Method for guiding web patching using a re-reeler and a corresponding system

A technology for rewinding machines and paper webs, which is applied in material analysis, papermaking, papermaking machines, etc. through optical means, and can solve problems such as the causal relationship investigation of deviations that hinder paper breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

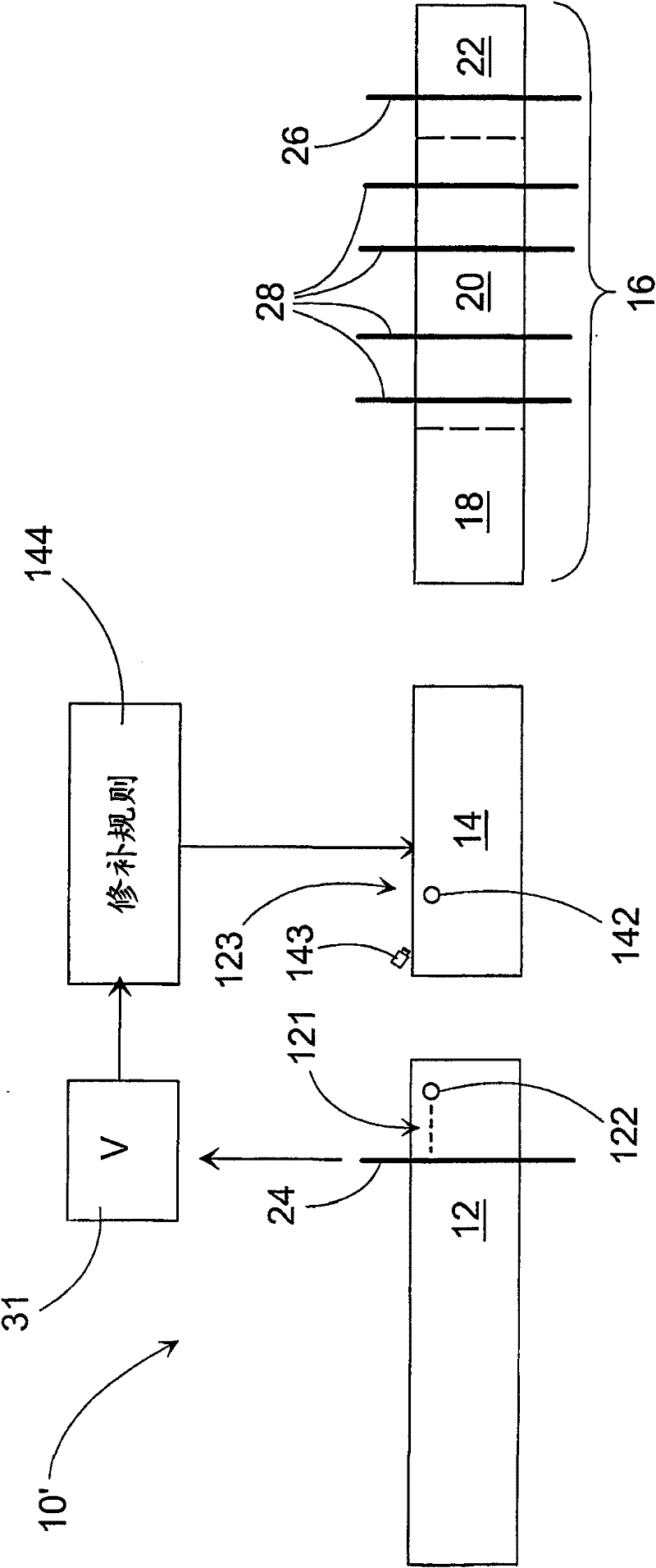

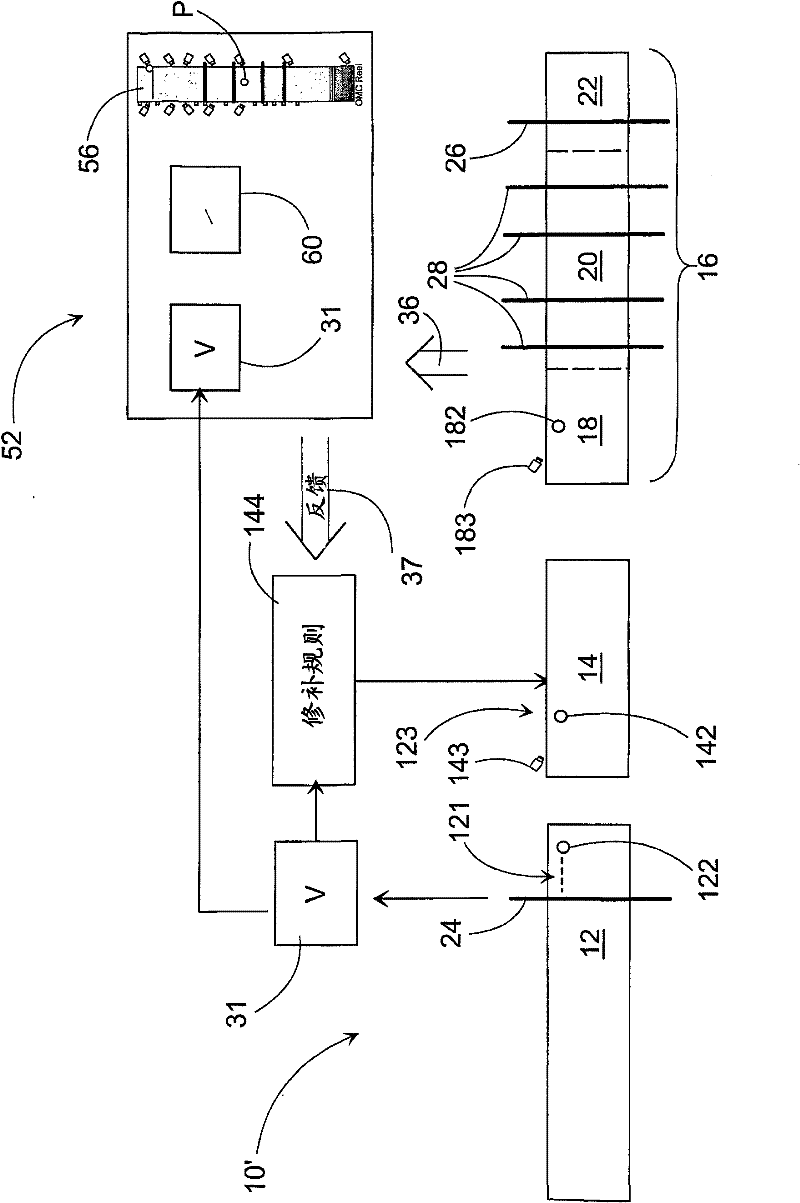

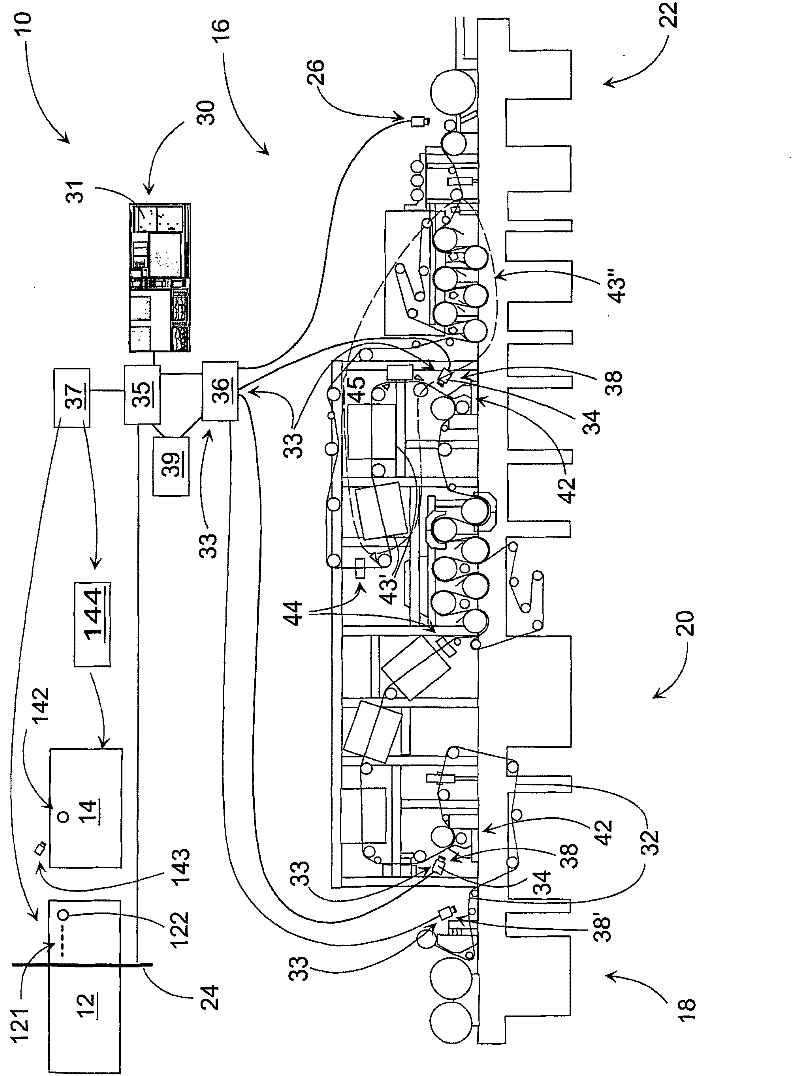

[0024] Figure 1a A system 10 ′ according to the prior art is shown in which a paper web is first produced on a paper machine 12 . The produced web is coated on an off-line coater 16 after being rewound on a rewinder 14, cut to standard width and repaired. Coater 16 is roughly divided into three sections, namely unwind 18 , coating section 20 and take-up 22 . After the coater, coating bumps and streaks are removed from the web on a second rewinder (not shown). Thereafter, the web can be calendered. The same rewinder that rewinds before the coater can be used in post-coater removal of coating pimples and streaks, but usually a second rewinder is used to rewind after the coater.

[0025] exist Figure 1a In the illustrated system according to the prior art, a defect map is generated for display to the operator of the coating machine from the defects in the web prior to coating. The defect map 31 is generated using image processing from image data imaged by the defect detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com