Method and device of tightness test for filler weld

A fillet weld and tightness technology, which is applied in the direction of using liquid/vacuum to measure the liquid tightness and detecting the appearance of fluid at the leakage point, etc., can solve the problems of inability to guarantee safe production, slow speed of tightness test, and poor quality and other issues to achieve the effect of shortening the production cycle, ensuring integrity and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

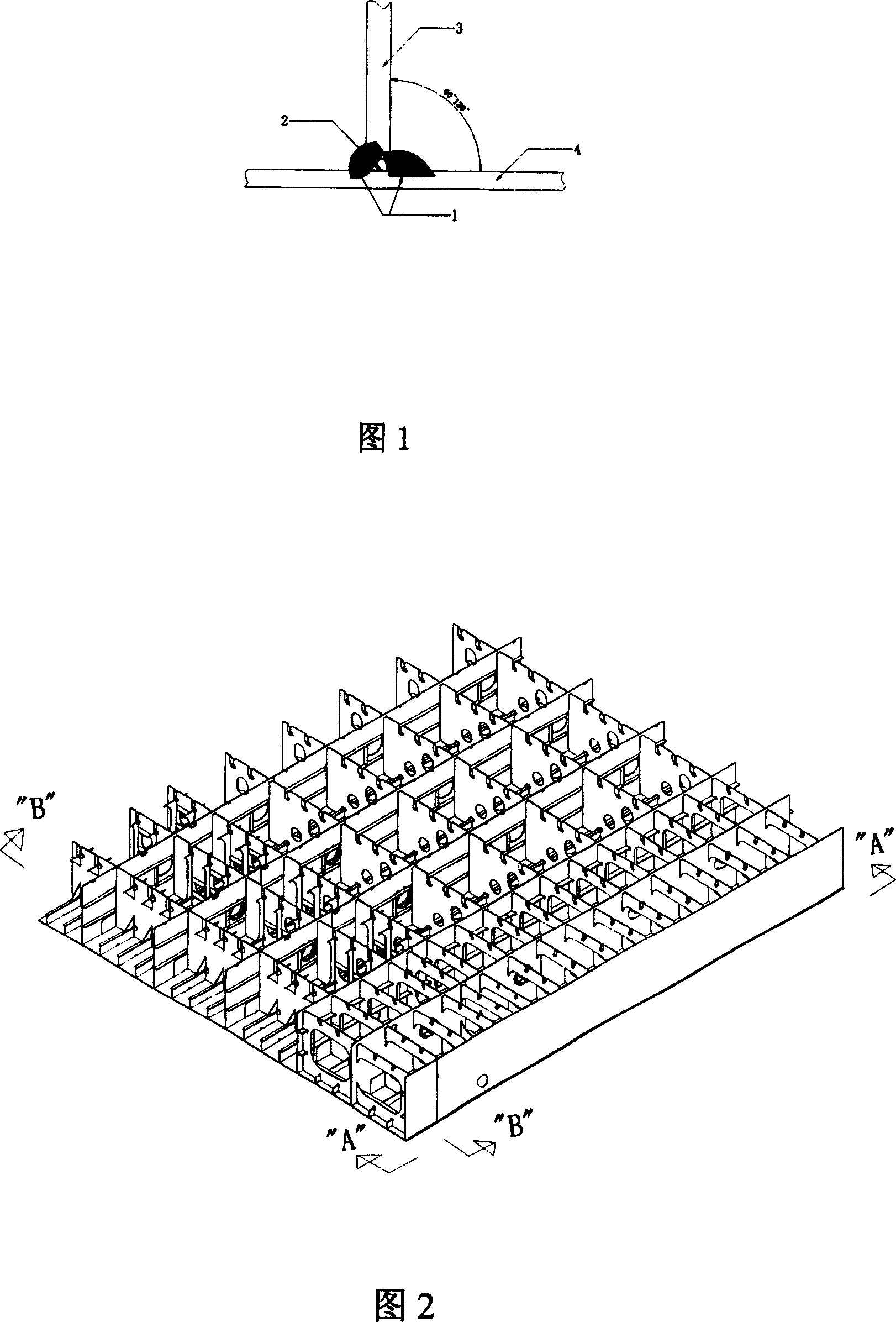

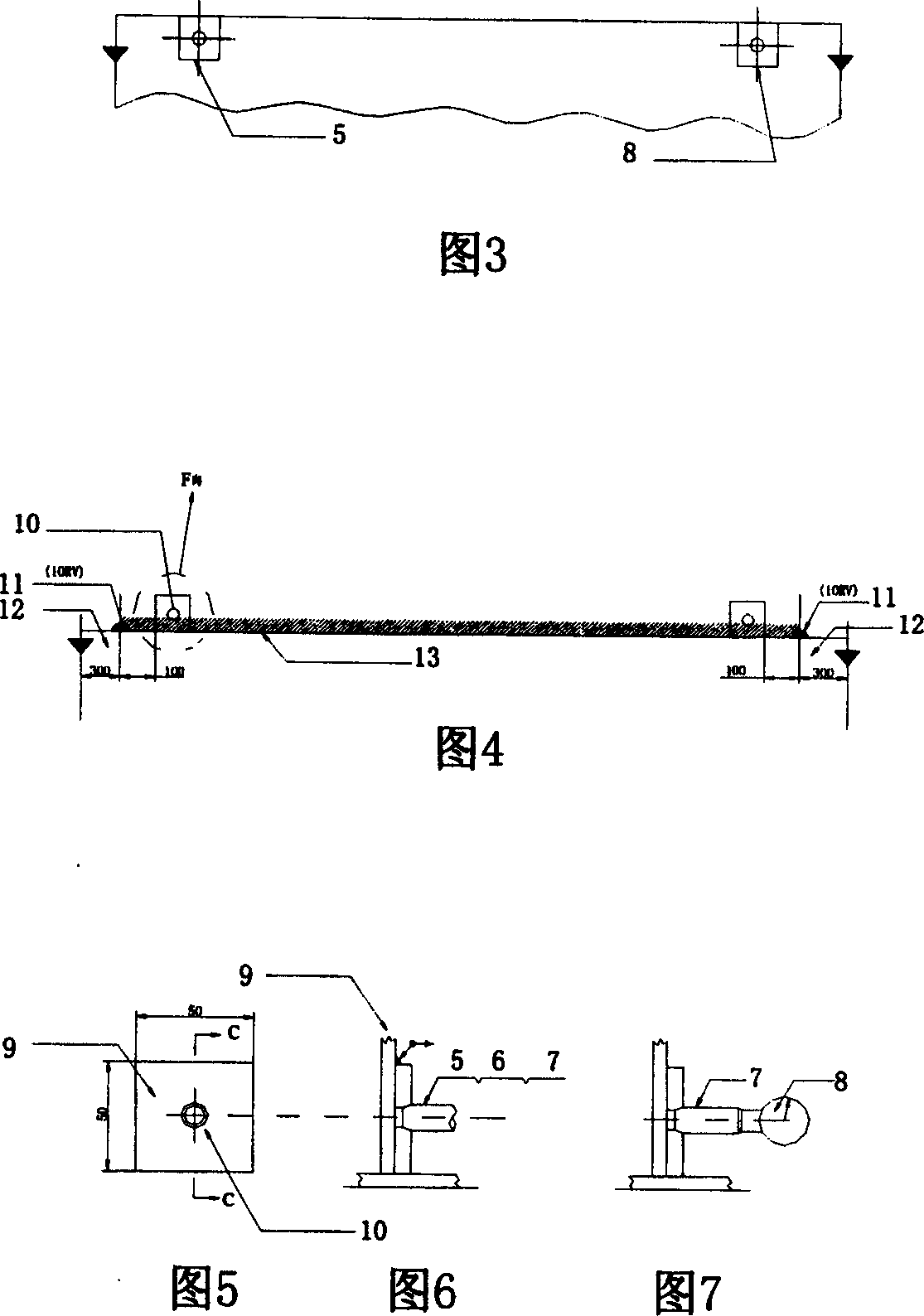

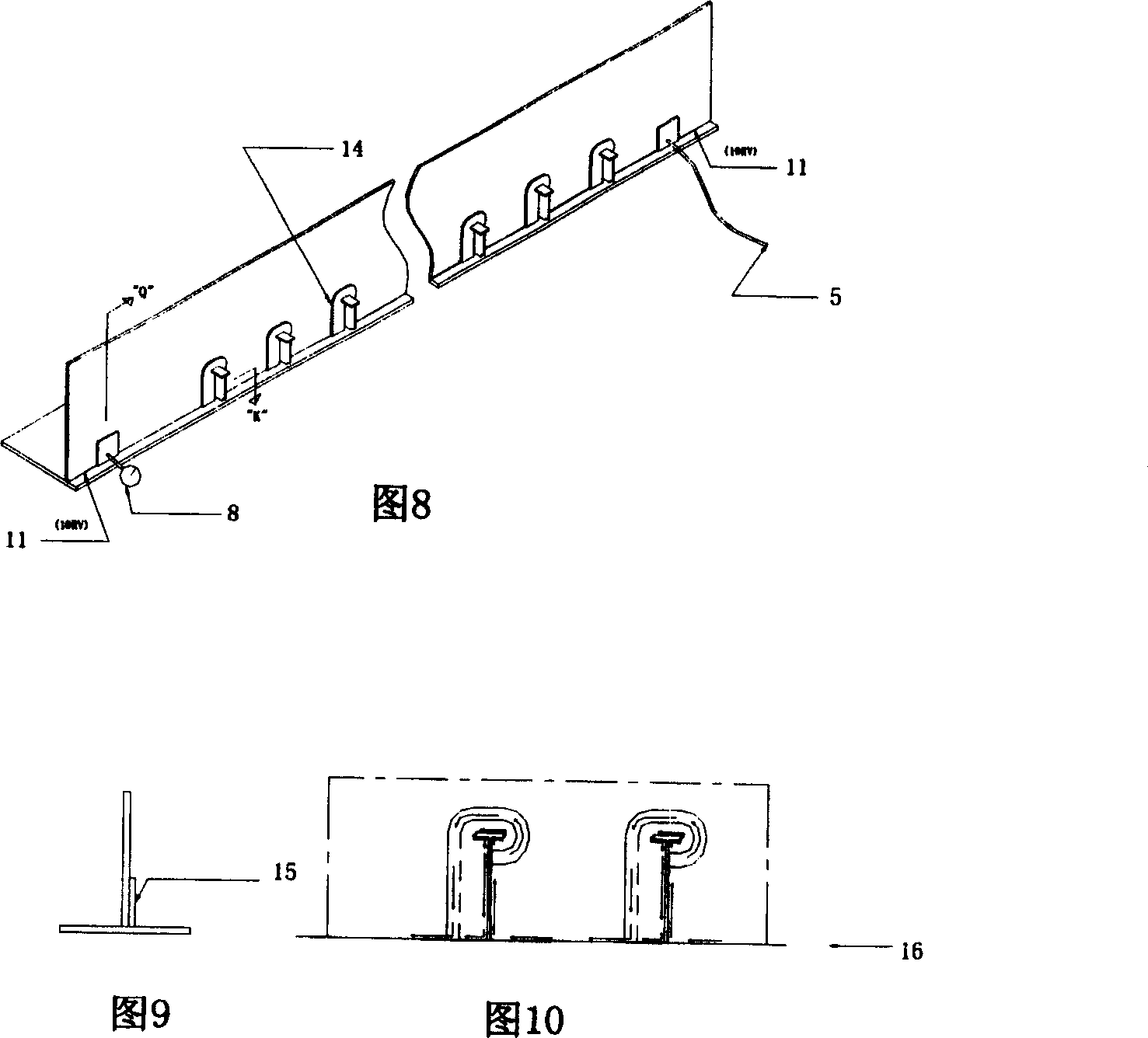

[0036] The present invention is described in detail as follows in conjunction with accompanying drawing:

[0037] The fillet weld airtightness test method and equipment described in the present invention are used for the airtightness inspection of plane sections in modern shipbuilding docks. The oil and water tanks of a part of the hull structure must be tested for tightness after the construction is completed, so as to check the tightness or strength of the welding or structure of this part. According to the construction policy, the segmental closed mouth fillet welds are welded when loading in the dock, and the cabin pressure test is done. The fillet weld tightness test is carried out on segments and segments. When the segments and segments are assembled and welded, the fillet weld tightness test can be carried out after the weld shape inspection is qualified. The fillet weld tightness test involves the hull bottom, side, deck, girder and other sections, accounting for 2 / 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com