Bulbous bow refit technology

A bulbous bow and craft technology, applied in the directions of transportation and packaging, ship parts, ships, etc., can solve the problems of inaccurate closing of the new bulbous bow and the original ship, the bulky size of the bulbous bow, and the damage to the original ship, etc. Construction time, easy and fast operation, accurate closing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

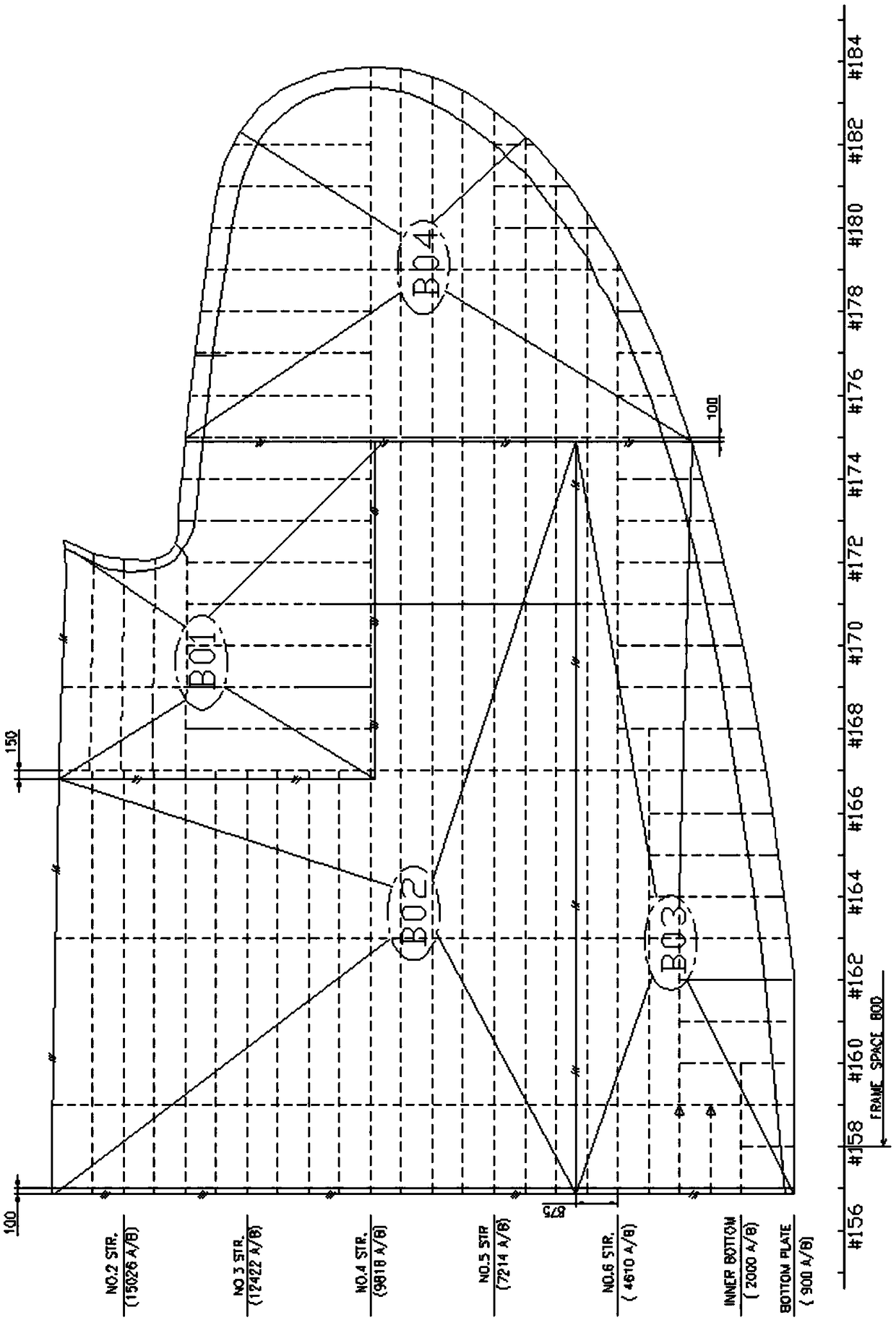

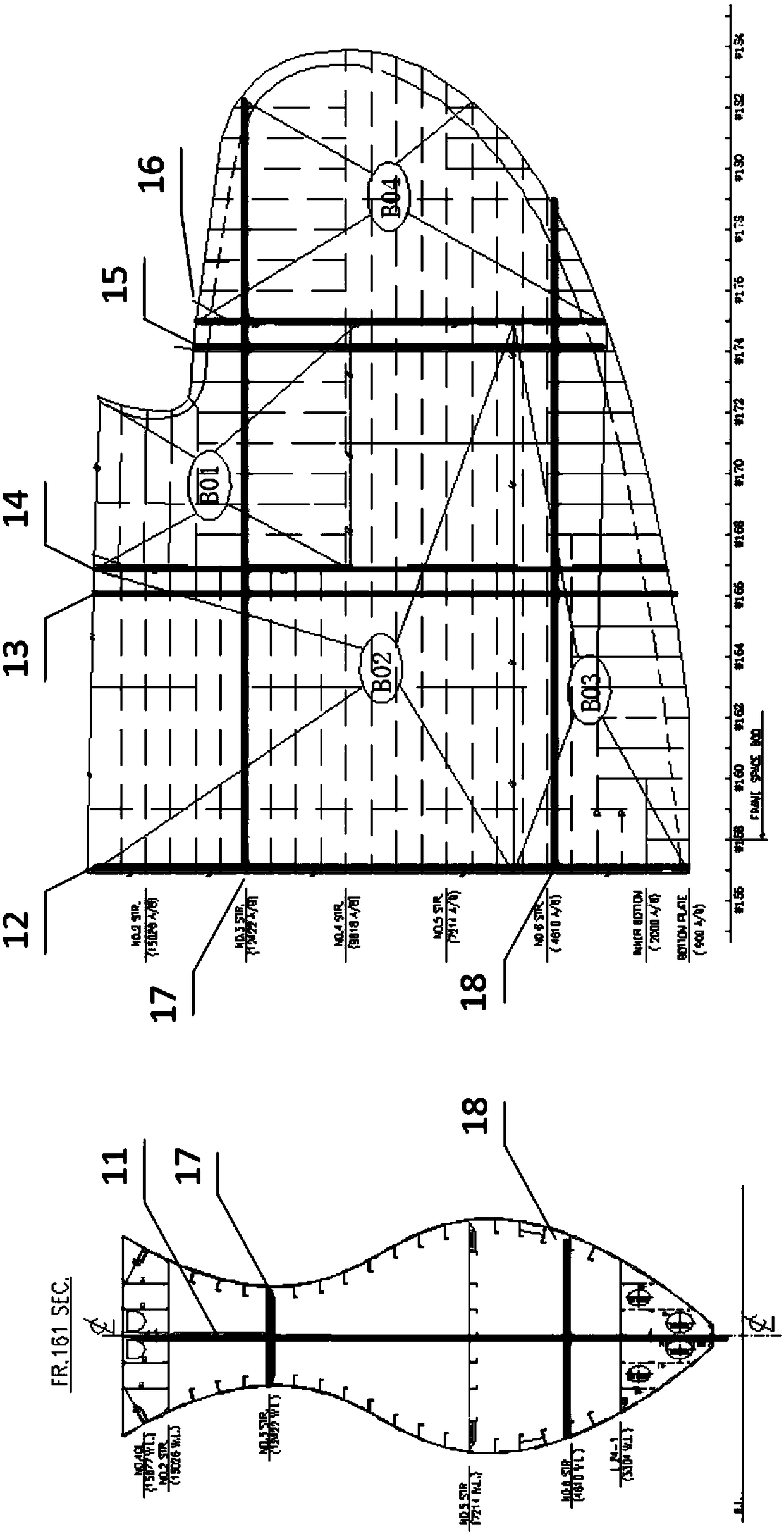

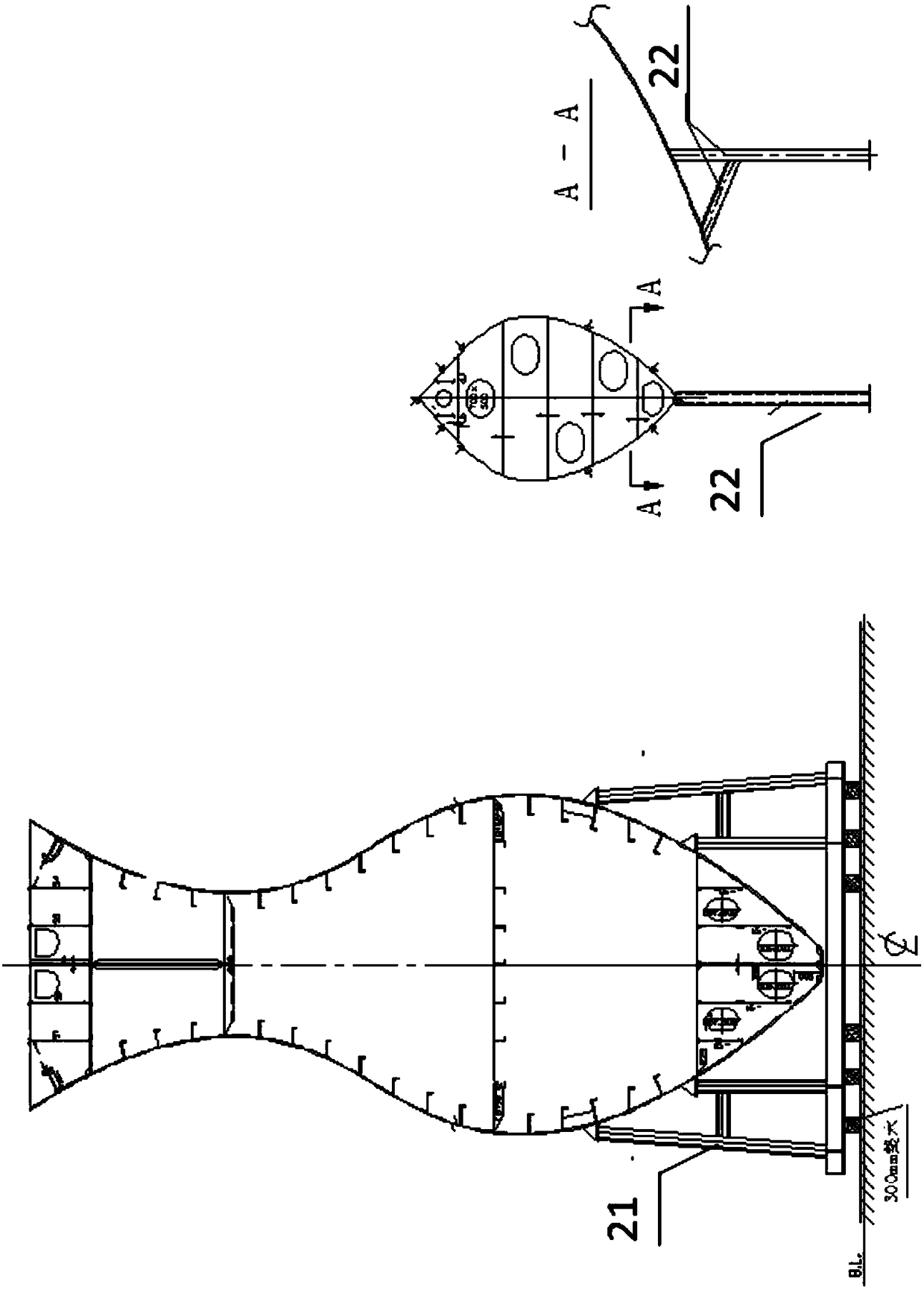

[0020] In the present invention, before the ship enters the factory, the new bulbous bow general section is prefabricated in the workshop according to the drawings. After the ship enters the factory, cut off the relevant position of the old bulbous bow in the dock according to the requirements of the drawing, and remove the cut part. Finally, use the floating crane to hoist the new bulbous bow section into the dock, pull it into place through the large-scale segmental shift tooling pre-installed on the bottom of the dock, and use a group of segmental positioning trolleys to move it in a small range , to accurately locate the general section of the new bulbous bow. Replacing the old bulbous bow with a re-optimized and designed structure can reduce the navigation resistance of the ship at low speed, reduce the fuel consumption of the ship, and reduce the shipping cost. At the same time, the refitting process of the present invention can greatly reduce the bulbous bow replacement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com