Safety protection tool in shipbuilding flat section production line

A technology of safety protection and plane segmentation, applied in the directions of ship parts, ship construction, transportation and packaging, etc., can solve problems such as easy pinching or damage of personnel, equipment and facilities, increase ship construction cost, damage to groove structure, etc. Construction cost, time saving, avoid the effect of repair processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

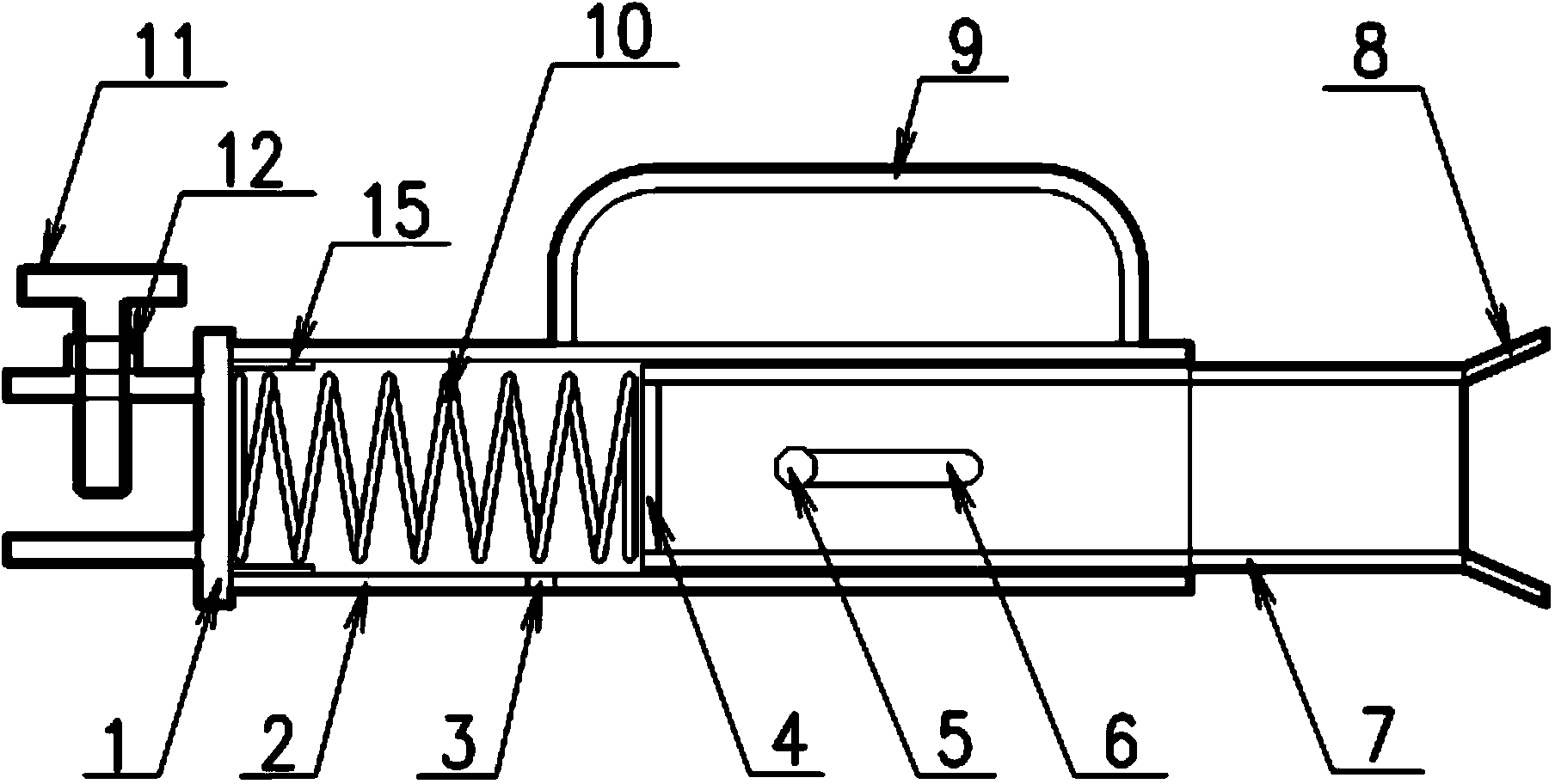

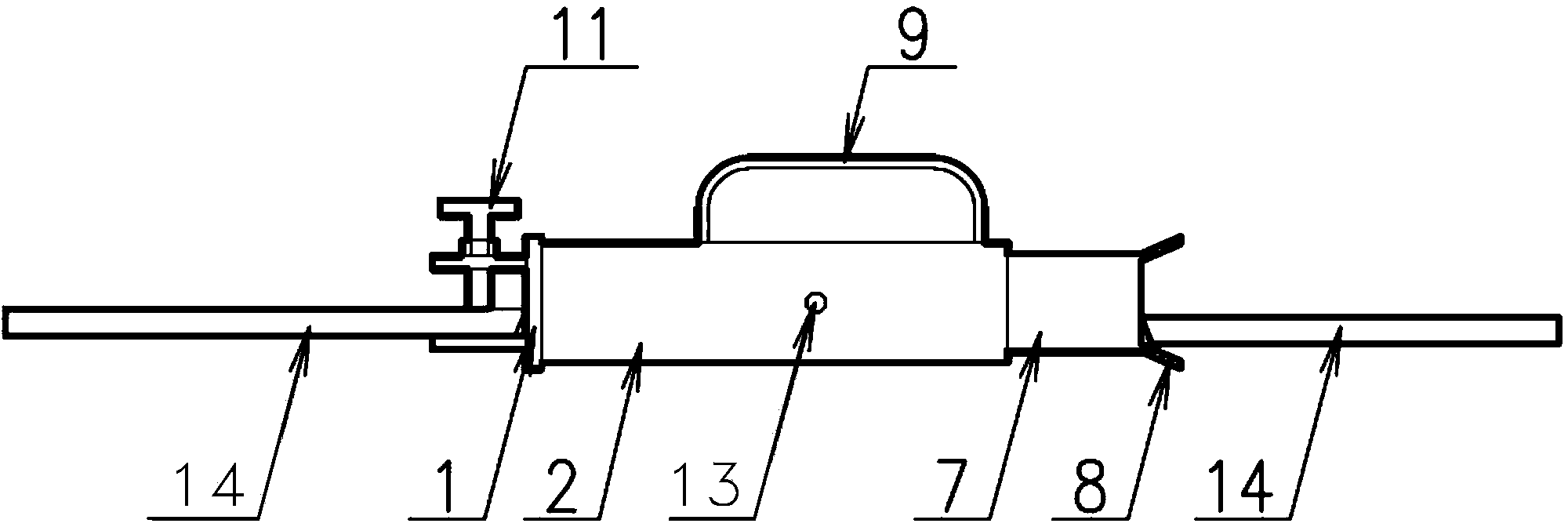

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0023] Such as figure 1 and 2 As shown, the safety protection tooling in the shipbuilding plane segmented assembly line includes main components such as the outer tube 2, the inner tube 7, the spring 10 and the clamping mechanism.

[0024] The outer tube 2 is a steel round tube with a length of 350 mm, an outer diameter of Φ90 mm, and a wall thickness of 6 mm. One end of the outer tube 2 is sealed by a welding clamping mechanism, and the other end is open. A handle 9 is fixed on the peripheral wall of the outer tube 2 by welding. Two through-holes 5 of Φ16mm are oppositely provided on the peripheral walls on both sides of the middle part of the outer cylindrical tube 2 .

[0025] The inner tube 7 is a round steel tube w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com