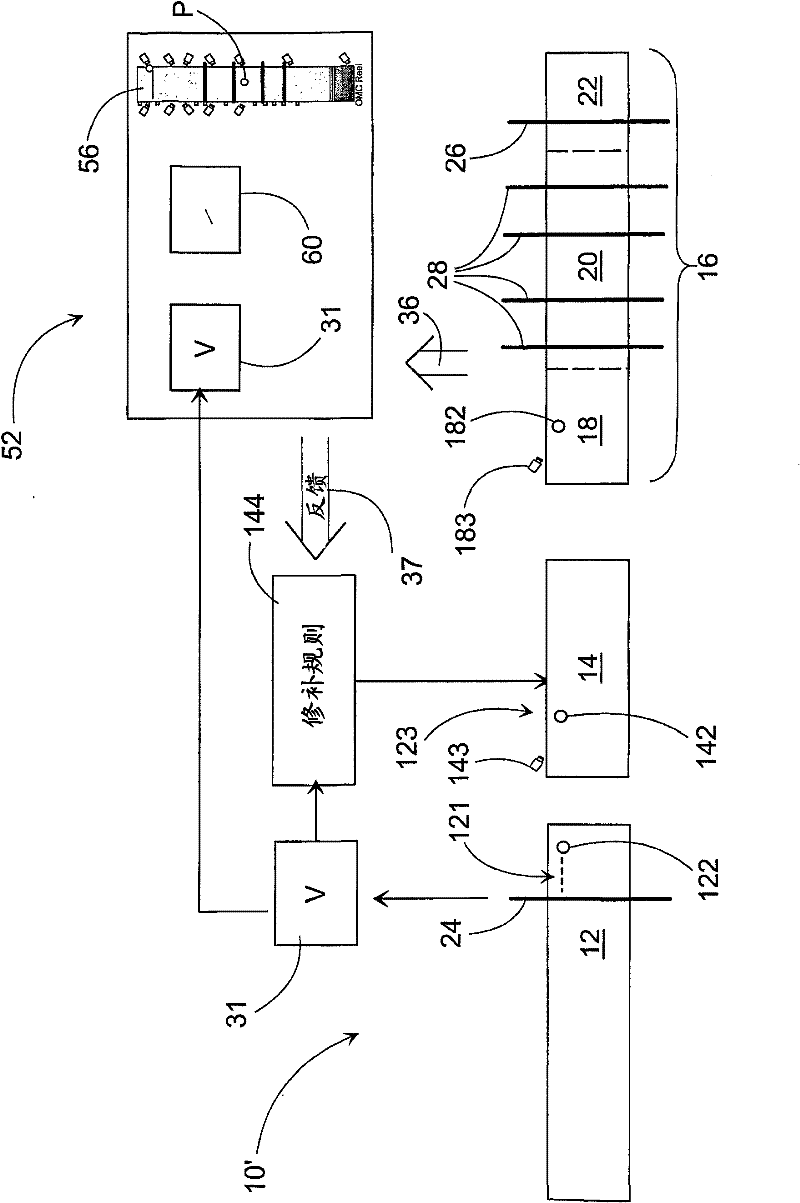

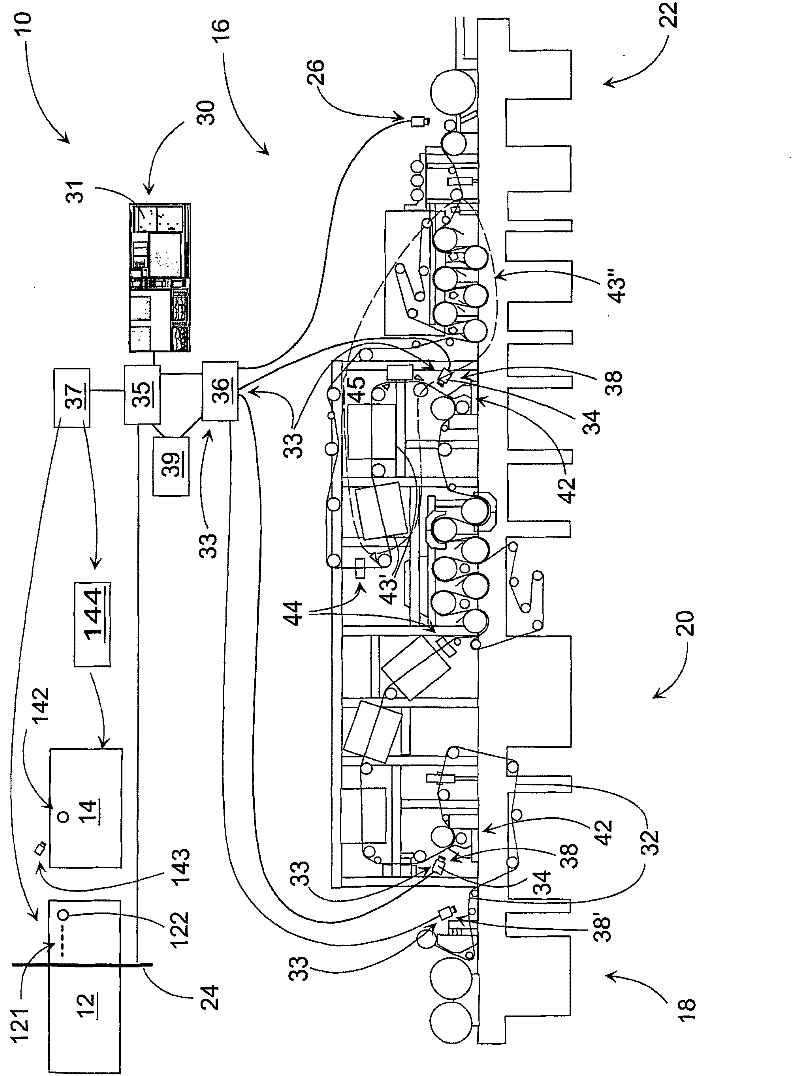

Method for guiding web patching using a re-reeler and a corresponding system

InactiveCN102224411AIt is beneficial to investigate the causal relationship of paper breaksAvoid paper breaksOptically investigating flaws/contaminationPaper-making machinesReelerCoating

The invention relates to a method for guiding web patching, using a re-reeler, in connection with a paper machine and an off-line coating machine (16), in which method a defect map (31) of the web is created on the paper machine (12), to show deviations (P), some of which are shown on the coating machine (16), using selected criteria, to the operator, the said deviations being patched using the re-reeler, guided by the defect map (31) and preset patching rules (144). On the coating machine (16), the virtual location of the selected deviations (P) is monitored through the coating machine (16),and if a possible web break occurs, a deviation (P) is localized relative to the web break, and on the basis of this monitoring, feedback (27) is provided to the patching rules (144) of the re-reeler(14), in order to optimize them.

Owner:METSO AUTOMATION OY

Socket-type pipe connection with anchor structure

The socket-type pipe interface with an anchoring structure of the present invention relates to a socket-type pipe interface with an anchoring structure for connecting ductile iron pipes. The purpose is to provide a socket-type pipeline interface that can improve anchoring reliability, extend structural life, reduce pipeline maintenance costs, facilitate optimization simulation of the interface structure, and increase pipeline transportation capacity. The invention includes a socket, a socket, and a seal between the socket and the socket for sealing and locking a pipeline interface; the socket includes a first annular vertical wall, a tapered wall, a cylindrical inner wall and a second annular vertical wall. The defined annular grooves are connected in turn; the sealing member includes an elastic material ring and a plurality of anchors embedded therein; the anchoring member includes a head and a plurality of meshing teeth; the anchoring member is provided with a center of rotation, and the head is connected to the annular groove The part where the grooves are in contact is an arc support surface; the contact area between the arc support surface and the annular groove is located at the intersection of the first annular vertical wall and the tapered wall.

Owner:XINXING DUCTILE IRON PIPES CO LTD

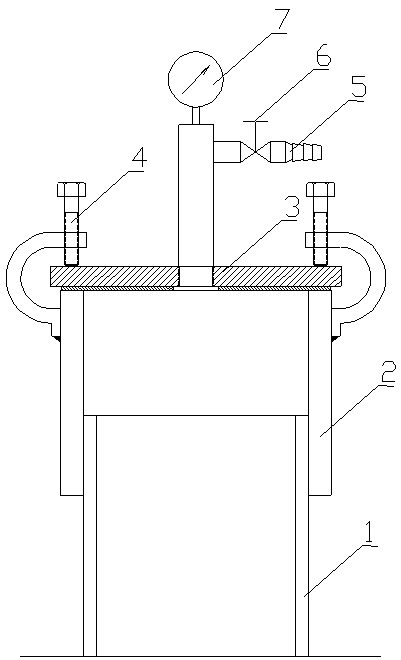

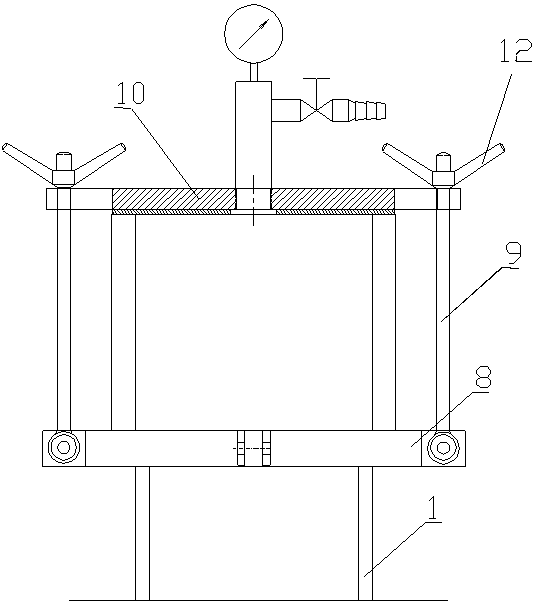

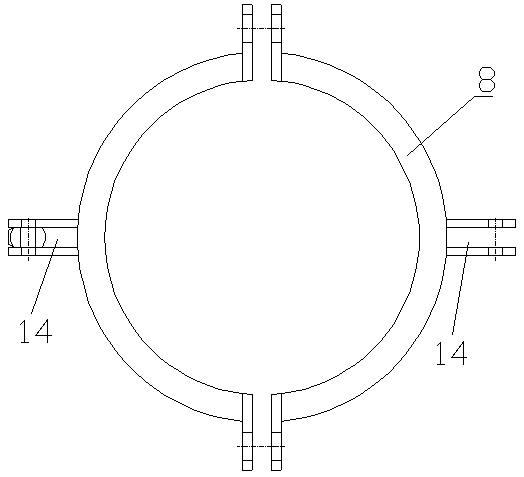

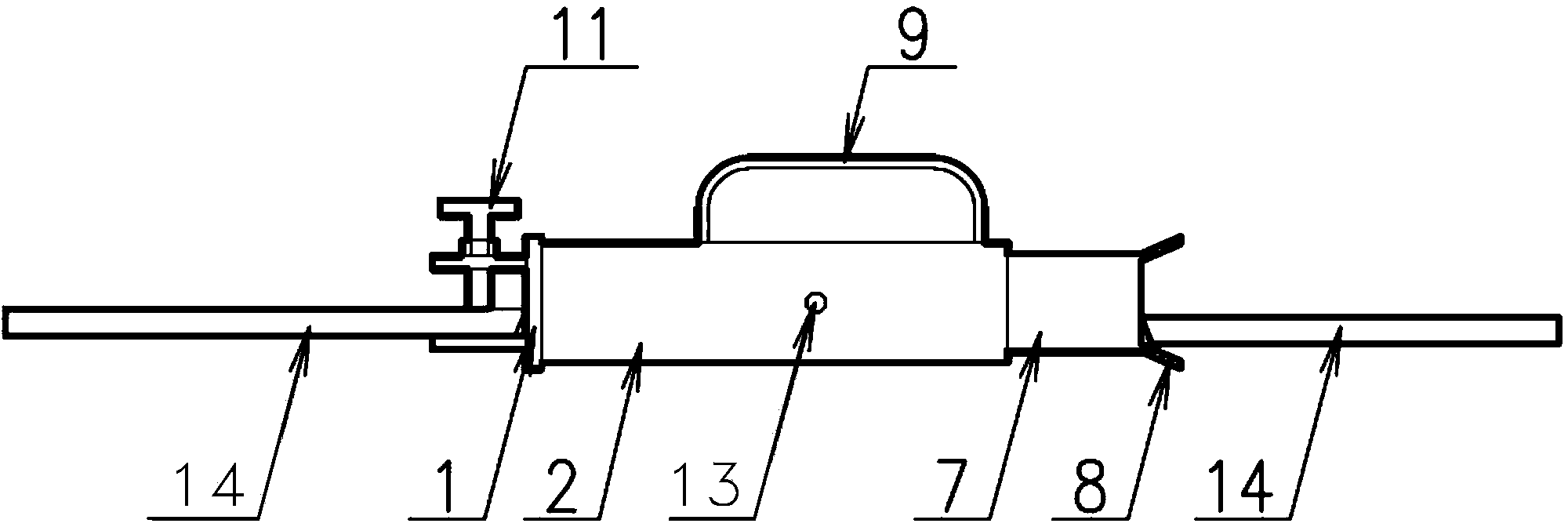

Tool for testing tightness test of ship pipeline

InactiveCN109540415AEasy to useSolve the shortcomings of slow speedMeasurement of fluid loss/gain rateEngineeringMechanical engineering

The invention discloses a tool for testing the tightness test of a ship pipeline. The tool comprises a sealing cover arranged on the pipe opening of a sleeve. A sealing rubber is arranged below the sealing cover, and a through hole formed in the middle of the sealing cover. One end of the through hole is communicated with the interior of the sleeve. The other end of the through hole is connected with an air inflation device. A clamping hoop is clamped at the joint part of the sleeve and the pipeline. The head parts of a plurality of bolts are configured to abut against the lower part of the clamping hoop. The tail parts of the bolts penetrate through the clamping hoop. The sealing cover protrudes out of the upper part of the sealing cover. A plurality of nuts are connected with the bolts in the one-to-one correspondence mode. The nuts abut against the upper portion of the sealing cover. According to the invention, the tool does not need to be welded in the installation process, thus being safe, quick and convenient in operation. Meanwhile, the damage of the paint in the welding process can be avoided. As a result, the paint can be prevented from being repaired.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

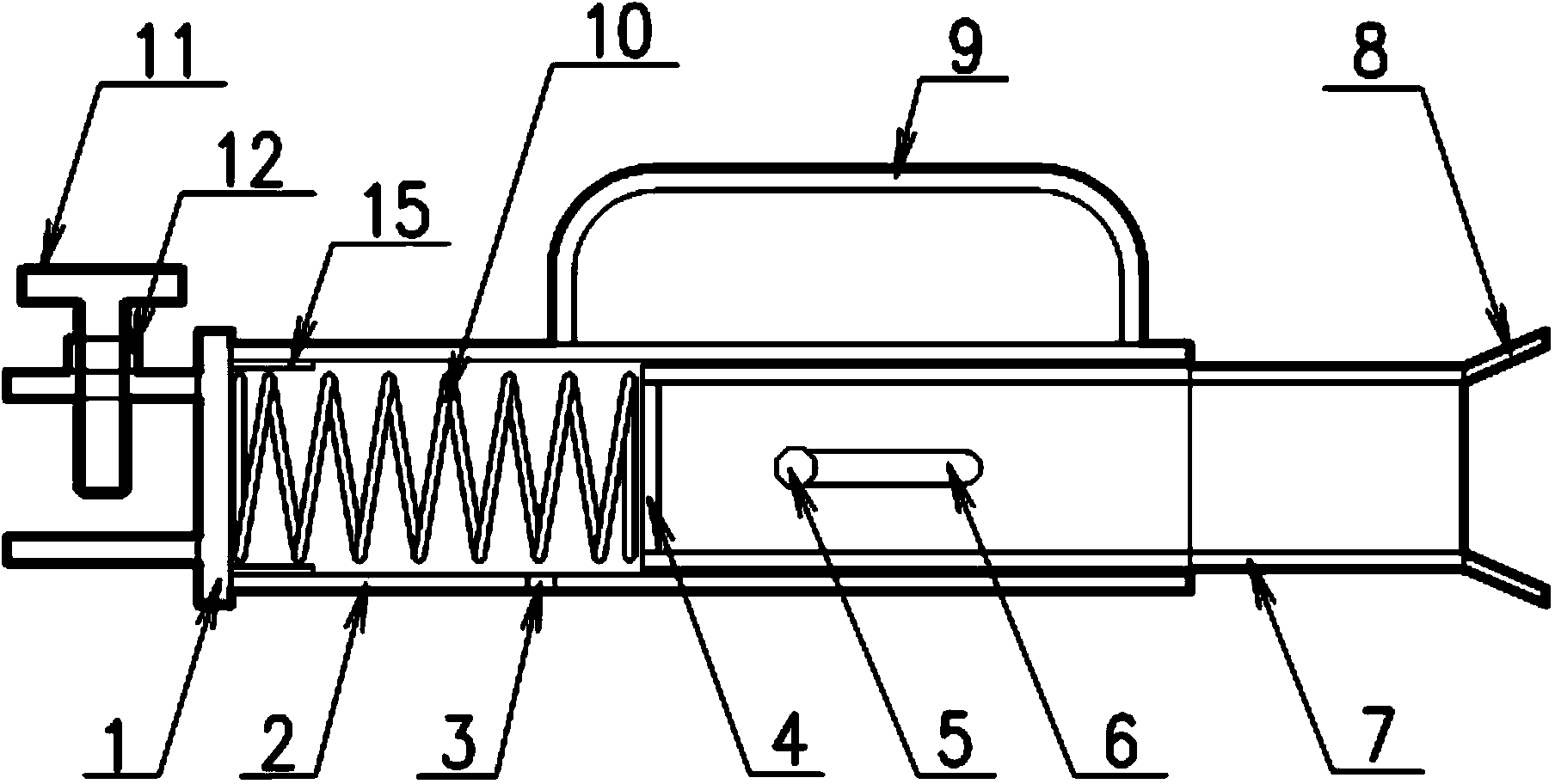

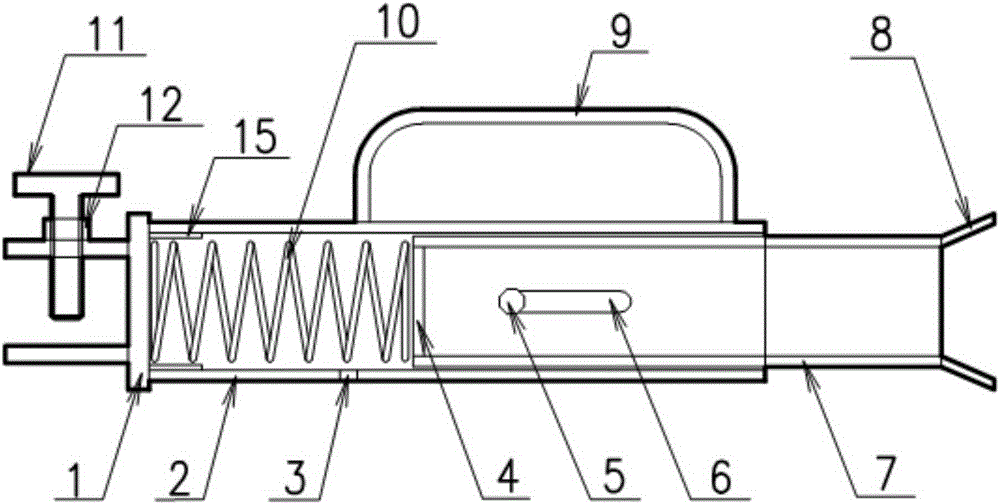

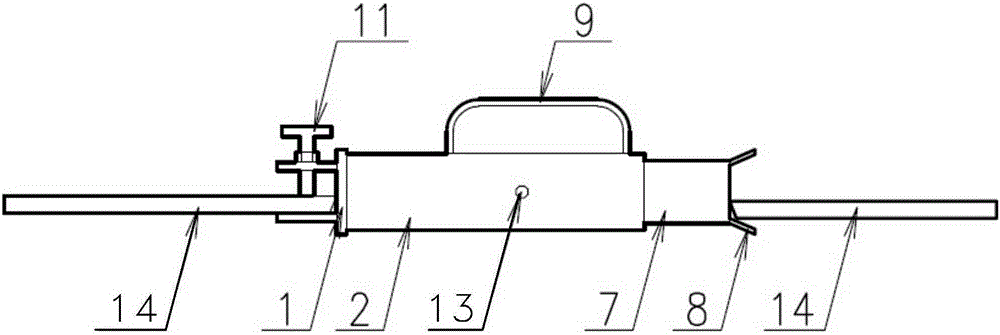

Safety protection tool in shipbuilding flat section production line

The invention provides a safety protection tool in a shipbuilding flat section production line. The safety production tool solves the problems that in an existing section production line, due to the fact that space between every two adjacent steel plates is difficult to keep, a person can be hurt through clamping or the steel plates can be damaged through crash. The safety protection tool in the shipbuilding flat section production line comprises an outer tube and an inner tube, wherein the outer tube and the inner tube are mutually connected in a sliding and sleeved mode. A clamping mechanism is fixedly arranged at the outer side of an end of one end of the outer tube, the inner end, penetrating through the outer tube, of the inner tube is a sealed opening, the outer end, extending out of the outer tube, of the inner tube is provided with a V-shaped expanding opening, a spring is further arranged in the outer tube, a gap is formed between the spring and the inner wall of the outer tube, one end of the spring abuts against the end of the outer tube, the other end of the spring abuts against the sealed opening of the inner tube, and a contactor sensor is fixedly arranged on the circumferential wall of the outer tube and is connected with an alarm through an electric signal. According to the safety protection tool in the shipbuilding flat section production line, the space between the steel plates in the production line is effectively controlled so that the person can be prevented from being hurt through clamping, groove damage caused by rigidity crash between the steel plates can be prevented, repair can be avoided, the building cost can be reduced, the circulation speed in the flat section can be increased, and the production efficiency can be improved.

Owner:QINGDAO BEIHAI SHIPBUILDING HEAVY IND CO LTD

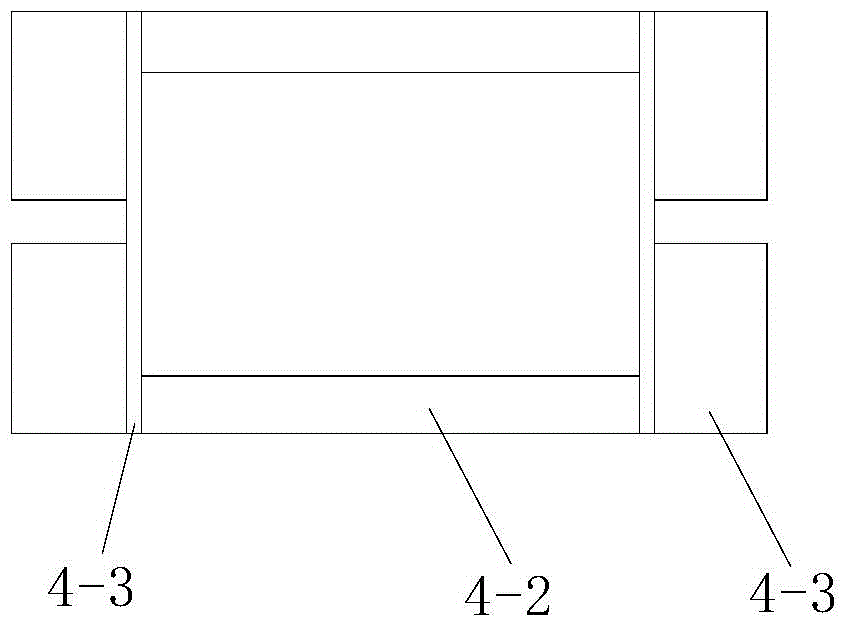

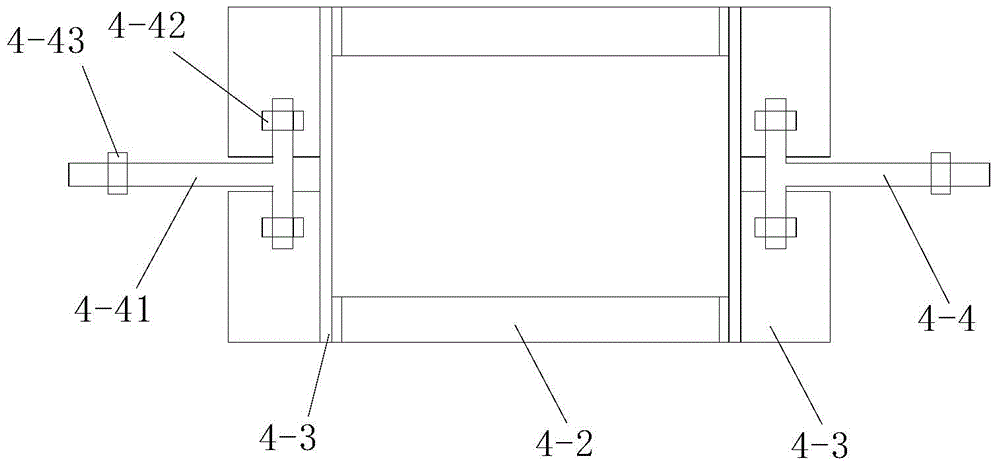

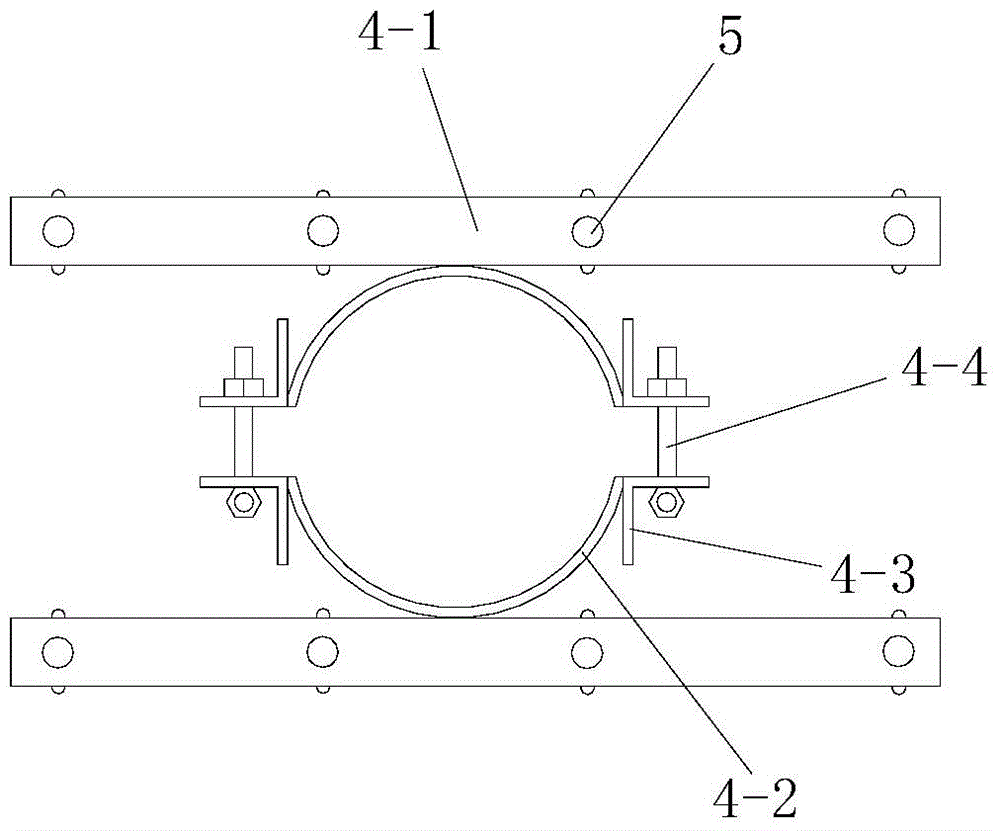

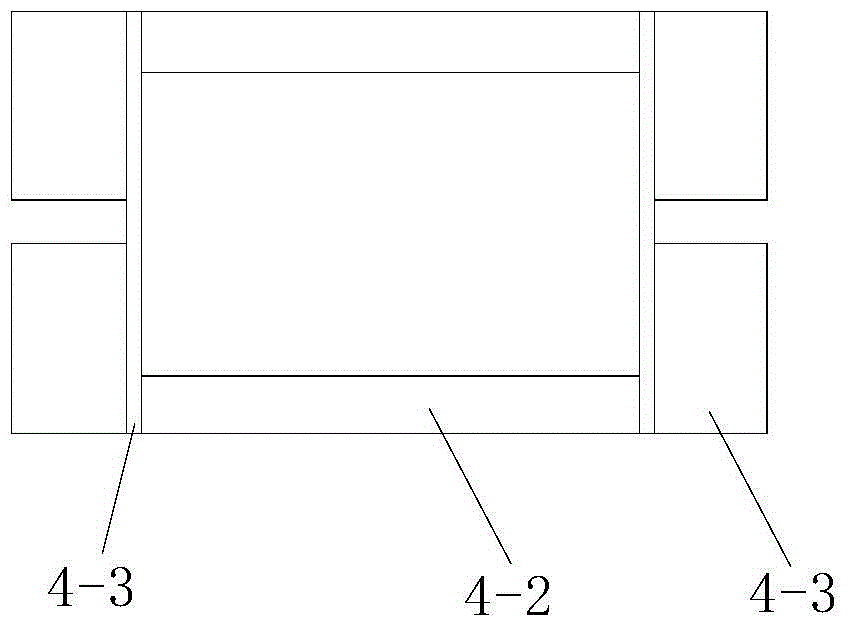

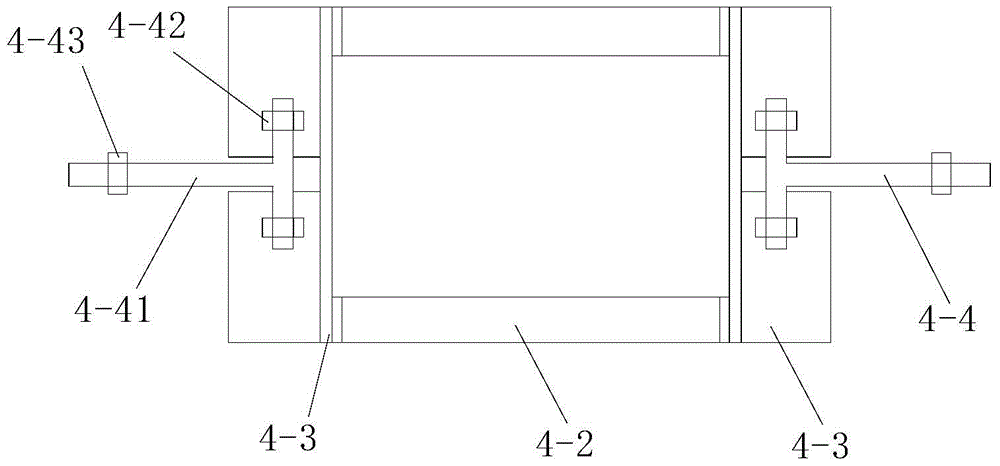

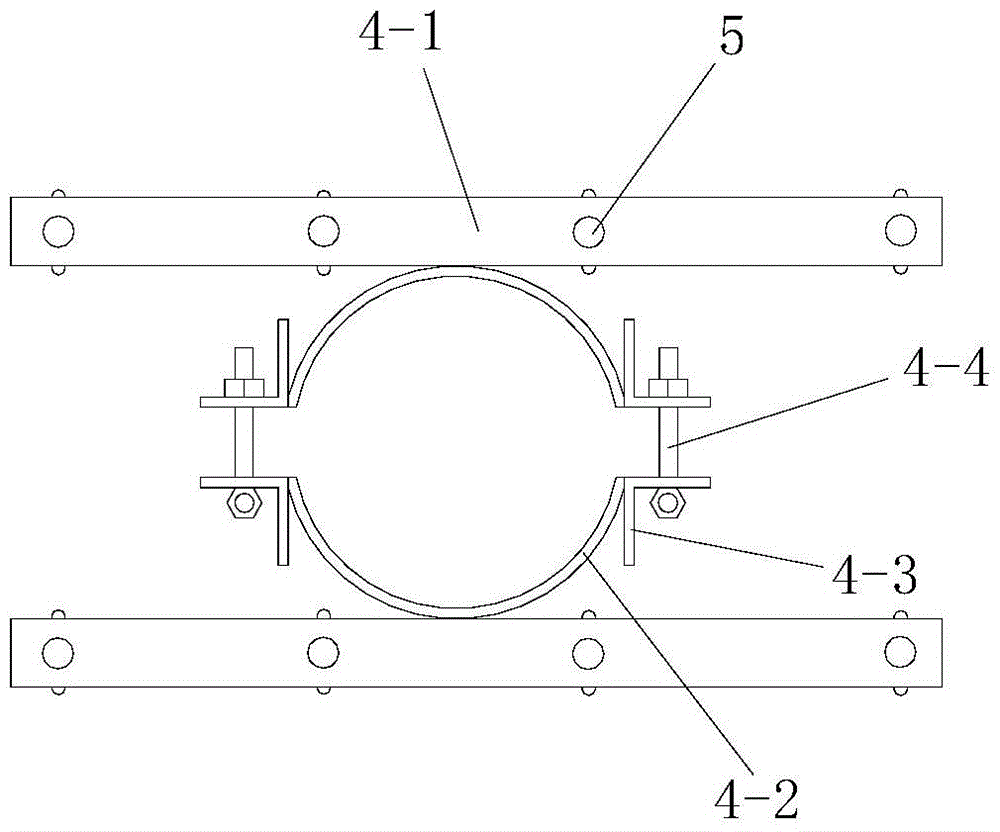

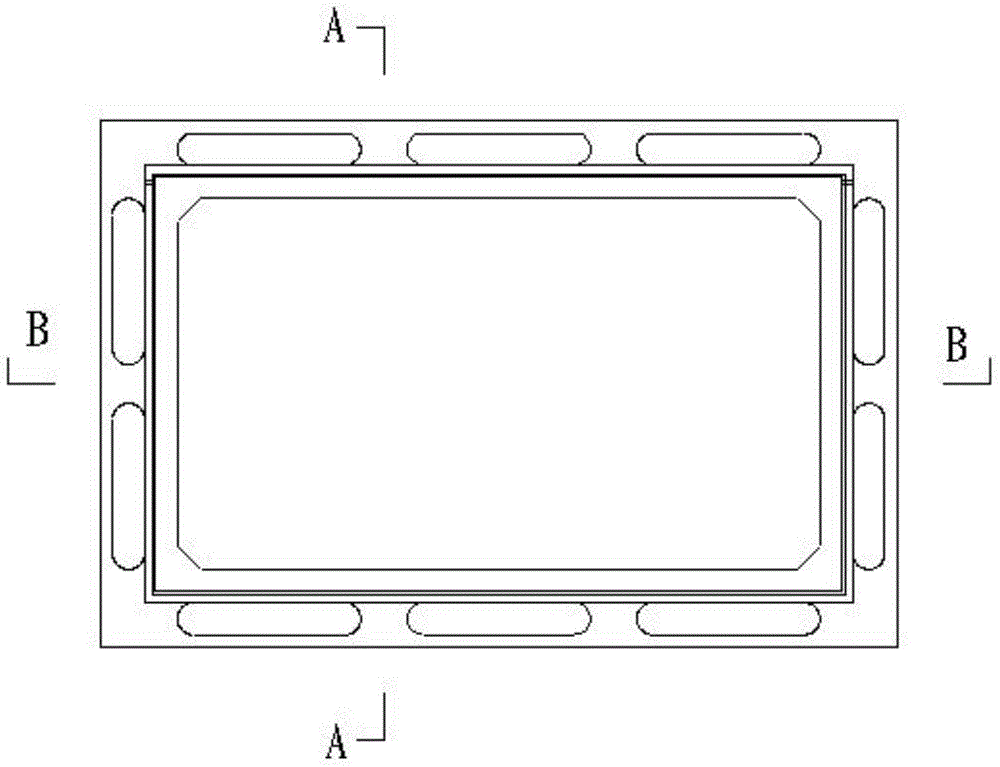

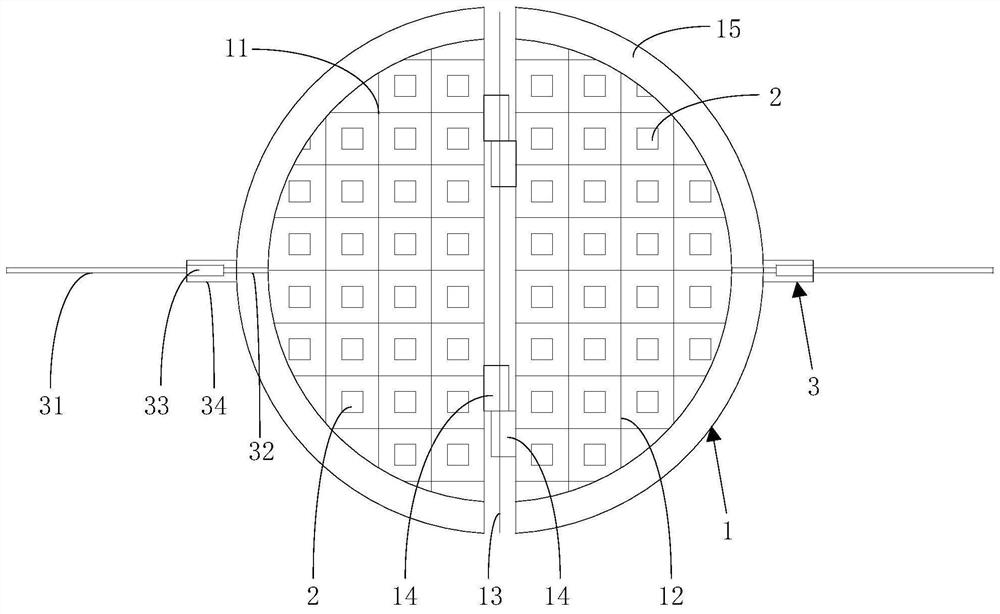

Plugging device for pipeline reserved hole of cast-in-situ slab and machining and plugging construction method

The invention discloses a plugging device for a pipeline reserved hole of a cast-in-situ slab and a machining and plugging construction method. The plugging device comprises a plugging template and a template support device. The template support device is arranged on a pipeline and comprises a hoop and two support beams. Each support beam is provided with multiple top-propping parts. Each hoop comprises two semi-hoop bodies connected by means of connecting parts. Each semi-hoop body comprises an arc plate and two side reinforcing parts. The machining method for the plugging device comprises following steps of machining arc plates, machining side reinforcing parts, machining semi-hoop bodies, machining connecting parts, installing connecting parts and machining and installing support beams. The plugging construction method comprises following steps of processing a concrete interface, installing the template support device, splicing the plugging template, adjusting a support platform, synchronously moving the template support device and the plugging template upwards, pouring concrete, maintaining concrete and removing a mold. The plugging device is reasonably designed, easily and conveniently used and operated and conveniently constructed and has a good construction effect and is capable of effectively plugging the reserved hole.

Owner:SHAANXI NO 8 CONSTR ENG

Excavation method of reverse construction method-constructed foundation pit

InactiveCN106988345AFlexible settingsResolve downtimeArtificial islandsExcavationsHigh pressure waterHigh pressure

The invention provides an excavation method of a reverse construction method-constructed foundation pit. The mechanical excavation and the hydraulic excavation are combined for construction in the reverse construction method-constructed foundation pit; when the mechanical excavation is convenient, the mechanical excavation is performed; when the mechanical excavation is limited, the hydraulic excavation is performed; a high-pressure water gun scours soil to form mud; the mud flows to a corresponding mud pool; the mud is conveyed to a mud treatment area through a mud discharge pipe; and meanwhile, a basement floor is cast to realize synchronous ground and underground construction. The excavation method effectively improves the soil excavation efficiency, is not limited by the traffic control, shortens the construction period, reduces the cost, saves the energy, and protects the environment.

Owner:WUHAN UNIV OF SCI & TECH

Double-layer support inspection well

ActiveCN105569086APrevent fallingPrevent movementArtificial islandsUnderwater structuresForeign matterEngineering

The invention relates to the technical field of road construction, and particularly relates to a double-layer support inspection well. The double-layer support inspection well has the beneficial effects that an anti-theft special-shaped bolt arranged on the double-layer support inspection well provided by the embodiment of the invention plays a role in preventing a well cover from being stolen, the compact connection of the well cover and a lifting support is ensured by adopting clamping nails and clamping grooves so as to prevent the well cover from making noise when the well cover is rolled after the well cover becomes loose; a sub well cover arranged in the inspection well can prevent the well cover from falling after the well cover is broken or other foreign matters from falling into the well when the well cover is absent; and a support body is fixed on a wellhole by adopting fixed parts, so that the support body can be prevented from moving. The double-layer support inspection well is guaranteed in terms of theft prevention, noise prevention, falling prevention, displacement prevention and the like. When being installed, the inspection well is installed layer by layer to avoid excavation and repairing of asphalt concrete at lower layers. The installation technology of the inspection well is simple. A road surface around the inspection well has good wholeness, and the quality of the road surface is ensured.

Owner:BEIJING BRIDGE RUITONG MAINTENANCE CENT +1

Concrete board and piping integrated forming method

InactiveCN113878707AImprove integrityThe molding process is simple and fastAuxillary shaping apparatusMould fastening meansArchitectural engineeringGrout

The invention discloses a concrete board and piping integrated forming method. The method comprises two working procedures of side pushing and pouring forming. A concrete form board is fixed on one side of a concrete piping pushing device through bent cover boards, the concrete piping pushing device is used for pushing a piping into the concrete form board, and pouring forming is carried out at a grouting opening in the top of the concrete form board; and an electric box forming device is arranged at the top of the concrete form board. Before concrete is poured and formed, the piping is pushed to the preset position, presetting and convenient mounting of the piping are guaranteed, the overall structure of a formed concrete board is guaranteed, and later construction and integrated forming are facilitated. The method is high in convenience degree, can effectively guarantee the construction progress of the concrete board and the piping, is high in technical application value, and is suitable for large-scale technical popularization.

Owner:CCCC FOURTH HIGHWAY ENG

Ship manufacturing method for pre-mounting steering engine base in segmentation step

The invention discloses a ship manufacturing method for pre-mounting a steering engine base in a segmentation step. The ship manufacturing method comprises the following steps of: carrying out segmentation on a deck of a steering engine room; drawing a gantry arrangement and reinforcement picture of an upper gantry of the deck of the steering engine room at a positive segmentation state; incorporating the gantry arrangement and reinforcement picture with a segmental fitting-out tray management list so as to ensure that the pre-mounting of the steering engine base is completed in a segmental manufacturing step, and the requirement on installation precision can be met; and conveying the deck of the steering engine room in a segmental manner to a next process in a positive state of the upper gantry. The steering engine base is welded before being coated in a segmental manner, so that the segmental fitting-out integrality can be improved. Therefore, the damage area of a coating layer of a ship stern ballast cabin is reduced, the risk of sand wash on the entire ship stern ballast cabin can be effectively reduced, a coating construction period is shortened, and a PSPC (Performance Standard for Protective Coatings) can be met.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Road rainwater grating well loop and method for constructing pavement structure layer comprising well loop

ActiveCN104712050ASimple structureEasy to installSewerage structuresTemporary pavingsStormwaterRoad construction

The invention relates to the technical field of town road construction and provides a road rainwater grating well loop and a method for constructing a pavement structure layer comprising the well loop. The road rainwater grating well loop is simple in structure and convenient to install. The anchoring depth of a grating well is increased through the well loop, under-layer bituminous concrete does not need to be excavated or repaired during installation, paving of under-layer bituminous concrete around the rainwater grating well can be achieved at a time, in this way, the rainwater grating well is anchored firmly, the integrity of the road surface around the rainwater grating well is high, quality is guaranteed, and damages are unlikely to occur. Furthermore, due to the fact that excavation and repair of under-layer bituminous concrete are avoided, materials and cost are saved. Finally, due to the fact that surface-layer bituminous concrete can be paved immediately after under-layer bituminous concrete is paved, construction time can be reduced by at least three to five days, and the road rainwater grating well loop is especially suitable for quick paving of town roads.

Owner:BEIJING BRIDGE RUITONG MAINTENANCE CENT +1

Motor vehicle painting process

InactiveCN105636710ACover up cosmetic imperfectionsAvoid patchingCoatingsSpecial surfacesMechanical engineeringVarnish

The invention relates to a process for painting a motor vehicle body, comprising at least the steps according to which at least one base that imparts the colour is applied to a vehicle body, then a varnish comprising matting agents that impart a matt finish and texturing agents that impart a textured finish that masks surface defects of said body is applied.

Owner:PEZHO SITROEN AUTOMOBILS SA

Penetration piece doubling plate pre-tightness manufacture and check method in ship section outfitting

InactiveCN102120483AImprove efficiencyShorten the production cycleVessel partsBill of materialsPipe fitting

The invention discloses a penetration piece doubling plate pre-tightness manufacture and check method in ship section outfitting, which comprises the following steps that: a penetration piece doubling plate with the screw hole specification of M10 is manufactured and classified into an outfitting bill of material management list, and is preassembled in a section manufacturing stage; a doubling plate manufacturer processes tightness screw holes according to a tightness screw hole standard, a marine pipe fitting factory manufacture a penetration piece, and a section manufacturer performs section preassembly; and two screw holes on the doubling plate are respectively provided with a pressure gage and a compressed air pipe through a special connecting piece, the welding line tightness state is checked, and the two M10 screw holes are subjected to repair welding and are detected by a dye penetrant inspection method to meet the tightness requirement so as to achieve the penetration piece doubling plate welding line pre-tightness. The welding line of the doubling plate of the penetration piece is subjected to a tightness test before section coating, so that the completeness of the section coating is improved; therefore, a coating damage area of a ship space is reduced, the coating construction period is shortened, and the new performance standard for protective coatings (PSPC) is met.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

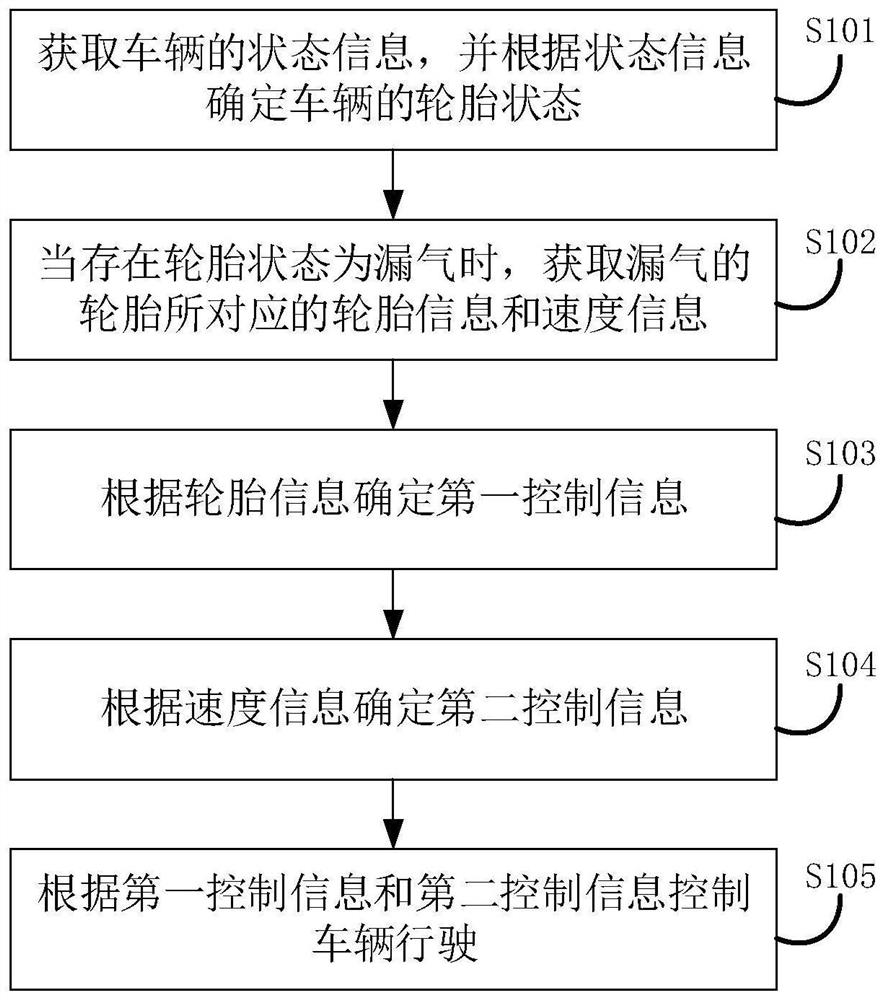

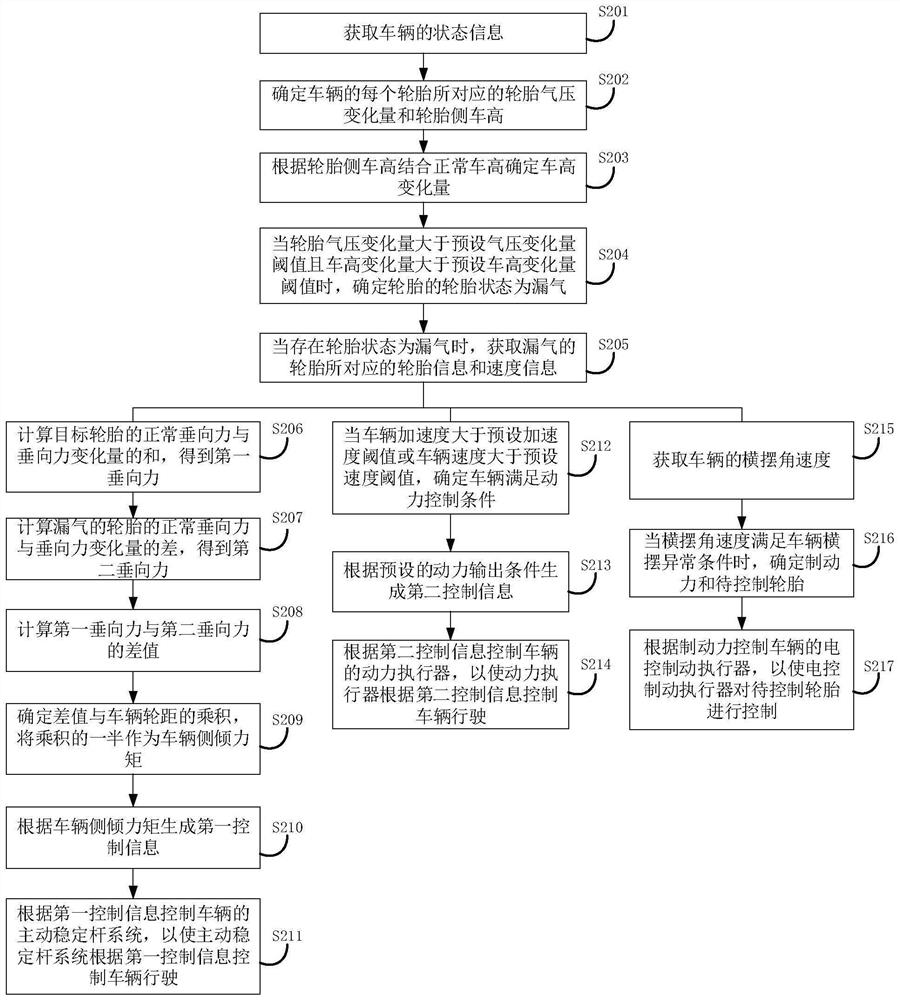

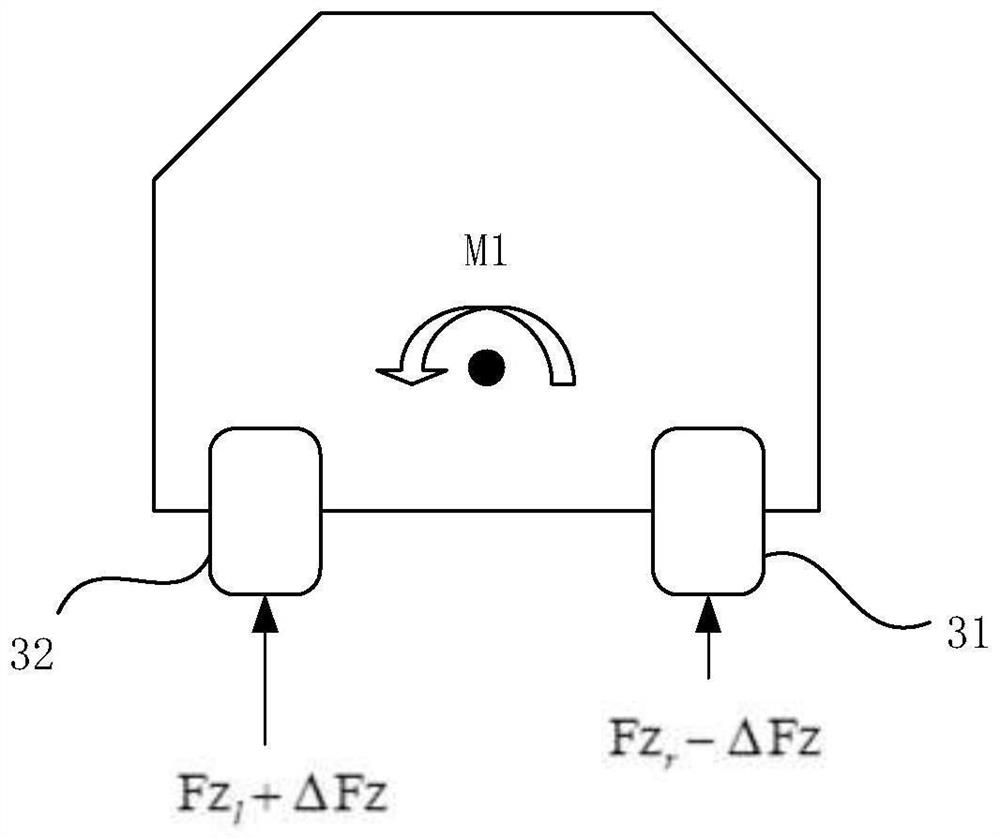

Vehicle driving control method, vehicle and storage medium

PendingCN114852053ASolve the costSolve operational problemsVehicle condition input parametersDriver/operatorVehicle driving

The invention discloses a vehicle driving control method, a vehicle and a storage medium, and the method comprises the steps: obtaining the state information of the vehicle, and determining the tire state of the vehicle according to the state information; when the tire state is air leakage, acquiring tire information and speed information corresponding to the air leakage tire; determining first control information according to the tire information; determining second control information according to the speed information; and the vehicle is controlled according to the first control information and the second control information, so that the problems of high cost and inconvenience in operation caused by replacement of a spare tire or repair of the tire when the tire leaks air in the vehicle driving process are solved, and the two aspects of the tire and the speed are considered when the vehicle is controlled; therefore, the vehicle can still run safely when the tire leaks, the tire is prevented from being replaced or repaired on the road, the cost of the vehicle is not increased, a driver does not need to master a method for replacing or repairing the tire, and the use of a user is facilitated; special tires are not needed, and cost is reduced.

Owner:CHINA FIRST AUTOMOBILE

Integrated forming and pushing method for concrete slab piping

InactiveCN113858419AAvoid extra kerf slotsAvoid installationCeramic shaping apparatusArchitectural engineeringStructural engineering

The invention discloses an integrated forming and pushing method for a concrete slab piping. By matching the method with a concrete formwork, the piping is distributed through a pushing device, and the concrete formwork and the piping are integrally formed; the pushing device comprises a rack portion, a hydraulic rod connecting portion and a piping pushing portion; and the hydraulic rod connecting portion and the piping pushing portion are both installed on the rack portion, and the hydraulic rod connecting portion is used for adjusting the position of the piping pushing portion. The method is high in convenience degree, capable of effectively guaranteeing the construction progress of a concrete slab and the piping, high in technical application value and suitable for large-scale technical popularization.

Owner:CCCC FOURTH HIGHWAY ENG

Mounting method for templates of box-type steel skeleton inclined column

ActiveCN102926532BAvoid tinkeringAvoid Welding Anchor BoltsForms/shuttering/falseworksInstabilityEngineering

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

A double-layer support inspection well

ActiveCN105569086BPrevent fallingPrevent movementArtificial islandsUnderwater structuresForeign matterRoad surface

The invention relates to the technical field of road construction, and particularly relates to a double-layer support inspection well. The double-layer support inspection well has the beneficial effects that an anti-theft special-shaped bolt arranged on the double-layer support inspection well provided by the embodiment of the invention plays a role in preventing a well cover from being stolen, the compact connection of the well cover and a lifting support is ensured by adopting clamping nails and clamping grooves so as to prevent the well cover from making noise when the well cover is rolled after the well cover becomes loose; a sub well cover arranged in the inspection well can prevent the well cover from falling after the well cover is broken or other foreign matters from falling into the well when the well cover is absent; and a support body is fixed on a wellhole by adopting fixed parts, so that the support body can be prevented from moving. The double-layer support inspection well is guaranteed in terms of theft prevention, noise prevention, falling prevention, displacement prevention and the like. When being installed, the inspection well is installed layer by layer to avoid excavation and repairing of asphalt concrete at lower layers. The installation technology of the inspection well is simple. A road surface around the inspection well has good wholeness, and the quality of the road surface is ensured.

Owner:BEIJING BRIDGE RUITONG MAINTENANCE CENT +1

Plugging device and processing and plugging construction method for reserved hole of cast-in-place slab pipeline

InactiveCN104912209BSimple structureReasonable designBuilding insulationsMachiningBuilding construction

The invention discloses a plugging device for a pipeline reserved hole of a cast-in-situ slab and a machining and plugging construction method. The plugging device comprises a plugging template and a template support device. The template support device is arranged on a pipeline and comprises a hoop and two support beams. Each support beam is provided with multiple top-propping parts. Each hoop comprises two semi-hoop bodies connected by means of connecting parts. Each semi-hoop body comprises an arc plate and two side reinforcing parts. The machining method for the plugging device comprises following steps of machining arc plates, machining side reinforcing parts, machining semi-hoop bodies, machining connecting parts, installing connecting parts and machining and installing support beams. The plugging construction method comprises following steps of processing a concrete interface, installing the template support device, splicing the plugging template, adjusting a support platform, synchronously moving the template support device and the plugging template upwards, pouring concrete, maintaining concrete and removing a mold. The plugging device is reasonably designed, easily and conveniently used and operated and conveniently constructed and has a good construction effect and is capable of effectively plugging the reserved hole.

Owner:SHAANXI NO 8 CONSTR ENG

Road rainwater grate well circle and construction method of pavement structure layer including the well circle

ActiveCN104712050BSimple structureStable structureSewerage structuresTemporary pavingsSurface layerGrating

The invention relates to the technical field of town road construction and provides a road rainwater grating well loop and a method for constructing a pavement structure layer comprising the well loop. The road rainwater grating well loop is simple in structure and convenient to install. The anchoring depth of a grating well is increased through the well loop, under-layer bituminous concrete does not need to be excavated or repaired during installation, paving of under-layer bituminous concrete around the rainwater grating well can be achieved at a time, in this way, the rainwater grating well is anchored firmly, the integrity of the road surface around the rainwater grating well is high, quality is guaranteed, and damages are unlikely to occur. Furthermore, due to the fact that excavation and repair of under-layer bituminous concrete are avoided, materials and cost are saved. Finally, due to the fact that surface-layer bituminous concrete can be paved immediately after under-layer bituminous concrete is paved, construction time can be reduced by at least three to five days, and the road rainwater grating well loop is especially suitable for quick paving of town roads.

Owner:BEIJING BRIDGE RUITONG MAINTENANCE CENT +1

Carboxypoly ose mixed resin mortar for strengthening concrete

InactiveCN1613815AGood physical propertiesImprove bindingBuilding repairsSynthetic resinMaterials science

A carboxymethyl glycan mixed resin grout for fixing and enhancing concrete consists of cement 10-50wt%, alumina cement 1-15wt%, silica sand 40-60wt%, lime rock 5-20wt%, carboxymethyl glycan 0.05-5wt% and powdery re-dispersing synthetic resin 1-10wt%. Its advantages include good combination and waterproof performance.

Owner:M&S IND

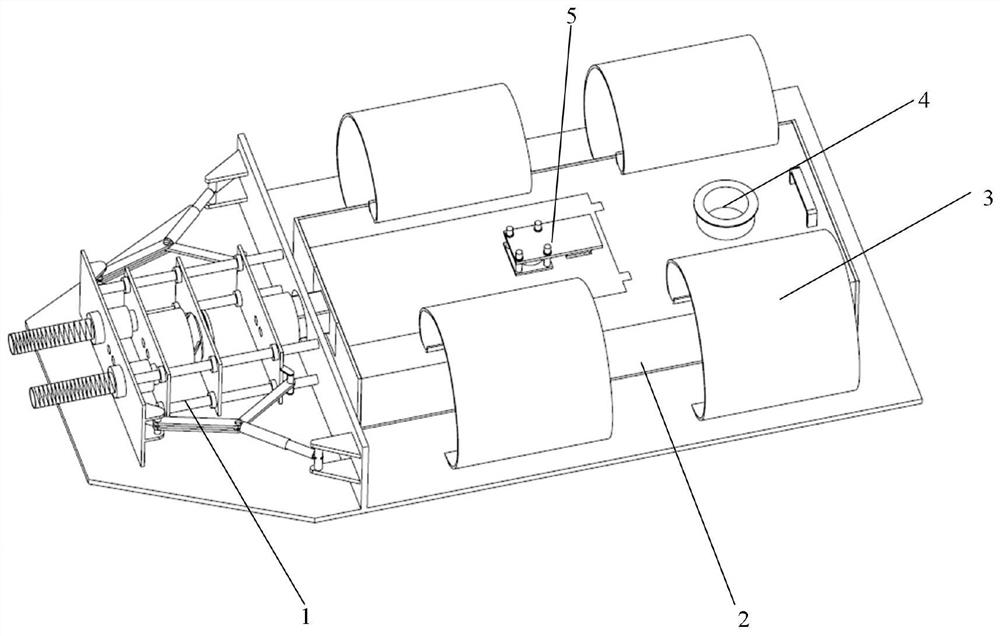

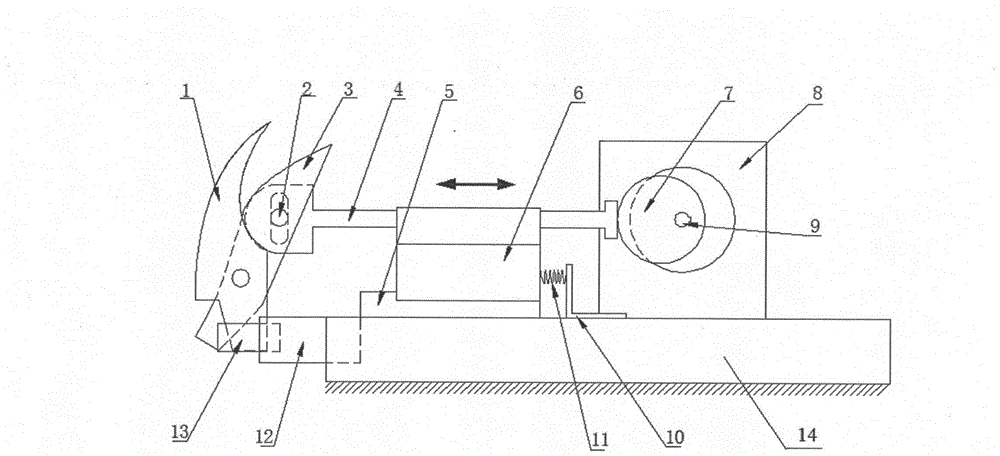

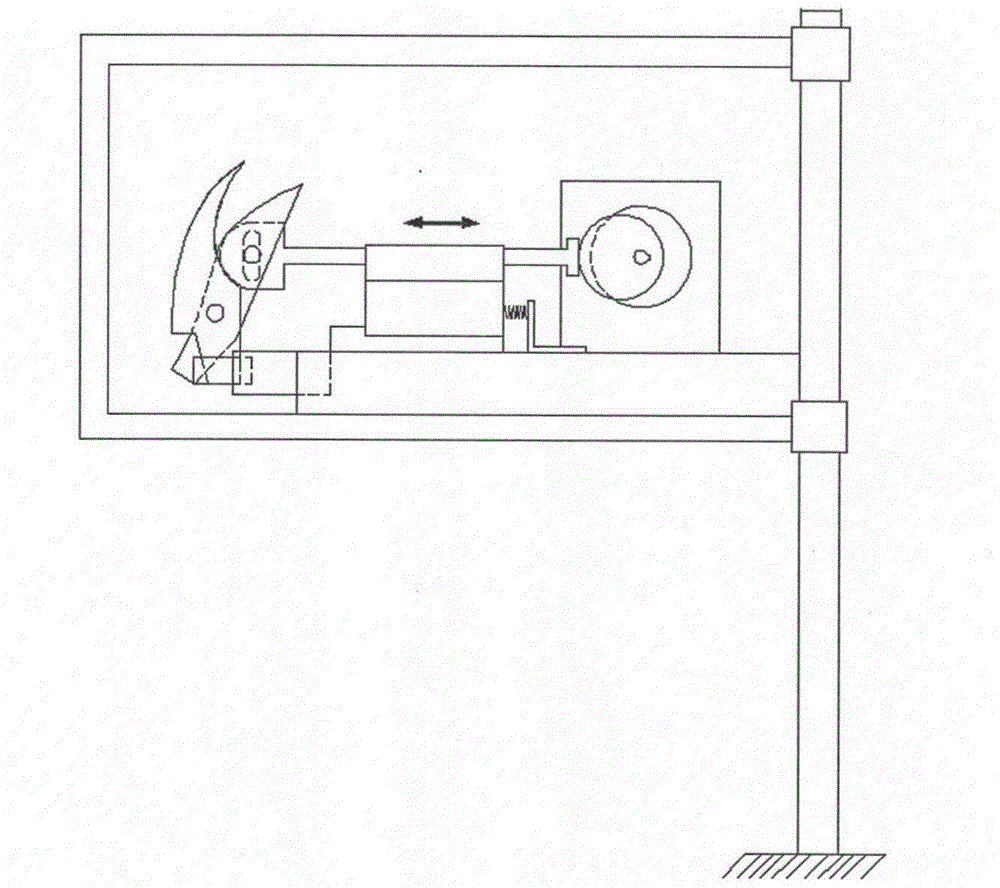

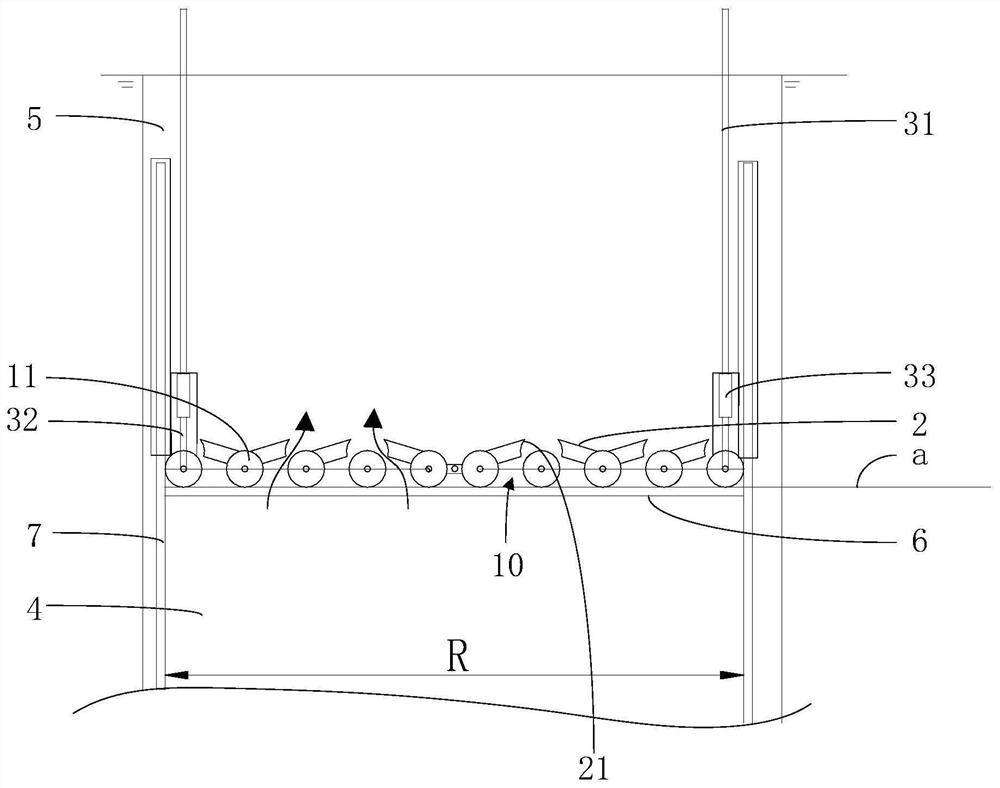

An automatic hook and yarn cutting device for repairing artificial turf

The invention provides an automatic yarn hooking and shearing device for repairing an artificial lawn. The automatic yarn hooking and shearing device is characterized by comprising a pair of hooking and shearing dual-use scissors, which is connected with a scissors connecting rod piece, a scissors driving device can drive the hooking and shearing dual-use scissors to shear off yarns through the scissors connecting rod piece, the pair of hooking and shearing dual-use scissors comprises a first part and a second part, the middle parts of the first part and the second part are connected by adopting a relative rotating manner, the upper part of the first part is shaped like a hook which can hook the yarns, the lower end of the first part is fixed on a base, and the upper part of the second part is connected with the scissors driving device through the scissors connecting rod piece. The repairing of the lawn completed by workers through a series of yarn hooking and shearing operations can be avoided through adopting automatic yarn hooking and shearing task, a great amount of manpower can be saved and the working efficiency can also be improved, and the current blank of lack of technology of automatically repairing the artificial lawn can be filled up.

Owner:DONGHUA UNIV

Safety protective tooling in the shipbuilding plane segmented assembly line

Owner:QINGDAO BEIHAI SHIPBUILDING HEAVY IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com