Nano-filtration membrane base material production method based on wet papermaking technology

A production method and technology of microfiltration membranes, applied in papermaking, papermaking machines, textiles and papermaking, etc., can solve the problems of large pore size and porosity, poor surface smoothness, poor tensile strength, etc., and achieve good pollution resistance, Uniform moisture and good paper evenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

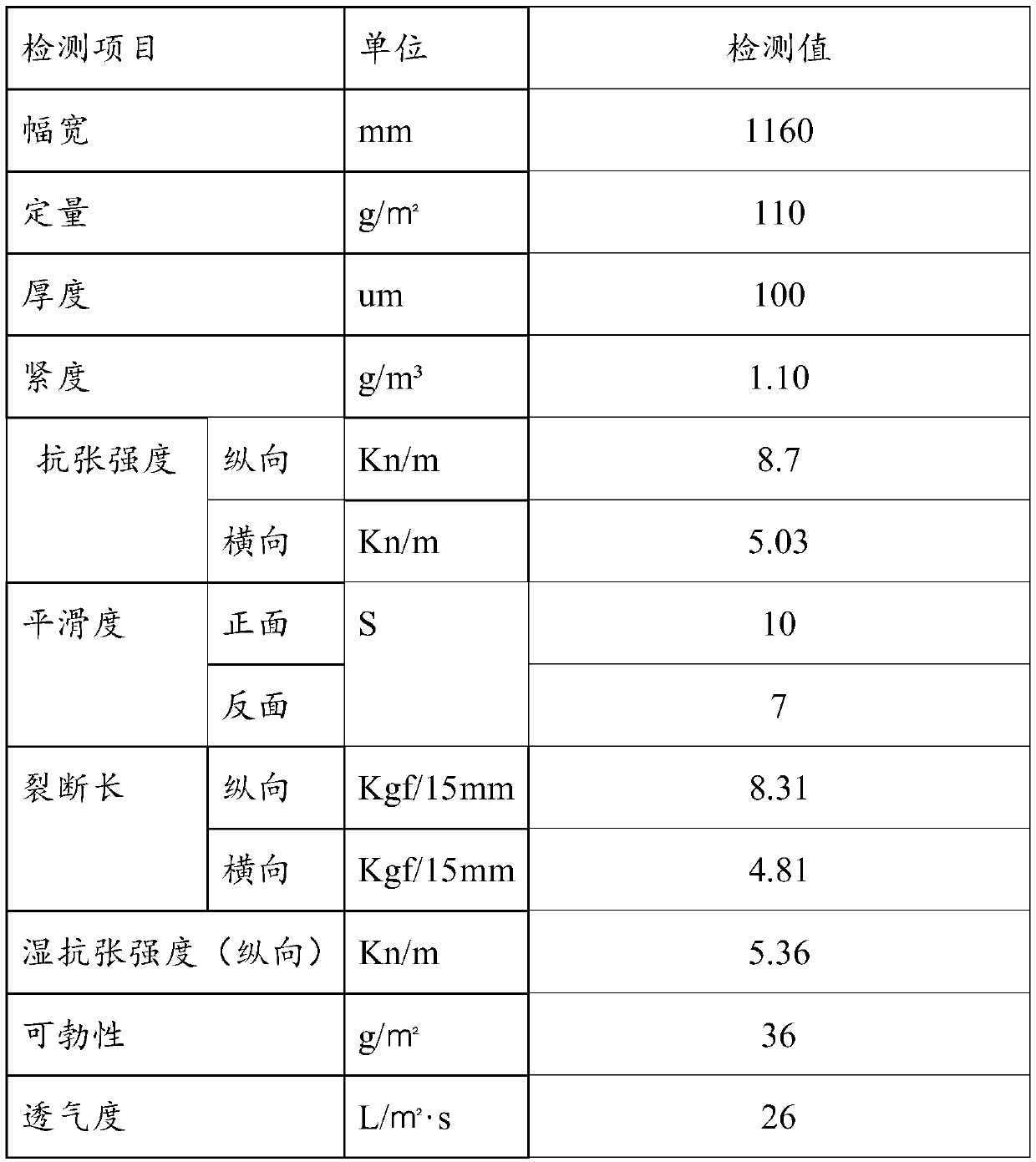

Embodiment 1

[0024] A method for producing a microfiltration membrane substrate based on wet papermaking technology, the steps of the method are as follows:

[0025] S1: After preparing the fluffed chemical fiber, mix the slurry, and control the mass concentration of the slurry to 0.5%;

[0026] S2: The slurry is added with a dispersant and defoamer before flushing, and then enters the sand remover. The amount of dispersant is 1% of the slurry mass, and the amount of defoamer is 0.01% of the slurry mass. There are three sections;

[0027] S3: enter the secondary flushing;

[0028] S4: After the second flushing, enter the pressure screen for processing, add PEO retention aid at the outlet of the pressure screen, and the mass dosage of PEO retention aid is 0.003%;

[0029] S5: the slurry in step S4 flows into the headbox and is copied on the Internet;

[0030] S6: press dehydration;

[0031] S7: drying treatment;

[0032] S8: Calender treatment;

[0033] S9: coiling, coupon cutting, pa...

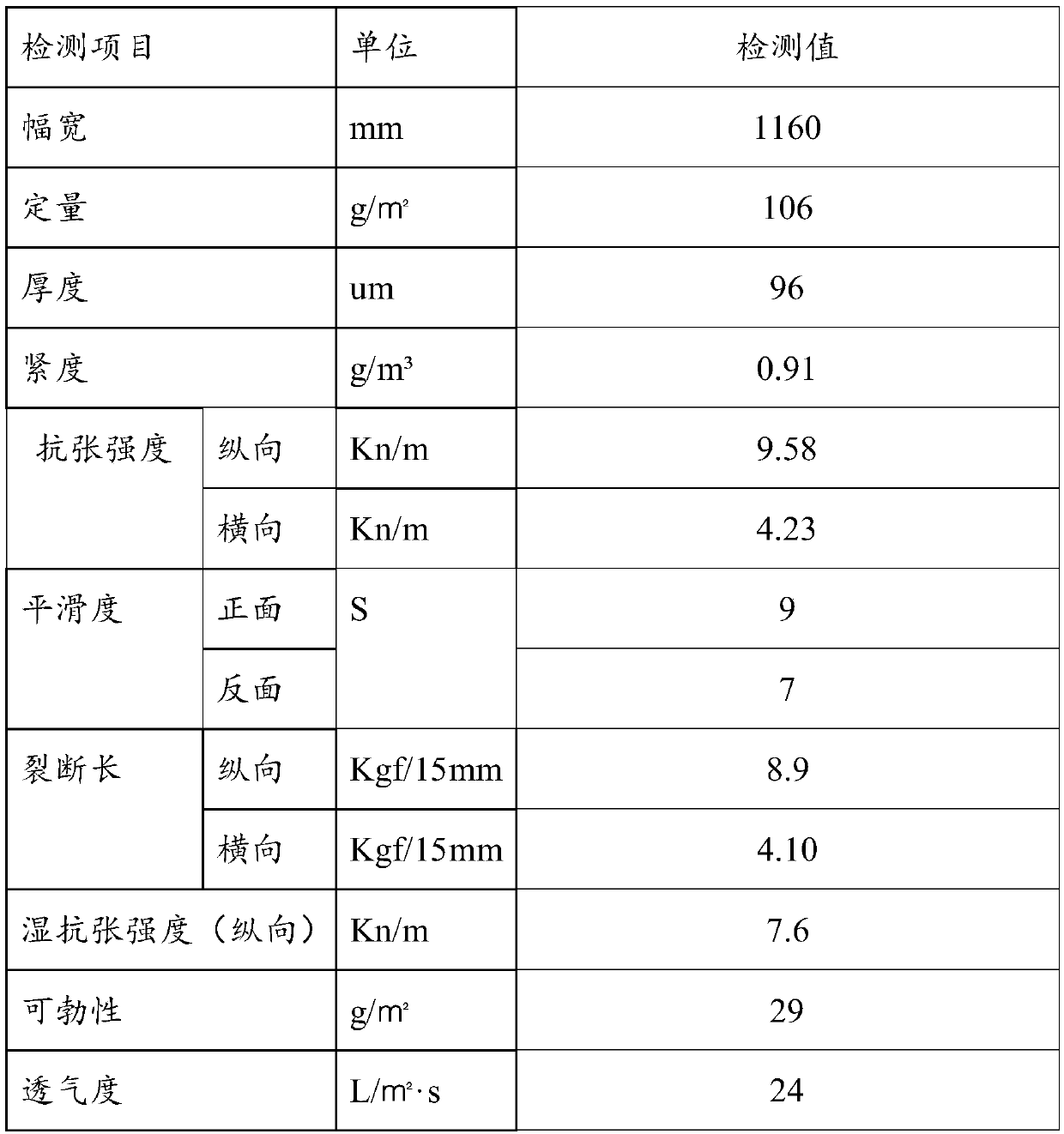

Embodiment 2

[0039] A method for producing a microfiltration membrane substrate based on wet papermaking technology, the steps of the method are as follows:

[0040] S1: After preparing the fluffed chemical fiber, mix the slurry, and control the concentration of the slurry to 3%;

[0041] S2: Add dispersant and defoamer to the slurry before flushing once, and then enter the sand remover. The amount of dispersant is 3% of the slurry mass, and the amount of defoamer is 0.03% of the slurry mass. There are three paragraphs;

[0042] S3: enter the secondary flushing;

[0043] S4: After the second flushing, enter the pressure sieve for processing, add PEO retention aid at the outlet of the pressure sieve, and the mass dosage of PEO retention aid is 0.006%;

[0044] S5: the slurry in step S4 flows into the headbox and is copied on the Internet;

[0045] S6: press dehydration;

[0046] S7: drying treatment;

[0047] S8: Calender processing;

[0048] S9: coiling, coupon cutting, packaging and...

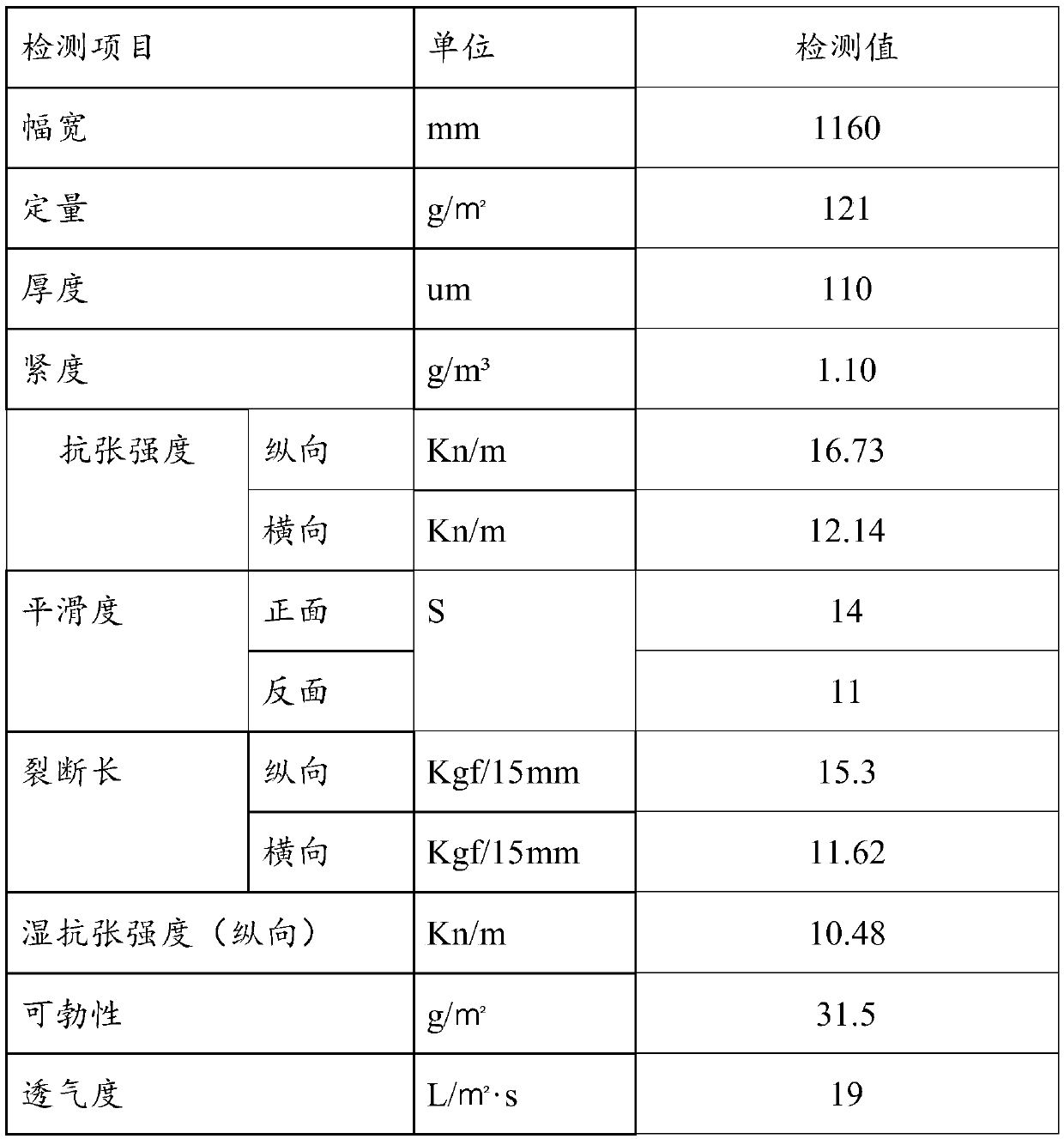

Embodiment 3

[0054] A method for producing a microfiltration membrane substrate based on wet papermaking technology, the steps of the method are as follows:

[0055] S1: After preparing the fluffed chemical fiber, mix the slurry, and control the concentration of the slurry to 2%;

[0056] S2: Add dispersant and defoamer to the slurry before flushing once, and then enter the sand remover. The amount of dispersant is 2% of the slurry mass, and the amount of defoamer is 0.02% of the slurry mass. There are three sections;

[0057] S3: enter the secondary flushing;

[0058] S4: After the second flushing, enter the pressure sieve for processing, add PEO retention aid at the outlet of the pressure sieve, and the mass dosage of PEO retention aid is 0.005%;

[0059] S5: the slurry in step S4 flows into the headbox and is copied on the Internet;

[0060] S6: press dehydration;

[0061] S7: drying treatment;

[0062] S8: Calender treatment;

[0063] S9: coiling, coupon cutting, packaging and wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation state | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com