Patents

Literature

39results about How to "Uniform and stable size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

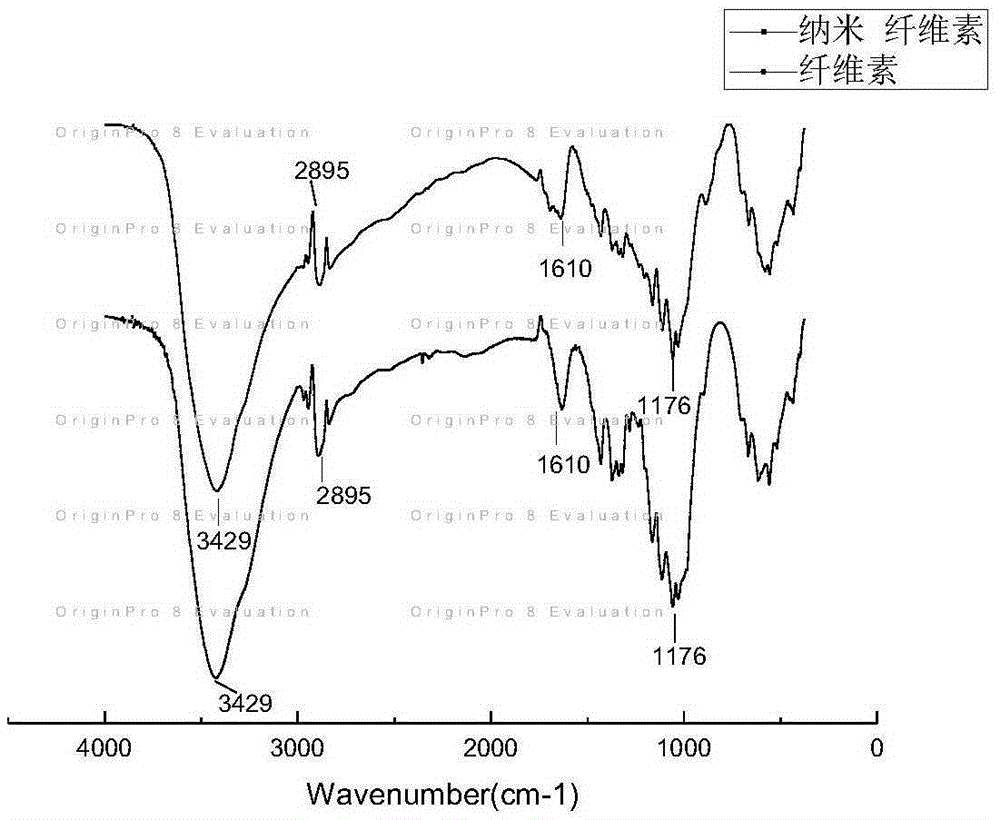

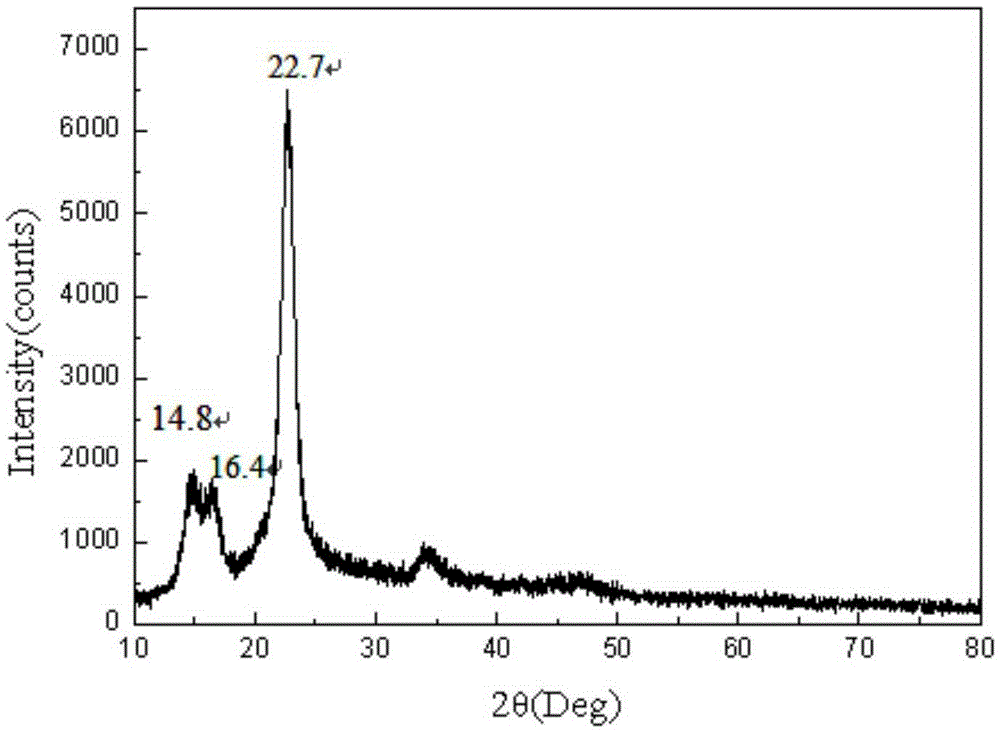

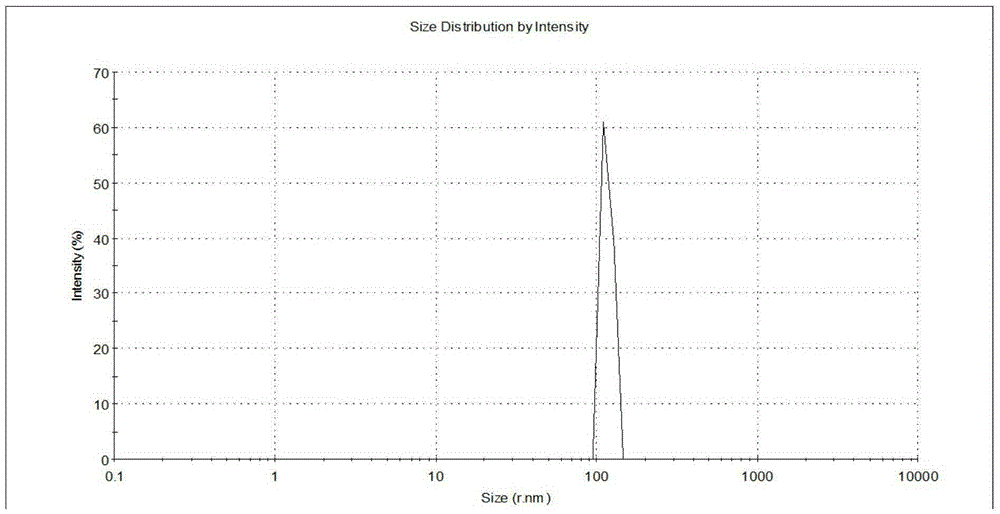

Nano cellulose, and preparation method thereof

The invention discloses a nano cellulose, and a preparation method thereof. The preparation method comprises following steps: a fiber raw material is smashed; lignin is removed with sodium chlorite; acidolysis of cellulose is carried out with phosphoric acid; an obtained material is subjected to centrifugation; and the nano cellulose is obtained via dialysis. The invention also provides the nano cellulose prepared via the preparation method. According to the preparation method, sodium chlorite is used for processing the fiber raw material; lignin is removed; acidolysis of cellulose with phosphoric acid is carried out; and the ideal nano cellulose is obtained. The preparation method is low in energy consumption; the obtained nano cellulose is convenient to disperse; size is uniform and stable; the preparation method is simple; residue acid can be washed with deionized water; and a problem of acid solution treatment is avoided.

Owner:QINGDAO UNIV OF SCI & TECH

Environment-friendly paper and preparation method thereof

InactiveCN101864691APromote absorptionGood printing adaptabilityInorganic fibres/flakesNon-fibrous pulp additionFiberPolyolefin

The invention provides environment-friendly paper and a preparation method thereof. The environment-friendly paper comprises the following components by weight percent: 65-85% of calcium carbonate fibers, 3-10% of thermoplastic starch, 10-20% of polyolefin resins and 2-5% of auxiliary components, wherein the calcium carbonate fibers are needle-like single-crystal fiber materials with average diameter of 0.5-1mu m and length diameter ratio being not less than 20 / 1; the thermoplastic starch is the micronized, plasticized and modified starch material; the polyolefin resins are polyethylene or polypropylene materials with melt index being 5-30; and the auxiliary components at least comprise surfactants with contents being not less than 1% and lubricants with contents being not less than 1%. The environment-friendly paper has the characteristics of low ration, little proportion and stable and uniform size, has good ink absorbency and printing adaptability, excellent performance indexes, such as whiteness, opacity, smoothness and tensile index and good texture and processability and can realize thermoplastic process. The environment-friendly paper accords with the present national development policy of the low carbon industry and has broad market prospect.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

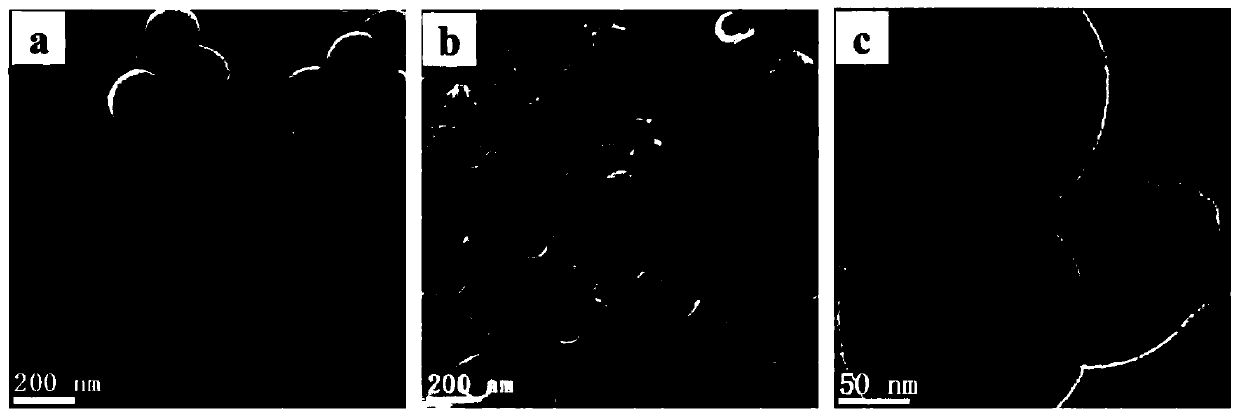

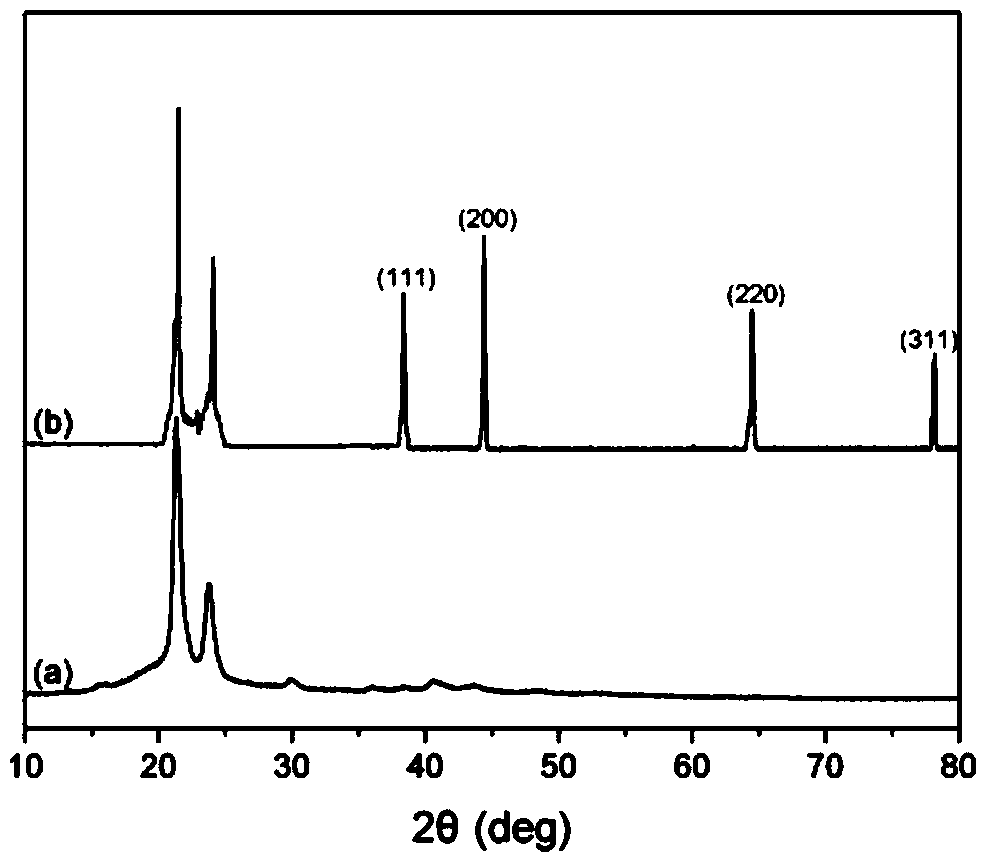

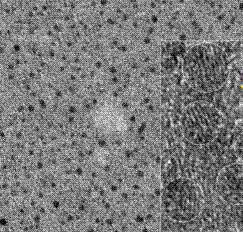

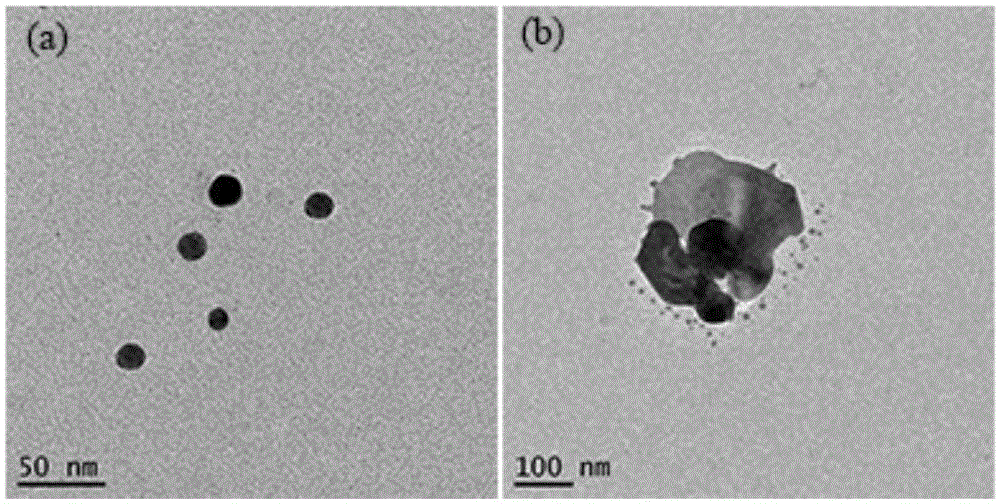

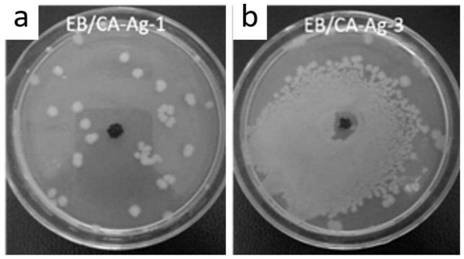

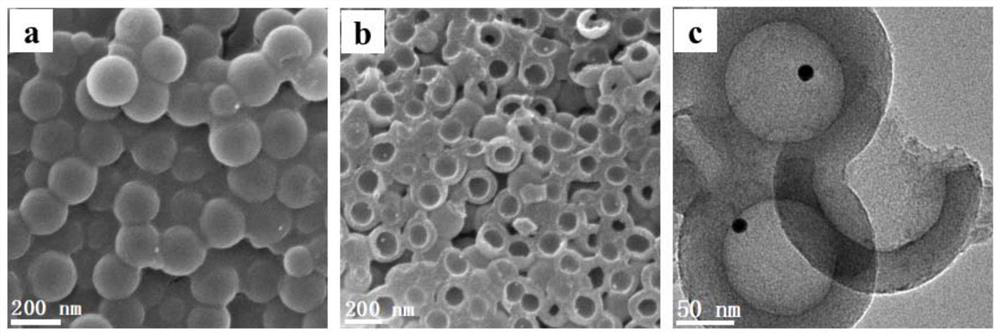

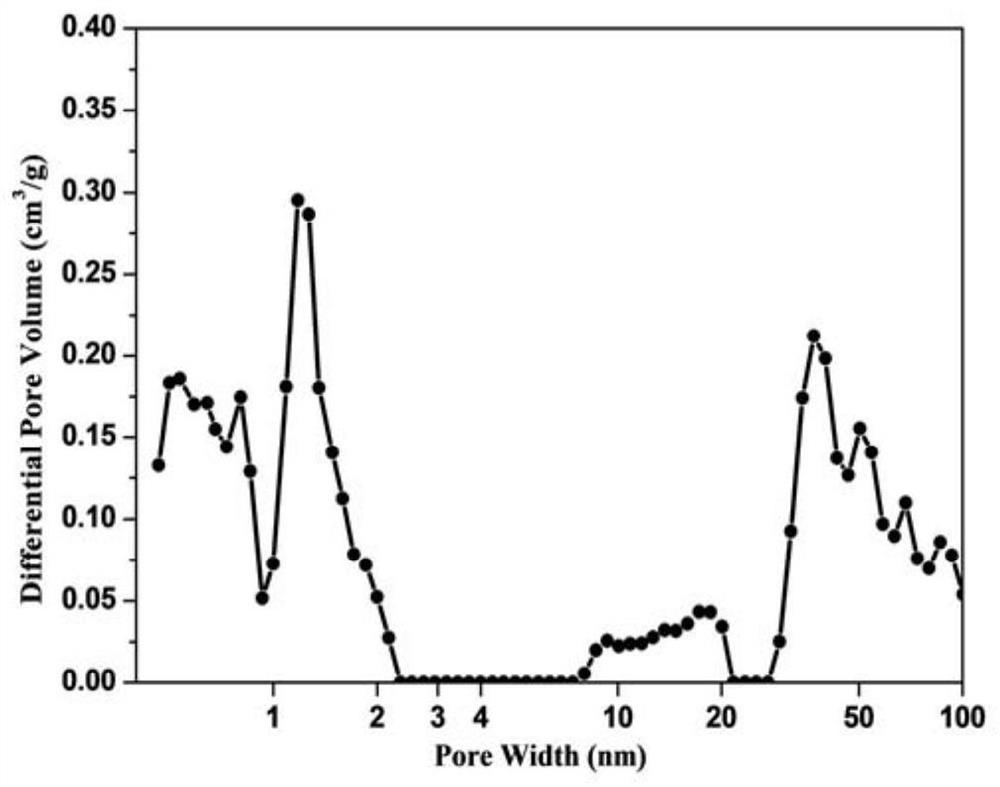

Yolk-eggshell structured noble metal @ hollow carbon nanosphere composite material as well as preparation method and application thereof

ActiveCN110405200AReduce pollutionLow costMaterial nanotechnologyTransportation and packagingCross-linkYolk

The invention belongs to the technical field of materials, and discloses a yolk-eggshell structured noble metal @ hollow carbon nanosphere composite material as well as a preparation method and application thereof. The preparation method comprises the following steps that on the basis of synthesizing the noble metal @ SiO2 core-shell nanospheres, by utilizing surface modification, emulsion polymerization reaction, so that a multi-core-shell-structure noble metal @ SiO2 @ polychloromethyl styrene composite nanospheres can be prepared; then, the methylene of chloromethyl styrene can be used forself-crosslinking reaction; under the condition that a cross-linking agent is additionally added, a rich microporous network structure can be built in the shell layer, the rigid structure of the polychloromethyl styrene shell layer is benefited, and after high-temperature carbonization and HF etching treatment, the yolk-eggshell structure noble metal @ hollow carbon nanosphere composite material is obtained. The composite material can be used as a high-activity p-nitrophenol reduction catalyst material, a high-capacity lithium-sulfur battery limited sulfur nano-carbon carrier material, a high-performance formaldehyde adsorption material and a biological antibacterial material.

Owner:SOUTH CHINA AGRI UNIV

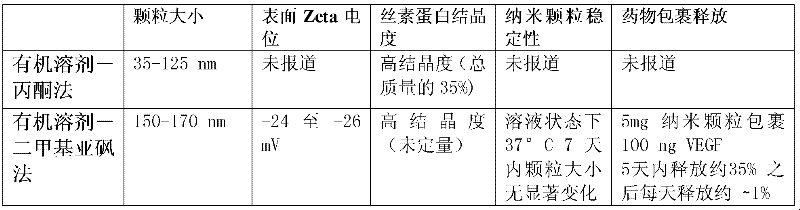

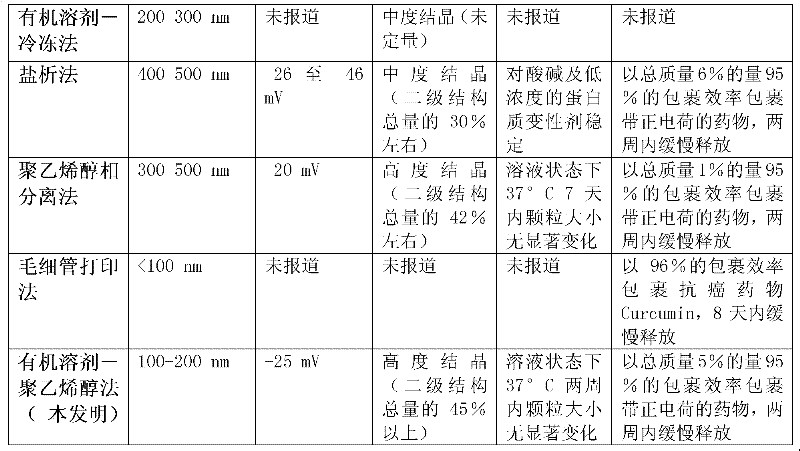

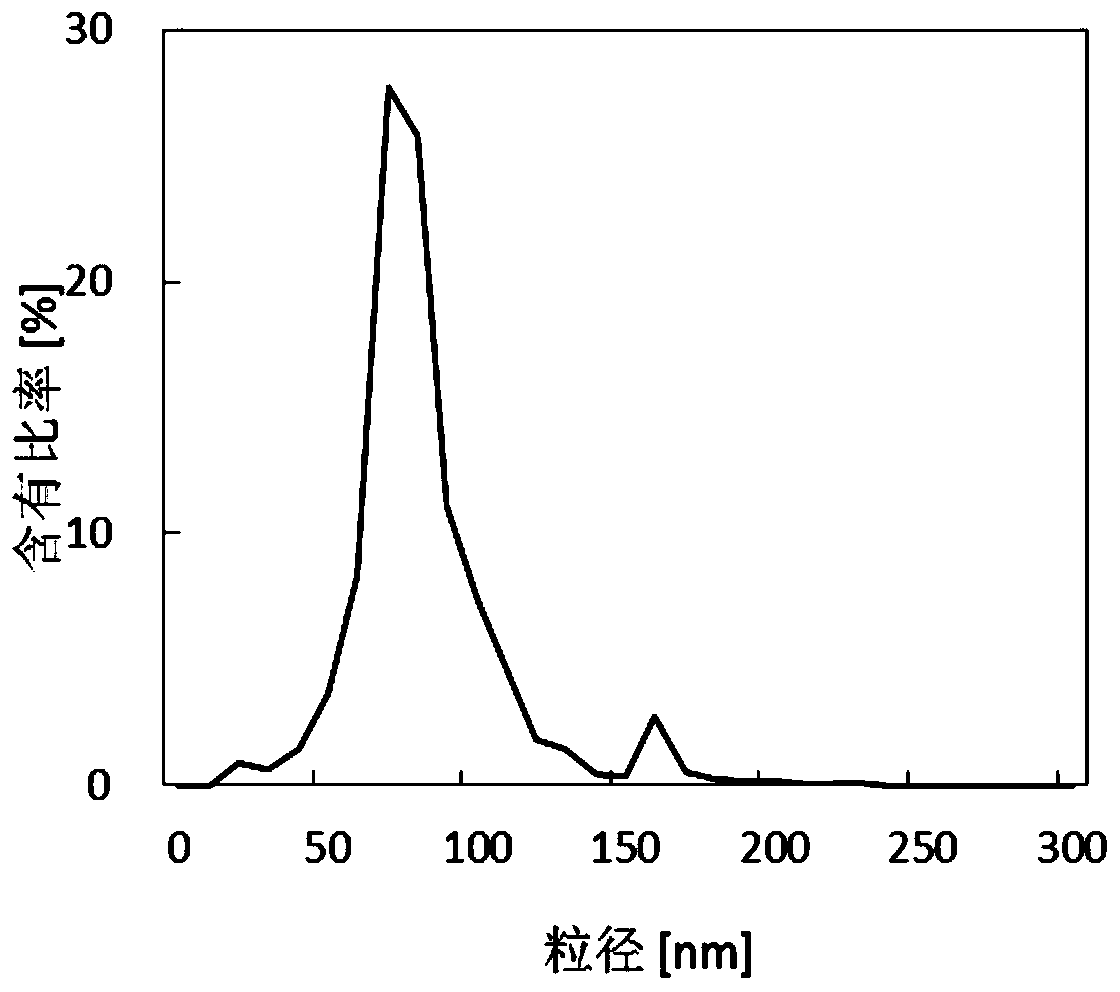

Method for preparing fibroin nanoparticles taking polyvinyl alcohol as stabilizer

InactiveCN102344686AAchieve mass productionEliminate the ultracentrifugation stepCosmetic preparationsToilet preparationsTissue repairOrganic solvent

The invention relates to a method for preparing fibroin nanoparticles taking polyvinyl alcohol as a stabilizer. The method comprises the following process steps of: (1) preparing fibroin extracted from silk into 5-8 percent by weight in volume of fibroin solution; (2) adding a polyvinyl alcohol solution into the fibroin solution to obtain a blended solution; (3) dropwise adding the blended solution into a water-soluble organic solvent which can be used for inducing beta-folding of the fibroin, and stirring continually for 1-6 hours to obtain a fibroin nanoparticle solution; (4) further purifying and enriching the fibroin nanoparticle solution to obtain uniform fibroin nanoparticles; and (5) storing the obtained fibroin nanoparticles. According to the preparation method, fibroin nanoparticles with uniform and stable particle sizes and high yield can be prepared; and the fibroin nanoparticles are suitable for large-scale production and are widely applied in a plurality of fields such as medicament release, patellofemoral joint biological lubricants, face-lifting, beauty treatment, tissue repair and the like.

Owner:SUZHOU SIMEITE BIOTECH CO LTD

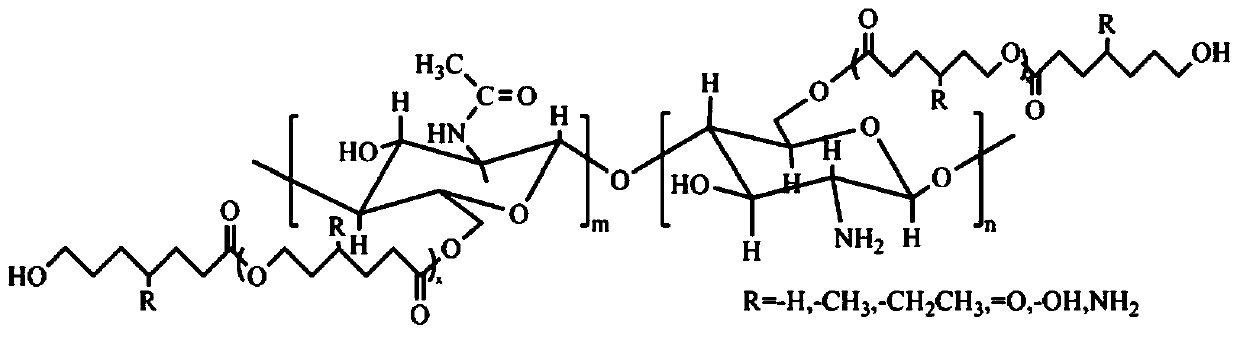

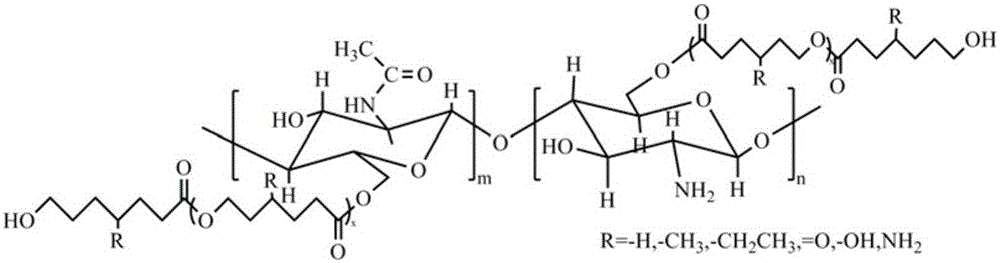

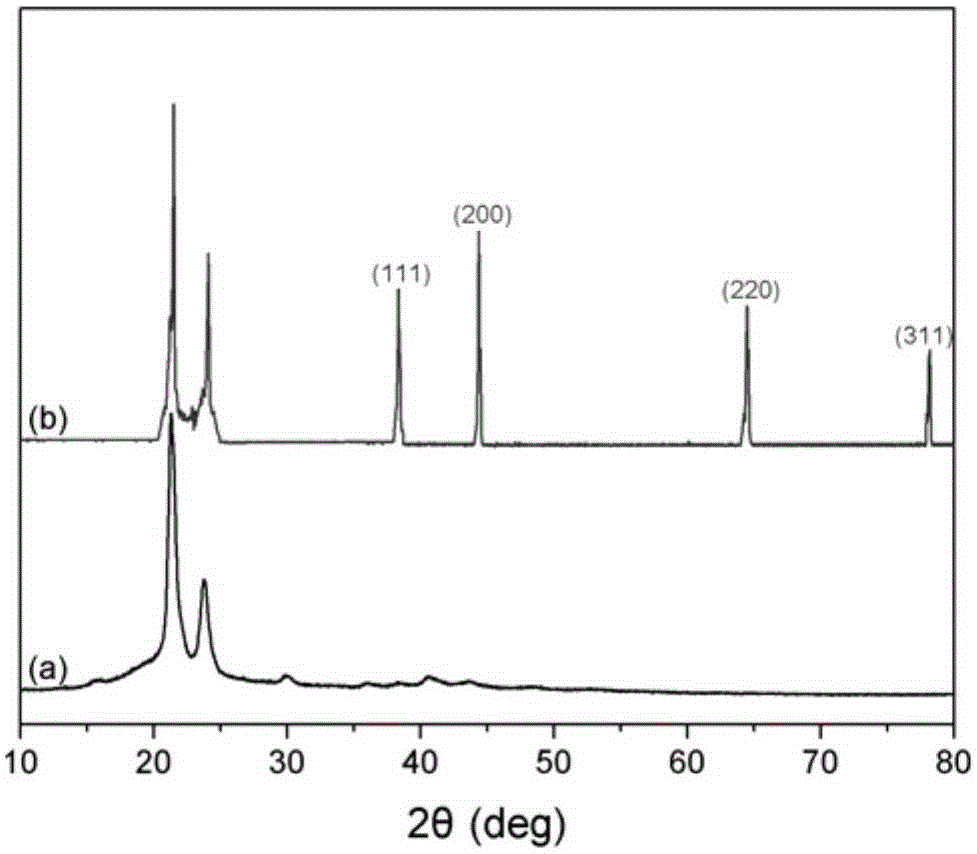

Method for preparing stable nano-silver

The invention provides a method for preparing stable nano-silver. The method comprises the steps that micelle of amphiphilic chitosan and polycaprolactone crafted copolymer or a derivative of the amphiphilic chitosan and polycaprolactone crafted copolymer serves as a stabilizer, and the stable nano-silver is obtained. The method for preparing the stable nano-silver has the advantages that formed silver nanoparticles of a good three-dimensional area center structure are evenly distributed and are uniform and stable in size, and not any reducing agents or complex methods are used in the preparation method of the nano-silver, so that repeatability is good. Compared with other micelle type stabilizers, the preparation process of a raw material and micelle aqueous solution of the raw material are simple, the material itself is non-toxic, small in use amount and fast in preparation speed. Compared with other existing preparation technologies, the method is convenient to operate, simple in process and fast in preparation speed. In addition, equipment is conventional, and irradiation time is short.

Owner:EAST CHINA UNIV OF SCI & TECH

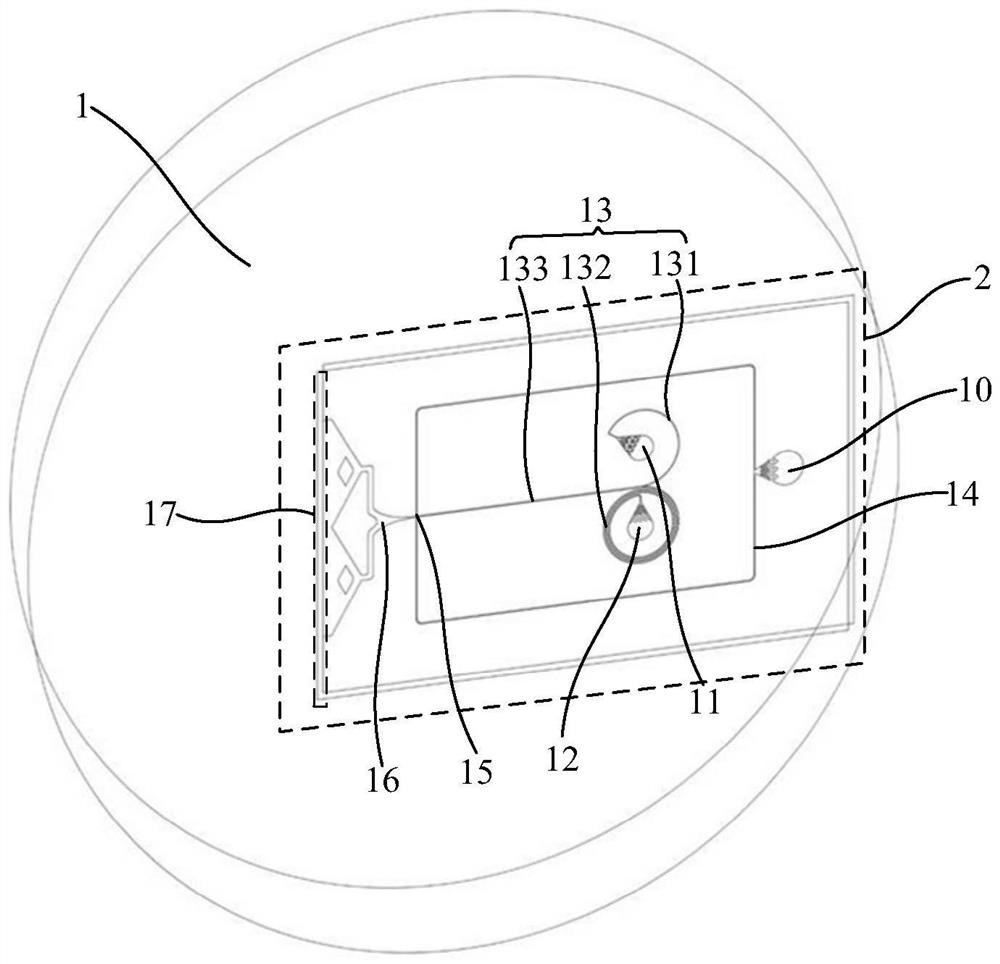

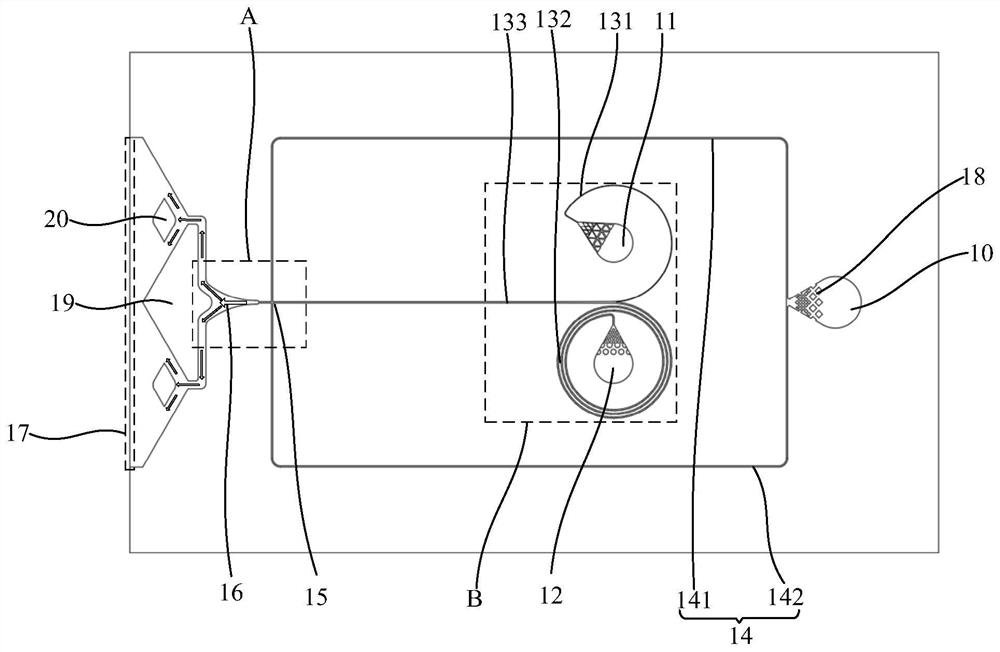

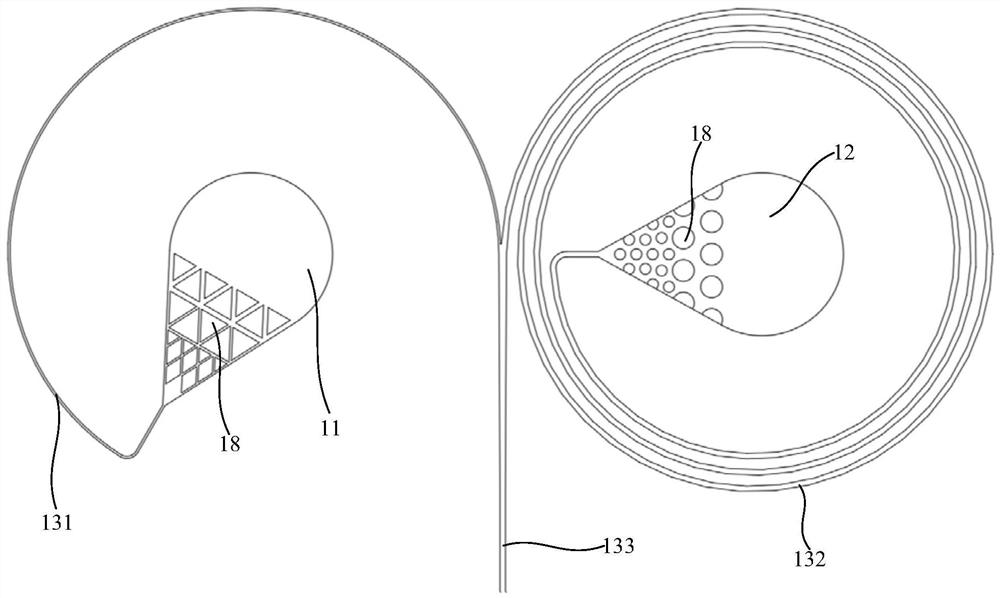

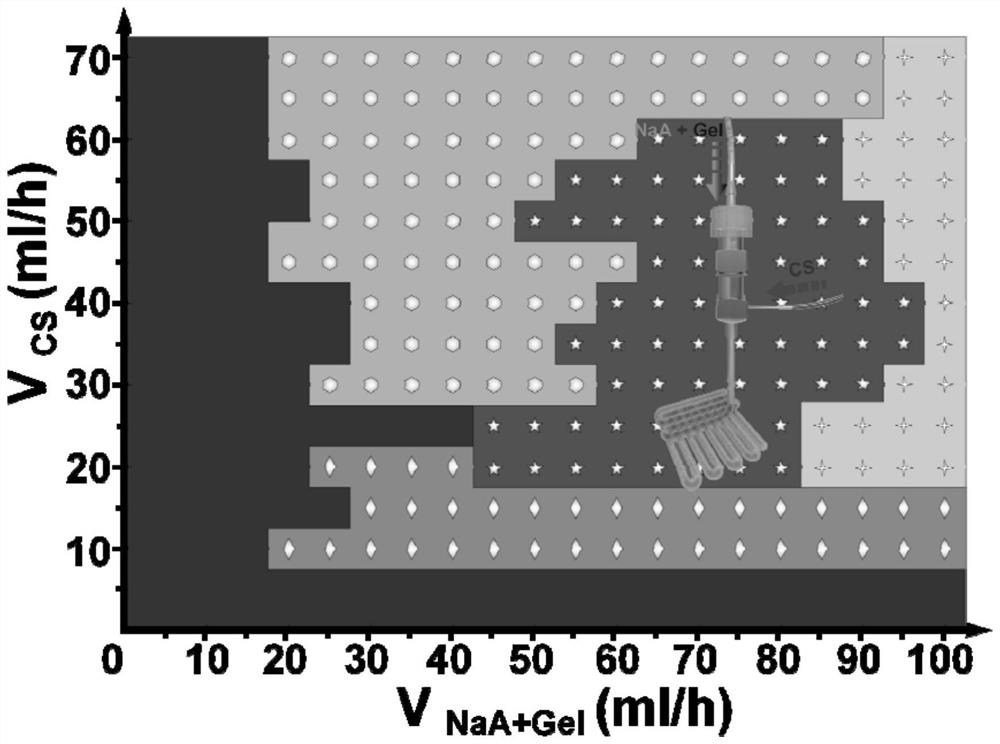

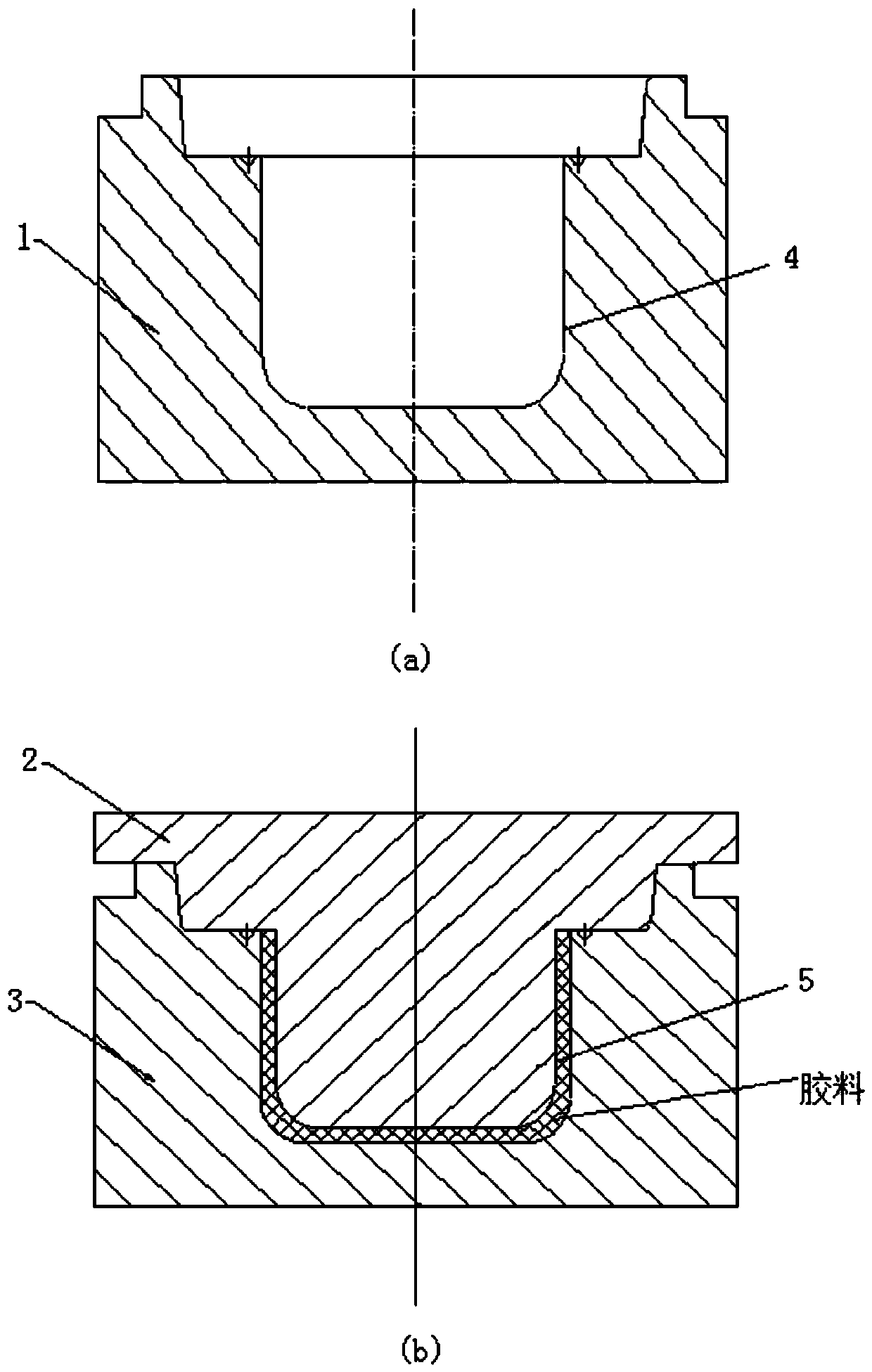

Micro-fluidic chip based on droplet micro-fluidic technology and detection method of micro-fluidic chip

ActiveCN112538428AUniform and stable sizeEasy to adjust the flow ratioBioreactor/fermenter combinationsBiological substance pretreatmentsHigh fluxEngineering

The invention provides a micro-fluidic chip based on a droplet micro-fluidic technology and a detection method of the micro-fluidic chip. Cells can be monodispersed by adopting a spiral disperse phaseliquid inlet channel according to an inertial focusing principle, so that the cells are uniformly distributed in the channel from front to back, and single-cell droplets with high wrapping rate are favorably formed; besides, the disperse phase liquid inlet channel and a continuous phase liquid inlet channel are intersected in a cross shape to form a cross-shaped droplet generation channel, the flow ratio of two-phase liquid is convenient to adjust, the length and the distance of generated droplets are controlled, and the sizes of the droplets are more uniform and stable; and moreover, the micro-fluidic chip is provided with an upper layer and a lower layer, the upper layer is used for capturing high-flux single cells, and the lower layer is used for culturing the single cells and enriching secreta of the single cells, so that the single cells are cultured in droplets for a long time, and researches such as single cell in-situ culture, cell co-culture, drug screening, real-time and high-sensitivity detection of the secreta can be carried out, and the micro-fluidic chip is simple and flexible to operate, high in flux, pollution-free, short in consumed time, low in cost and wide in application range.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

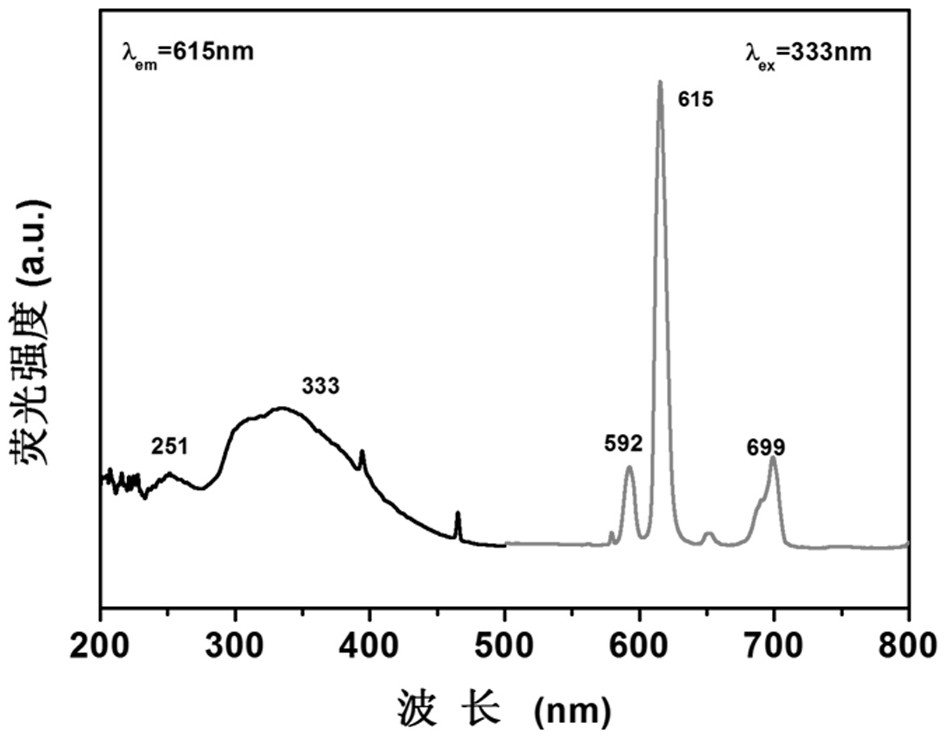

Preparation method of green environment-friendly water-soluble Ag-IN-S/ZNS quantum dot material

InactiveCN107880878AUniform and stable sizeStructural quantum dots have excellent performanceMaterial nanotechnologyNanoopticsQuantum yieldPhotoluminescence

The invention provides a preparation method of a green environment-friendly water-soluble Ag-IN-S / ZNS quantum dot material. According to the water-soluble light-emitting Ag-IN-S / ZNS quantum dot material, a precipitation method is adopted to prepare core-shell type quantum dots. AIS (AIS / Zn quantum dot luminescence) with a fraction up to 10-11 is selected, and the color range of visible light waveband which can be covered is from deep red to blue green, wherein the photoluminescence (Pl) quantum yield can reach 80%. The material is free of toxic heavy metals such as cadmium and the like, is green and environmentally friendly, and can be widely applicable to the aspects of biological fluorescence labeling, display illumination and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

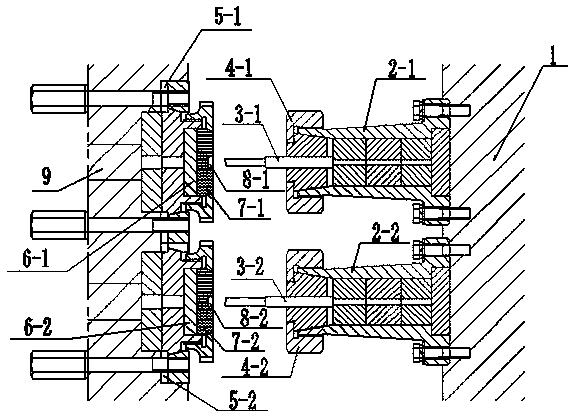

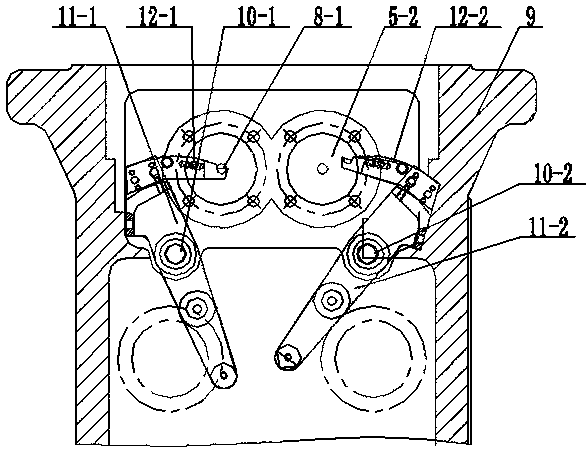

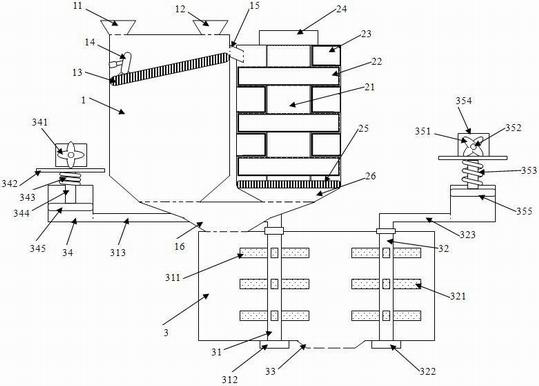

Horizontal dual-mold cold extrusion mechanism and forming production process

The invention discloses a horizontal dual-mold cold extrusion mechanism and a forming production process. The horizontal dual-mold cold extrusion mechanism comprises a multi-connecting-rod toggle rodtype mechanical driving mechanism, an automatic feed mechanism and a body, wherein the multi-connecting-rod toggle rod type mechanical driving mechanism comprises a sliding block; the front end of thesliding block is connected with two punching head bases; the front ends of the two punching head bases are connected with two convex molds respectively; the body is provided with two transversely parallel dip mold holes; the two dip mold holes are internally provided with two concave mold cushion blocks respectively; the front ends of the two concave mold cushion blocks are provided with two concave molds respectively; the two concave molds are both internally provided with concave-mold mold cavities; the multi-connecting-rod toggle rod type mechanical driving mechanism is connected with theautomatic feed mechanism through a gear and a lever shaft; the lever shaft is located on an oscillating rod; the oscillating rod is connected with two manipulators respectively. Horizontal dual moldsare subjected to cold extrusion at the same time and outputs products at the same time; the continuous and high-efficiency production is realized; the convex molds and the concave molds are both provided with adjustment and fixation devices; products subjected to cold extrusion forming are uniform and stable in size, thick at bottoms, small in wall thickness tolerance high and precision; the mechanical performance of the products subjected to the cold extrusion forming is improved and the percent of pass is high.

Owner:江苏启力锻压机床有限公司

Preparation technique of nanoparticle composite material film for welding

The invention relates to the technical field of preforming welding material, and particularly discloses a preparation technique of a nanoparticle composite material film for welding; the technique includes steps of material mixing-vacuum defoamation- curtain coating and film formation-drying and curing-after-treatment. The preparation technique is featured by simple and feasible practice, strong controllability, high efficiency, and low cost; the technique can effectively guarantee the component of the prepared nanoparticle composite material film, uniform and stable dimension, excellent processing performance and high reliability of low-temperature sintering and welding; the preparation technique can be widely applied to the field of preforming welding material.

Owner:SOLDERWELL MICROELECTRONIC PACKAGING MATERIALS CO LTD

Method for preparing stable nano silver

InactiveCN103752849BGood cuboid structureEvenly dispersedNanotechnologyRepeatabilityAmphiphilic chitosan

The invention provides a method for preparing stable nano-silver. The method comprises the steps that micelle of amphiphilic chitosan and polycaprolactone crafted copolymer or a derivative of the amphiphilic chitosan and polycaprolactone crafted copolymer serves as a stabilizer, and the stable nano-silver is obtained. The method for preparing the stable nano-silver has the advantages that formed silver nanoparticles of a good three-dimensional area center structure are evenly distributed and are uniform and stable in size, and not any reducing agents or complex methods are used in the preparation method of the nano-silver, so that repeatability is good. Compared with other micelle type stabilizers, the preparation process of a raw material and micelle aqueous solution of the raw material are simple, the material itself is non-toxic, small in use amount and fast in preparation speed. Compared with other existing preparation technologies, the method is convenient to operate, simple in process and fast in preparation speed. In addition, equipment is conventional, and irradiation time is short.

Owner:EAST CHINA UNIV OF SCI & TECH

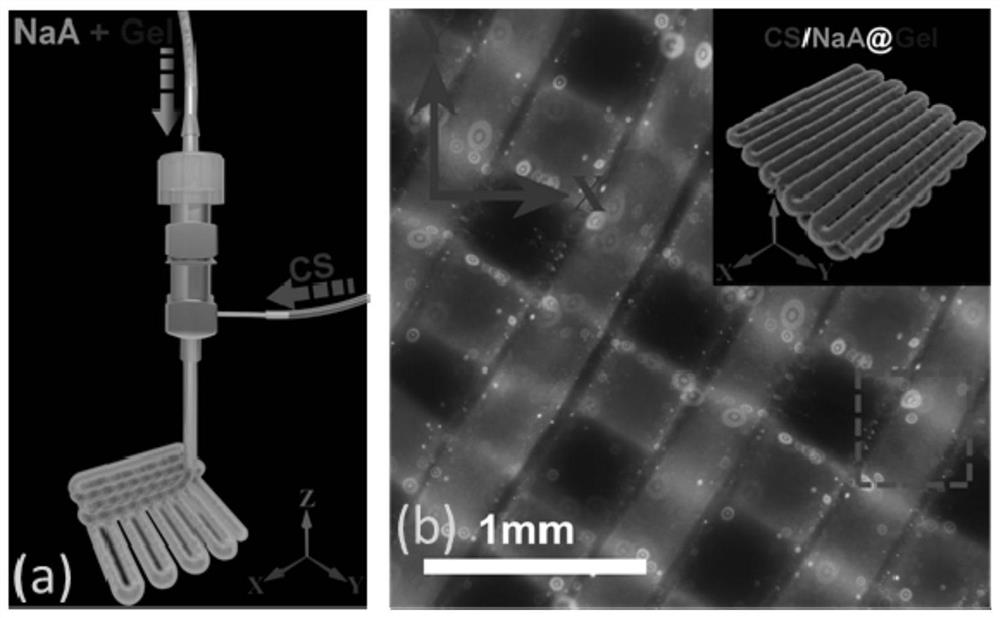

Preparation method of bioactive medical dressing

ActiveCN113246468AAdjustable structureUniform and stable structure3D object support structuresManufacturing data aquisition/processingDiabetic foot ulcerationComputer printing

The invention discloses a preparation method of a bioactive medical dressing. The method comprises the following steps of S1, taking raw material solutions for later use, and performing printing through a microfluidic 3D printing assembly; and S2, introducing contents into all channels in a multi-channel coaxial jet head, controlling the flow speed, setting parameters of a 3D printer, and using the 3D printer to control a micro-fluidic chip to print the three-dimensional diabetic foot ulcer functional medical dressing, wherein the raw material solutions comprise an alginate solution, a first high-molecular polymer solution, a bioactive component solution and a second high-molecular polymer solution. According to the method, the process is simple, subsequent treatment of the dressing is not needed, the production efficiency is high, the cost is low, the product is stable, the precision is high, and the experimental repeatability is high.

Owner:WUYI UNIV

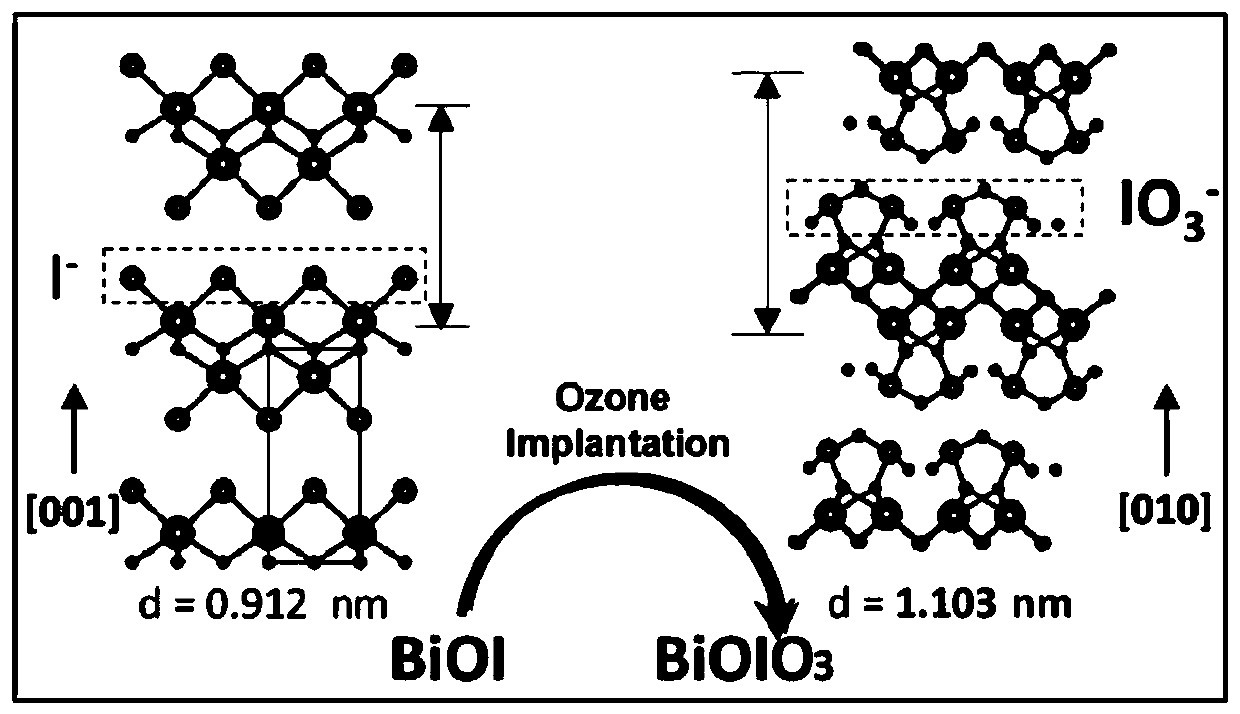

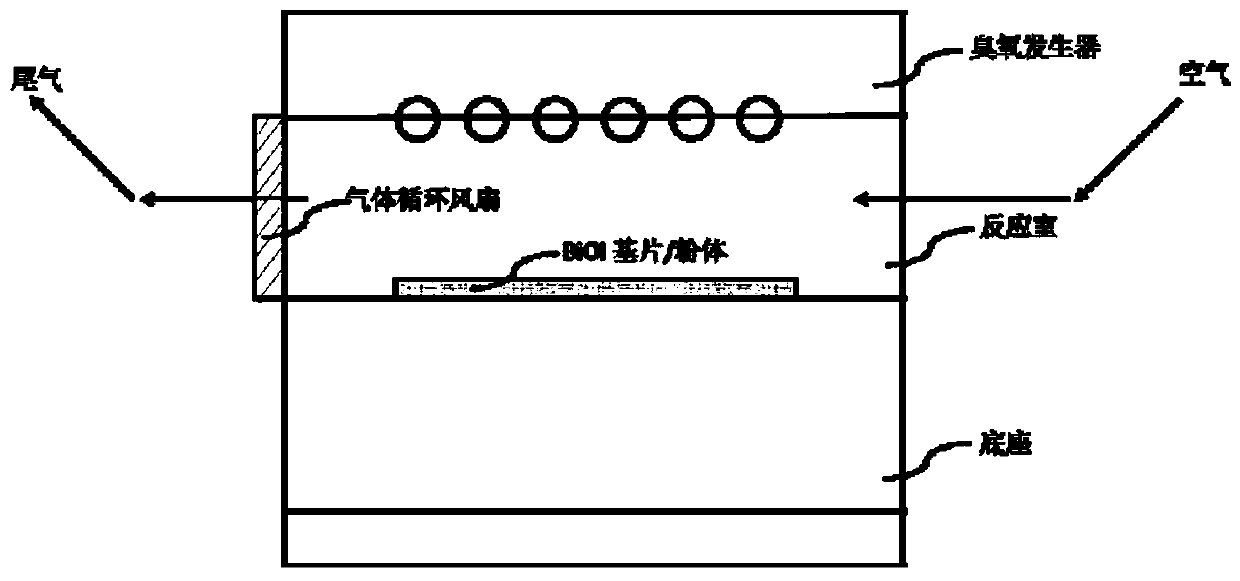

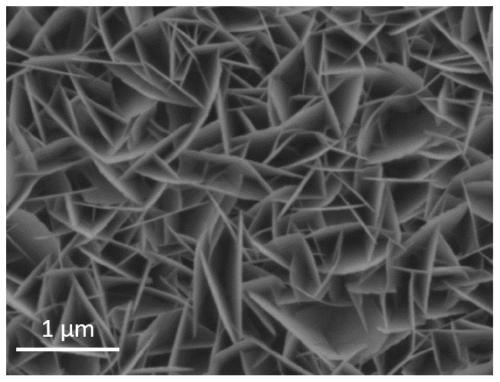

Bismuthyl iodate nanosheet material and preparation method thereof

The invention provides a bismuthyl iodate nanosheet material and a preparation method thereof. The method includes the steps of: providing a bismuth oxyiodide nanosheet material; and placing the bismuth oxyiodide nanosheet material in ozone atmosphere for reaction for 3-20h, with the ozone content of the ozone atmosphere being 5%-80%. In the reaction process, the I ion in bismuth oxyiodide crystalis oxidized to IO3<-> ion, and the morphology of bismuthyl iodate nanosheet remains unchanged, thus obtaining the bismuthyl iodate nanosheet material. The invention adopts gas phase oxidation method,because of the particularity of gas, no separation process is needed after reaction, and the bismuthyl iodate nanosheet material characterized by uniform size and regular product structure can be prepared directly from the bismuth oxyiodide nanosheet material; the reaction gas can be reutilized to improve the utilization rate; and the preparation time is short and the reaction temperature is low,therefore the method has better industrial application prospects.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

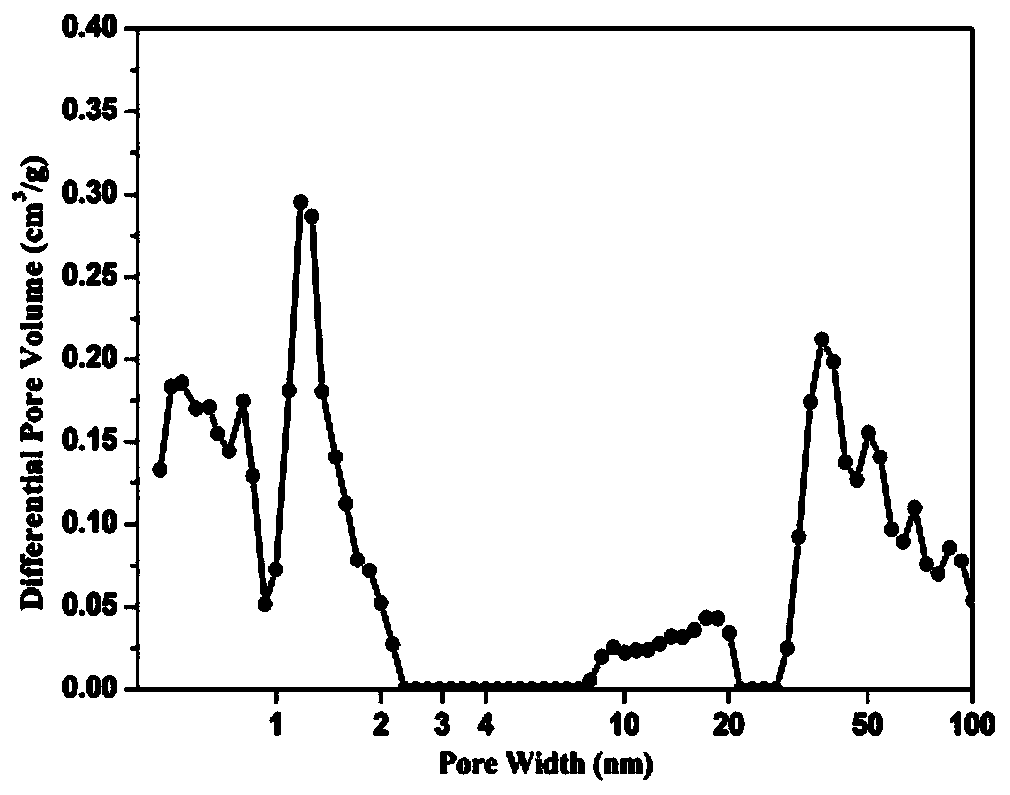

Composite for organic metal catalyst and preparation method thereof

InactiveCN109174205AReduce stickingDense porous structureGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsCross-linkOrganometallic catalysis

The invention discloses a composite for an organic metal catalyst and a preparation method thereof, and relates to the technical field of denitrification catalyst. The composite adopts cross-linked modified carbon nanotubes for being loaded with V2O5-MoO3 / TiO2 having good catalytic oxidation denitrification performance, adopts attapulgite to wrap platinum metal so as to improve the catalytic oxidation activity of the platinum metal, and is prepared from a common organic metal catalyst dioctyl tin dilaurate as a heat stabilizer with a variety of fillers and additives. The preparation method issimple. The composite for the organic metal catalyst has the advantages of large specific surface area, good thermal stability, and good activity and selectivity, and cannot cause alkali metal poisoning, sintering, blockage and erosion phenomena after long-term use.

Owner:广州优润合成材料有限公司

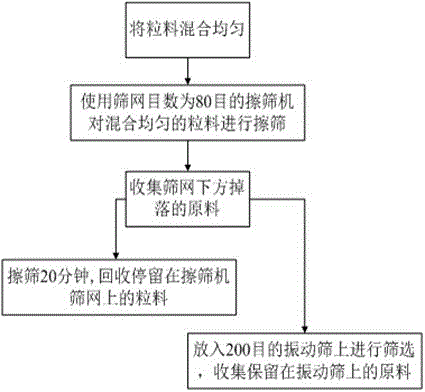

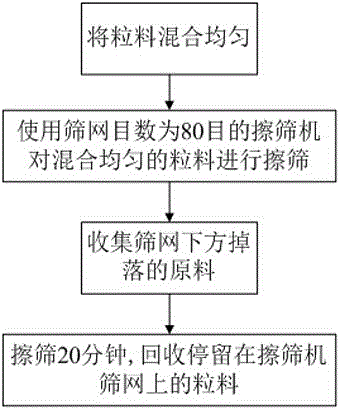

Method for finishing aggregates for pressing disc cutters

The invention discloses a method for finishing aggregates for pressing disc cutters. The method comprises the following steps of (A), mixing the aggregates uniformly; (B), rubbing and sieving the uniformly-mixed aggregates through a rubbing and sieving machine with the mesh size of 80 meshes and collecting the falling raw materials below a sieve; (C), stopping the rubbing and sieving machine 20 minutes after rubbing and sieving and recycling the aggregates remaining in the sieve of the rubbing and sieving machine; and (D), putting the collected falling raw materials below the sieve of the rubbing and sieving machine onto a vibrating sieve with the mesh size of 200 meshes, sieving the collected raw materials and collecting the raw materials remaining on the vibrating sieve to serve as pressing materials of the disc cutters. The method for finishing the aggregates for pressing the disc cutters aims at achieving the purposes that the raw materials for pressing the disc cutters are sieved, the grain size of the raw materials is improved, and the rejection rate of the disc cutters is lowered.

Owner:SICHUAN YR NEW MATERIAL TECH

Environment-friendly paper and preparation method thereof

InactiveCN101864691BPromote absorptionGood printing adaptabilityInorganic fibres/flakesNon-fibrous pulp additionFiberPolyolefin

The invention provides environment-friendly paper and a preparation method thereof. The environment-friendly paper comprises the following components by weight percent: 65-85% of calcium carbonate fibers, 3-10% of thermoplastic starch, 10-20% of polyolefin resins and 2-5% of auxiliary components, wherein the calcium carbonate fibers are needle-like single-crystal fiber materials with average diameter of 0.5-1mu m and length diameter ratio being not less than 20 / 1; the thermoplastic starch is the micronized, plasticized and modified starch material; the polyolefin resins are polyethylene or polypropylene materials with melt index being 5-30; and the auxiliary components at least comprise surfactants with contents being not less than 1% and lubricants with contents being not less than 1%. The environment-friendly paper has the characteristics of low ration, little proportion and stable and uniform size, has good ink absorbency and printing adaptability, excellent performance indexes, such as whiteness, opacity, smoothness and tensile index and good texture and processability and can realize thermoplastic process. The environment-friendly paper accords with the present national development policy of the low carbon industry and has broad market prospect.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

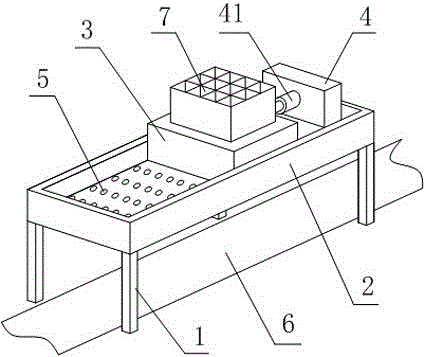

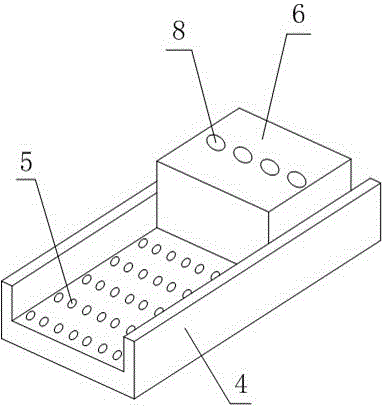

Rub screening machine structure for producing wafer cutter raw materials

InactiveCN106180697AUniform and stable sizeConvenient supplementSievingScreeningEngineeringBlock match

The invention discloses a rub screening machine structure for producing wafer cutter raw materials. The structure comprises a bracket; a groove is fixed above the bracket; multiple circular through holes with diameters of 0.18 mm are uniformly distributed in the surface of the groove; the circle center distances of two adjacent circular through holes are 1 mm; a slide pushing block matched with the groove is arranged in the groove; the width of the slide pushing block is consistent with the internal width of the groove; a storage box is fixed above the slide pushing block; the upper part of the storage box is opened, and the lower part is welded on the slide pushing block; a driving device is fixed at one end of the groove; a driving end of the driving device is connected with the slide pushing block; and a belt conveying belt is arranged below the groove, moves in the long axle direction of the groove, and penetrates from the bottom of the bracket. The rub screening machine structure for producing the wafer cutter raw materials rubs and screens raw materials for pressing wafer cutters to improve the particle sizes of the raw materials so as to guarantee the pressed wafer cutters to have excellent metallographic phases.

Owner:SICHUAN YR NEW MATERIAL TECH

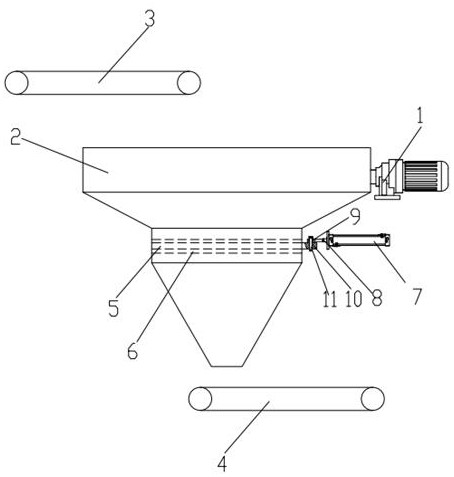

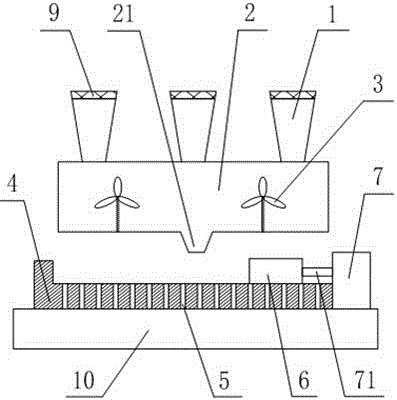

Screening device for metallurgical furnace burdens

InactiveCN111617869AUniform and stable sizeStable and controllable qualityGrain treatmentsMetallurgySmelting process

The invention discloses a screening device for metallurgical furnace burdens. The screening device comprises a furnace burden pulverizer, a conical pulverizing bin, a feed conveying belt and a discharge conveying belt; the furnace burden pulverizer is arranged at a middle position in the conical pulverizing bin; the feed conveying belt is connected with an entrance at the upper end of the conicalpulverizing bin; the discharge conveying belt is connected with an exit at the lower end of the conical pulverizing bin; a drawer-type vibrating screen is arranged in the conical pulverizing bin; andthe drawer-type vibrating screen is arranged at the lower part of the furnace burden pulverizer. According to the screening device, the metallurgical furnace burdens are pulverized and screened beforebeing added into a metallurgical furnace, thereby guaranteeing the size uniformity and stability of the metallurgical furnace burdens, thus guaranteeing that efficient and sufficient reaction can berealized after the furnace burdens are added into the metallurgical furnace, and accordingly the stability and controllability of the quality of a steel smelting process are guaranteed, and the quality of smelted steel is promoted.

Owner:邓玉儿

cuins 2 Preparation method of alloy quantum dots

ActiveCN106634975BReduce pollutionUniform and stable shapeGallium/indium/thallium compoundsNanoopticsChemical physicsCu2 ions

The invention provides a preparation method of CuInS2 alloy quantum points. The method comprises the following steps of preparing In2S3 quantum points; providing inorganic indium salt, elemental sulfur, organic amine or organic phosphorus; mixing the inorganic indium salt, the elemental sulfur, the organic amine or the organic phosphorus; performing stirring in insert atmosphere, and performing degassing treatment to form a mixed solution; heating the mixed solution to 80 to 150 DEG C in the insert atmosphere; continuously heating the materials to 180 to 250 DEG C; performing preparation to obtain the In2S3 quantum points; preparing CuInS2 alloy quantum points; dissolving the In2S3 quantum points into a non-polar solvent; performing stirring treatment in the insert atmosphere to obtain an In2S3 quantum point solution; dissolving copper ion precursors into thiol; performing stirring treatment in the insert atmosphere; obtaining a Cu-thiol ligand solution; injecting the Cu-thiol ligand solution into the In2S3 quantum point solution at uniform speed to perform cation exchange; performing purification treatment; obtaining the CuInS2 alloy quantum points.

Owner:TCL CORPORATION

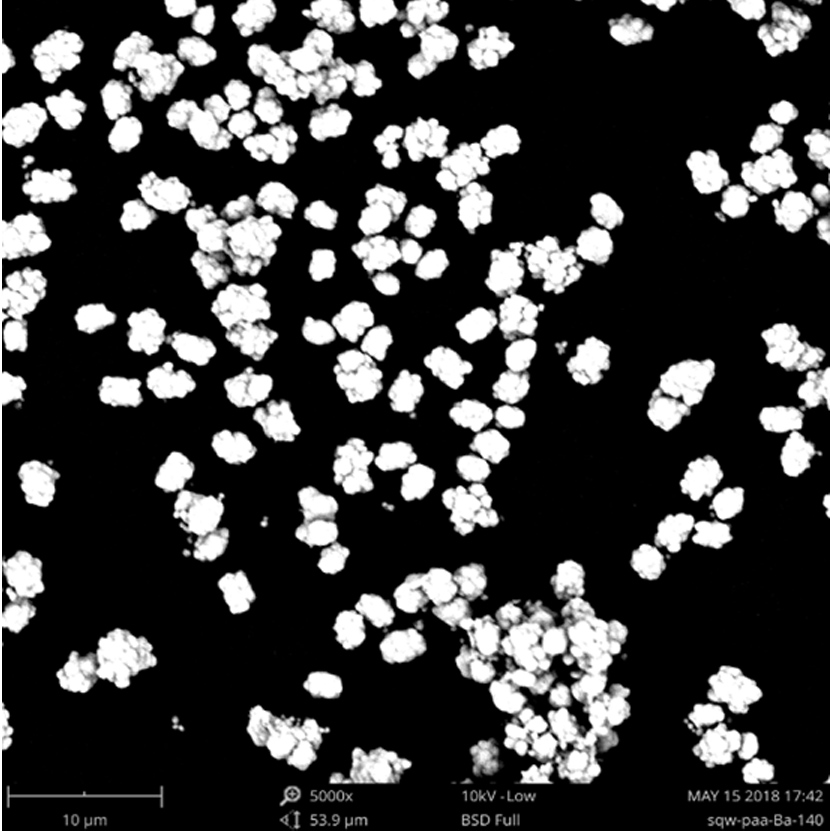

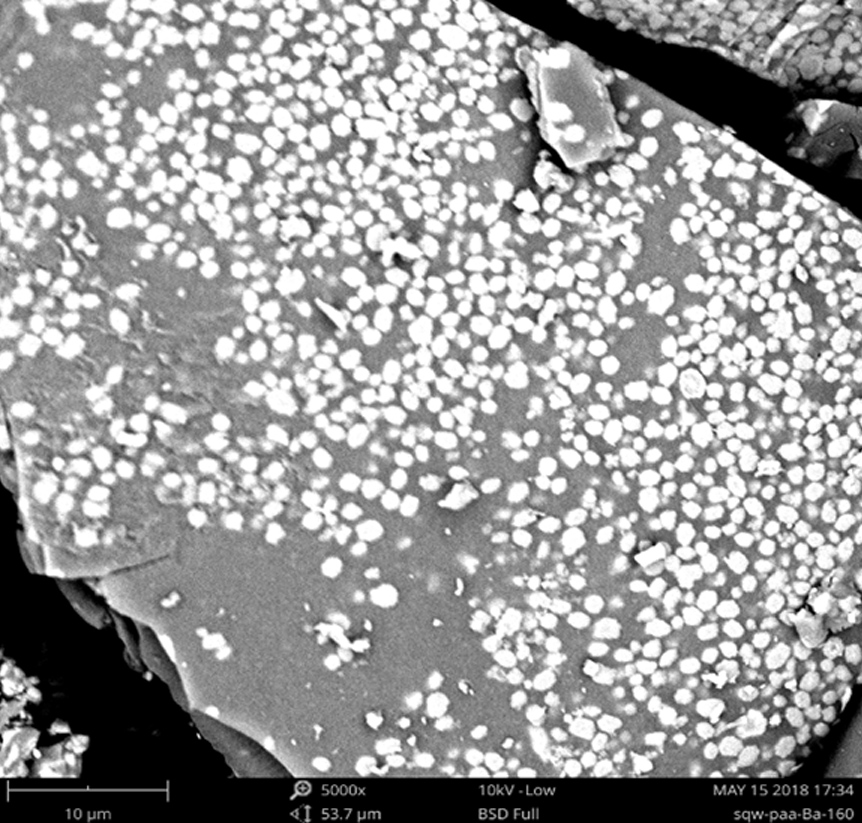

A kind of preparation method of mulberry-shaped barium polyacrylate powder doped with europium

ActiveCN110183555BNo pollution in the processLarge specific surface areaLuminescent compositionsALLYL SUCROSEAqueous solution

The invention provides a kind of preparation method of mulberry-shaped barium polyacrylate powder doped with europium, the preparation method comprises the following steps: a, weigh Ba(NO 3 ) 2 Dissolved in water to give Ba(NO 3 ) 2 solution; b, in Ba(NO 3 ) 2 Eu(NO 3 ) 3 Solution and 50wt% polyacrylic acid aqueous solution, stir evenly to obtain a mixed solution; c, put the mixed solution in a reaction kettle, and conduct a hydrothermal reaction at a temperature of 120~140°C for 4~16h; d, filter after the hydrothermal reaction is completed , the resulting precipitate was washed and dried to obtain a mulberry-like europium-doped barium polyacrylate powder. The preparation method of the present invention uses hydrothermal reaction, the preparation method is simple, does not need high-temperature roasting, and is suitable for large-scale industrial production. By controlling the hydrothermal reaction temperature and other conditions, the mulberry-shaped barium polyacrylate powder is obtained. The product size is uniform and stable, the shape is controllable, and it has a large specific surface area and good photoluminescence performance.

Owner:HEBEI UNIVERSITY

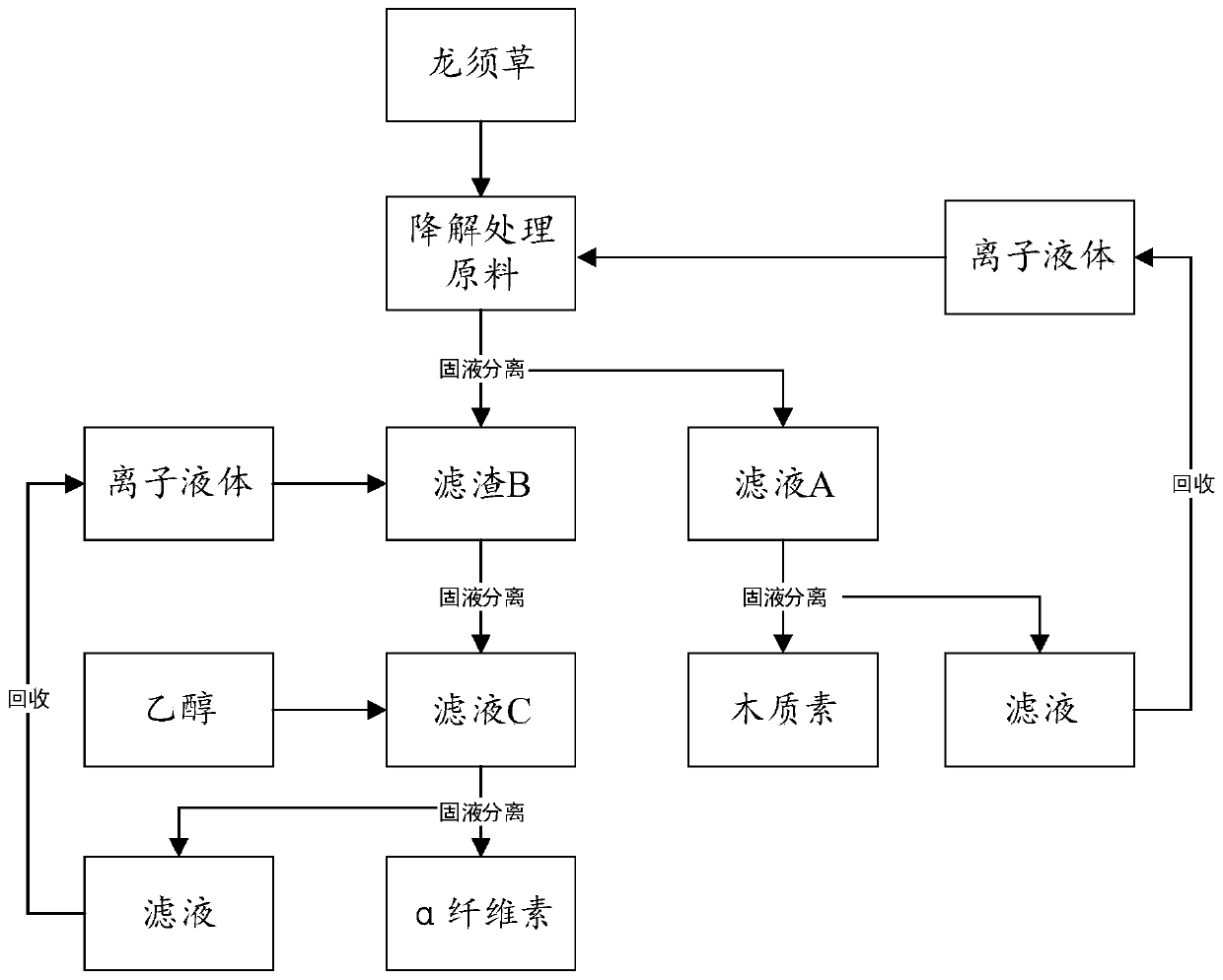

A preparation method of nanocellulose, nanocellulose and water purification membrane, and a preparation method of water purification membrane

ActiveCN107353352BHigh purityReduce manufacturing costMembranesSemi-permeable membranesPhysical chemistrySulfone

The invention belongs to the technical field of water purification and particularly relates to a preparation method of nanocellulose, the nanocellulose, a water purifying membrane and a preparation method of the water purifying membrane. The preparation method of the nanocellulose comprises steps as follows: raw material pretreatment; preparation of alpha cellulose and preparation of nanocellulose. The nanocellulose is prepared with the preparation method. The water purifying membrane comprises the nanocellulose. The preparation method of the water purifying membrane comprises steps as follows: preparation of a lignin base layer, preparation of a polyether sulfone ultrafiltration layer and preparation of the water purifying membrane, wherein the raw material lignin of the lignin base layer is a product separated in the preparation method of the nanocellulose. The preparation method adopts mild conditions, pollution emission is avoided, and the finally prepared nanocellulose meets requirement for preparation of the water purifying membrane. Further, the content of the nanocellulose in the water purifying membrane obtained with the provided preparation method of the water purifying membrane is high, the service life is longer and the water purifying effect is better.

Owner:青岛诺亚水务工程有限公司

A kind of egg yolk-eggshell structure precious metal@hollow carbon nanosphere composite material and its preparation method and application

ActiveCN110405200BReduce pollutionLow costMaterial nanotechnologyTransportation and packagingYolkPtru catalyst

The invention belongs to the field of material technology, and discloses an egg yolk-eggshell structure precious metal@hollow carbon nanosphere composite material and its preparation method and application. The preparation method is: in the synthesis of noble metal @SiO 2 On the basis of core-shell nanospheres, the multi-core-shell structure noble metal @SiO was prepared by surface modification and emulsion polymerization. 2 @Polychloromethylstyrene composite nanospheres, followed by the self-crosslinking reaction of the methylene group of polychloromethylstyrene, under the condition of adding a crosslinking agent in disorder, it can be inside the shell A rich microporous network structure is built, benefiting from the rigid structure of the polychloromethylstyrene shell, after high-temperature carbonization and HF etching, the egg yolk-eggshell structure noble metal@hollow carbon nanosphere composite material is obtained. The invention can be used as high-activity p-nitrophenol reduction catalyst material, high-capacity lithium-sulfur battery limited sulfur nano-carbon carrier material, high-performance formaldehyde adsorption material and biological antibacterial material.

Owner:SOUTH CHINA AGRI UNIV

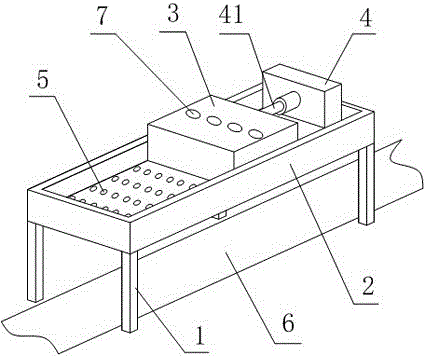

Wiping and screening device for raw materials pressing disk cutters

The invention discloses a wiping and screening device for raw materials pressing disk cutters. The wiping and screening device for the raw materials pressing the disk cutters comprises feeding ports which are each provided with a filter screen with the mesh number being 20; the feeding ports communicate with a stirring chamber which is internally provided with stirring devices; a rectangular groove is formed below the discharging end of the stirring chamber; a plurality of round through holes with the diameter being 0.18 mm are evenly distributed in the surface of the groove; the circle center distance between every two adjacent round through holes is 1 mm; a sliding material pushing block matched with the groove is arranged in the groove; the width of the sliding material pushing block is consistent with the inner width of the groove; a driving device is arranged at one end of the groove; the driving end of the driving device is connected with the sliding material pushing block; and a material receiving device is arranged below the groove. The wiping and screening device for the raw materials pressing the disk cutters aims at achieving the purposes that the raw materials for pressing the disk cutters are screened, and it is guaranteed that the pressed disk cutters have a good metallographic phase.

Owner:SICHUAN YR NEW MATERIAL TECH

Auxiliary rubbing and screening machine for compression production of round-flat slitters

InactiveCN106180699AUniform and stable sizeUniform and stable density distributionTurbinesOther manufacturing equipments/toolsLong axisEngineering

The invention discloses an auxiliary rubbing and screening machine for compression production of round-flat slitters. The auxiliary rubbing and screening machine comprises a support, a trough is fixed on the support and is rectangular, a plurality of round through holes with the diameter being 0.18 mm are evenly distributed in the surface of the trough, and the circle center distance between every two adjacent round through holes is 1 mm; a sliding push block matched with the trough is arranged in the trough, and the width of the sliding push block is consistent with the internal width of the trough; a driving device is fixed at one end of the trough, and the driving end of the driving device is connected with the sliding push block; and a conveyor belt is arranged below the trough, moves in the long axis direction of the trough and penetrates through the bottom of the support. By means of the auxiliary rubbing and screening machine for compression production of the round-flat slitters, the problems in the prior art can be solved, rubbing and screening of raw materials for compression of the round-flat slitters are achieved, the grain size of the raw materials is improved, and the purpose that the compressed round-flat slitters have the good metallographic phase is achieved.

Owner:SICHUAN YR NEW MATERIAL TECH

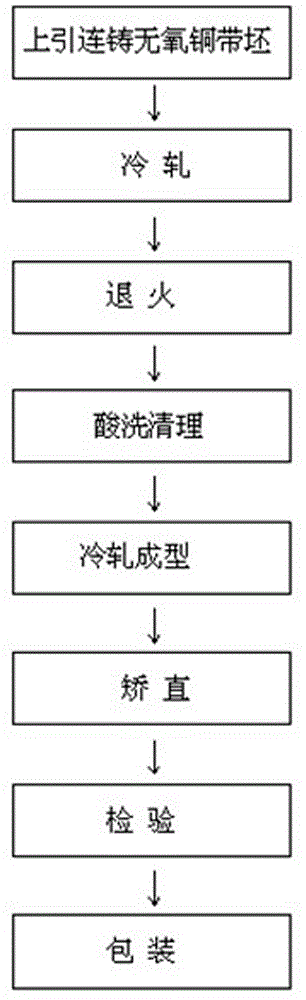

Production technology for hollow abnormal-shape electric anaerobic copper plate

The invention provides a production technology for a hollow abnormal-shape electric anaerobic copper plate, comprising the following technologies of: upwards leading a continuous anaerobic copper strip blank, carrying out cold rolling, annealing, brushing in an acid washing way, carrying out primary cold-rolling forming (a cold rolling method), straightening, testing, and packing. Compared with the prior art, the production technology has the following advantages that 1) the production technology is high in production efficiency, and the cold rolling technology primarily and coldly rolls double rows of continuous electric convex hulls through a specific abnormal-shape hole pattern, so that the primary forming can be carried out; 2) the product is regular in appearance shape, the electric convex hulls which are primarily formed by the cold rolling method and the cross-section shapes are regular in shapes, and are stable and even in size, and the defect problem such as the 'bamboo joints' shape caused by the repeated press forming in the conventional technology can be avoided; 3) the production technology is short in technological process, is low in cost, and is directly and coldly rolled into stripe materials as required by upwards leading the continuously-cast anaerobic copper strip blank, the primary cold-rolling forming can be carried out after the thermal treatment, the higher-cost procedures such as the heating and the hot-rolling cogging can be eliminated, the technology can be optimized, and the production cost can be reduced; and 4) the product is good in product quality, and has the characteristics of being high in purity, low in oxygen content, high in electric conductivity, and good in surface quality.

Owner:白银有色西北铜加工有限公司

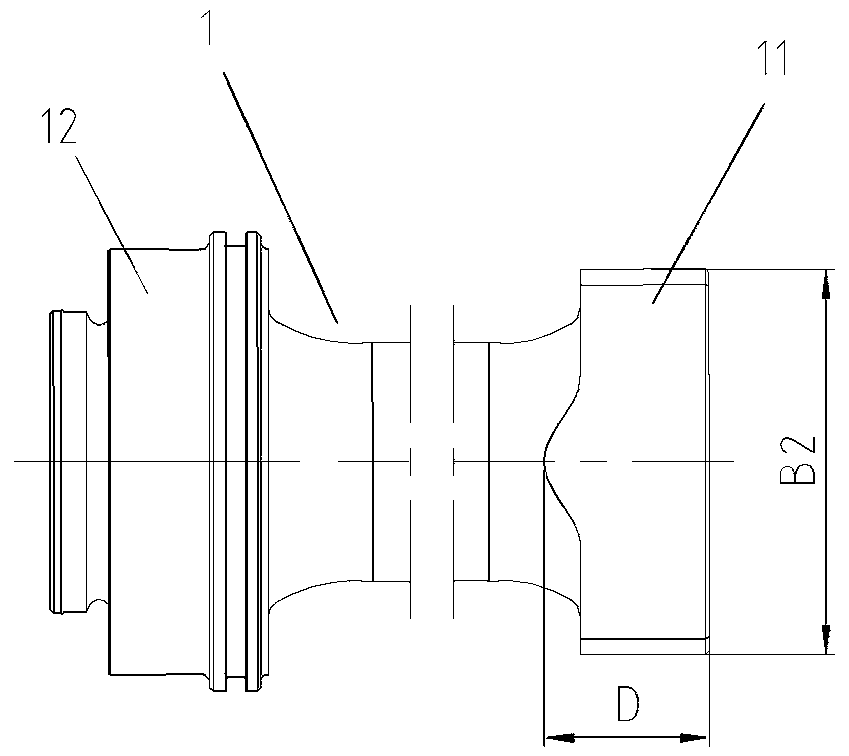

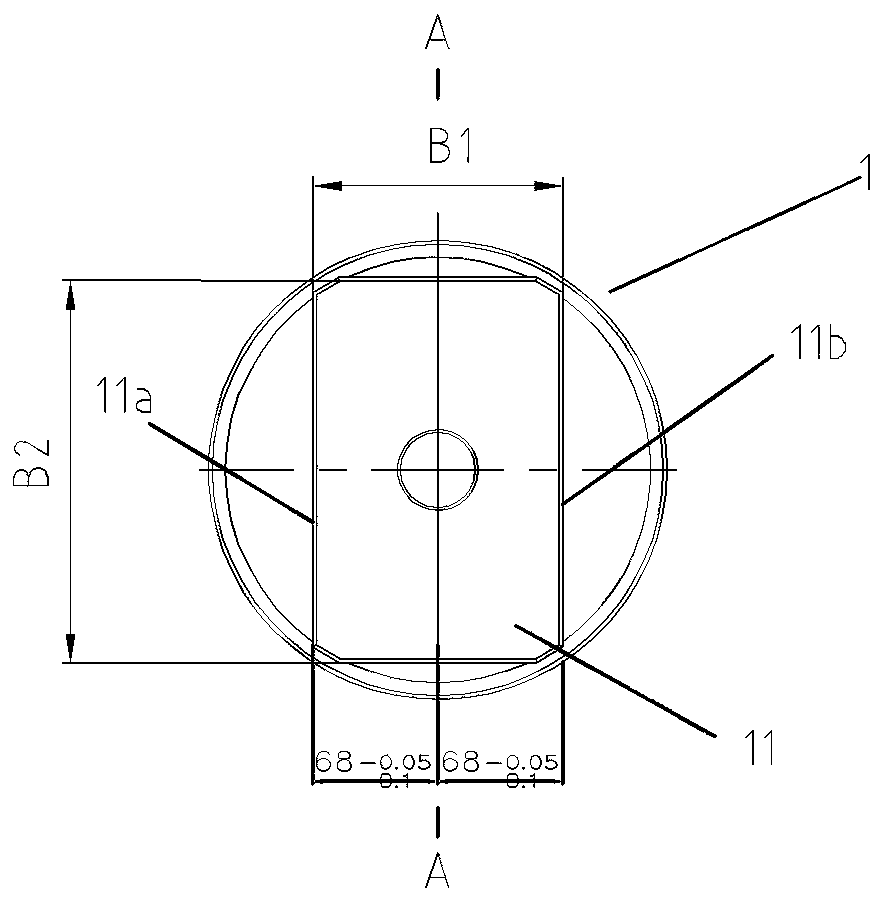

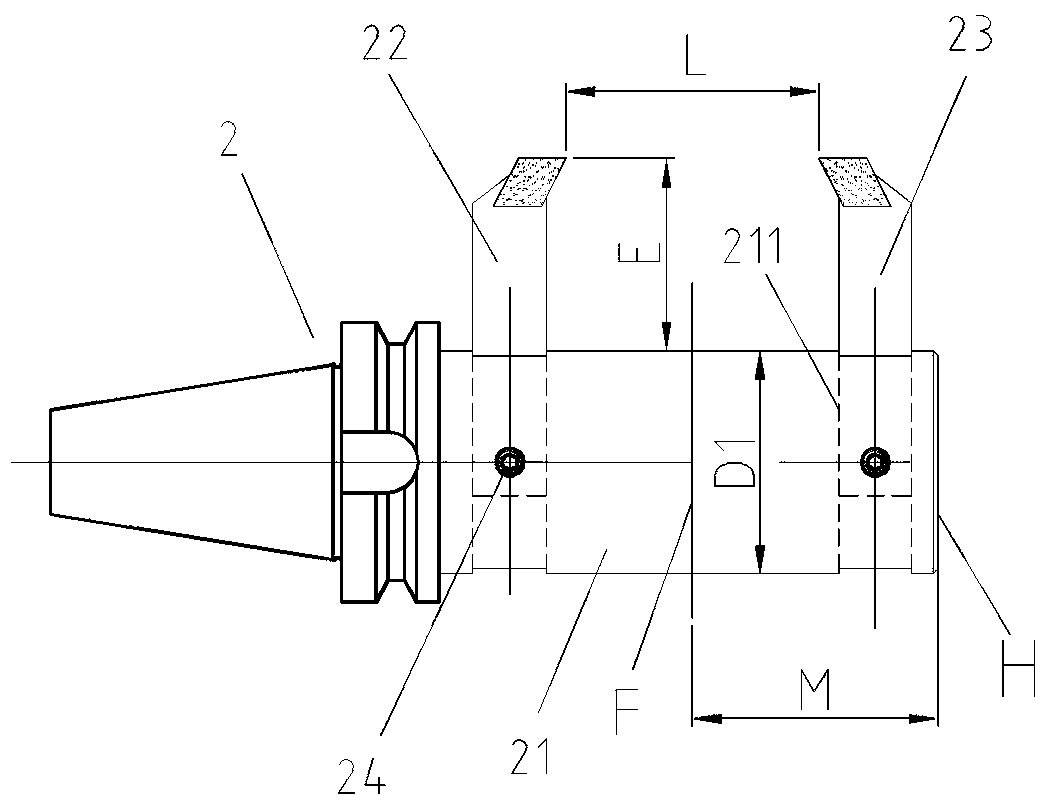

Piston rod flat square end finish-milling forming cutter and positioning tool and method

PendingCN110625171AReduce manufacturing costEasy to operateMilling cuttersPositioning apparatusEngineeringMachine tool

The invention discloses a piston rod flat square end finish-milling forming cutter and a positioning tool. The finish-milling forming cutter comprises a cutter bar, a left offset cutter and a right offset cutter, the lower end of the left offset cutter and the lower end of the right offset cutter are perpendicularly fixed to the middle of the cutter bar separately, and the distance L between two blade tips arranged at the upper ends of the left offset cutter and the right offset cutter of which the blade tips are oppositely arranged is equal to the opposite edge distance B1 of the left side and the right side of the piston rod flat square end. The positioning tool comprises a base and two groups of V-shaped block fixtures fixed to the base at intervals, and the lower side of the base is fixed to a machine tool workbench. A machining method comprises the following steps that (1), the positioning tool and the finish-milling forming cutter are installed; (2), a piston rod is positioned and fixed into the V-shaped block fixtures; (3), the finish-milling forming cutter is installed, and the machine tool spindle stretching position is adjusted; and (4), the piston rod flat square end isfinish-milled. According to the piston rod flat square end finish-milling forming cutter and the positioning tool, the manufacturing and cutter consumption cost is low, operation is easy and convenient, the skill requirement for operators is greatly reduced, and the machining efficiency is significantly improved.

Owner:CSSC MARINE POWER

Screening method for pressing materials of round-flat slitter

The invention discloses a method for screening disc-knife-pressed materials, which comprises the following steps: (A) mixing the granules uniformly; (B) wiping the uniformly mixed granules by using a sieve wiping machine with a mesh number of 80 meshes. Sieve to collect the raw materials falling below the sieve; (C) Stop the sieve wiper after 20 minutes of sieve wiper, and recover the pellets that stay on the sieve wiper screen. The invention proposes a screening method for pressing materials of disc knives, so as to realize the purpose of screening the raw materials for pressing disc knives, improving the particle size of the raw materials, and reducing the reject rate of the disc knives.

Owner:SICHUAN YR NEW MATERIAL TECH

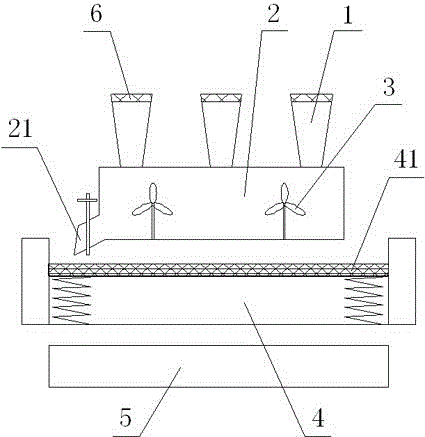

Forming device and process for rubber sponge barrel-shaped sectional material

ActiveCN111452277AUniform and stable cell sizeImprove product quality consistencyMoulding deviceManufacturing engineering

The invention discloses a device and a process for forming a rubber sponge barrel-shaped sectional material. The device comprises a sizing grinding core rod, a sizing die and a forming die lower die,wherein the sizing die and the forming die lower die are the same in shapes, the sizing grinding core rod is matched with the tops of the sizing die and the forming die lower die, a first U-shaped barrel-shaped filling cavity is arranged in the sizing die, and a second U-shaped barrel-shaped filling cavity is arranged in the forming die lower die; by means of the device, the sponge barrel-shaped sectional material which is uniform and stable in foam hole size, of a micropore closed structure and low in apparent density can be prepared through the processes of sizing, vulcanizing and aftertreatment sectional forming; and the device has the advantages of simple structure, simple process, practicability and high efficiency.

Owner:XIANYANG KELONG SPECIAL RUBBER PROD

Upstream auxiliary tool for round-flat slitter pressing

InactiveCN106180701AExtended service lifeUniform and stable sizeSievingScreeningMechanical engineeringEngineering

The invention discloses an upstream auxiliary tool for round-flat slitter pressing. The upstream auxiliary tool for round-flat slitter pressing comprises a feeding opening; a screening net with 20 meshes is arranged on the feeding opening; the feeding opening communicates with a stirring cabin; a stirring device is arranged inside the stirring cabin; a vibrating screen is arranged below a discharging end of the stirring cabin; the vibrating screen is provided with three layers of screening nets; the mesh numbers of the three layers of the screening nets are 40 meshes, 60 meshes, and 80 meshes in sequence from top to bottom; and a material receiving device is arranged below the vibrating screen. According to the upstream auxiliary tool for round-flat slitter pressing provided by the invention, the purpose that the defective rate of the round-flat slitter is reduced is achieved.

Owner:SICHUAN YR NEW MATERIAL TECH

A stirring device for architectural paint

ActiveCN108854629BEnhanced vortex effectImprove the mixing effectTransportation and packagingRotary stirring mixersMechanical engineeringPaint product

The invention relates to a building paint stirring device, which comprises a filter chamber, a grinding chamber, a mixing discharge part, a stirring chamber, a first air piston part and a second air piston part. The paint with different particle sizes is classified through the filter chamber, and the large-grained paint is further ground by setting the grinding parts to achieve the uniform particle size of the paint and avoid the inhomogeneity of the paint. By setting up a stirring device with a specific structure and setting the air jet, the stirring process of the paint is more uniform and stable, thus achieving a high degree of stability and uniformity of the paint product.

Owner:重庆绿泰园林装饰工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com