Production technology for hollow abnormal-shape electric anaerobic copper plate

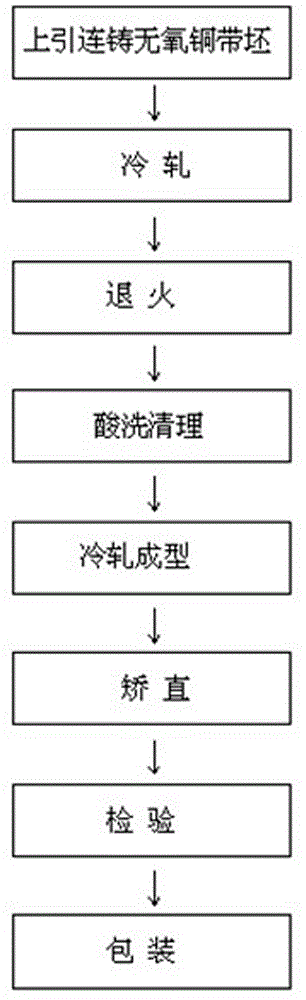

A conductive copper plate and production process technology, which is applied in the production process field of hollow-core special-shaped conductive oxygen-free copper plate, can solve the problem of affecting the appearance quality and cross-sectional shape of the hollow-core special-shaped conductive plate, making it difficult to realize continuous large-scale production, time-consuming and labor-intensive work Efficiency and other issues, to achieve the effect of good overall appearance quality, improved product quality level, simple operation and time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Upward continuous oxygen-free copper strip billet

[0029] Choose high-purity cathode copper with not less than 99.95% Cu+Ag as the raw material, preheat and dry it and place it in the melting furnace to melt it. In order to isolate it from the air, prevent the copper liquid from absorbing oxygen on the surface of the copper liquid in the melting furnace Cover with a layer of charcoal with a thickness of 80mm. Then press the traction wheel, turn on the servo system, select the pitch and drawing speed (the drawing speed of the continuous oxygen-free copper strip billet for the upward drawing is controlled at 50mm / min), and start casting the copper liquid on the upward drawing oxygen-free copper continuous casting machine The continuous oxygen-free copper strip billet for up-drawing is 30×270mm (thickness×width). During the casting process, the temperature of the molten copper in the holding furnace of the upward-drawing oxygen-free copper continuous casting machin...

Embodiment 2

[0046] 1) Upward continuous oxygen-free copper strip billet

[0047]Choose high-purity cathode copper with not less than 99.95% Cu+Ag as the raw material, preheat and dry it and place it in the melting furnace to melt it. In order to isolate it from the air, prevent the copper liquid from absorbing oxygen on the surface of the copper liquid in the melting furnace Covered with a layer of graphite flakes with a thickness of 80mm. Then press the traction wheel, turn on the servo system, select the pitch and drawing speed (the drawing speed of the continuous oxygen-free copper strip billet for the upward drawing is controlled at 80mm / min), and start casting the copper liquid on the upward drawing oxygen-free copper continuous casting machine The continuous oxygen-free copper strip billet for up-drawing is 30×270mm (thickness×width). During the casting process, the temperature of the molten copper in the holding furnace of the upward-drawing oxygen-free copper continuous casting m...

Embodiment 3

[0064] 1) Upward continuous oxygen-free copper strip billet

[0065] Choose high-purity cathode copper with not less than 99.95% Cu+Ag as the raw material, preheat and dry it and place it in the melting furnace to melt it. In order to isolate it from the air, prevent the copper liquid from absorbing oxygen on the surface of the copper liquid in the melting furnace Covered with a layer of graphite flakes with a thickness of 100mm. Then press the traction wheel, turn on the servo system, select the pitch and drawing speed (the drawing speed of the continuous oxygen-free copper strip billet for the upward drawing is controlled at 80mm / min), and start casting the copper liquid on the upward drawing oxygen-free copper continuous casting machine The continuous oxygen-free copper strip billet for up-drawing is 30×270mm (thickness×width). During the casting process, the temperature of the molten copper in the holding furnace of the upward-drawing oxygen-free copper continuous casting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com